Application & Construction

Reducing the negative impact of buildings on the environment

Autoclaved aerated concrete in sustainable construction

Loading...To support sustainable construction, AAC producers have defined Sustainable Development Goals that will have the greatest impact when implemented. Manufacturers will focus on tasks resulting from the following Goals:

• Innovation, industry, infrastructure (Goal 9).

• Clean and available energy (Goal 7)

• Clean water and sanitary conditions (Goal 6).

• Responsible consumption and production (Goal 12).

• Good health and quality of life (Goal 3).

• Climate action (Goal 13).

• Sustainable cities and communities (Goal 11).

Although none of the 17 global Sustainable Development Goals relates directly to construction, the necessity of changes that must take place in this sector cannot be ignored. Production facilities need to be operated with a view to limiting their harmful impact on the natural environment while ensuring the comfort and quality of life of the users of the products. The concept of sustainable construction also applies to the declining life stage of the production facility, i.e. demolition and recycling - also at this stage, the environmental burden of the facility should be minimized.

Less energy, less smog

According to the EPBD directive of the European Commission, the construction industry uses directly and indirectly, mainly during the use of buildings, about 40% of the total energy produced and is responsible for 36% of the total CO2 emissions in the European Union. The emphasis on energy efficiency in construction has resulted, among others, in introducing the obligation to develop the energy performance of buildings and tightening the regulations on thermal insulation of partitions. From January 2021 in Poland, the heat transfer coefficient for external walls is in force at a level not higher than U = 0.20 W/(m2K). The key here is the selection of appropriate materials. Among masonry elements, cellular concrete undoubtedly boasts the best results in terms of thermal insulation.

Stable temperatures at the right level inside the interior of buildings means not only lower energy consumption, but also perfect conditions for building users. Moreover, cellular concrete is a material with high vapor permeability, thanks to which there is a favourable air-humidity microclimate in the rooms. Additionally, the lime contained in the products and the resulting alkaline reaction prevents the development of harmful microorganisms and biological corrosion. Fungi and mould in damp walls constitute the most common factors that threaten the health of residents of single-family houses.

The natural radioactivity of building materials also has a direct impact on people in the building. AAC, made of natural raw materials, is classified as so-called low-active and does not emit any toxic substances. The cooperation of producers with customers in terms of awareness in these areas is no less important - that is why activities such as LEED / BREEAM certification or preparation of instructions for end users of residential buildings are more and more frequent.

Responsible production and consumption

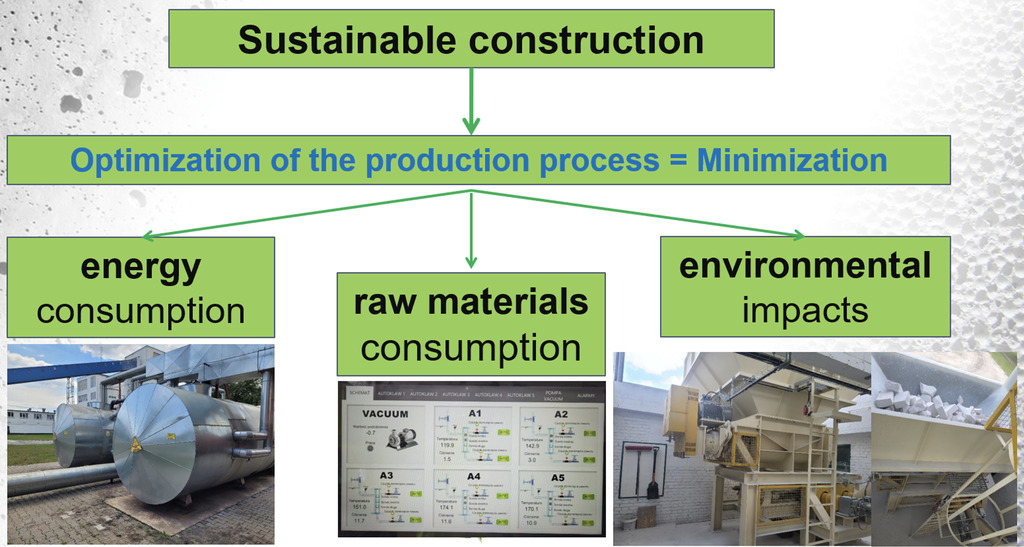

Polish AAC producers make every effort to ensure that the production process is as least harmful to the environment as possible. Most of the AAC producers associated in the Polish Concrete Producers Association (SPB) use renewable energy sources in their production processes, in particular photovoltaics and wind energy. In many cases, producers are switching from traditional fossil fuels such as coal to natural gas. Internal transport is carried out with the use of gas-powered or electric forklifts. In addition, production is characterized by the absence of wastewater, which is achieved thanks to the full consumption of water used in the production process, and the waste generated in the production processes is fully recycled for reuse.

