ARTICLE

Dongyue Machinery Group Co., Ltd., 276303 Linyi City, China

Synergizing large and small AAC plants: A strategic Integration

In densely populated countries like China and Indonesia, the AAC industry has matured and is characterized by advanced construction techniques and refined production processes. However, amid economic restructuring, rising demands for low-carbon products, and intensifying market competition, the AAC sector must pivot toward smarter, greener, and more sustainable solutions.

Since 2023, Dongyue has pursued technological innovation, industrial upgrades, and management reforms to unlock new growth opportunities, empowering manufacturers to enhance competitiveness and achieve sustainable development.

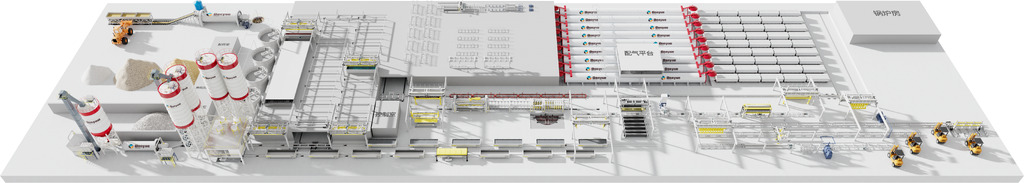

Design innovation: Building an intelligent, efficient, and energy-saving system

Dongyue optimizes resource allocation, boosts production efficiency, and minimizes costs through rational factory planning, process layouts and equipment configuration. Examples include increasing mould curing stations to reduce lime consumption, deploying automated feeding systems to reduce labour and improve safety, adding flexible packaging stations to accommodate diverse product specifications, and implementing waste heat recovery systems to achieve zero steam emissions.

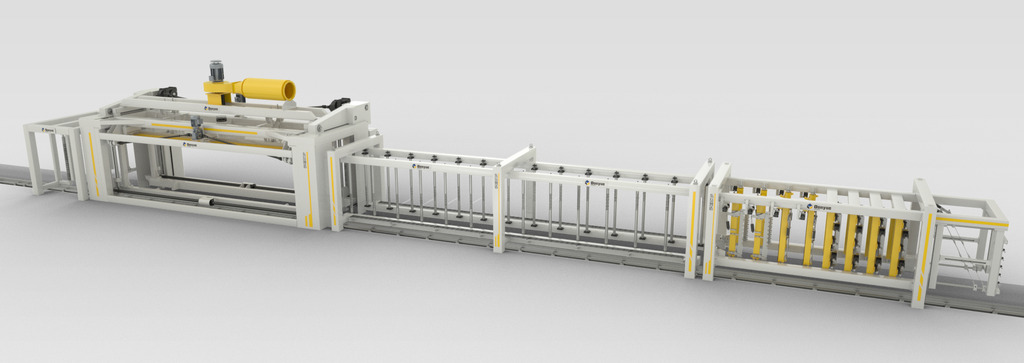

Equipment innovation: Enabling high-speed, high-capacity, and high-efficiency production

To maximize output and reduce unit costs, equipment must operate at peak efficiency. Related innovations include dual pouring systems for simultaneous mould filling, dual clamping and packaging systems to accelerate product handling, and enhanced hydraulic and electrical systems achieving a 90-second cycle time per mould. Such an AAC production line can now achieve an annual capacity of 1 million cubic meters, which is ideal for high-demand, competitive markets.

Management optimization: Reducing labour and enabling full digitalization

Through MES (Manufacturing Execution Systems), Dongyue integrates production data to monitor energy consumption, product output and defect rates in real time. For example, sensors adjust steam supply dynamically based on autoclave pressure and temperature, cutting energy waste.

Dongyue is also pioneering single-operator factories, where one worker can initiate full production with a single command.

Production optimization: Flexibility and rapid response

To meet customized block and panel demands, Dongyue developed smart mould systems for quick product specification changes, enabling 48-hour order turnaround. Future integration with automated logistics and AI-driven warehousing will further reduce inventory and expedite deliveries.

Challenges of traditional large AAC plants

Large AAC plants (annual capacity >300,000 m³) face hurdles in sparsely populated, resource-scarce, or underdeveloped markets:

· Limited and volatile market demand: Large factories face unstable construction market demand, leading to idle capacity and surging marginal costs. This makes it challenging to sustain the break-even point for such plants.

· Supply chain bottlenecks: AAC production relies on centralized raw material supplies (e.g., silica sand, cement, lime). In remote regions, transportation costs can exceed 40% of total material expenses, exacerbating logistical challenges.

· Energy infrastructure weaknesses: Insufficient local power or natural gas infrastructure often force production cuts due to energy shortages, further straining operational efficiency.

