ARTICLE

Dongyue Machinery Group Co., Ltd., 276303 Linyi City, China

Application of various siliceous materials in AAC production

AAC makes use of siliceous and calcareous materials as the main constituents. After mixing with water and adding of a foam agent, pores are formed through chemical reaction. In the mix composition, siliceous constituent materials account for about 60-75%. The main component of siliceous materials is SiO₂, and the main chemical component of sand is SiO₂. Therefore, sand has become the most widely used siliceous material in the production of AAC, especially quartz sand with a SiO₂ content of more than 90%, which is the first choice for the production of AAC products.

Due to the limitation of natural resources and the increasing price of sand and gravel, the industry needs to consider alternatives. Therefore, Dongyue Machinery actively explores and expands the selection range of siliceous materials and uses industrial wastes such as mining tailings and crushed stone to replace natural sand. These materials can be used after experimental verification in accordance with the technical and environmental requirements of production. This article presents successful case studies implemented by Dongyue Machinery.

Fly ash AAC

In China, numerous thermal power plants are distributed throughout the country and a large amount of fly ash is generated every year. Therefore, in the production of AAC blocks, fly ash has become the second main siliceous material to replace sand. The main chemical compositions of fly ash are SiO₂ and Al₂O₃, with small amounts of Fe₂O₃, CaO, MgO and other trace components. The main role of fly ash in AAC is to provide SiO₂. Meanwhile, in addition to participating in the hydration reaction during the autoclave curing process, Al₂O₃ also plays a significant role in the curing process after pouring. The production of AAC blocks has certain technical requirements for fly ash. The ignition loss should be less than 8%, the fineness (0.080 mm square hole sieve residue) should be less than 25%, and the SiO₂ content should be greater than 45%.

AAC projects undertaken by Dongyue Machinery, including Liaoning Dongshen Construction New Material Technology Co., Ltd. and Shaanxi Jiutai Hejia Building Materials Co., Ltd., and others, use fly ash as a siliceous material. In India, there exist a large number of factories, operated by customers of Dongyue, that use fly ash to produce AAC blocks. Dongyue has extensive production experience in using different grades of fly ash to produce AAC products.

Iron tailings

Iron tailings are a composite mineral material representing the waste residue left after iron ore is screened from iron concentrate. The main components of iron tailings are SiO₂, Al₂O₃, Fe₂O₃, CaO and MgO. The content of chemical components varies greatly with different regions. Generally, iron tailings contain over 60% of SiO₂ and a portion of Fe₂O₃. When the SiO₂ content is low, a certain proportion of high silica sand can also be added for blending to improve the strength of the product. Under autoclave curing conditions, the calcareous material in the mixture hydrates to form Ca(OH)₂, which reacts with free SiO₂ and Al2O3 in iron tailings and quartz sand. The crystal clusters and aggregates of hydration products interweave together to form a good network and a dense structure, which has a positive effect on improving the strength of the product. The compressive strength of AAC products made with iron tailings exceeds 3.5 MPa and the dry density is 620 kg/m3, meeting the requirements of A3.5 qualified products.

