Application & Construction

Today’s smart housing construction

Serial and digital construction of variable living space with AAC

Loading...

Prof. Dr.-Ing. Michael Eisfeld is Professor of Structural Engineering and Construction Informatics. His work is concerned with the application of BIM and AI for digital serial planning and construction. His research focuses on practice-oriented solutions to increase productivity in structural design and construction. He is a member of the board of directors of Eisfeld Ingenieure AG and a verification engineer for structural design.

Current situation on the housing market in Germany

The housing market situation in Germany is a highly debated topic, as it is becoming increasingly difficult to find affordable housing. In recent years, rental rates and purchase prices have risen steadily, while the supply of apartments has not been able to keep pace with the rising demand. Politicians are trying to meet this challenge through various measures. For example, there is social housing, for which the public sector promotes the construction of affordable housing. Despite these and other measures, however, the housing market situation remains tense, so that there is currently a shortage of around 700,000 apartments in Germany [1].

There are various reasons why few social housing or low-price apartments are currently being built in Germany. Two of the most important factors are the shortage of skilled workers and the increase in the price of construction materials. In order to counteract these factors, approaches are increasingly being developed in Germany that enable the industrial production of residential buildings with optimal use of materials and digital model-based process chains. Two main solutions are modular and serial construction.

Modular construction refers to the construction of buildings through the use of prefabricated modules manufactured in a factory and then transported to the construction site [2]. The modules therefore have limited variability with regard to possible floor plans as well as feasible design layouts in the urban context. The increased transport costs are only partially sustainable. The modular concept presupposes that a large part of the interior design is installed in the modules during factory production. Due to the high investment volume for the required automated production facilities, these concepts result in a small number of module manufacturers on the market. In addition, the production facilities should be located close to the construction site, in order to avoid that transport becomes a major cost factor.

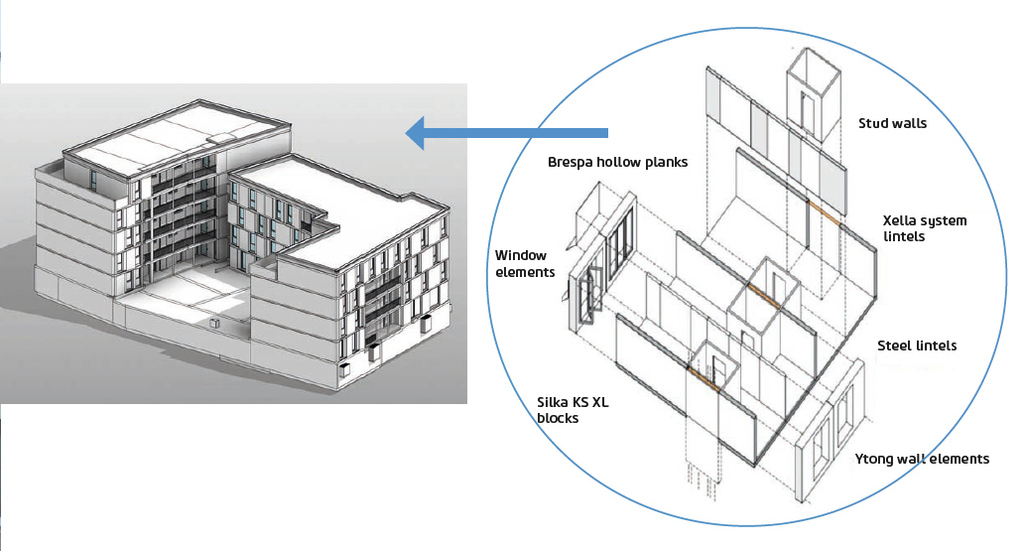

Serial construction, on the other hand, refers to the erection of buildings with repeating identical elements or units, which are prefabricated in serial production in the factory and assembled on site [3].The advantage of serial construction is the use of standard production capacities for the individual building elements as well as the possible flexibility in residential floor plans, which is particularly important in inner-city areas. Thus, a large construction volume can be realized with this construction method. Figure 1 shows the model project "Variowohnen" in Kassel, which was implemented with the serial construction system VarioFab for multi-storey construction of residential building frames and shells. It shows the flexible building volume and façade design based on the serially manufactured floor-to-ceiling system wall elements made of AAC as well as floor slab elements made of prestressed concrete. This system was developed in the research project Model Project Variowohnen within the framework of Zukunft Bau [4].

