ARTICLE

Masa GmbH, 32457 Porta Westfalica, Germany

Manufacture of autoclaved aerated concrete with the impact table technology

Mr. Björn Gorka started to work for Masa GmbH as a process engineer in 2007, and he is Masa´s expert for all questions around the topics related to raw material analysis and process technology. Mr. Gorka studied civil engineering focusing on building materials and refurbishment at the Bauhaus-Universität Weimar from 1996 to 2002. Since 2007, he has been responsible for the Masa laboratory in Porta Westfalica, and he also advises and trains our customers. The Masa customers benefit from Mr. Gorka’s expertise, whether for the setup of a new sand lime brick or AAC plant or for plant optimizations and troubleshooting.

Western Europe: Casting technology – the popular method

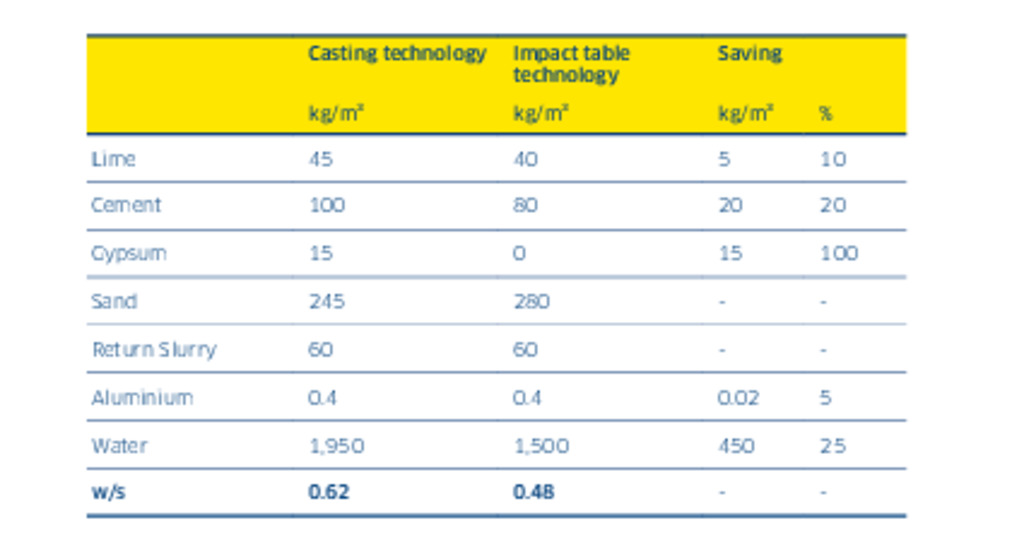

In Western European countries, the so-called casting technology is the most established manufacturing method for autoclaved aerated concrete. Over the years, the technique has been optimized to meet market and quality requirements. The proportion of hydraulic binders (lime and cement) has been modified during the past decades. The originally lime-active recipes shifted to cement-active, aiming for lower raw densities and thermal conductivity. What remained constant notwithstanding all innovations, however, are the high requirements on the used raw materials and the high water consumption of the AAC mixture. This can be up to 40 % of the dry weight of the AAC mixture.