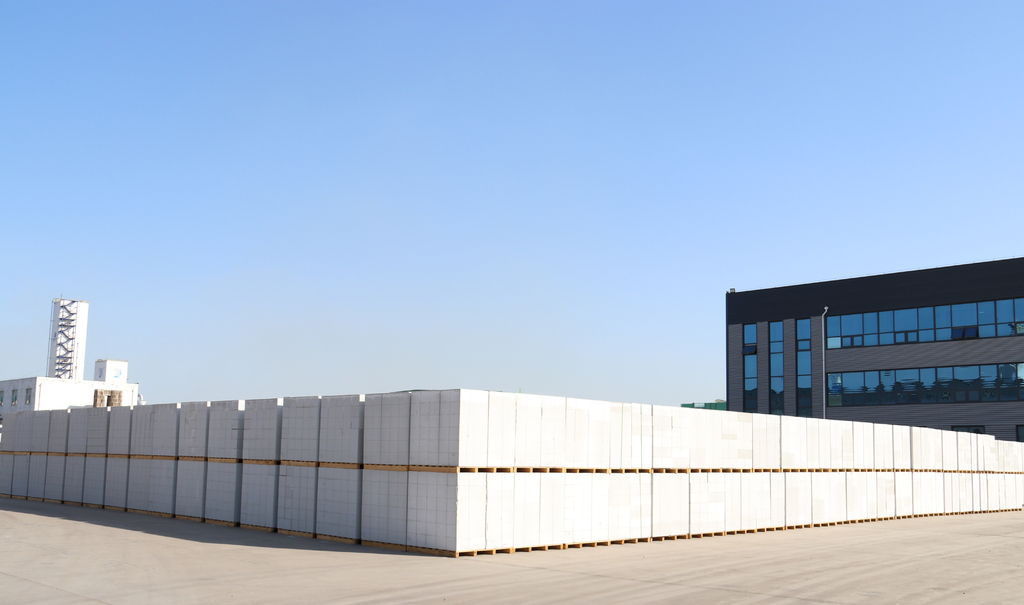

At the end of 2019, a strategic cooperation was reached between Dongyue Machinery and Ma Steel, introducing a 6.0 m double AAC production line to produce two types of products: AAC blocks and AAC panels, with an annual production capacity of up to 600,000 m3. This project provides new technologies and models for the transformation and upgrading of mines and the extension of green industrial chains.

Gold tailings

Gold mine tailings refer to the waste residue discharged after extracting useful target components from gold ore sorting operations. The gold tailings mainly contain SiO₂, as well as small amounts of CaO, Al₂O₃, Fe₂O₃, MgO, precious metals and heavy metals. Most gold tailings contain over 75% of silicon aluminum oxides and other components, which are similar in composition to many industrial building materials. Shandong Zhongchang Development and Construction Group Co., Ltd is located in Laizhou City, Shandong Province. Laizhou is an important gold production base in China. Every year, a large quantity of gold tailings is produced. Relying on its superior geographical location, Zhongchang Company invested in two AAC production lines, designed 18 autoclaves and produces AAC blocks and panels using local gold mine tailings. Dongyue Machinery provided EPC services for the Zhongchang AAC project, which became a demonstration project for handling gold mine tailings, providing a learning base for the sustainable development of resources and the utilization of solid waste.

Fluorite tailings

The chemical composition of fluorite slag formed after fluorite mining and processing is 42.8% silicon dioxide, 7.6% aluminum oxide, 1.0% iron oxide, 39.0% calcium oxide, etc. From the perspective of chemical composition, fluorite slag can be used to produce AAC products, but silica sand and some additives need to be added for process formula adjustment.

Jiangxi Jianshi New Material Technology Co., Ltd. relies on the rich tailing resources of Xinheng Mining Co., Ltd., with a planned annual output of 600,000 m3 of AAC blocks and panels, with the production line supplied by Dongyue Machinery Group. The dosing ratio of fluorite slag can reach 50%, and the product performance has passed inspection by the quality supervision department and received third-party certification.

This project is a nationally recommended project for green and environmentally friendly building materials, conforming to the development strategy of "adhering to energy conservation, water conservation, soil conservation, environmental protection, and fully utilizing renewable resources", which the country is supposed to follow in developing new building materials.

Glass tailings

The raw materials of glass production mainly include quartz sand, borax, boric acid, limestone, feldspar, etc. Different types of glass have different requirements for the content of SiO₂, but the content is generally required to be more than 99%. Therefore, during the production process, some residues with unqualified SiO₂ content and particle size are produced, but the composition of these residues fully meets the requirements for the production of AAC products.

Chongqing Chuansheng Building Materials Science and Technology Co., Ltd. is jointly funded by Chongqing Yuhu Glass Co., Ltd. and Chongqing Xintai Glass Co., Ltd. It has built three AAC block and panel production lines in Chongqing using leftover quartz sand powder from the two glass factories, with all the equipment manufactured and supplied by Dongyue. The 40th annual meeting of China's AAC industry in 2020 was held in Chongqing, which was facilitated by Dongyue Machinery. The Chongqing Chuansheng project has become a demonstration production line for China's AAC industry, with a high degree of automation as well as recovery and utilization of autoclave residual steam and condensate, opening a precedent for the production and use of AAC panels in Southwestern China.

Granite saw mud

Huada New Building Materials is located in Zhongshan County, Hezhou City, Guangxi Province. It is a granite stone production base. Stone powder and saw mud are the main solid wastes produced. The solid waste management attracts high annual costs. Huada has invested 120 million Yuan (approx. 15 million Euros) and covers an area of 110 acres, using saw mud from granite to produce AAC blocks.