The building frame and shell contributes a considerable proportion of the construction costs, as it not only has a significant influence on the construction duration, but also on the existing cost risk. For example, the average frame and shell construction costs are around 1,200 to 1,800 Euros per square meter of living space in Germany in 2023, based on traditional construction with in-situ concrete and masonry [5]. The VarioFab system was therefore developed by Ingenieurbüro Eisfeld Ingenieure AG in the federal research project "Variowohnen" for the construction of variable, cost-effective living space. The VarioFab system leads to reductions in building frame and shell construction costs and construction times of approximately 20% and 30%, respectively [6]. The system is characterized by model-based integrated planning and construction using serially manufactured components, which combine planning knowledge and know-how of product manufacturers for pricing and construction time optimization for frame and shell construction.

VarioFab, the digital and serial construction system for the building shell and frame

Figure 2 shows the system concept borrowed from the automotive industry. It corresponds to the method of free knowledge-based configuration [7], since no predefined composition of individual components is possible as in the automotive industry - for example, a building does not always have the same set of components like a car always has four wheels. The volumetric composition of the shell consists of apartments and adjacent areas for further development, whereby apartments with their rooms consist of serially manufactured building elements, which are planned, produced and then installed in a digital twin. Through the variety of possible combinations, this approach offers the possibility to meet variable requirements of individual clients. Thus, the methodology used here is a modification of the "mass customization" approach commonly used for serial components. Here, the properties of individual components are not fixed, like in typical serial construction, but are adapted for the specific prevailing requirements (parameterization). The integral use of knowledge along the entire value chain by means of the digital twin not only results in reduced construction costs, but also a shorter construction time, which in particular entails lower risks with regard to interim financing and subsequent finishing trades.

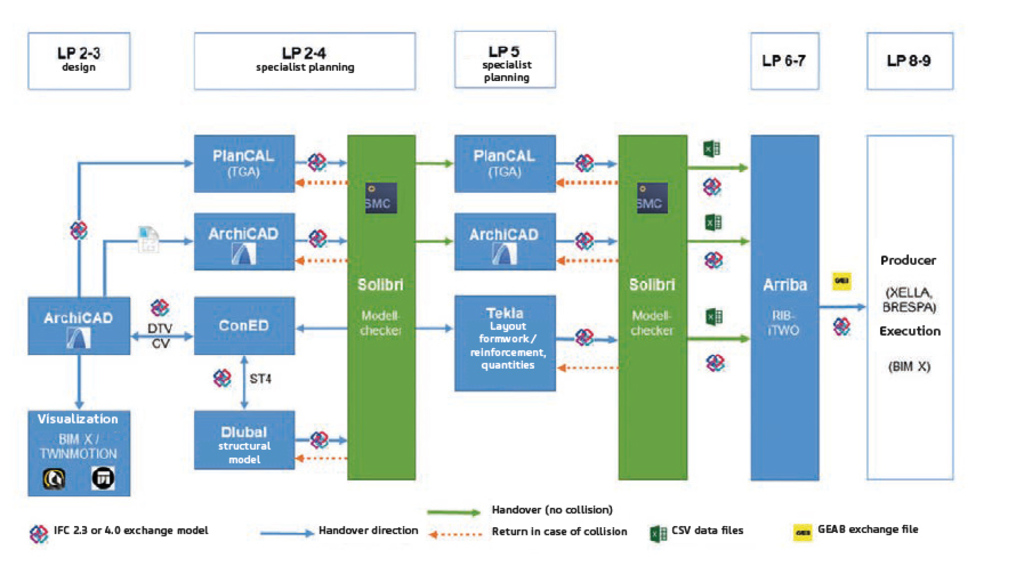

An integral, standardized open BIM approach is based on the digital twin, in which all information is linked in virtual compartments (3D models) via digital workflow. All relevant information on the components, whether obtained from the product manufacturers or the specialist planner, is derived from this in IFC format, exchanged via a coordination model and updated over the life cycle LOD (level of development).