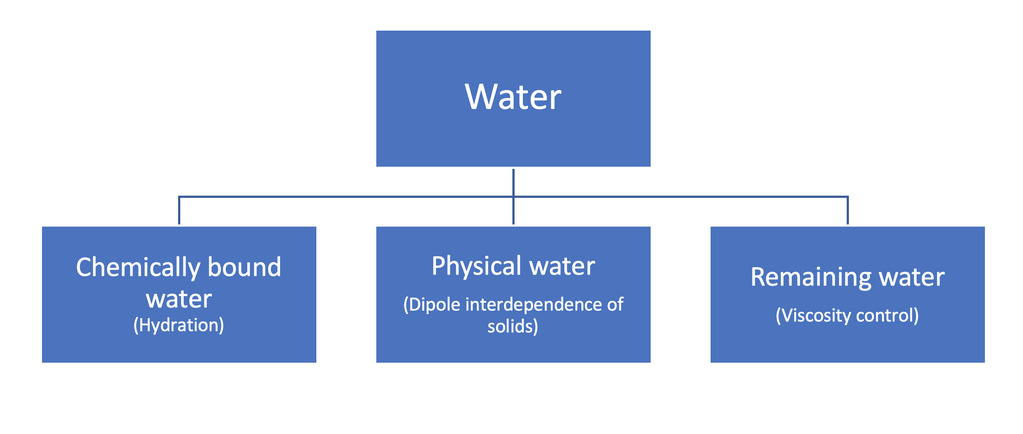

Water is very important for the manufacture of autoclaved aerated concrete. It serves as reacting agent, reaction medium, and hydraulic binder. The very fine ground raw materials require a lot of water for a sufficient moistening of the surface to achieve an optimum casting viscosity (approx. 2,500 to 3,000 mPa x s).

The low viscosity is necessary to enable the hydrogen gas in the alkaline AAC mixture to generate pores that can stabilize then. For the described casting technology, the process water has a key position, but may have some disadvantages at the same time: The moulds have to stay longer in the waiting area (3 – 5 hours). Furthermore, the cakes have considerably more moisture before autoclaving which means a longer autoclaving time and a higher energy consumption.

In general, the formation of the cellular structure of the autoclaved aerated concrete is determined by two characteristics:

1. The producible volume of the pore builder (aluminium)

2. The rheologic qualities of the AAC mixture

The reaction kinetics, that is, the cycle of the chemical reaction, generally depends on various parameters, such as the initial condition of the mixture, CaO content, viscosity, temperature, gas development, and dynamic effects.

In case of the casting technology, the kinetics of the increase in volume is determined by the quantity and quality of the used raw materials only. Dynamic effects on mould and mixture play a minor role and are usually avoided.

Eastern Europe: Impact table technology as an alternative

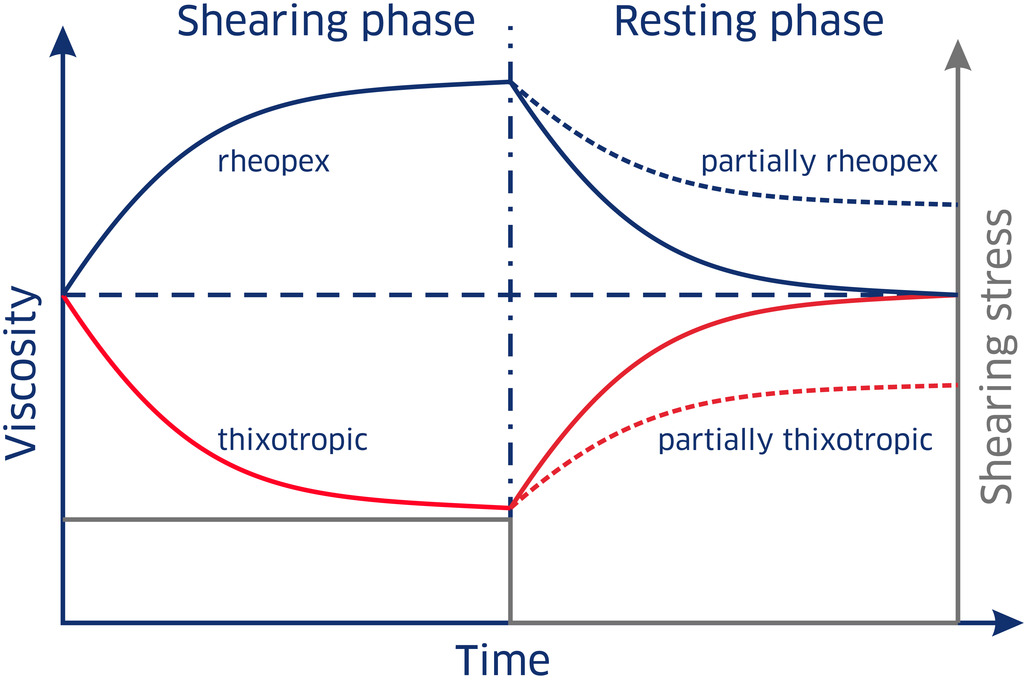

In contrast to the casting technology, the impact table method developed in Eastern Europe has a different focus. By means of the specific generation of dynamic forces, the rheologic characteristics (thixotropy) of the mixture are used and modified.

