Application & Construction

Zoerobot Technology Limited

Fast and efficient construction with AAC panels and robotics

Loading...The Aerated Autoclaved Concrete (AAC) market in China has grown rapidly during the past five years. While AAC production lines are implemented in plants and AAC wall panels are used in construction projects around the country, construction methods with higher degrees of safety, efficiency and lower carbon emission are also increasingly needed. Zoerobot´s customer review shows that, although AAC prefabricated materials present a modern construction innovation, associated design methods and construction procedures are burdensome, dangerous and outdated in China and many other parts of the world.

In response to these problems and worries in the AAC industry, the Zoerobot Technology worked with construction management companies and professional contractors in mainland China and Hong Kong to investigate the situation of prefabricated construction and developed the smart construction solution for the whole industry chain of AAC, consisting of the Smart Design Development System, the transportation robot, and the installation robot.

Smart design and management

The design tools for prefabricated buildings in China remain the same as those for traditional buildings, which causes a series of problems in the construction process with prefabricated materials, especially in the construction of interior walls, such as AAC wall panels. Most of the design is implemented on 2-dimentional CAD platforms instead of Building Information Modeling software. Designing the layout of AAC wall panels in one project usually takes several days. On the other hand, the present design methods are not detailed enough to account for corners in the installation of wall panels. For example, if a section of a wall panel could be reused after cutting, the design output would not notify the workers. These problems keep AAC production too complex to be managed properly, and the construction with AAC wall panels remains inefficient.

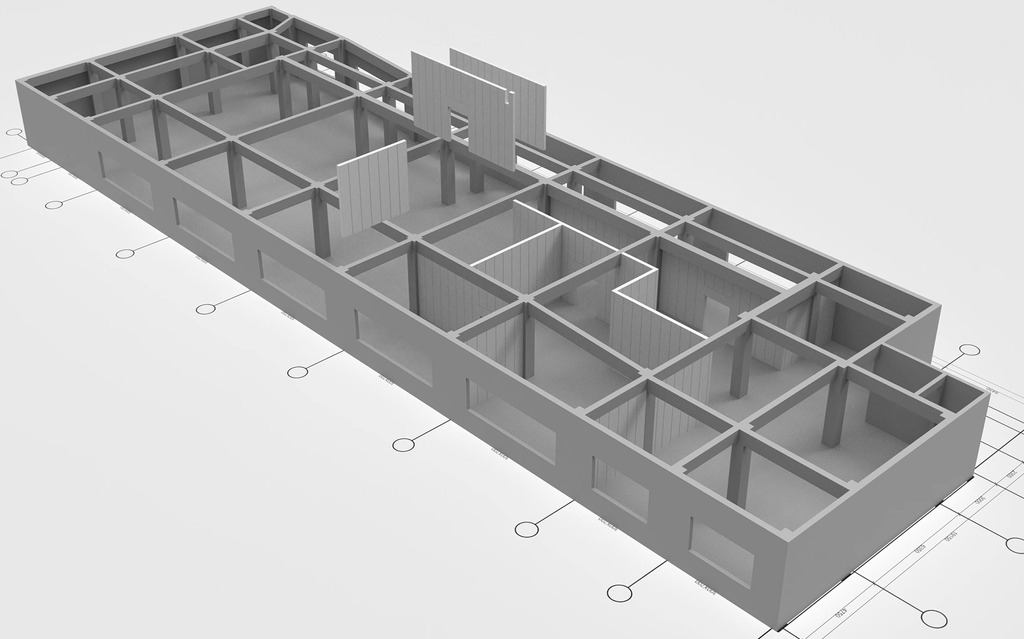

With the determination to build a full chain construction automation solution for the AAC industry, Zoerobot provided the Smart Design Development System to AAC construction designers and contractors. The system is equipped with pattern comprehension abilities, structure generation algorithms and automated layout functions for the design. In the Smart Design Development System, by uploading a 2-dimentional structural layout of the building and applying a few simple clicks in the system, the design development of the AAC wall panels is significantly accelerated, from days to minutes, with a higher degree of accuracy and stability, especially for public buildings with a complex design layout. A conflict between structures is also detected automatically at this stage. Also, the structure generation and layout algorithms lower the material wasted to the minimum of 1.5%. The whole system is deployed on cloud and based on website, which makes all the data accessible for customers in any time and anywhere.

This fully online system is easy to comprehend, operate and maintain, providing superior efficiency and accuracy to designers and construction contractors in the AAC industry. Customers can download the design development layout, BIM-related information, as well as quantities for production scheduling all at once.

Construction robots

The major challenge in the construction with AAC wall panels is related to the nature of this material. With its size and weight, construction workers can hardly transport and install the AAC wall panels without any supplementary devices. However, the devices utilized now are incapable of ensuring quality and safety in the construction. Reworking and safety accidents often happen in the situation of incorrect operations.