When discussing building materials, one should not forget about the need to consider them in the context of the entire product life cycle. More and more emphasis is placed on the so-called circular construction, which includes keeping materials in circulation for as long as possible, followed by their effective recycling.

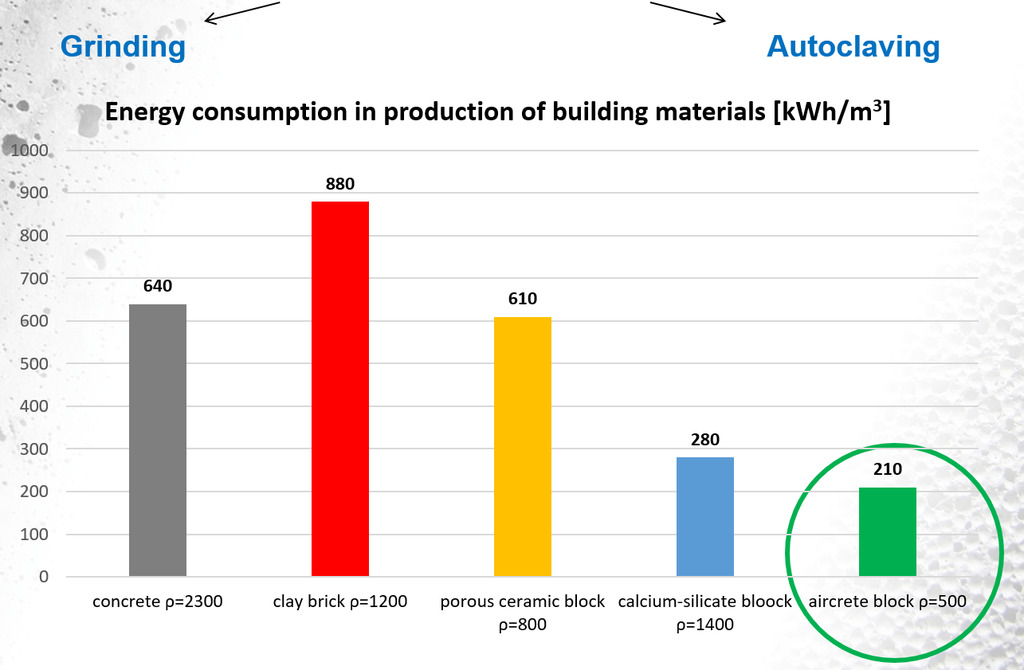

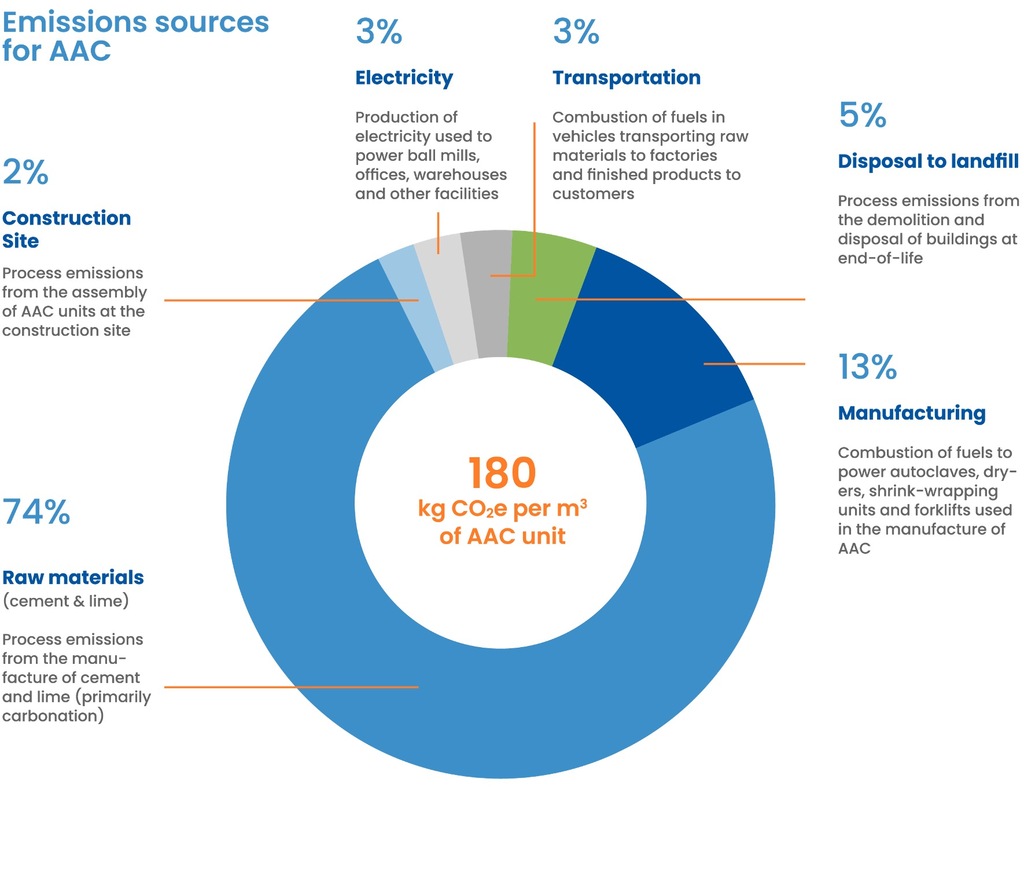

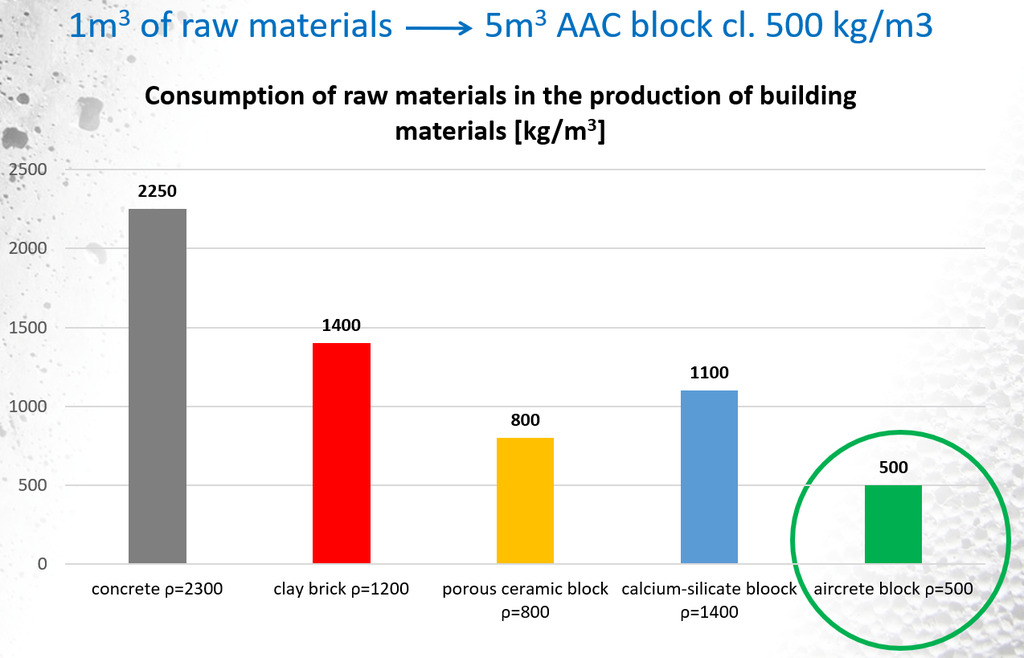

In the scope of AAC production, only natural raw materials are used, and the production process takes place in a closed cycle with the use of steam generated with low energy input - its consumption is only 210 kWh/m3 for AAC. For comparison, the production of silicate masonry requires 280 kWh/m3, and in the case of ceramic bricks about 610 kWh/m3.

The Environmental Product Declaration (EPD) signals the manufacturers’ commitment to measuring and reduce the environmental impact of their products and services and communicates this impact very clearly. Through the EPD, manufacturers report comparable, objective and third party-verified data that show good and bad indicators for the environmental performance of their products and services.

When developing an EPD, the environmental performance of a product is described from a life cycle perspective by carrying out a Life Cycle Assessment (LCA) of the product. The LCA test results and other information required should be compiled in the EPD reporting format. The EPD will then be verified by an approved independent verifier before it is registered and published in the international EPD system via the EPD portal of the SPB.

EAACA (European Autoclaved Aerated Concrete Association) indicates in the EPD, AAC products can absorb 77 kg

of CO2 per m3, with 80% of re-carbonation achieved after 50 years and 95% within 80 years.

