ARTICLE

Wehrhahn GmbH, 27753 Delmenhorst, Germany

It’s all in the ingredients – the importance of raw material suitability

Following this aspiration, Wehrhahn is not only an AAC plant supplier with outstanding levels of productivity, flexibility and in-house developed automation systems. Being a competent partner regarding raw materials, product quality, and the production process is a big part of the company's ambition. Wehrhahn offers essential assistance to high quality products with its special in-house laboratory. Here, the customer's raw materials are analysed, AAC formulations are created and even sample blocks can be produced. In fact, what the producer does on a large scale can be replicated on a small scale in the Wehrhahn laboratory.

The highly skilled staff members of the R&D department with utmost expertise in AAC chemistry and technology grant high quality support, verifying Wehrhahn’s position as a global market leader in AAC technology.

„We are successful, if our customers are successful. The most important issue for us is to provide solutions that enable our customers to operate successfully in the market.“ (Torsten Dietz, Managing Partner, Wehrhahn)

The first step for a prospective customer – this often influences the choice of the site for the production plant – is to find the right sand source with suitable quartz sand (SiO2 >75%). Of course, in the Wehrhahn laboratory, all relevant tests are conducted. The X-ray fluorescence (XRF) analysis shows the chemicals composition and reveals potentially harmful ingredients. X-ray diffraction (XRD) analysis is used to identify the mineralogical composition (such as quartz, feldspar, calcite, mica) of the sand. Especially, if there is a significant quantity of "silt" with particles < 63 µm, this examination is helpful. "Silt" mainly contains clay minerals such as smectite, kaolinite or chlorite. These phyllosilicates have the ability to store water in between the layers and influence the viscosity of the AAC castings negatively. The determination of the grain size distribution with an air jet sieve machine completes the evaluation regarding the actual suitability of the tested sand.

In the next step, the customer can continue seeking out other regionally available raw materials, such as lime, cement, and gypsum/anhydrite. In the Wehrhahn laboratory, the chemical composition of all raw materials is deconstructed by using an XRF. A laser scattering particle size distribution analyser even detects particles down to 0.1 µm in detail, whereas traditional sieving methods with air jet sieving or vibration screening machines are limited to 32 µm. In cement and quick lime, there are large quantities of particles with sizes smaller than 32 µm to be found.

In some countries, such as Great Britain, China or India, fly ash and meanwhile even deposit ash is widely used as a substitute for sand. The analytical methods are similar, but the AAC recipes differ significantly. The R&D department has vast experience in handling fly ashes and deposit ashes to achieve excellent AAC qualities.

