ARTICLE

Masa GmbH, 32457 Porta Westfalica, Germany

Sand preparation – quite simple with the right equipment

To start with: The appropriate raw material

Already in the run-up to the planning and dimensioning of an autoclaved aerated concrete plant, the analysis and evaluation of the major raw material sand regarding its physical and chemical qualities are of tremendous significance.

The silica existent in the sand reacts with the water and the burnt lime. Therefore, it is essential that the SiO2 content of the sand is more than 75 %. The higher the proportion of SiO2, the higher the quality of the finished product. Contamination by e.g. clay and humic substances should be avoided. These materials can lead to unwanted chemical reactions during the manufacturing process and thus affect the quality of the finished product.

In the manufacture of autoclaved aerated concrete, the wet grinding process is an efficient solution for the sand preparation. Precisely dosed raw sand and water are fed into a wet ball mill and processed to sand slurry. This slurry has a precisely defined consistency with a specific slurry density and grinding fineness.

Therefore, two parameters of the sand are essential for an efficient design of the ball mill:

One important point is the grain size of the raw sand. To achieve an energetically efficient grinding process, it is recommended to keep a particle size d80 of maximum 1.5 mm, that is, 80 % of the particles have a diameter smaller than 1.5 mm.

Beside the mill capacity and the required fineness of the prepared sand slurry, the comminution behaviour of the sand, usually evaluated by a standardized procedure, has to be considered. The Bond Work Index determined thus indicates the mass-related energy required to comminute the ground material to a certain fineness under defined operating conditions.

In its in-house laboratory, Masa GmbH offers the possibility of test milling by means of a laboratory ball mill. Other relevant raw material parameters can be tested and determined there as well. In general, Masa sees itself as a technology partner with extensive know-how, which is gladly shared with customers.

To evaluate the milling quality continuously during the production process, it is recommendable to take random samples. Ideally, every autoclaved aerated concrete plant should have its own laboratory. With the Masa laboratory manuals, laboratory technicians or plant operators have access to a wide range of information with detailed descriptions so that they can carry out these important tests during the milling process. In addition, Masa can offer workshops and training courses in process technologies, individually tailored to the needs of the customers. These can be held on site or at Masa's premises.

