Application & Construction

Factory Assembled Housing

Use of Load Bearing AAC Panels in Transportable, Prefabricated, Pre-Finished, Modular Housing

Loading...

Creating a New Transportable Home Solution – With Solid AAC:

AAC has many benefits that can transform the performance and quality of transportable homes. The use of solid structural AAC components to replace lightweight steel or timber supportive structural framing provides many performance benefits while retaining speed of construction. A solid transportable AAC modular building system provides the following features:

· The low noise transmission and high insulation benefits of solid AAC construction.

· It is integrally load-bearing to minimize the need for other structural framing components.

· Offers flexible design to ensure a wide variety of house designs and configurations.

· Accurately constructed in a controlled factory environment, and fast to assemble on site.

· The modular elements are small enough to transport on standard road vehicles.

· The modules are light enough to suit smaller cranes and easy to maneuver on site.

· The AAC homes are robust, pest resistant, and highly resilient to external Bushfire events.

The challenge for using AAC in a PPVC home building method was how to create a fully loadbearing transportable AAC structure that was robust enough to withstand considerable movement during transportation and then be able to be crane lifted onto the final site location. To achieve this, the portable AAC modules rely on the combined integrity of all the connected AAC elements, and utilize some unique assembly methods to create strong, robust transportable modules.

Modifying a Proven In-situ AAC Panel Building Method into a Transportable Home System

CSR Hebel Australia had previously developed a custom-sized load bearing AAC panel home system. This system was assembled with large individual 200mm and 250mm thick AAC wall and floor panels, up to 6 metres in length and individually positioned on-site in horizontal alignment. In a continued partnership with CSR, The Building Supply Company (TBSC) in regional Australia undertook to expand on this original concept and transform this proven in-situ load-bearing AAC panel construction method into a faster-to- construct, factory assembled, fully transportable building system made from similar thick reinforced AAC wall and floor panels. TBSC has broad skills in construction engineering, and comprehensive experience as both a builder and a contractor. CSR Ltd Australia manufactures Hebel branded AAC panels under license with Xella International. CSR Ltd is one of Australia’s largest manufacturers of building products and has world-class capability to manufacture a wide variety of AAC panels into cut, shaped, drilled, and routed AAC components. This combination of CSR Hebel manufacturing capability in AAC panels, and TBSC experience in modular construction methods, has underpinned the development of the transportable, solid, modular, load-bearing AAC building system.

