ARTICLE

Masa WhiteHub, 32457 Porta Westfalica, Germany

AAC panels – Part 1: Invisible strength with advanced reinforcement

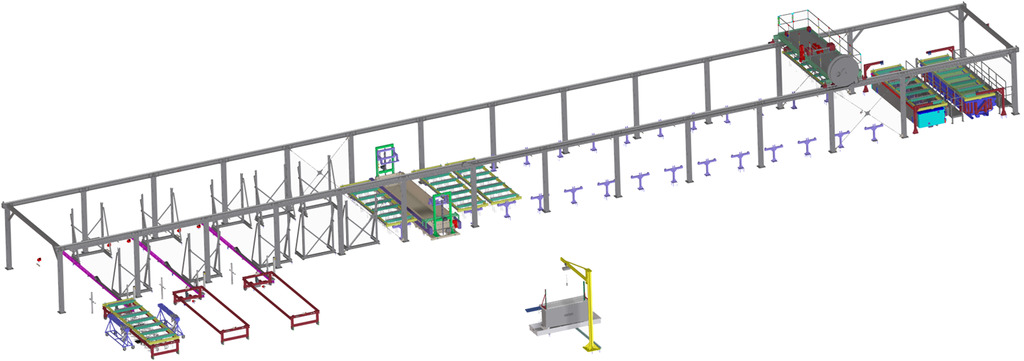

Reinforcement manipulator and area for preparing the mounting wagons (outside the working range of the automatic manipulator).

In April, the bauma in Munich will once again provide the international construction machinery industry with a platform for profitable innovations and cross-border exchange. Masa WhiteHub, as part of the Masa family, will be focusing on the topic of reinforcement in one area of the exhibition stand, among other things.

Depending on the desired range of reinforced AAC products (lintels, partition wall panels, wall panels for cladding, load bearing wall panels, panels for flooring/ceiling etc. or a combination of these) and their respective capacities, Masa WhiteHub can offer solutions ranging from simple (mostly manual or semi-automatic versions) to highly sophisticated fully automatic reinforcement systems. Attention must be paid to the reinforcement steel itself and to the handling system for the reinforcement.

The reinforcement steel

The first step is to manufacture the appropriate reinforcement steel itself. Both the individual reinforcement parts, such as bars, meshes or cages, and the spacers have to be considered.

Variants of the reinforcing parts

At the beginning, several possible variants for the specific reinforcement parts are discussed and defined together with the customer and potential reinforcement machine manufacturers:

Variant 1: The customer can start, for example, with steel reinforcement bars. These can be purchased tailor-made or produced by the customer. If the customer only wants to produce partition wall panels, for example, only rods/reinforcement bars (so-called ‘wires’) are sufficient as reinforcement.

Variant 2: If steel mesh is required for reinforced products, the customer can have it welded together manually or opt for a machine-based (semi- or fully automatic) production process. With a machine-based solution, the customer can choose between starting with reinforcement bars (if the desired capacities allow) or with coils.

Variant 3: For even more heavily loaded reinforced products, reinforcement cages are required. These can also be hand or machine welded. If machine-welded, the customer can again choose whether to start from reinforcement bars (if capacity allows) or from coils. In many cases, several (separate) machines are required to produce the reinforcement cages in several stages. Various suppliers also offer highly automated systems in which the reinforcement cages are completed in one step.

Whichever variant is choosen, there is one important requirement: every weld has to be performed in accordance with the specifications for reinforced AAC products.

Plus, the reinforcement mesh or cage has to be designed and calculated for each desired product, according to the forces that the product has to absorb at the position in the building where it is installed. The consistent and reliable quality of this mesh/cage forms the basis for the stability of the product.

Spacers

In addition to the meshes and/or cages, spacers (in various sizes) are required. These connect the steel meshes to each other and insert/hang the reinforcement steel into the reinforcement frames. The reinforcement frames then lower the reinforcement into a specific mould. Although these spacers can be bent and welded manually, it is usually advisable to use an automatic machine for this.