Serially manufactured building components correspond to VarioFab BIM objects with different LOD's over the planning and construction period. These objects are predefined with their properties but can be freely assigned within the scope of the production possibilities. For example, certain dimensions must be maintained for system wall and floor slab elements in order to avoid cutting the elements on site or in the factory, which leads to higher costs and contradicts the serial approach. As a result, components are only adapted on a project-by-project basis and described in detail along the service phases with all information on costs, time and quality in the digital twin. The way in which the components can be developed along their service life corresponds to the know-how of the VarioFab system. The digital workflow uses the method of knowledge-based configuration from the field of artificial intelligence. The VarioFab system can therefore only be used for residential buildings with the following characteristics:

· The building envelope is divided into Vario apartments and other areas.

· A Vario apartment is represented in the raw building shell by a spatial configuration of known serially manufactured parameterizable building components.

· Only geometries of floor plans can be created that have a section-by-section rectilinear boundary.

· The façade structure is based on serially manufactured vertical or horizontal system wall elements.

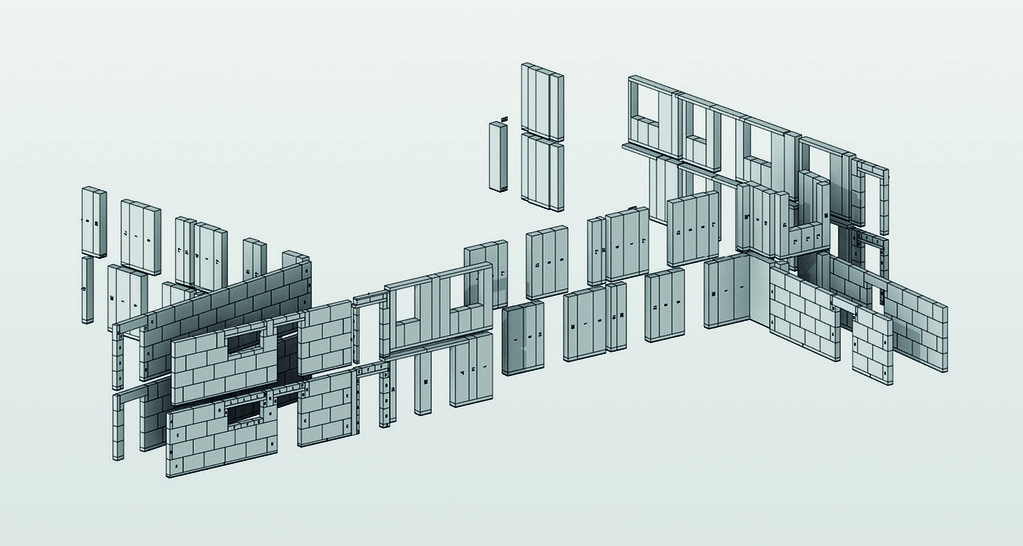

The advantage of these limitations is not only the serial production of the components, but also the automation of individual steps in the process by means of knowledge application during planning and production in the VarioFab system. For this purpose, we have formally mapped knowledge components of the planners and product manufacturers. Examples include knowledge on the structure of configurations with their individual parts, or attributes of components with their dependencies on each other, such as the joining of components on the construction site. This ensures that the designed Vario apartments can also be sensibly realized according to the rules of technology and the requirements of production. For example, it is possible to generate components or segment walls from the digital twin on the basis of standard rules. Figure 3 shows the outer wall divided into separate elements and a segmentation of the inner walls for the structure shown in Figure 2. This strategy of dividing the structure into individual components can then be used in the process to control production digitally and to plan delivery and installation.

