ARTICLE

Wehrhahn GmbH, 27753 Delmenhorst, Germany

Different technologies for handling and cutting AAC cakes

Klaus Boderke studied process engineering in Clausthal-Zellerfeld. After being plant manager in several plants and meanwhile having 30 years experience in AAC plants he now supports plants worldwide for quality and output increase, cost reduction, change and project management, safety and environmental assessments with profound skillness in staff training and leadership.

boderke@wehrhahn.de

Transport of the cake into the cutting line

Tilt cake cutting systems

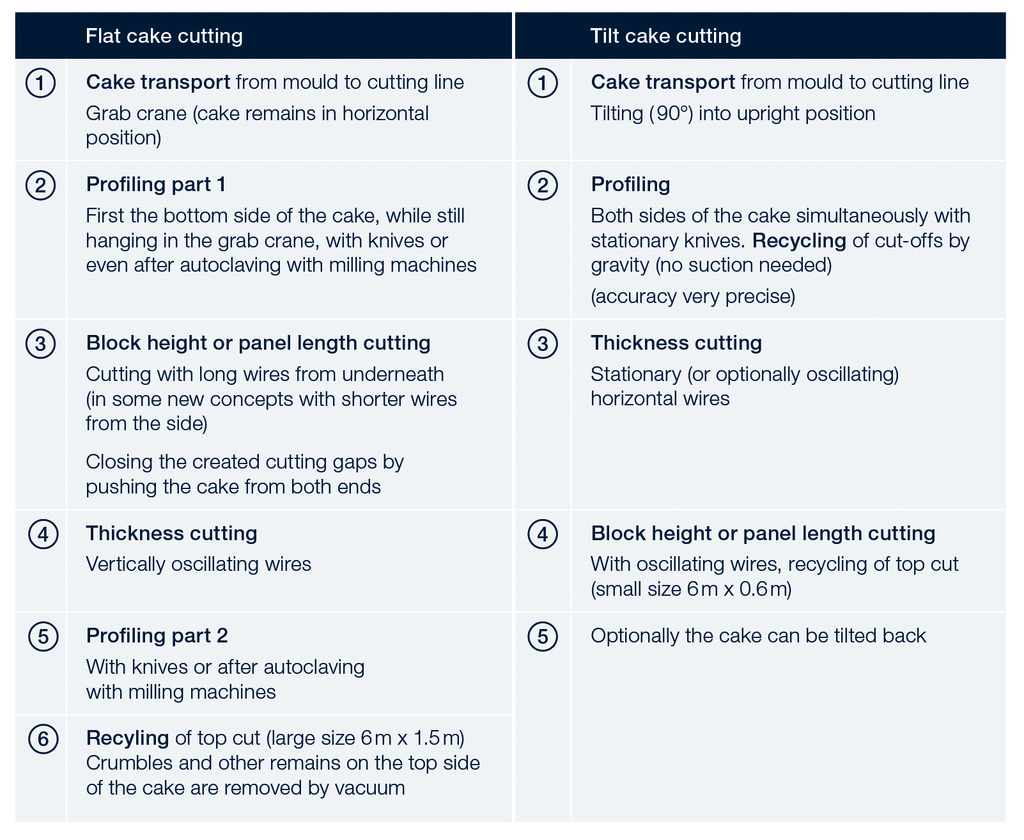

Here the mould is tilted by 90 degrees into an upright position and placed onto a cutting pallet. Then the cutting pallet with the cake passes through the cutting line (Fig. 1). In the tilting process, cakes with a lower hardness can be processed because the mechanical stress is reduced to a minimum.

The cutting pallet on which the cake rests during cutting is easy to clean and requires hardly any maintenance.

Flat cake cutting systems

In flat cake cutting systems a grab crane squeezes the two longitudinal sides of the cake, lifts it, and moves the cake to the cutting line to lay it flat on a grid.

A cake that is squeezed by a grab crane requires a higher green strength which is achieved by a higher amount of binders, mainly cement, and/or by sufficient precuring times. The quantity of binding materials and the precuring time must be adapted to the requirements for handling the cake with a grab.

Cutting and profiling

Tilt cake cutting systems

After tilting the cake, 5 sides of the cake are easily accessible as the cake moves through the cutting line stages.

First stationary wires/knives profile both sides of the cake simultaneously. This ensures high accuracy. All cut-offs fall by gravity and only the top layer is sucked off by vacuum later and fed into the return slurry.

In the second step the product thickness is cut by stationary or oscillating wires. All cutting wires can be very short, approx. 75 cm (30 in), which facilitate best possible cutting accuracy. The uniform distribution of cutting wires in a very long cutting machine reduces stress applied on the cake which is in particular important for thinner products (less than 75 mm thickness). (Fig. 3).

Finally, the block height or panel length is cut in the cross cutter. The cross cutter operates with two oscillating cutting frames. The wire tension is kept constant, thus providing cutting accuracy and extended wire life.

The accessible sides of the cake allow profiling of grip holes for blocks when required.

Flat cake cutting systems

In flat cake cutting systems profiling is usually done during the transport of the cake from the mould into the cutting line or after autoclaving using milling machines. In the green stage, the cake is still hanging in the grab crane and knives carry out the profiling from underneath the cake. The top part of the cake is profiled later during the cutting process.

Then the cake is placed in the cross-cutting section, where oscillating wires cut the block height or panel length.

Before the thickness cut, the cutting gaps caused by the cross cutter will be closed. This is important to prevent the wires of the thickness cutter from escaping into these gaps and causing damage. The cake is sliding on the grid during this process step.

Finally, the top part of the cake can be profiled with knives. Cut-offs are collected by vacuum from the surface of the cake.

The grid on which the cake rests during the entire process (cutting and autoclaving) comprises of thin lamellas which have to be well maintained to avoid collision with the wires of the thickness cutter.

Both technologies presented here for handling and cutting autoclaved aerated concrete cakes have their advantages for certain products. From a historical perspective, both technologies have evolved and been optmised over the decades.

Wehrhahn supplies complete AAC plants or individual machines, depending entirely on specific requirements of its clients. Wehrhahn takes account of all the relevant factors and conditions, such as production quantities, location, space available, level of investment and much more.

Wehrhahn’s advanced, modular and versatile plant systems allow investors to select the best suited plant from a choice of AAC plant systems all formed by repositioning and combining the proven Wehrhahn machines in different sequences and positions. It is common in all plant types that the cake is cut in vertical position. This ensures highest cutting accuracy and facilitates profiling and cutting of hand holds prior to autoclaving.

This WEHRHAHN channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about WEHRHAHN are available for free. Feel free to share information from this website with other industry professionals!

Wehrhahn GmbH

Muehlenstrasse 15

27738 Delmenhorst

Germany

T +49 4221 12 71 0

F +49 4221 12 71 80

mail@wehrhahn.de

www.wehrhahn.de

Die Tabelle hat keine Überschrift...