Comprehensive advice

In view of the numerous options available for producing the required reinforcement, prior consultation and discussion is essential. The Masa WhiteHub team offers comprehensive advice on this. The chosen reinforcement solution can then be provided either as a complete package or in collaboration with a renowned reinforcement manufacturer.

The handling system

After the individual steel wires, meshes or cages have been manufactured, the steel reinforcement has to be placed in a specific mould/cake. A typical workflow would be as follows.

Preparation of the individual reinforcement

The entire reinforcement for each cake is first prepared on a special mounting wagon per cake. The dimensions of the provided wagons correspond to the actual moulds.

Mounting of the reinforcement parts

The reinforcement will be implemented by means of reinforcement holding frames, which will be placed on top of the mounting wagons. By using holding beams and needles, the reinforcement parts can be mounted (in most cases manually) and suspended from the holding frame. After assembly, the needles can be locked to the holding beams, thereby fixing the complete reinforcement for a cake to the holding frame.

In highly advanced plants, the entire reinforcement for each cake can also be made up fully automatically. In this case, no mounting wagons are required.

Preparation of the needles – needle bath

The needles that, together with the holding beams, are needed to mount the reinforcement parts on the reinforcement frame are used several times. To ensure that these needles can be retrieved from the cake with minimal effort, they must not become dirty and/or sticky. This is mainly achieved by immersing them in a bath of paraffin wax. There are two options for setting up the so-called needle bath:

· ‘free-standing’, i.e. out of reach of the gantry/manipulators: this solution is generally used for smaller capacities. The process is manual or semi-automatic.

· under the gantry: the needle bath is integrated into the fully automatic cycle of the reinforcement area. In this case, an automatic mechanical cleaning/brushing system for the needles is usually also provided.

Moving of the mounted parts

Once the preparation on the mounting wagon is complete, the wagon is moved under a gantry structure where one or more reinforcing manipulators carry out all other required processes. First, an (automatic) manipulator lifts the holding frame – with the complete reinforcement for a cake – from the wagon. After that, the manipulator (or manipulators) carries out all further processes to finally insert the reinforcement into an AAC cake. The empty mounting wagon is immediately moved out from under the gantry and can be used to prepare the reinforcement for another cake.

Further required operations and processes

All of the following steps are handled and controlled by the reinforcement manipulators. During each work step, the manipulators always lift and move a complete reinforcement holding frame with the entire reinforcement parts for a complete cake.

Step 1: Immersion of the reinforcement in a coating bath of latex paint (preferably water-based) to protect it from corrosion.

Step 2: Drip off excess paint and allow to dry in so-called drip-off and waiting positions

Step 3: The holding frame is placed on a mould with fresh cast AAC product and the entire reinforcement is inserted into the fresh cake. The holding frame for the reinforcement remains on the mould, which is transported to the rising area.

Step 4: After the rising, the reinforcement manipulator lifts the holding frame before the subsequent cutting process. The reinforcement remains in the green cake. To pull out the reinforcement frame with the needles, the needles must first be disconnected/unlocked from the reinforcement.