Developing AAC Modules as Transportable Residential Room Pods

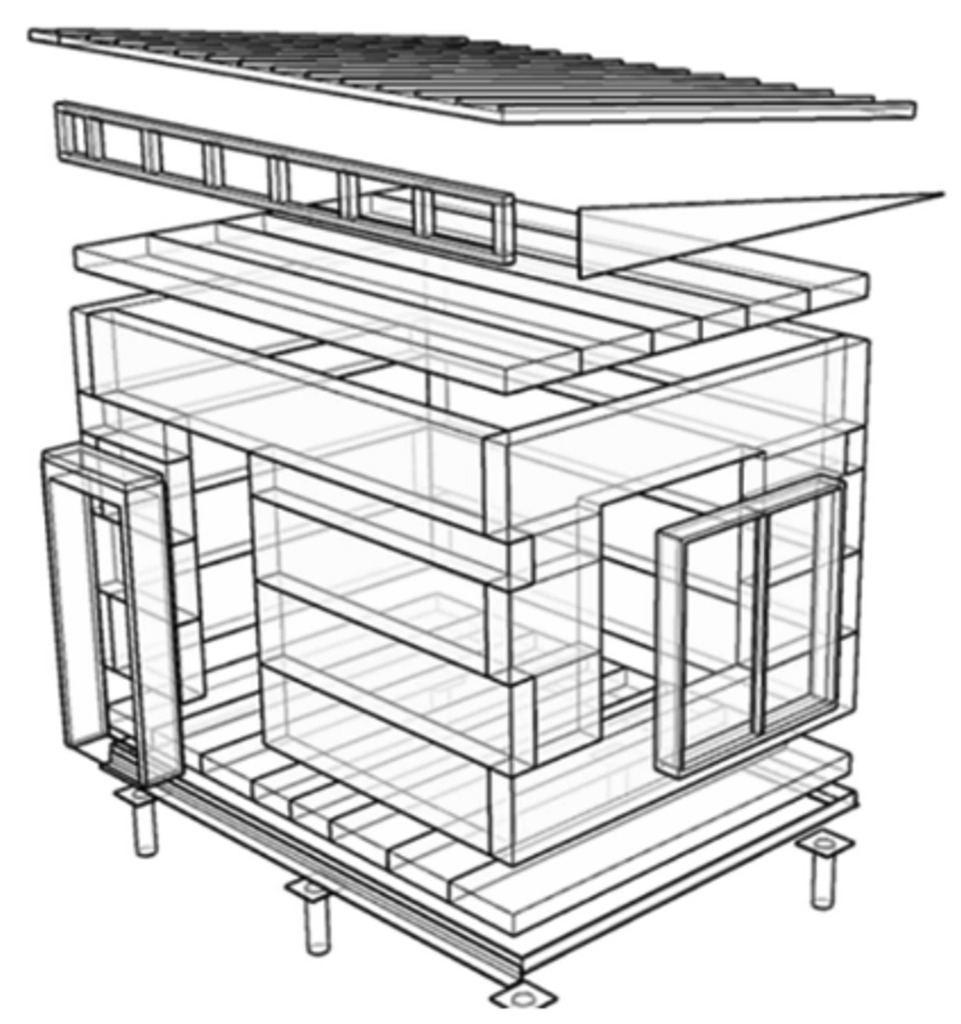

The core of the AAC transportable home system is the separate, free-standing, 6-sided cubic room ‘pods’ made from thick AAC panels. Each pod creates a usable 4.5 x 3.3m floorspace, and the internal height of 2.7 metres further promotes a feeling of spaciousness compatible with the modern design requirements for homes and multi-residential developments.

The room pods are self-supporting and load bearing. They are fast to construct, able to be factory fitted with doors and windows, then transported directly to site as a finished room element. The room pods can be fully fitted out internally with electrical fittings, wardrobes, and floor coverings. Pods can also be made as completed bathrooms with all plumbing fitments installed.

The walls, ceiling and floor are all constructed from steel reinforced AAC panels, with the floor and roof panels free spanning the interior wall spaces to maximise the cubic space within the pod. The composite strength provided by a fully braced and integrally connected AAC cubic element greatly increases robustness during transportation, yet the module, which depending on size and fit-out is usually between 8 and 12 tonnes, remains light enough to be easily transported on a wide range of delivery vehicles. The challenge was to include sufficient strength in the connections between those floor, wall, and ceiling AAC panels so that they can be lifted safely and reliably as a solid single unit. Each completed AAC pod element is no heavier than 12 tonnes to permit a relatively easy lifting load for most portable cranes. This target weight also allows 2 completed pods to be carried on a universally common 24-tonne capacity semi-trailer vehicle, and therefore maximize transport economy.

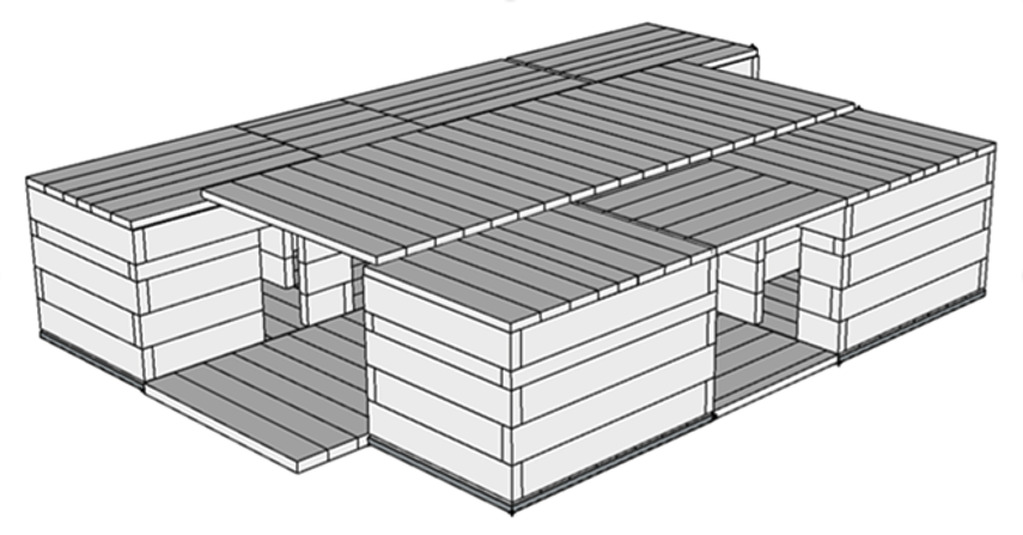

Transforming the AAC Modular Room Pods into a Spacious Modern Home

The key to the AAC modular pod room system becoming a completed home is using additional AAC floor and ceiling cassettes to create the larger living spaces, and structurally lock the prefabricated room pods together. These connecting cassettes form the necessary larger spaces for a modern open-plan home design. The convenient 4.2 x 3.5m size of the connecting cassettes allows them to be aligned and combined in many combinations. This not only makes it easy to create homes of 2,3,4,5 and more rooms, but it also allows for flexible design of the living spaces. These additional pod connection cassettes are easily transported on the same trucks as the AAC room pods. The roof and ceiling AAC cassettes are placed into position using the same crane, between the strategically spaced room pods.

The result is a high-specification solid AAC home structure. The pods are factory manufactured with high dimensional accuracy, and a 3- or 4-bedroom home can be assembled on-site to secure lock-up stage within a few days. A further appeal of these solid AAC transportable homes is that they look and feel like traditional in-situ built masonry homes, with characteristic deep window reveals and visibly thick external walls. The 200mm AAC walls perform acoustically in a similar way to traditional brickwork, but additionally provide the considerable insulation benefits of lighter density AAC. Being solid AAC construction on all sides, as well as a solid AAC floor and ceiling, the pods are highly fire-resistant to external fire such as a bushfire or a neighboring property fire.