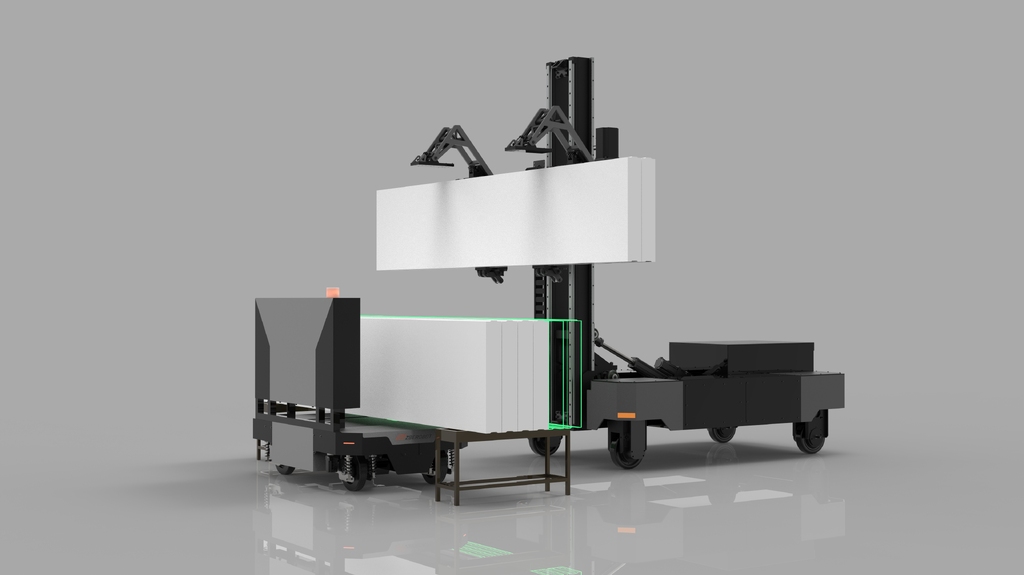

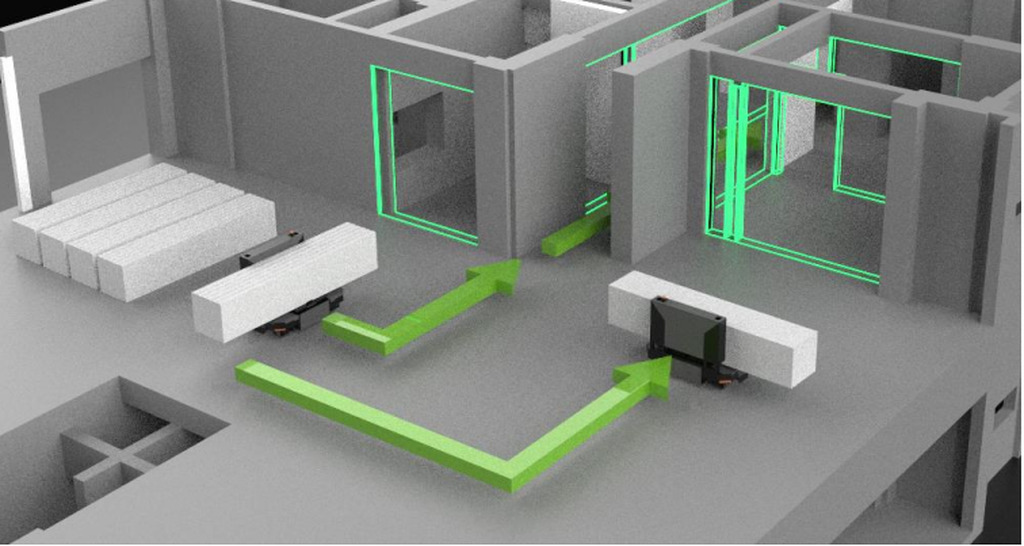

The transportation robot is a remote-controlled carrier vehicle with all-directional movement and obstacle-overcoming abilities to navigate and transport AAC wall panels on construction sites. Compared with the traditional ways of transporting wall panels from the stocking area to the workplace, the transportation robot co-works with its operator to achieve every mission in a fast, safe and reliable way. The robot is powered electrically with a lithium-iron phosphate battery, while a protective module ensures the safety under extreme conditions. With its maximum load capacity of 1200 kg, four all-directional swerve systems and a size of 0.9 x 1.2 x 1 m, the robot is able to climb inclines of 10 %, overcome 5 cm obstacles, and pass through doors on the construction site.

Similar to the transportation robot, the installation robot is characterized by its high load capacity and mobility, featuring stable manipulation of AAC wall panels in the workplace. With the controlling, sensing and actuation modules, an operator using the installation robot can effortlessly grasp, lift and move the 6-meter AAC wall panel in the workplace. Working with the installation robot prominently ensures the worker’s safety, as well as the efficiency and quality of the AAC installation. Grasping and lifting 3 m to 6 m long and 200 mm thick AAC wall panels, a standard work team with the robot consists of three workers, and the time required for installing one AAC wall panel is 10 minutes.

Solution and service

Last year, Zoerobot Technology provided smart design development, construction robots and solutions to AAC plants and construction projects around the country and achieved management and construction quality upgrades for these customers.

On a public building project in Shenzhen, Zoerobot Technology’s field application engineers worked with construction contractors from the designing stage to the working stage. With the design development layout drawn and the production quantity calculated in the Smart Design Development System, the workplace is divided into different functional areas. The construction manager planned the route of AAC wall panel transportation and installation with this available information. In this project, transportation using the robot is 200% more efficient, compared to traditional methods. With the installation robot, the lifting and placing of a single AAC wall panel only needs two workers and 8 minutes.

In addition, Zoerobot has cooperated with constructors and plant owners in the Modular Integrated Construction industry to develop innovative robotic solutions. The company will continue to provide technological impulses and professional services to customers from the construction industry.

Customer statement

“Zoerobot Technology's innovative construction solutions are bringing new opportunities to our business, while creating great impulses to the industry. We believe that 2024 is the year of breaking-through together, and we must overcome any difficulties by our strength and teamwork.” By Mr. Maobiao Ke, the Vice President of Guangdong Langdao Building Materials & Technology Limited.

See here a video about the Zoerobot Technology: https://www.aac-worldwide.com/videos/1623

QR-Code fürs Heft