Essential: The proper equipment

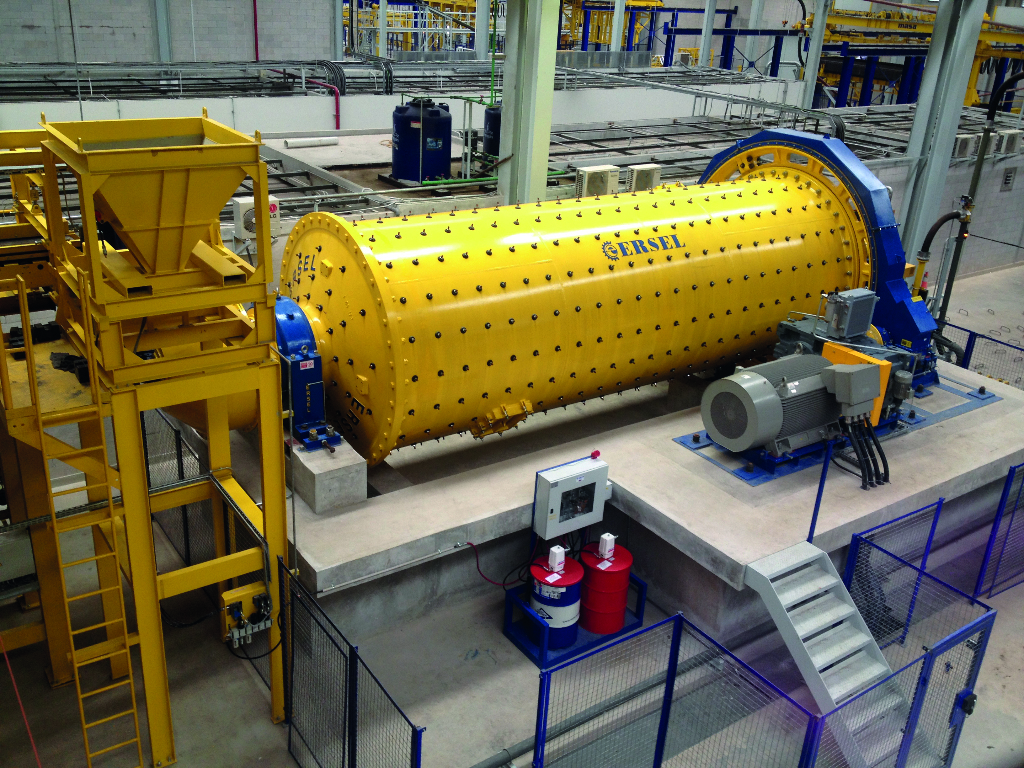

a) Wet ball mill

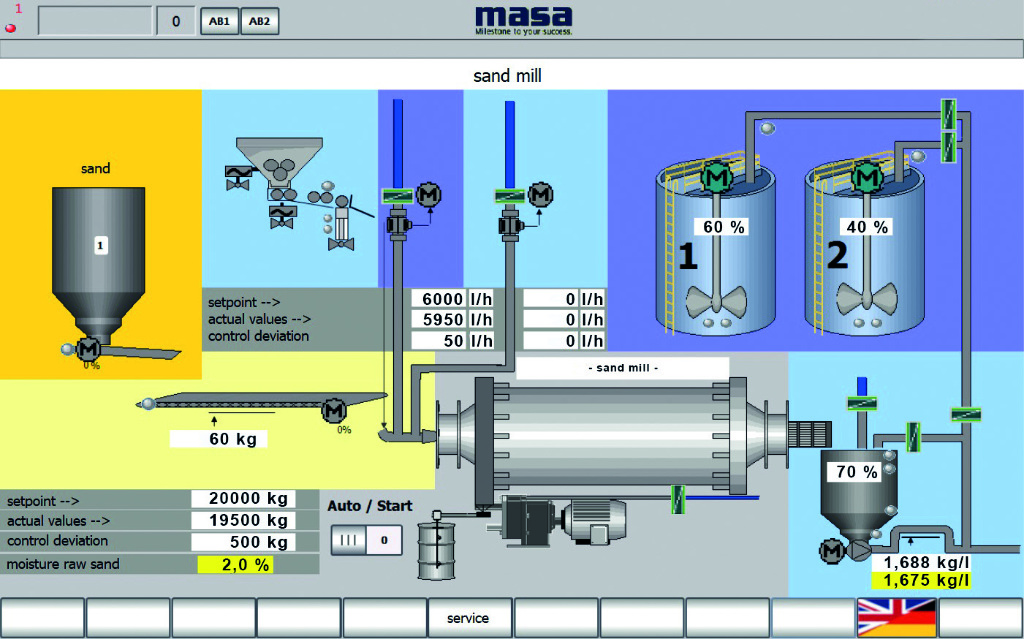

The sand passes through several important stations before it is fed to the mixing plant. First of all, the sand is fed into a sand bunker or silo by means of trucks or a wheel loader. Discharge conveyors or chutes then transport the sand to the ball mill. As for the sand feeding process, it has to be ensured that the volume of transported sand is constant but also adjustable. The added quantity of water is dosed proportionally to the sand quantity so that a continuous sand slurry quality is guaranteed. The slurry density and the material flow rate are monitored and controlled with the Masa plant control system.

The requirements for the water are higher than for the production of normal concrete; it must always be of drinking water quality. To reduce the consumption of fresh water, Masa plants are generally laid out for the use of condensate. The proportion of condensate that is generated in the autoclave hardening process of autoclaved aerated concrete can be pre-selected in the plant control system. A clear advantage to improve the profitability of the plant.#

For the design of the mill, the sand quality and the production capacity of the plant as well as composition and density of the autoclaved aerated concrete have to be considered. As this plant component has a high power consumption, a best possible design is essential to reduce energy costs. The parameters for this are milling capacity, type of plating, filling level, type of grinding bodies, size of grinding bodies, and speed. The mill should technically be adapted to the available sand. Deviations in the raw material can well lead to problems during operation. Therefore, Masa GmbH always tries to reach the optimum operating point of the mill. This can be adapted by a variation of the speed by means of the frequency regulation of the drive motor.

