ARTICLE

Masa GmbH, 32457 Porta Westfalica, Germany

State-of-the-art sawing plant: The key to a wide range of products

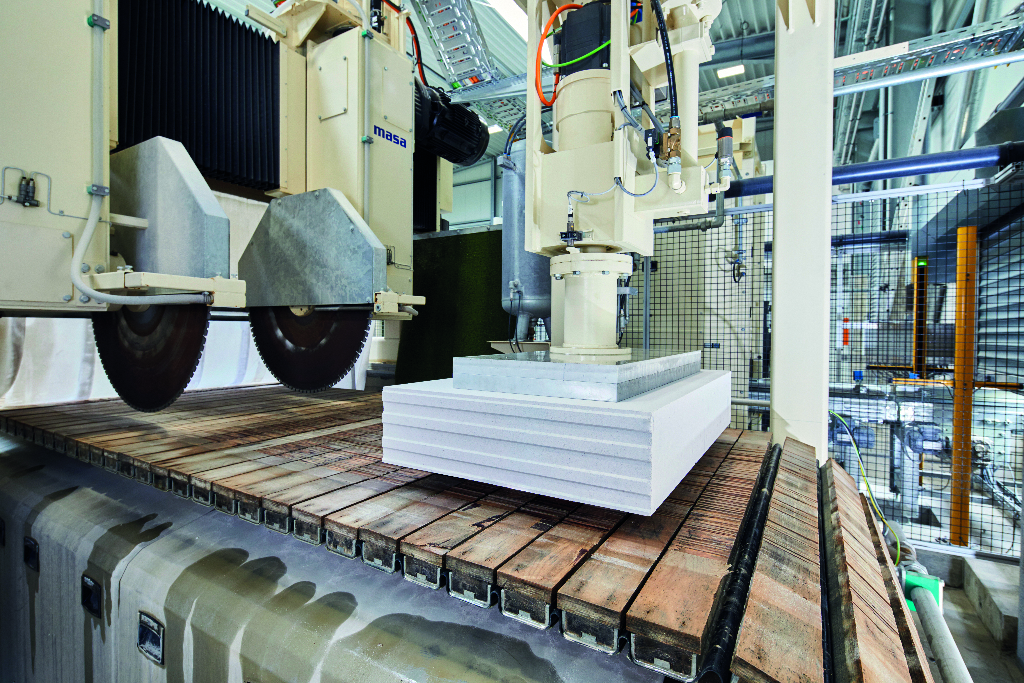

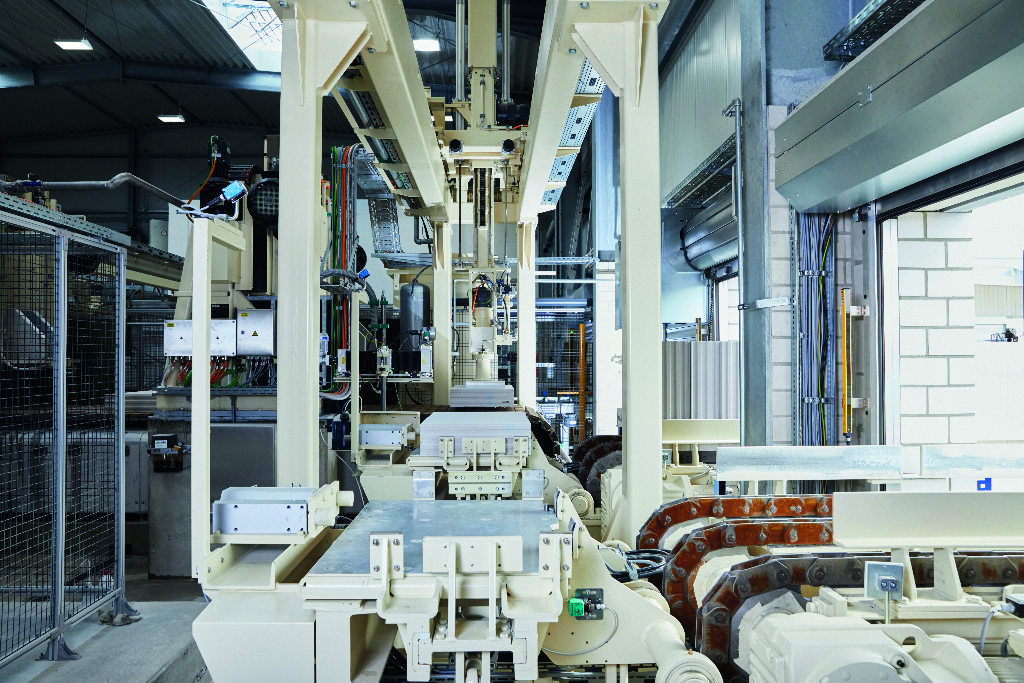

For the manufacture of these precise fitting supplementary bricks, Masa can supply a range of sophisticated equipment that is being continuously developed.