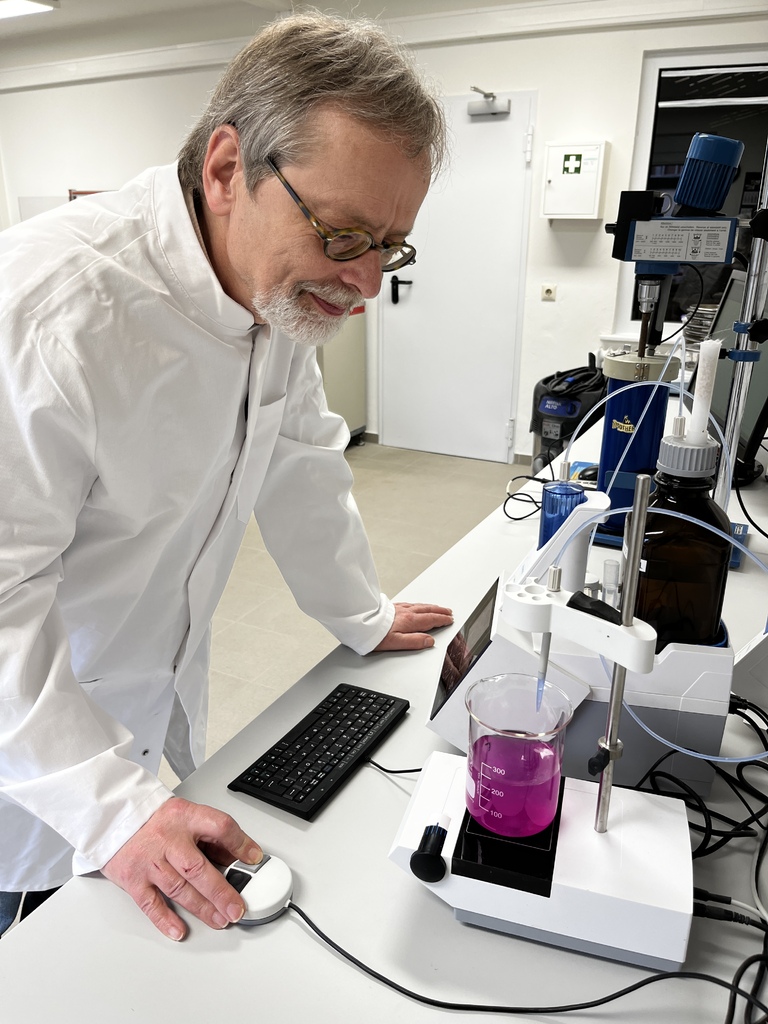

Sand or ash are the dominating constituents in the mix. Quicklime however, plays an important role in the precuring process (heat generation, aluminium reaction) and in the autoclaving process (building of CSH-phases, tobermorite). Therefore, considering the calcium oxide (CaO) content and the reactivity of the quicklime is necessary, since these parameters decisively influence the recipe calculation. In the Wehrhahn laboratory, the CaO content is determined by a titration apparatus.

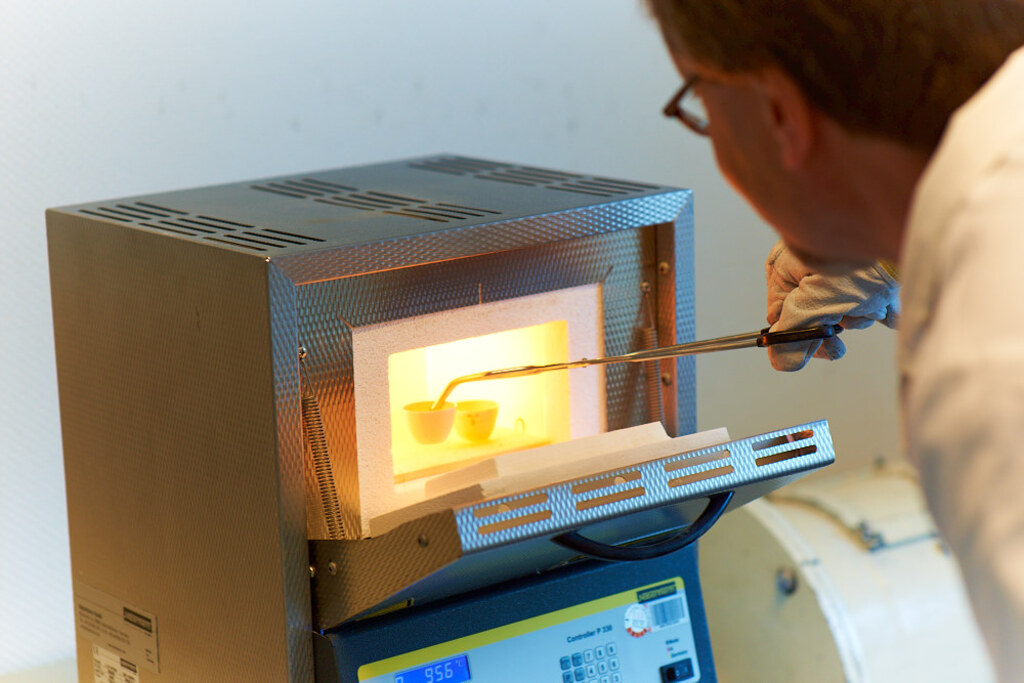

Using hydrochloric acid (HCl) as a solvent, the total alkalinity of lime (CaO, Ca(OH)2, CaCO3, but also MgO, MgCO3) can be determined by the retitration with sodium hydroxide (NaOH). Using boiling water as a „solvent“ and hydrochloric acid for titration, the available calcium oxide content is determined according to DIN EN 459-2:2010-12; chapter 5.8. The available CaO-content (CaO and Ca(OH)2) represents the part of the quicklime that participates in the hydrothermal reaction in the autoclave. To complete the chemical analysis, the quicklime is heated in a furnace in two steps, first to 550°C and then to 1025°C. The loss on ignition (LOI) is determined. This enables the calculation of the amounts of unburned calcium carbonate CaCO3, the already hydrated lime Ca(OH)2, and the active CaO (the pure calcium oxide that hydrates during the precuring time connected with generation of heat (1187 kJ/kg).