The basic idea is that each component, such as the system wall element, is subject to a clear life cycle from the beginning of planning to installation and dismantling, with the corresponding life cycle information stored in the digital twin. This makes it possible to intelligently process the initially virtual object "wall" into a real object on the construction site in an installed state, whereby a digital process chain is established in our system. The result is a significant optimization of planning, production and assembly, as currently also done by other companies, which ultimately leads to error-free, more cost-effective and faster erection of the building frame and shell.

This is made possible by a digital twin that digitally and precisely maps the VarioFab system to the computer from the beginning of planning, but at the latest by performance phase 3 (detailed design of the structure), in order to optimally incorporate the economic advantages in terms of construction costs and construction time into the architects' design process. It is difficult to consider the system later in the planning process, as the design with its floor plans and façade design must be coordinated with the system.

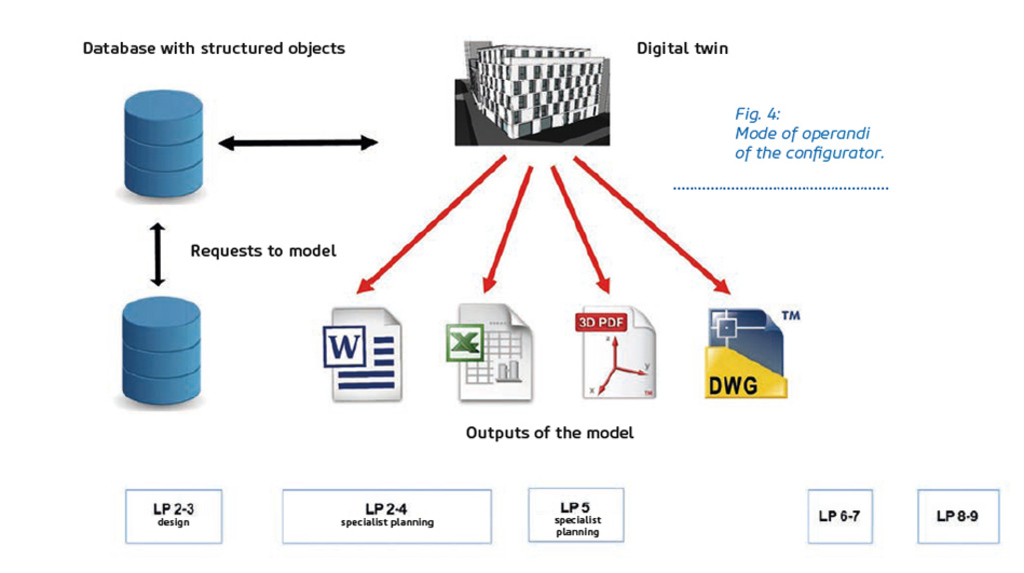

Figure 4 shows the conceptual structure of the configurator with its functionality and the different components in a simplified way, whereby the process diagram (Fig. 5) implements the arrows in the digital workflow. Two basic modes of operation can be distinguished: 1. Red arrow: Deriving documents from the digital twin, 2. Black double arrow: Further development of the digital twin via various authoring software for planning and shell construction trades as well as application of knowledge on the automatization of individual process steps.

The database with structured objects keeps the following objects persistently in its memory, which can be created or modified using a range of authoring software:

· Project data structure on part-of relationships of the building with floors, apartments, rooms and building elements as root objects.

· Definition of apartments via BIM shell elements, which are defined by parameterization using LOD for different service phases and which must meet the specified vario-constraints.

· Spatial arrangement of the Vario apartments in the building envelope.

The knowledge base with rules consists of the following components, which are used either for model checking or for creating new objects in the database:

· Definition of a Vario apartment in description logic as a rule scheme (terminology) for permitted living space configurations.

· Model data structure as schematic for the shell and frame construction.

· Templates for components in ArchiCAD for deriving three-dimensional BIM objects from two-dimensional data.