The Masa sawing plant: Effective and Efficient

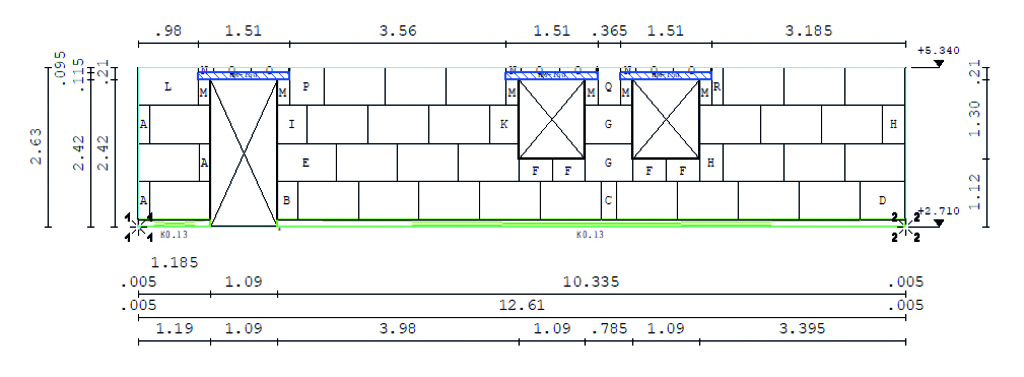

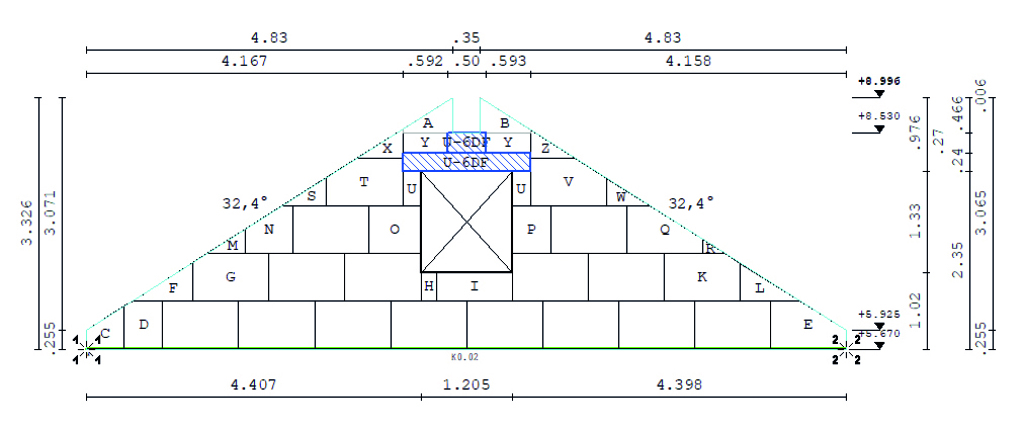

The fitting pieces required for a certain building are planned individually beforehand according to the architect's drawing and the wall development plans. The plans comprise all construction details, such as wall connections, window and door lintels, or gables with different angles.

Elaborate plant control system and configuration

Continual developments in the control software are essential to increasing the profitability of the sawing plant. The maximum utilization of a plane element is improved considerably by using special storage tables within the process sequence. The control software automatically optimizes the cuts by considering the defined fitting pieces for the respective building stage. This leads to a considerable reduction of waste when comparing it to solutions found in conventional plants.

The plane elements as well as the fitting pieces are transported to the different processing stations of the plant by means of transfer grabs or robots. All geometrical details of the various products have to be considered for this. Hence, special vacuum plates are used to lift the products. These plates are divided into several sections that can be individually activated or de-activated. With the latest generation of these vacuum plates, the division of the individual sections was modified once again. The results are impressive: Particularly small or narrow products as well as gables can be transferred safely and smoothly. Besides being a highly reliable process, this also enlarges the range of products that can be handled.

As the sawing plant is always fed with finished complete plane elements, it can be operated independently, no matter which products are manufactured in the sand lime brick plant at that time. This guarantees that the demand for fitting pieces can also be satisfied in case of planned plant shutdowns, such as maintenance work in the winter, which is common in many sand lime brick making plants. Compared to a sawing plant integrated into a sand lime brick making plant, the independent solution provides a high degree of flexibility.

Waste management preserves resources

The waste incurred in the sawing process does not have to be disposed of. In fact, it is a good raw material that is crushed and can then be returned to the manufacturing process via the mixing plant. A possible correction of the grain distribution curve and a reduction of the lime consumption are positive side effects of this procedure.

Experience and market presence

Masa GmbH is a competent partner for all topics around the manufacturing of sand lime bricks. In many plants worldwide, the innovative Masa sawing technology for the manufacturing of fitting pieces as well as the modern Masa sand lime brick press types HDP 800 and HDP 1200 Jumbo for the manufacturing of small and large products can be found. Decades of experience and market presence assure the success of our customers around the globe.

[1] Cp. Statistisches Bundesamt (Destatis), 2020: Baufertigstellungen von Wohn- und Nichtwohngebäuden (Neubau) nach überwiegend verwendetem Baustoff - Lange Reihen ab 2000, 2019, Charts 1.1.1 and 2.1.1

Masa's aerated concrete installations are proven advanced technology processes, designed according to customers specific requirements. This approach allows complete solutions to ensure highly efficient, optimised processes resulting in consistent final product quality.

This Masa Company channel is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about Masa are available for free. Feel free to share information from this website with other industry professionals!

Masa GmbH

Osterkamp 2

32457 Porta Westfalica

Germany

T +49 5731 6800

F +49 5731 680183

info@masa-group.com

www.masa-group.com