ARTICLE

HESS AAC Systems B.V., 7547 TN Enschede, The Netherlands

The latest development for automatic unloading and packing of AAC production

As a result, production monitoring is centralized and employees sit in an air-conditioned room watching the screens, thus intervening remotely only when necessary. For such systems to work free of error and interruption, it needs state-of-the-art solutions.

One such workstation is the stacking area for frames before and after autoclaving. Besides being hot there, health and safety measures should also be considered. Hess AAC Systems has been active in the autoclaved aerated concrete market for 40 years and has, since then, pursued the goal of supporting AAC manufacturers and those who want to become such with expert knowledge and customized solutions to strengthen their position.

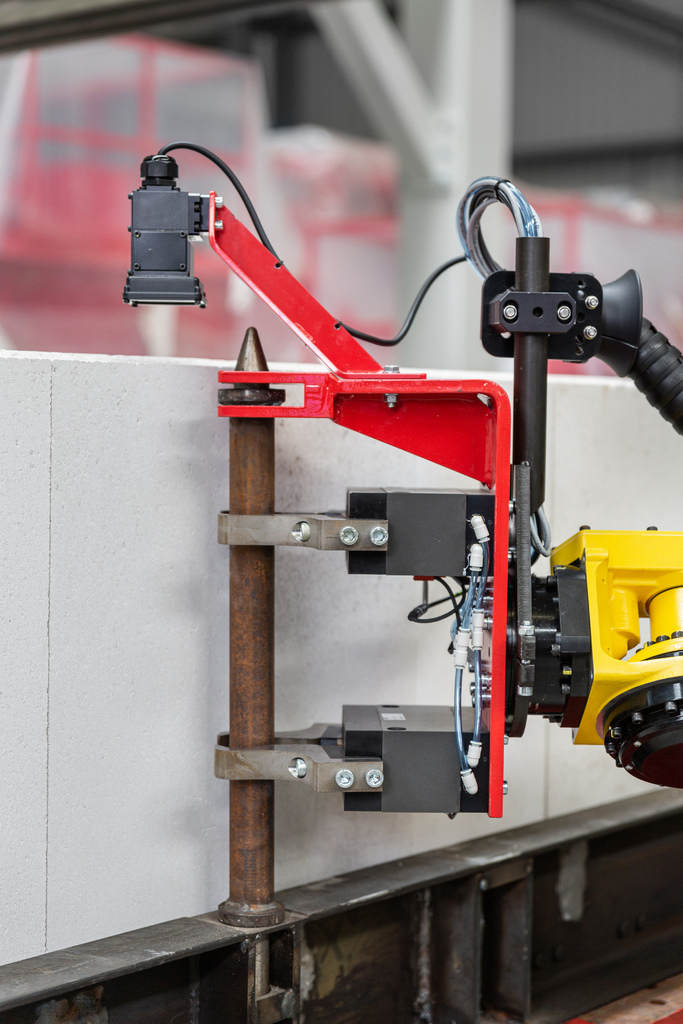

Keeping in mind the industrial challenges, the engineering department of Hess AAC Systems has developed a new solution for automatic unloading and packing of AAC production: a multi-axis robot that stacks and restacks the pins automatically and with high precision.

The system is highly flexible and can be used not only for the plants of Hess AAC Systems. Thanks to its design, it can be installed in any other system where pins need to be handled, regardless of the technology used and the size of the frame. This robot system is not only good for the new plant with high capacity and a high degree of automation, but also a valuable add-on for the existing AAC factory.

Michael Deissing, an expert in the AAC production industry, is very optimistic about the latest development: “I believe that this system can help the AAC manufacturers to minimize the waiting times, save costs & produce more efficiently.”

Learn more about the Stacking Pin Robot in a detailed report in issue 4/22 of AAC Worldwide.

Michael Deissing is Sales Manager at Hess AAC Systems; with over 30 years of professional background in AAC production both on the side of the AAC manufacturer as well as on the side of machinery and plant engineering has proven himself as an expert in the industry.

As Regional Production Manager at ACICO Group, Michael was responsible for AAC plants in Kuwait, Dubai, Saudi Arabia, and Qatar. He took care of product development and improvement, especially for reinforced AAC panels. His further main tasks at ACICO Group were raising funds for the development, quality and quantity improvement of AAC production.

As a production manager at Hebel Building Solutions Germany, Michael Deissing ensured the quality and quantity of AAC block and panel production. He was also responsible for investments, marketing, and customer service in his additional role as Deputy Factory manager.

It is the philosophy of Hess AAC Systems to deliver a manufacturing system to its customers which is designed to address the specific requirements of their market in terms of capacity and product portfolio.

The Hess AAC Systems Keen-Crete systems guarantee this high degree of flexibility in system planning, based on our know-how and experience in the field of cutting systems for tilt-cake and flat-cake processes. Use of time-proven standard machines and components ensures premium reliability.

This HESS AAC SYSTEMS Company channel is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about HESS AAC SYSTEMS are available for free. Feel free to share information from this website with other industry professionals!

HESS AAC Systems B.V.

Aluminiumsteden 10

7547 TN Enschede, The Netherlands

T +31 53460 1700

F +31 53460 1799

((BAUMA-Sticker: For more details, visit our booth Nr. B1. 226 at bauma))