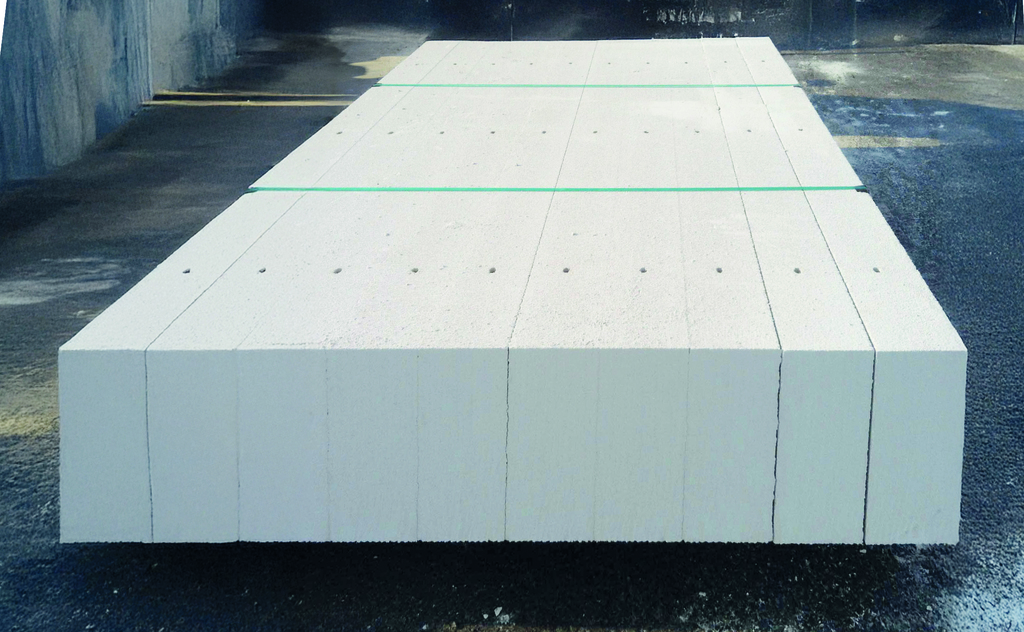

Step 5: Later, the green cake with the invisible reinforcement is treated like a cake for blocks. However, in the cutting line, it is necessary to ensure that the cutting wires are correctly positioned to cut only into the green aerated concrete material and not into the steel.

Keeping an eye on the inside: Product tracking

Especially for load-bearing wall panels and AAC floor and ceiling panels, the architect must determine, in consultation with a structural engineer, what type of reinforcement is required for each individual panel. This depends mainly on the position in the building where the panels are used and what loads need to be taken into account there.

Therefore, at the end of the production process, namely when the panels are being packed or prepared for transport, it must be clear for which project, building, floor and position the respective panel is to be used.

This allocation/identification and tracking can be done manually on paper for small capacity plants.

However, for larger capacity plants in particular, an extension of the standard control systems with a data tracking system is recommended. This system can track every cake across the entire production line and, for panels, even every single element.

Concepts for existing and new plants

An AAC manufacturer can either start from the beginning with a portfolio of reinforced elements or expand production later. For this, the expansion must be considered in the basic planning of the plant. Below, the two different concepts are described. Both solutions have been successfully realised by Masa GmbH as well as Hess AAC Systems B.V. – now part of the Masa WhiteHub umbrella brand – in projects for international customers.

Expansion of existing plants

Many customers choose to establish their AAC production plant in multiple phases. This approach allows for a smaller initial investment to kickstart the project. As the project progresses, the focus can shift to increasing production capacity or expanding the product range. To ensure long-term success, it is essential to consider as many aspects as possible during the design and planning phase to enable the cost-effective and sustainable expansion of a plant. When planning for expansion from the outset, the necessary conversions and the integration of additional plant sections and parts can be carried out during operation for the most part. This forward-looking strategy results in considerable time and cost savings for the customer.

One example of successful expansion is the plant of a Mongolian AAC manufacturer. ‘Mongolian Gold’ (MAK) LLC. became a pioneer in introducing European standards and technologies to Mongolia, starting the MAK Euro Block plant in 2015 and the MAK Euro Cement plant in 2017. The company has become a respected and important brand in the Mongolian construction market. It now operates under the name ‘MAK Building Materials’, creating more than 1,500 jobs in the construction sector, promoting national production and working with national companies and organizations.

In the MAK plant, the preparation area for the steel reinforcement was composed of an automatic mesh welding machine, an automatic spacer welding machine (both starting from coils) in combination with a manual installation for welding cages.

Mounting wagons have been supplied along with the required reinforcement frames, needle holders, and sets of needles for lintels and wall panels.

