ARTICLE

Wehrhahn GmbH, 27753 Delmenhorst, Germany

The „all-new“ AAC panel production plant generation

Growing demand for vertically applied wall panels

These days, investors can choose between different technologies and the discussion concerning “which is the best technology?” has almost become philosophical. Typical questions are: Should a modern AAC plant cut cakes in upright or in flat position? Should a cake be separated during the "green stage" or after autoclaving? Should a cake preferably be autoclaved in flat or in upright position? The answer is: As in many other aspects of life, there is not just black and white. Investors need experienced plant suppliers - with all-embracing knowledge and proven technical solutions to meet their individual requirements. Entering a dialogue with an investor and comprehensive consulting is important to reach the goal!

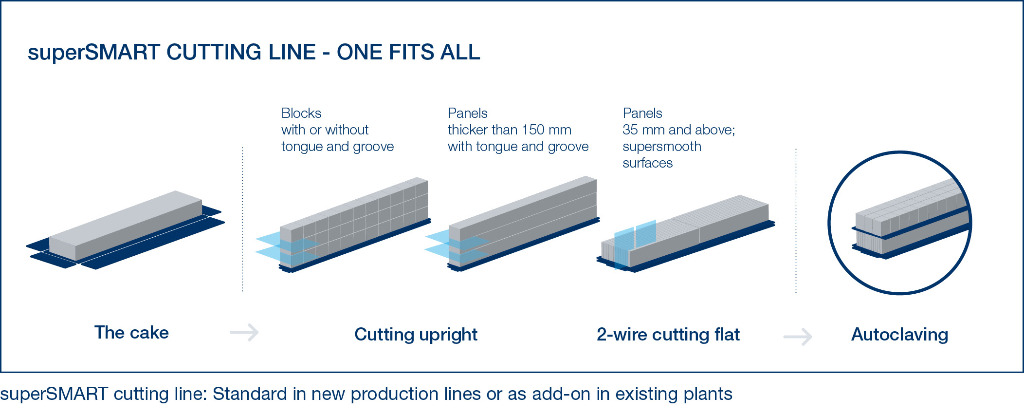

Wehrhahn plants feature tilt-cutting technology, the leading technology for blocks and thicker panels with tongue and groove. The latest innovation is the development of a new thickness cutter as an add-on for the Smart Plant Generation. This cutter was primarily designed to produce thin panels (35-100 mm thickness) with super smooth surfaces. However, the thickness cutter is also the ideal choice for all other kinds of panel products.

The new concept combines the advantages of tilt cutting and flat cake cutting technology

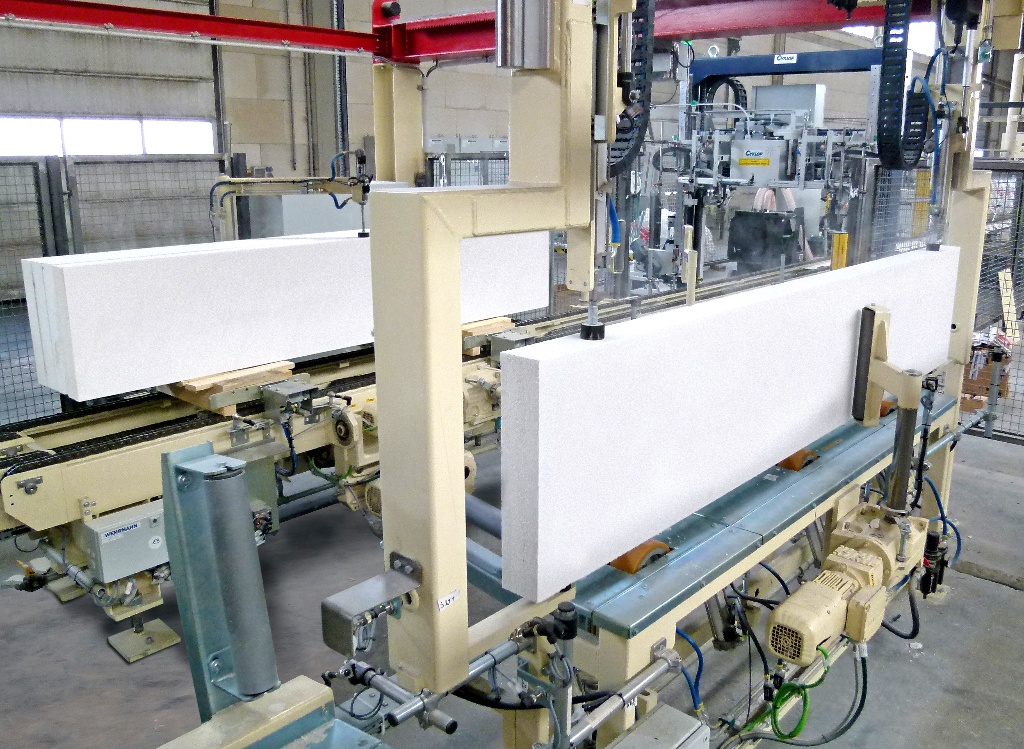

New implemented flat cake thickness cutter

The technology uses the Wehrhahn tilting machine, which brings the cake back into a flat position, onto a high-performance conveyor system. The conveyor transports the horizontally placed cake through the thickness cutter. A double cutting wire system, oscillating at ultra-high speed, facilitates the thickness cut. The first wire cuts the thickness, followed by a second wire to smoothen the cutting surface. The result is a precise and super smooth surface of the cut panel.