The reactivity of the lime is calculated automatically by determining the wet slaking curve according to DIN EN 459-2:2010-12; chapter 6.6.

Cement is the second source of CaO that is involved in the hydrothermal reactions to give CSH-phases like tobermorite-11 Å (Ca5Si6O17·5H2O). From the XRF-data, it is possible to calculate the main clinker composition (C3S, C2S, C4(A,F), C3A), using the Bogue calculation. The clinker composition, which is tested in the Wehrhahn laboratory by a Vicat-test according to DIN EN 196-3 influences the setting behaviour. Moreover, the fineness of the cement is important and needs to be evaluated. Therefore, the particles size distribution is also tested by using the laser scattering particles analyser. The specific surface is determined by a Blaine-test according to DIN EN 196-3.

Small quantities of gypsum CaSO4·2H2O or anhydrite CaSO4 influence the precuring process and the quality of the AAC in a positive way. In some countries, natural gypsum or anhydrite is hard to obtain. Simple tests are necessary to distinguish between gypsum, anhydrite and the not recommendable hemihydrate CaSO4•½H2O (plaster of Paris) which immediately stiffens when in contact with water.

Provided the analytical data of the raw materials are in compliance with the specifications set out by Wehrhahn, a first cake based on a standard recipe is made. This practice allows to determine the suitability of the raw materials for high quality AAC production. In a second step, the optimisation of the mix formula in view of quality and feasibility is carried out.

The raw materials are mixed with a special mixer and finally the slurry is poured into a mould. During the precuring process, the temperature and the rising of the green cake is continuously monitored until a sufficient hardness and cake height is reached. Afterwards, the green cake is autoclaved in the Wehrhahn laboratory autoclave with a volume of 500 l. Up to 8 cakes can be autoclaved simultaneously. The autoclave is equipped with an external steam generator and, as in the full-scale plant, it is possible to apply vacuum at the beginning of the autoclave cycle. Controlled by the Wehrhahn autoclave control system Waco, the real hardening process in a production plant can be simulated.

After autoclaving, the important quality parameters of the produced AAC have to be tested. The compressive strength is determined at cubes of 100x100x100 mm using an electronically controlled testing machine according to DIN EN 772-1:2011-07. After drying to a constant mass at 105°C, the dry raw density is calculated. AAC samples are stored in a climate chamber at 20°C and 45% relative humidity to measure the shrinkage according to DIN EN 680:2005-03.

Investors, but also experienced customers, can benefit from Wehrhahn’s R&D facilities to obtain reliable and detailed information about the suitability of raw materials. Consequently, constantly high quality and marketable AAC blocks and panels can be produced right from the beginning at the plant start-up. Quality risks are minimised. Nevertheless, Wehrhahn R&D experts support customers continuously, to elaborate a wide portfolio of products for different strength classes, reinforced panels, as well as low density insulation materials.

The laboratory specialists are experienced in executing all relevant laboratory tests on-site. For process optimisation, they train plant operators in operating the dosing and mixing control Wecomix and the autoclave control program Waco. Often, these trainings take place on-site or in the Wehrhahn laboratory. Due to the pandemic, online workshops are offered additionally through Remote Technical Service (RTS).

Dipl.-Chem. Uwe Schley has joined the Wehrhahn Laboratory in 2002 and he accompanied many of Wehrhahn´s customers worldwide to ensure a smooth and fast plant start-up and production of high quality AAC.

Wehrhahn supplies complete AAC plants or individual machines, depending entirely on specific requirements of its clients. Wehrhahn takes account of all the relevant factors and conditions, such as production quantities, location, space available, level of investment and much more.

Wehrhahn’s advanced, modular and versatile plant systems allow investors to select the best suited plant from a choice of AAC plant systems all formed by repositioning and combining the proven Wehrhahn machines in different sequences and positions. It is common in all plant types that the cake is cut in vertical position. This ensures highest cutting accuracy and facilitates profiling and cutting of hand holds prior to autoclaving.

This WEHRHAHN channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about WEHRHAHN are available for free. Feel free to share information from this website with other industry professionals!

Wehrhahn GmbH

Muehlenstrasse 15

27738 Delmenhorst

Germany

T +49 4221 12 71 0

F +49 4221 12 71 80

mail@wehrhahn.de

www.wehrhahn.de