Education

Sustainable construction is a very topical topic in the entire European economy and for several years, this is one of the reasons why it has become important also in the AAC and precast concrete industries. On a daily basis, experts from companies associated with SPB conduct seminars at technical universities, focusing on sustainable construction. Education in the industry is not only cooperation with universities and schools, but also aims at local communities in which we build and influences the awareness and everyday behaviour of employees in factories and offices and on construction sites.

Goals of sustainable construction

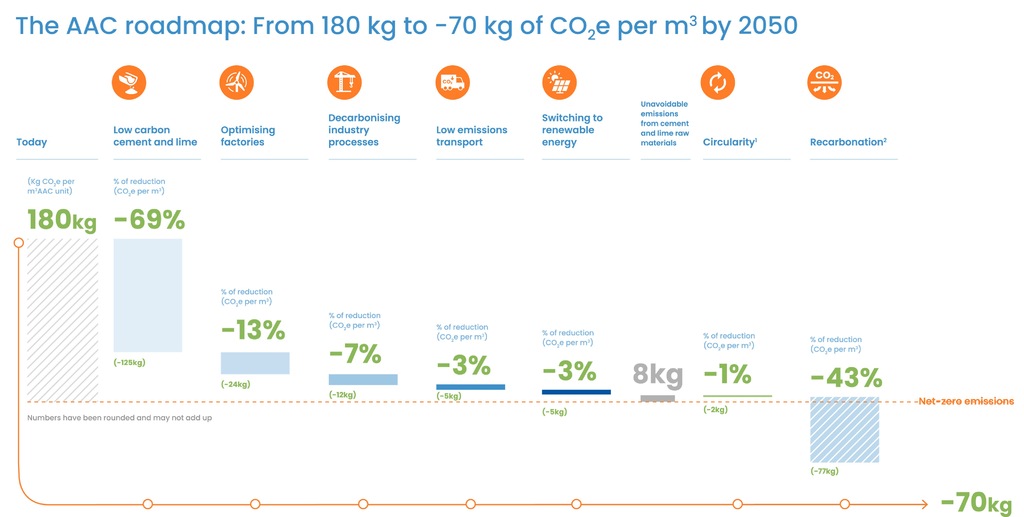

The EAACA defined a decarbonisation roadmap for AAC products. This roadmap sets out a pathway for AAC products to reach net-zero emissions by 2050 with the potential to become carbon negative, thereby absorbing more carbon dioxide from the atmosphere than was released during their production.

The roadmap aligns EAACA and its members with the objectives of the Paris Agreement to limit global warming to 1.5°C and supports policies to decarbonise Europe’s buildings and construction sectors.

Most of AAC manufacturers associated in EACCA declared Net-Zero Roadmap by 2050 reducing significantly emissions.

Communication with investors and stakeholders

Corporate Social Responsibility (CSR) is a concept that has become part of many companies. Although it concerns sustainable development, its actions in the face of the growing climate crisis have proved insufficient. CSR has been treated by many companies as a good marketing strategy that will help to improve the company's image in the eyes of customers and potential investors. For this purpose, not only independent positions were created, but also entire CSR departments, which thus strengthened the brand's prestige. Years later, it turned out to be off little value, so today this concept is being replaced by a broader issue, which is Environmental Social Responsibility Governance (ESG).

Many Polish and international companies in the construction industry declare net-zero emissions by 2050. How a given company approaches a topic and shares information about the targets covered, in a way making a commitment to provide feedback to all stakeholders, especially investors, demonstrates the responsibility and maturity of the management board.

Initiatives for sustainable development: the example of AAC producers in Poland

Which initiatives in the field of sustainable development should AAC producers implement in the next 5 years?

· "Zero" white waste - 100% used / recycled during the production process.

· "Zero" wastewater - circulating wastewater.

· Reduction in energy consumption (10% in 5 years) through renewable energy and energy source switching as well as heat recovery.

· Reduction in water consumption (10% in 5 years) in the production process.

· Reduction of CO2 emissions thanks to the gradual replacement of the transport fleet with a hybrid fleet and the change of energy sources.

· Demolition process construction (legal) obligations of the parties.

· More emphasis on ECO / Sourcing suppliers.

· Reduction / optimization of transport (emissions).

Why are these initiatives important?

· AAC producers are perceived as ethical and responsible stakeholders in the sustainable development process.

· Brand, products and company - AAC manufacturer ecological recognition by the market / customer.

· Reducing the cost of the production process.

· Meeting the growing legal requirements.

· Positive image of the employer.

What are the challenges to be overcome?

· Awareness to be developed in view of the rapid climate change.

· Resources: CAPEX / Know-how, people, time.

· The legal requirements are not yet adequate.