When dynamic forces are put on the casting mould and the AAC mixture, the viscosity decreases during the period of the strain, and in the resting period, the viscosity rises to the initial level again.

The considerably reduced quantity of water in the mixture – which is an essential part of this technology – leads to a massive increase of the mix viscosity.

As described above, for the normal course of the expansion process of the mixture it is necessary to achieve an optimum viscosity, in this case to decrease it by a thixotropic liquefaction of the mixture. The phenomenon of thixotropy consists in a destruction of weak structures by means of dynamic effects and a transition of encased (immobilized) and partially adsorbed water to free water.

The challenge is to find the best way to achieve the desired effect on the mixture. The dynamics of the liquefaction can be regulated by the intensity and frequency of the impacts. The degree of the dynamic effects is limited. Firstly, by too strong thixotropic liquefaction which can happen when gas develops too fast at the beginning of the forming process, this can even lead to a destruction of the macro structure at the end of the forming process. Secondly because of insufficient liquefaction which can also lead to a destruction of the structures.

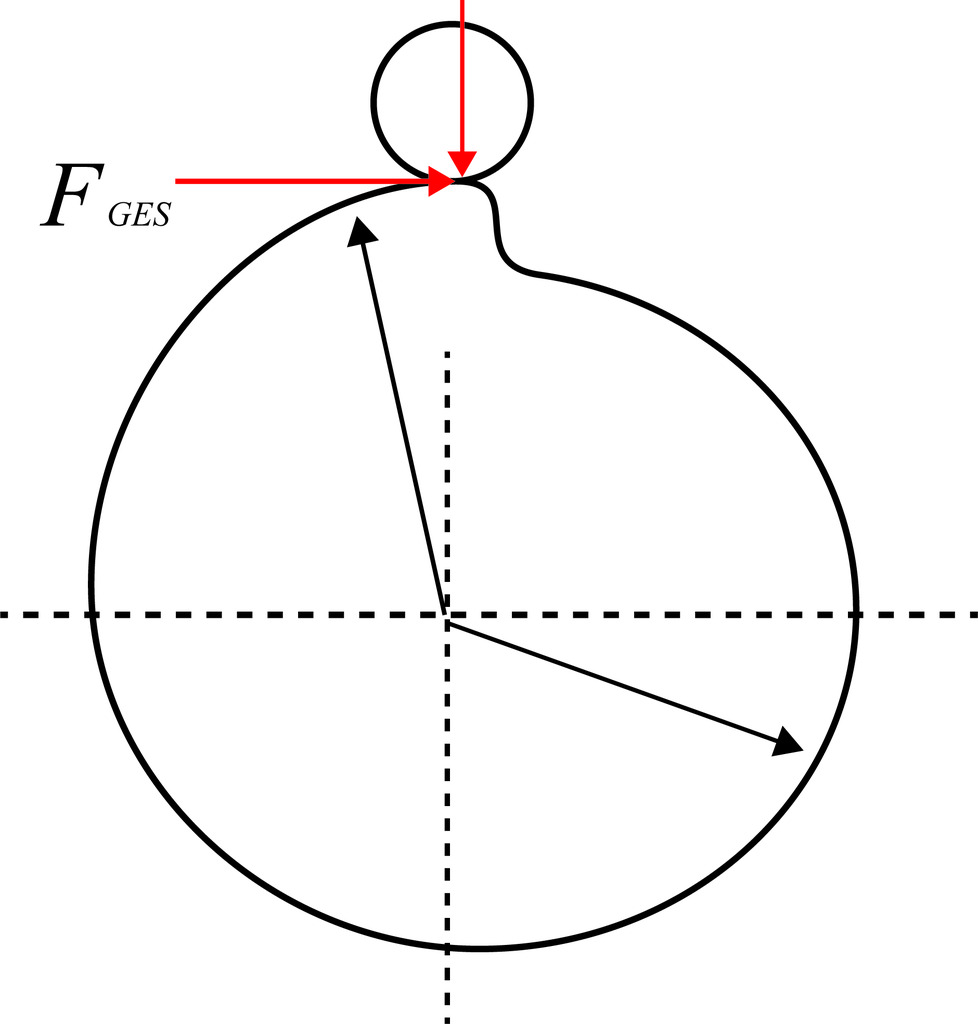

The AAC mixture passes through three phases in one impact cycle:

1. Resting phase

2. Free fall of the mould

3. Hard impact (shearing phase)

The dwell time of the moulds on the impact table depends on the required raw density and is approximately eight ± three minutes. With an increasing raw density, the impact time rises linearly. At the end of the impact process, the AAC mixture has reached its defined expansion height, and the increase in viscosity transfers the cake into a very stable condition.

To reduce the required quantity of water it is partly necessary to reduce the sand slurry with its bound water. To achieve this, the compound grinding method is used: A part of the sand is ground together with lime. Thus, part of the sand slurry can be substituted by the lime/sand mixture. Furthermore, the plant operator can grind his own lime and can adapt the mixture specifically to his requirements [2].

Advantages of the impact table technology

The described method offers various benefits for an AAC production plant. The reduction of the fermentation time to up to 90 minutes can cut the required number of casting moulds in half compared to the casting technology. The space required in the fermentation area can be downsized accordingly. The installation of more compact AAC plants is possible thus.

An optimum utilization of the rheological properties of the autoclaved aerated concrete compound in the expansion process can help to reduce the raw material consumption. With the impact table technology, savings of 20 - 30 % of cement, 10 - 15 % of lime, and 5 - 10 % of aluminium [3] are possible.

Autoclaving times can be shortened because the green cakes are moved into the autoclave with a lower moisture content. Also, the moisture of the cakes after autoclaving is much lower than that of cakes manufactured with the casting technology. Using this technology can lead to a considerable reduction of power consumption and CO2 emission.