· Corresponding costs and times for individual components, which are attached to the BIM objects, for example in order to quickly and automatically determine quantities and costs for a new configuration.

The digital twin is formed by the connection of the database, in which the specific BIM model is kept, with the knowledge base and the possible requests from the system. The knowledge components are described as much as possible via schema entities or relationships of the IFC data model. The exchange between the different tools takes place via IFC files, which represent a configuration as an instantiation on the IFC schematic. In order to use available RDF reasoners, an instantiated data structure is transformed using simple text translators [8]. This is possible because the languages of RDF and IFC are similarly strong, like those of entity-relationship diagrams.

According to the invitation to tender, there are requirements (so-called constraints) for apartments that are funded in the Vario programme, which must be fulfilled. In the Variowohnen project, financing from the WI-Bank of the Federal German State of Hessen was also used for "student housing". This creates additional requirements for the apartments in terms of structure, room sizes and equipment. If an apartment does not meet the requirements, it does not qualify for subsidy and thus reduces the total funding amount. Therefore, it is of immense importance for the investor/builder that all apartments formally meet the requirements not only in the application process, but also after construction.

Since some requirements were not taken into account in the design planning by the architect and the processors, the client wanted to ensure an automatic review of the design with regard to the requirements. Consequently, we developed a tool for the model project with which the planner/builder can check the design in LOD 300 and the digital twin in LOD 500 for correctness with the help of model verification. For this purpose, an apartment object is transferred to a so-called "assertion box" to check it for correctness. Implicit dependencies are also considered, which go beyond pure syntactic control of the data structure [9].

If the architect designs an apartment that does not meet these requirements, the system recognizes this and points it out. All instantiated objects/rooms of a residential unit are taken into account. For this purpose, the design is exported as an IFC file and translated into an RDF (Rich Description Framework) file, which allows the design to be logically checked for correctness according to the rules set with a classic RDFS reasoner. In this way, it is attempted to find an interpretation as a model that satisfies the sets of rules and the design at the same time. The knowledge base can be used for further projects and it can also be expanded, provided that these projects are planned within the framework of the above-mentioned funding schemes.

Planners usually work on the basis of floor plans. This means that a functionality had to be created in ArchiCAD that identifies individual parts of a floor plan on the basis of the shell geometry in order to generate serial BIM components with a three-dimensional geometry and the corresponding attributes in each service phase.