In order to protect the investment interests of its customers, Dongyue tested the raw materials before the equipment was collected and processed, and produced qualified test blocks in the laboratory, so that customers could invest with confidence. It also opened a new path for Zhongshan County to use granite solid waste and has become a leading scientific and technological enterprise in Hezhou City for solid waste recycling.

In addition to supplying equipment, Dongyue has a mini laboratory with mini crusher, mini ball mill, mini autoclave, etc. It cannot only assist customers with raw material testing and analysis, but also with conducting small sample tests to address their investment concerns. Dongyue adheres to the one-stop service concept and provides free factory planning, investment budgeting, production cost calculations, equipment selection, transportation schemes, production management training and other services.

Dongyue has built offices in India, Indonesia, Uzbekistan, Vietnam and other countries and invites more clients to understand and consult on AAC products, promoting the use of AAC blocks and panels.

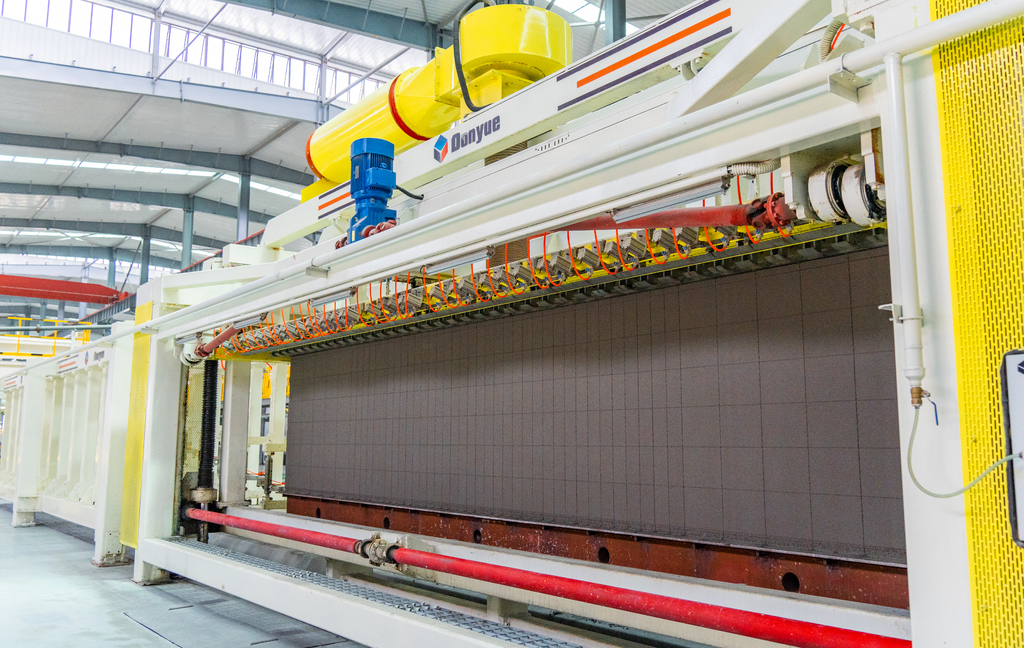

Dongyue Machinery Group former: Shandong Dongyue Building Machine CO,LTD, founded in 1994, established in June 2012, including Dongyue Machinery Group Co.,Ltd, Linyi Dongyue Import & Export Co.,Ltd, Linyi Dongyue Pressure Vessel Manufacturing Co.,Ltd. The company is a high-tech industry in Shandong Province. It has a provincial enterprise technology center and a mechanical engineering laboratory for building materials in Shandong Province. The company has a technical department, and has successively carried out technical cooperation with China Academy of Building Research and Germany Katz Beton Group.

Operating range: autoclaved aerated concrete equipment, cutting machines, panel wall machine manufacturing, sales, block forming machine, hollow brick machine, burn-free brick machine, mixer and many more.

Main business: The company is mainly engaged in the research and development, design, production and sales of AAC block and panel production lines.

This DONGYUE channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about DONGYUE are available for free. Feel free to share information from this website with other industry professionals!

Dongyue Machinery Group CO.,LTD

AAC Block & Panel Production Line Manufacturer

Dongyue Technology Industry Zone

276303 Linyi City, China

T +86539 3628888

machinery@dongyuegroup.com

www.dyjxjt.com

www.chinablockmachine.com