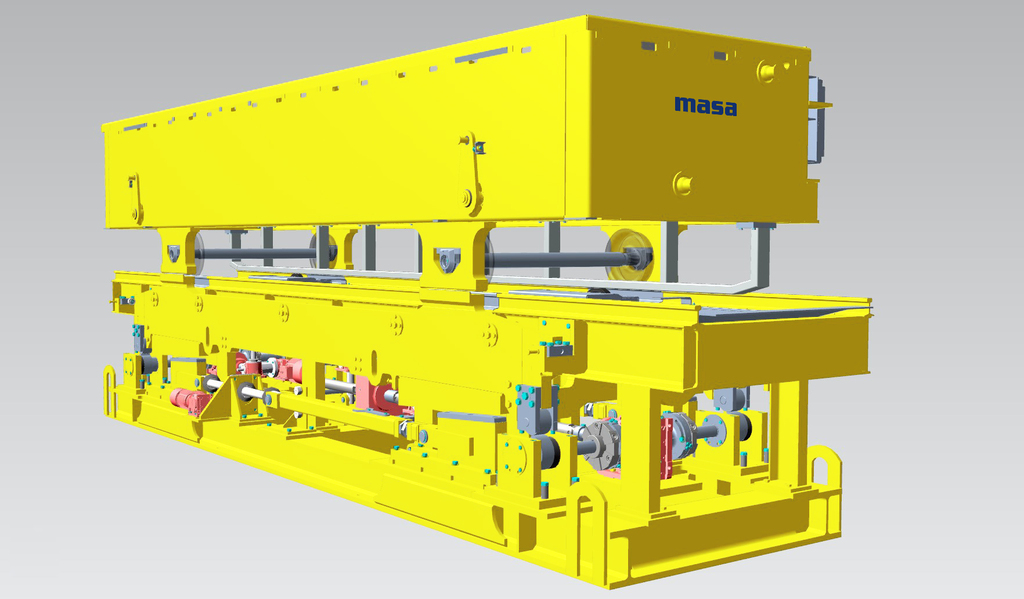

Design of the Masa impact table

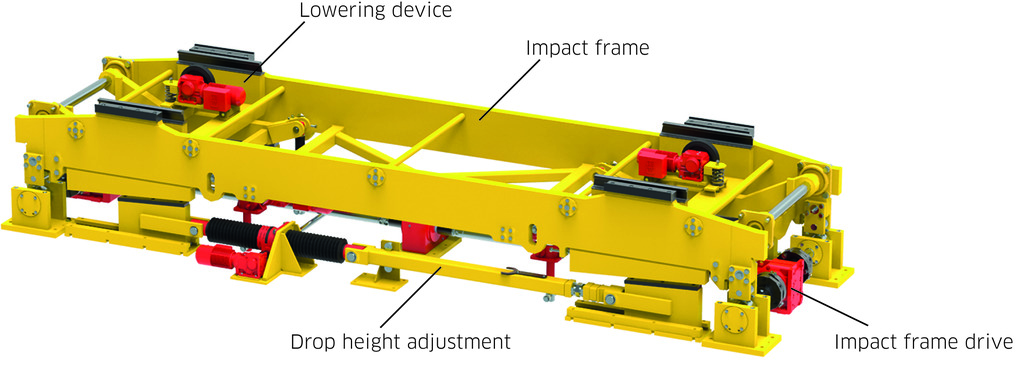

The technology described above has led to the development of the Masa impact table, a massive steel construction consisting of a travelling platform, the impact frame with driven cam discs, lowering device, and drop height adjustment. As soon as the driven cam discs have reached a defined position, the mould filled with AAC compound drops abruptly and collides with the support beams that are fixed to the lower and upper frame. To control the intensity of the impacts to the AAC mixture during the expansion process, the platform is equipped with an automatic drop height adjustment device.

To guarantee a continuous transfer of the forces into the mould via the impact strips and to protect the wheels of the mould, the Masa impact table is equipped with a lowering device for the travelling platform. The drop height adjustment enables a stepless adjustment of the expansion process of the autoclaved aerated concrete mixture.

For the impact table technology, the Masa casting moulds have been modified in that way that the mould is seated planely to the impact frame at four points. In case of a later modification of the plant to the impact table technology, each Masa casting mould can be adapted accordingly.

Control system

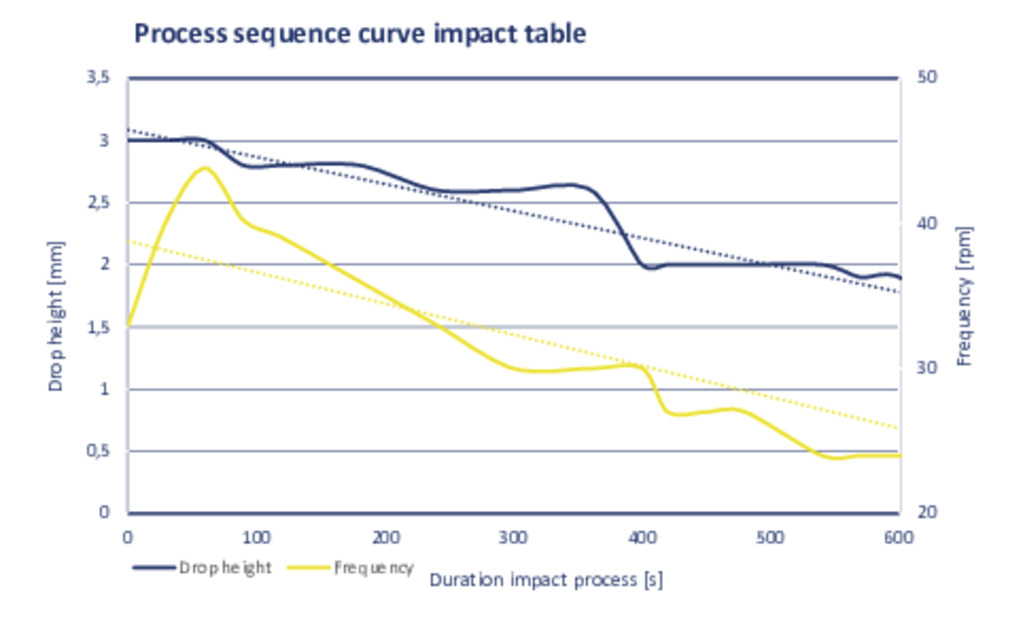

The Masa control system for the casting and fermentation area also comprises the supervision for one or two impact tables. In the visualization system, all required parameters for various recipes can be entered and stored separately.