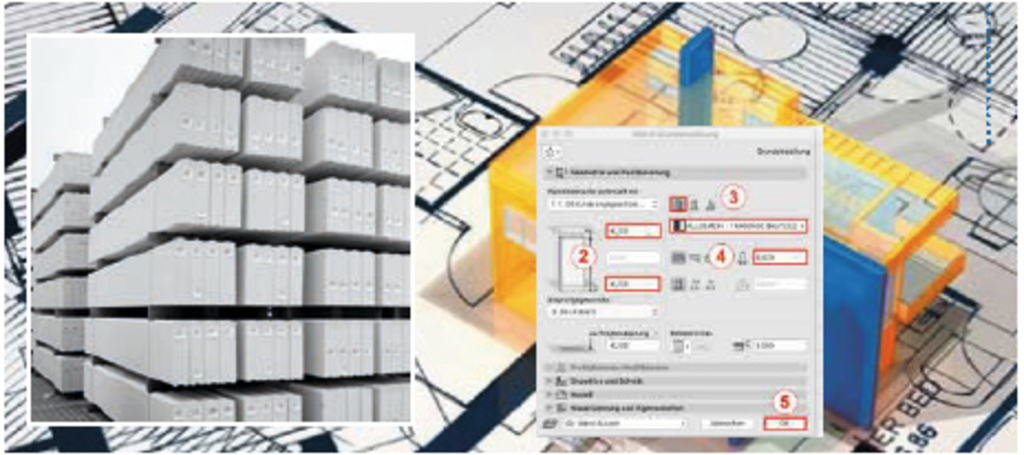

To ensure the planning quality in the digital twin, individual BIM objects, in particular the parametric objects for the shell and frame construction, were developed with the help of the ArchiCAD authoring software. The starting point for this is, for example, the definition of predefined element sizes by the manufacturer (Xella), which serve as the basis for wall lengths and wall openings. This is shown as an example for the Xella system wall elements in Figure 6. After entering the floor plan into the software, the planner can place suitable system wall elements, which are stored in the database. These are then automatically assigned to the housing unit. Labor and production time values as well as material costs per element are also stored in the database of the product manufacturer. These are used on the one hand in another application to calculate the costs and production times for the configured shell construction, and on the other hand to carry out a pre-check by the product manufacturer him/herself in order to ensure the technical feasibility and the sensible dismantling of walls into SW elements.

Conclusion with advantages of the VarioFab system

The presented system is suitable for multi-storey residential buildings as well as townhouses. It allows a wide range of possible floor plans and façade designs in order to be versatile in the inner-city environment. The digital twin as a planning and construction model forms the basis for a closed digital process chain from planning to construction via the various frame and shell construction trades. During the development of the system, the construction costs and the construction time were in the foreground as target criteria. However, the system must meet other requirements in order to be successful in the current market. An important requirement is a high quality of the frame and shell construction. This is achieved by serial prefabrication. By simply assembling the system with just a few joints, errors can be ruled out. This is particularly important for high building physics requirements, for example in view of reducing the risks of thermal bridges or leaks in vapour barriers, which can be achieved with monolithic construction. There is no susceptibility to bad weather, as no hygroscopic insulation materials are used, which otherwise often lead to major damage, especially in insulated timber buildings or insulated brick structures. Furthermore, the system is completely unproblematic regarding compliance with fire protection regulations, because the serially manufactured components have sufficient approvals.

In Germany, there are high demands on the sustainability of new buildings. The system fulfils this requirement, as new studies for AAC show that up to 60% of the CO2 produced during production can be consumed and bound over the lifetime of the structure. Likewise, simple dismantling of the structure is possible due to the low number of different materials installed in superstructures (walls and floor slabs). Further, with sufficient quality of the system wall elements, interior plaster can be completely dispensed with, which greatly simplifies separation during dismantling. By storing the Environmental Product Declarations in the digital twin, the sustainability of the shell can already be verified in the planning process, which will become increasingly important in the future due to legal regulations.

An outstanding distinguishing feature compared to modular construction is that a high degree of architectural freedom is provided, thanks to great variability in component assembly. This includes not only the floor plans, but also the façade design, which the project "Variowohnen in Kassel" impressively demonstrates.

References

[1] Die Zeit online: Wohnungsmangel in Deutschland so hoch wie seit 30 Jahren nicht mehr, accessed 03.03.2023.

[2] Wikipedia – Die freie Enzyklopädie: Modulares Bauen, accessed 03.03.2023.

[3] Die Wohnungswirtschaft Deutschland: Serielles Bauen, accessed 03.03.2023.

[4] B. Mons und M. Eisfeld: Endbericht “Forschungsprojekt Variowohnen Kassel, Zukunft Bau Modellvorhaben, 2020.

[5] Chat GPT: Abfrage zu Rohbaukosten in Deutschland am 27.02.2023.

[6] L. König Castro: Vergleichsstudie zu Baukosten und Bauzeit am open BIM-Projekt „Variowohnen Kassel“ im Hinblick auf die Nutzung vorgefertigter Decken- und Wandsystemelemente mit BIM-Objekten, Bachelorarbeit, FH Bielefeld, 2019.

[7] A. Günter: Wissensbasiertes Konfigurieren – Ergebnisse aus dem Projekt Prokon, Infix Verlag, 1995.

[8] W3C – Semantic Web: RDFS Reasoner, accessed 03.03.2023.

[9] Franz Baader, D. Calvanese, D. L. McGuiness, D. Nardi, P. F. Patel-Schneider: The Description Logic Handbook: Theory, Implementation, Applications. Cambridge University Press, 2003.