Table 1: Advantages of the new system

1) The high-performance conveying system allows to close the gap between two panels. No need to push the cake on a grid. |

2) The wires of the thickness cutter are electro-mechanically operated by synchronised and frequency-controlled motors. No crank system running in an oil bath necessary. |

3) After cutting, the cake is autoclaved on standard Wehrhahn autoclave pallets. No cutting grids enter the autoclaves. No maintenance required for such grids. |

4) Tongue and groove are precisely cut during the green stage. No white milling needed, except for surface appealing decoration if required. |

5) Panel cut does not require any further separating (no green or white cake) as the gap created during cutting remains open. No risk of sticking. |

6) The new concept can be added to Wehrhahn Smart plants as an add-on. Existing moulds, autoclave pallets and other accessories can be used. |

Damming wall system for flexible panel length in the mould

During panel production, it may happen that the full length of the mould cannot be utilised. This is the case when one or multiple panel lengths do not match the typical length of 6m. Some producers try to overcome these difficulties by the combined production of blocks and panels in one cake. This, however, is not always possible, as the required densities of blocks and panels are different.

The most appropriate solution is to adjust the usable mould length by using movable damming walls. The unique Wehrhahn mould with four hinged walls facilitates the use of damming walls in an easy and safe way. After cleaning and oiling, the damming wall is automatically positioned in the mould by high precision stacking devices. The position is precisely chosen to utilise the mould length in the most feasible way. Once positioned, the mould walls are automatically closed and the damming wall is properly fixed inside the mould. A reliable sealing system prohibits any leakage after the slurry has been poured into the mould.

The smart system even allows to position the damming wall, based on the mould volume, set in the mix formula in the Wecomix dosing and mixing system. It has successfully been in use in several plants for many years and has become even more important recently, due to an increasing market for reinforced products.

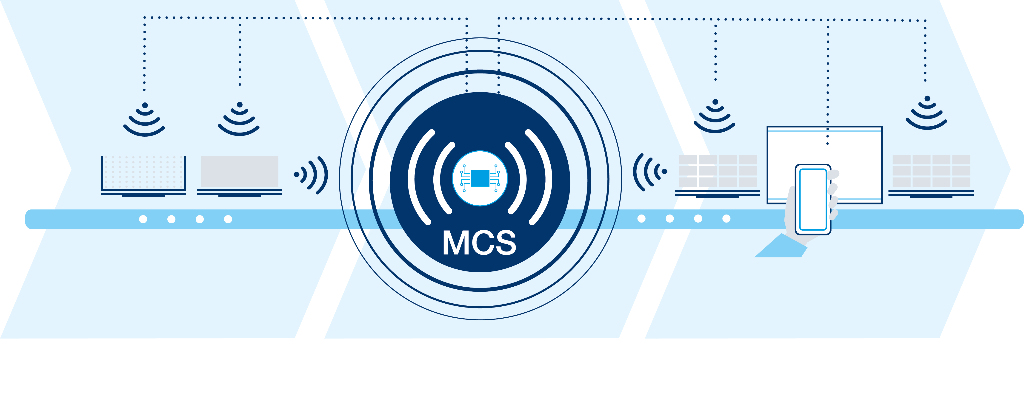

MCS Master Control Server for a smart production

Investors, who rely on high quality products, are known to have high demands on the quality of their production plant and nevertheless on the production process. They can rightly expect intelligent automation modules to be integrated into their production systems in order to run a smooth ("smart") production process with simple operation and self-optimisation. The key to higher efficiency is the advanced automation technology: During the production process, comprehensive data is collected, evaluated by algorithms and used to control and optimise all process and plant parameters. Integrated as standard, the new AAC plant generation uses “smart” technology and produces more efficiently than ever before. All formerly known modules such as PCI, EnMS, service interval application and report management system are now combined in the MCS (Master Control System).

Remote Technical Service

Versatile possibilities of remote service, remote installation and remote training complement the smart production. This is essential in times, when quick action is necessary, and also under exceptional conditions, for example in case of restricted travelling, when face-to-face meetings are difficult to realise.

The intelligent combination of the all-in-one cutting technology, complemented by flexible mould length adaptation is the key for advanced and feasible panel making solutions.

Having found the final piece of the puzzle, the Master Control Server (MCS) easily controls and manages the fully automatic „all-new“ AAC plant generation.

Wehrhahn supplies complete AAC plants or individual machines, depending entirely on specific requirements of its clients. Wehrhahn takes account of all the relevant factors and conditions, such as production quantities, location, space available, level of investment and much more.

Wehrhahn’s advanced, modular and versatile plant systems allow investors to select the best suited plant from a choice of AAC plant systems all formed by repositioning and combining the proven Wehrhahn machines in different sequences and positions. It is common in all plant types that the cake is cut in vertical position. This ensures highest cutting accuracy and facilitates profiling and cutting of hand holds prior to autoclaving.

This WEHRHAHN channel and all information presented here is provided by AAC Worldwide - the journal for the Autoclaved Aerated Concrete industry. All articles about WEHRHAHN are available for free. Feel free to share information from this website with other industry professionals!

Wehrhahn GmbH

Muehlenstrasse 15

27738 Delmenhorst

Germany

T +49 4221 12 71 0

F +49 4221 12 71 80

mail@wehrhahn.de

www.wehrhahn.de