· Market mismatch: Poor market alignment arises from the conflict between product standardization and diverse demands. Large factories that prioritize efficiency typically produce uniform specifications, whereas sparsely populated regions often require customized dimensions (e.g., non-standard blocks tailored to traditional architectural structures), resulting in excess inventory.

· Logistics costs: Long-distance transportation costs erode profits. If a factory is located far from the end market, the logistics costs for AAC products may exceed the product’s own value.

As a consequence of the above considerations, large plants are not universally viable, as they may be related to high investment costs and low returns.

The Mini AAC Factory solution

Dongyue targets niche markets with mini AAC plants (annual capacity: 10,000 - 60,000 m³), lowering upfront costs and shortening payback periods.

Table 1: Dongyue AAC plant portfolio

Production plant type | Annual production (m3/year) | Equipment selection |

Mini Plant | 30,000-60,000 | DY2.4x1.2x0.6m DY3.0x1.2x0.6m DY3.6x1.2x0.6m DY4.0x1.2x0.6m DY4.2x1.2x0.6m DY4.8x1.2x0.6m DY5.0x1.2x0.6m DY5.4x1.2x0.6m DY6.0x1.2x0.6m DY6.0x1.5x0.6m DY7.2x1.2x0.6m DY7.5x1.2x0.6m |

Small Plant | 60,000-150,000 | |

Medium Plant | 150,000-300,000 | |

Large Plant | 300,000-500,000 | |

Very Large Plant | 500,000-1,000,000 |

Core advantages of Mini AAC Factories

· Cost-effectiveness: Low upfront investment and flexible operations. The entry barrier is reduced by 50%: A mini AAC production line requires only RMB 7–15 million (appr. 1-2 million EUR), and offers phased expansion options. For example, a compact plant in Nepal achieved an annual output of 30,000 m³ of AAC blocks with an initial investment of just RMB 8 million (appr. 1 million EUR).

· Energy efficiency: Mini plants feature lower installed capacity, minimizing power waste even during low-load production. Smaller autoclaves and reduced boiler specifications ensure efficient steam utilization.

· Automation: Compact yet fully functional. Even mini AAC plants can adopt fully automated operations, eliminating challenges in worker recruitment and management.

· Asset-light, on-demand production: Factories dynamically adjust capacity based on orders to avoid inventory waste. In a pilot project in Mongolia, a mini plant achieved an 85% capacity utilization rate, compared to 35% for local large plants.

· Rapid delivery & customization: Mini plants switch product specifications within 48 hours to fulfil small-batch orders. For instance, producing ultra-lightweight AAC insulation panels for a 500 m³ order still yielded profitability.

· Community-driven sales networks: Direct partnerships with local builders and contractors shorten supply chain layers. In rural India, the “One Village, One Agent” model tripled product penetration compared to traditional channels.

Mini AAC factories break traditional industrial barriers through “lightweight investment, localized production and smart responsiveness.” Their value extends beyond economical benefits, fostering inclusive global construction by delivering affordable, high-performance materials to remote regions.

Global success stories

Dongyue Machinery’s mini AAC plants have been successfully established in countries such as Nepal, Russia, India and Indonesia, receiving strong client acclaim. This further validates that mini AAC factories are a critical component in the globalization of the AAC industry.

Future vision

Amid fierce market competition, Dongyue employs a triple-strategy approach – "technological innovation + lean management + market focus" – to help clients reduce costs and enhance efficiency. Looking ahead, Dongyue aims to leverage AI technology to solidify AAC’s central role in the global green building movement.

Dongyue Machinery Group former: Shandong Dongyue Building Machine CO,LTD, founded in 1994, established in June 2012, including Dongyue Machinery Group Co.,Ltd, Linyi Dongyue Import & Export Co.,Ltd, Linyi Dongyue Pressure Vessel Manufacturing Co.,Ltd. The company is a high-tech industry in Shandong Province. It has a provincial enterprise technology center and a mechanical engineering laboratory for building materials in Shandong Province. The company has a technical department, and has successively carried out technical cooperation with China Academy of Building Research and Germany Katz Beton Group.

Operating range: autoclaved aerated concrete equipment, cutting machines, panel wall machine manufacturing, sales, block forming machine, hollow brick machine, burn-free brick machine, mixer and many more.

Main business: The company is mainly engaged in the research and development, design, production and sales of AAC block and panel production lines.

This DONGYUE channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about DONGYUE are available for free. Feel free to share information from this website with other industry professionals!

Dongyue Machinery Group CO.,LTD

AAC Block & Panel Production Line Manufacturer

Dongyue Technology Industry Zone

276303 Linyi City, China

T +86539 3628888

machinery@dongyuegroup.com

www.dyjxjt.com

www.chinablockmachine.com