Using a single-level gantry and a reinforcement manipulator, the steel parts are coated, dried, and inserted into the moulds. The needle bath is a standalone wax bath equipped with a pillar jib crane for lowering and lifting the beam with needles in and out of the bath.

Additionally, a lintel cutter and a collection table for the lintels have been provided in the packaging area. The customer decided on a manual solution for unloading and packaging the panels.

All other machinery was already delivered with the order for the initial AAC block plant and used for block production. These components could be left unchanged with the expansion; the operators just have to select different product types/dimensions. In addition, the process flow for the autoclaves had to be adapted for the panel production:

Compared to block production, the rate at which pressure/temperature rises or falls in the autoclaves needs to be reduced. This extends the entire hardening process by approximately two to four hours. The various autoclave steps are individually set in the autoclave control system.

Installation of plants for the production of reinforced AAC elements from the outset

In other projects, the customer can opt from the very beginning to set up a plant for the production of reinforced AAC elements, and with a large capacity – similar to that which the customer would like to achieve with blocks. The focus could be on one or more specific products or on a comprehensive portfolio (lintels, partition walls and/or different kind of loadbearing panels – for walls and floors/ceilings).

To meet the requirements for high volumes a fully automatic plant should be installed, whereby the following elements should be produced:

• The reinforcement wires, meshes or cages are produced fully automated. In fact, the specifications for the reinforcement, which come directly from the structural engineers' calculations, are digitally loaded into the machines, which then produce the desired reinforcement fully automatically.

• The reinforcement can be suspended on the holding frames in (multiple) mounting wagons, but there is also the option to have it hung automatically on the frames. Afterwards, the reinforcement holding frames will be handed over to the reinforcement manipulators for a specific mould/cake. Depending on the required capacity, a single- or double-layer gantry structure can be provided.

• Again, depending on the desired capacity, up to four reinforcement manipulators can be provided. The scope of supply can also include: one or two coating baths, multiple waiting positions, a fully automatic needle wax bath, preceded by a needle cleaning installation, automatic locking and unlocking systems and provisions to lower the reinforcement frames in the moulds and to lift off the holding frames from the moulds. The comprehensive control system of the reinforcement manipulators ensures that these processes are carried out automatically in the correct sequence and within the required times.

• Additionally, a data tracking system can be installed in the plant to ensure that all moulds can be tracked from casting to the cutting line. This means that it is possible to trace what type of reinforcement is contained in each cake/element. In most cases the data tracing system links also the raw material data, mixing tower batches, etc. to each cake. The tracking of the cakes also continues along the cutting line, on the hardening grids and on the hardening cars that pass through the autoclaves. That way, each individual panel can be tracked using a separate coding system for the panels. The cake's journey through the production process and the reinforcement it contains can be traced at any time.

Further equipment

Besides the parts for manufacturing and treating/handling of the reinforcement, a fully automated plant for producing reinforced AAC panels will contain many other equipment/machinery, including, for example, a lintel cutter to produce lintels with the required heights, additional autoclaves with different process parameters and additional specific laboratory and measuring/testing equipment for panels – to conduct pressure tests.

Special attention should also be paid to the specific packaging requirements for the panels. Usually, in parallel to the packaging line for blocks, a separate packaging line is set up for the panels, including:

· Necessary equipment to treat lintels

· Panel unloading system for treating the panels individually (if required) and on edge

· Options for partition walls for grouped handling and packaging

· Options for other panels for individual handling and packaging

Preview: Read more about these topics in one of the next issues of AAC Worldwide: AAC panels – Part II.

Masa's aerated concrete installations are proven advanced technology processes, designed according to customers specific requirements. This approach allows complete solutions to ensure highly efficient, optimised processes resulting in consistent final product quality.

This Masa Company channel is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about Masa are available for free. Feel free to share information from this website with other industry professionals!

Masa GmbH

Osterkamp 2

32457 Porta Westfalica

Germany

T +49 5731 6800

F +49 5731 680183

info@masa-group.com

www.masa-group.com