The major parameters "height" and "frequency" are defined according to the predetermined process sequence curves. The process runs automatically down to the defined dwell time of the mould on the impact table. The plant operator can see all necessary parameters in the visualization system of the fermentation area.

In the Masa recipe calculation of the mixing plant control system, the frequently used compound grinding process of lime and sand is particularly considered. Parameters from the raw material preparation and from the laboratory of the plant are integrated into the calculation.

Impact table technology in use

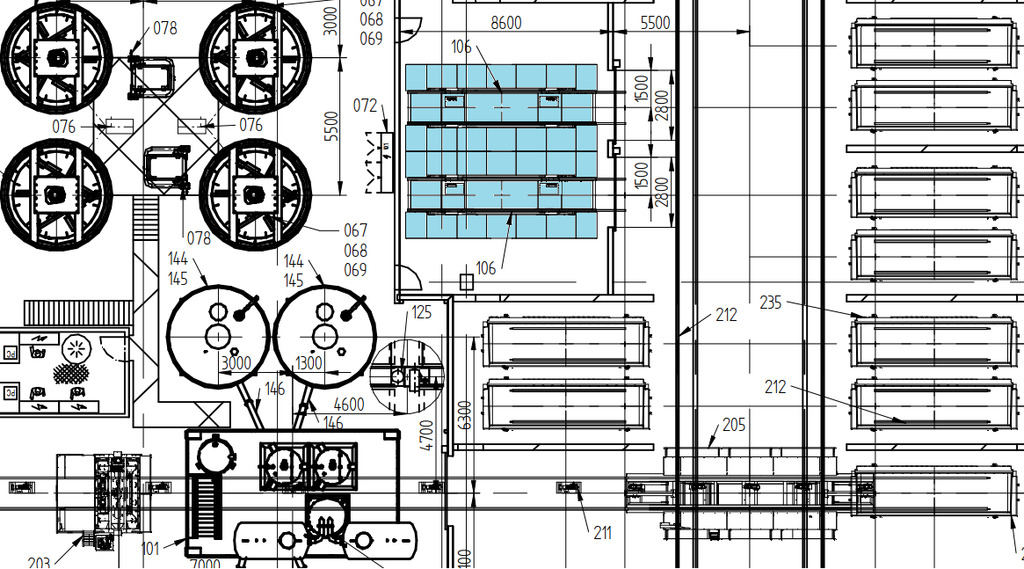

In 2019, another AAC production plant in Russia was successfully equipped with the Masa impact table technology. This factory has two impact tables and manufactures AAC blocks of the raw density class 300 – 600 kg/m³ with a daily capacity of 1.200 m³.

As a global supplier for this unique technology, Masa has comprehensive expertise and a treasure trove of experience. Of course, the impact table method can be considered and offered as an option in the project development.

Sources

[1] Wikipedia, https://de.wikipedia.org/wiki/Thixotropie

[2] Saznev N.P., Saznev N.N., Sazneva N.P., Golubev N.M. (2010). Производство ячеистобетонных изделий. Теория и практика

[3] Saznev N.P. (2011). Shock-moulding technology of manufacturing cellular concrete units. 5th International Conference on Autoclaved Aerated Concrete, 509-511

Masa's aerated concrete installations are proven advanced technology processes, designed according to customers specific requirements. This approach allows complete solutions to ensure highly efficient, optimised processes resulting in consistent final product quality.

This Masa Company channel is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about Masa are available for free. Feel free to share information from this website with other industry professionals!

Masa GmbH

Osterkamp 2

32457 Porta Westfalica

Germany

T +49 5731 6800

F +49 5731 680183

info@masa-group.com

www.masa-group.com