The grinding process is carried out with steel grinding bodies of various sizes. As the grinding bodies wear off, new ones are added automatically at regular intervals via the ball feeding device.

The mill lining is liable to wear as well. Therefore, robust rubber plates and rubber lifting beams are used that can endure several years.

The specific surface (cm²/g) of the sand is another important parameter for the quality of the autoclaved aerated concrete. This value is determined in the laboratory with a Blaine device and indicated as "Blaine value". Depending on the product, the Blaine value should be between 1,900 and 2,400 cm²/g after processing. By changing the sand throughput, this parameter can be influenced.

In the next step, a sieve at the mill outlet separates oversize grains and remains of grinding bodies from the sand slurry. With the help of a submersible pump, the sand slurry is then transported into the sand slurry silos. An automatic density measurement serves as another quality control of the sand slurry. With a pipe loop scale installed in the pipe system, Masa plants offer a low-maintenance and precise measuring device. In general, the slurry density should be between 1.67 and 1.71 kg/m³. Due to the automatic recording of all process-relevant data in the Masa plant control system and the automatic process control, it is guaranteed that only sand slurry is produced and fed into the sand slurry silos that complies with the product requirements.

b) Sand slurry silo with planetary mixer

The sand slurry is stored in special silos until it is required in the mixing plant. The size of these silos should correspond to the production capacity of the plant. In practice, the use of two sand slurry silos has proven successful. This means that one silo serves to supply the mixing plant and the second one to be fed by the sand mill – clearly an advantage with regard to the flexibility of the production process.

Furthermore, the increased temperature of the sand slurry after discharge from the ball mill has to be considered. A too short waiting time in the silo means a too high temperature of the sand slurry for the following reaction in the fermentation process. A reduction of the temperature by adding cold water is possible to a certain extent only, as the mixture allows a limited water content only. Using more than one silo with sizes of 150 m³ to 250 m³ means that the slurry can cool down to the appropriate temperature over several hours.

Because of the great difference in density of water and sand, the sand slurry tends to sediment soon when stored in the silo. To avoid this, the sand slurry silos are equipped with stirring devices. Masa uses planetary mixers to maintain a homogenous consistency of the sand slurry. To ensure a continuous operation of the mixers also in case of a power failure, Masa recommends to install an emergency power generator.

With their around-the-clock operation, stirring devices are strong work horses. Compared to central stirring devices, planetary mixers have an advantage regarding their power consumption, as the following example shows: In a plant with an annual production capacity of 500,000 m³, two silos with a volume of 250 m³ each are used. Masa requires a motor capacity of 18 kW per silo for the stirring device including the turning device. Based on 330 working days, the power consumption of both silos amounts to 285,120 kWh per year. Efficient central stirring devices in sand slurry silos require a minimum motor capacity of 37 kW. This means that the annual power consumption for such a configuration would amount to 586,080 kWh. Thus, the use of a planetary mixer means possible power savings of more than 50 %, a clear advantage that contributes to the profitability of a Masa autoclaved aerated concrete plant.

Masa – a reliable partner

Sand preparation for the manufacture of autoclaved aerated concrete requires the consideration of many parameters. This guarantees a smooth production process and minimizes downtimes. Therefore, it is particularly important for manufacturers to be supported and supervised comprehensively right from the start.

Masa as a strong partner for machinery and process technology supplies proven equipment that enables reliable production. The customers' success motivates and inspires Masa to design and manufacture machines that can fulfill all expectations of quality and reliability. In addition, as a member of the sand lime and autoclaved aerated concrete associations, Masa has access to a wide range of information and know-how. Thus, Masa ist able to advise and support its customers in nearly all technical questions regarding the sand lime and autoclaved aerated concrete production.

Masa's aerated concrete installations are proven advanced technology processes, designed according to customers specific requirements. This approach allows complete solutions to ensure highly efficient, optimised processes resulting in consistent final product quality.

This Masa Company channel is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about Masa are available for free. Feel free to share information from this website with other industry professionals!

Masa GmbH

Osterkamp 2

32457 Porta Westfalica

Germany

T +49 5731 6800

F +49 5731 680183

info@masa-group.com

www.masa-group.com