Construction Overview of the Transportable Solid AAC Room Modules

Floor Assembly

The construction of each load bearing room pod commences with the assembly of the base floor cassette, which will be the main structural support element for each room pod. The 150mm thick AAC floor panels are laid flat and aligned in a purpose-built angle base frame. This base frame will permanently remain with the room pod and acts as the perimeter ring anchor for the AAC floor system, and as a bearing beam that will engage with the building support piers.

The AAC floor panels are of conventional Hebel AAC floor panel design with a rhombic rebate cut into one side of the top longitudinal edge of each panel. A steel re-enforcing rod is placed along each of these pocket voids and welded at each end to the inside edge of the steel perimeter base frame. A low shrink grout is then poured into this grid work of voids to engage the reinforcing bar and lock all panels permanently into place.

Wall Assembly

The thickest component in the transportable modules is the 200mm thick AAC wall panels, installed horizontally aligned as load-bearing AAC elements. These form the walls of each room-sized transportable ‘Pod’. The wall panels are of conventional Hebel AAC tongue and groove profile design.

Each wall panel is factory drilled with a circular vertical core void at each end of the panel which aligns with the location of the rising vertical threaded rods from the floor cassette. The AAC wall panels are lowered over these threaded rods and initially locked together using adhesive along the lengths of each tongue and groove joint. A series of stainless-steel joining plates also connect the wall panels together at each corner of the pod for each level of horizontal panels.

Room Pod Ceiling Assembly

The final step in creating the cubic modular room pod is to install a solid AAC panel ceiling. This ceiling is constructed of 150mm flooring-grade AAC panels assembled as a separate solid element and manufactured in a similar way to the structural floor cassette.

Using Connecting AAC Floor and Ceiling Cassettes to Create Living Spaces

The key to the flexible design and large living spaces of the Transportable AAC Solid Pod system are the additional connecting ‘drop-in’ floor and ‘drop-on’ ceiling cassettes. These elements are manufactured up to 4.2x3.5m in size, both separating and locking the room pods together. This creates a large solid AAC floor space, and a fire resistant and solid AAC ceiling.

To enclose the ends of the larger living areas formed by the connective cassette panels, solid AAC panel walls can be used. Alternatively, 75mm thick AAC wall panels are vertically clad onto a lightweight wall frame. These frames are designed with the required door and window openings to suit the home design. They can be prefabricated as factory-made elements and lifted into place, or simply constructed from standard framing components and clad with 75mm AAC panels on site.

Site Preparation for Transportable AAC Homes

With a solid AAC floor already included in each room module, and the connecting floor cassettes free-spanning between the room modules, there is no need for an in-situ concrete floor slab to be poured on site, so site preparation is relatively quick and simple. Steel engineered screw piles are placed directly into the soil to form a network of supportive steel piers for the modular pods and their connecting floor and ceiling cassettes.

Delivery and Assembly on Site of Modular AAC Components

The AAC room pods, and connection cassettes, are loaded onto vehicles for delivery to site. The compact size of each module pod and their separate connective floor or ceiling cassettes make loading the vehicle much easier than a full-sized transportable home.

A mobile crane is strategically placed on site to be able to lift the modules directly from the delivery truck and place them onto the relevant steel piers. When suspended by the crane the modules are easy to maneuver into their final position.

Only the room pods will be positioned onto the structural steel screw piles, as the connecting floor cassettes free span between the pod modules and bear on steel angle supports that are connected to the base of the pods. The steel perimeter base of each room pod rests on the top plate of the screw pile.

Roofing and Final Construction Details

A lightweight composite steel roof panel system is then placed over the drop-on AAC ceiling cassettes and the room pods to provide the final exterior weatherproof roofing for the home. The AAC ceiling cassettes therefore do not need to be waterproof as they will be fully covered, but they will continue to provide thermal insulation and fire protection for the home. The air gap between the roof and the AAC ceiling further increases the total thermal insulation.

Guttering and Fascia’s are installed where required to close off and complete the roof installation. Plumbing and electrical services are connected to the home, and easily connected between pods by utilizing the subfloor space which is provided by the gap between the ground and steel piers.

Once all services are installed, lightweight 75mm AAC panels are then screw-fixed to horizontal purlins around the base of the home to cover all the piers and close off the sub-floor space. The 75mm base panels will decoratively extend the solid AAC appearance of the exterior walls down to ground level.

With the home now fully assembled the floor coverings are installed in the large living spaces and the interior fit-out and painting can be completed. The final decorative colour and weather resistant paint coatings are applied to the exterior walls. Bathroom and Laundry room pods can be fitted out, plumbed, and tiled at the factory before they are delivered to site, assuring a high-quality finish.

Room pods can also be delivered with built-in wardrobes installed and floor coverings in place. Where applicable, electrical wiring can be chased into the thick AAC walls, hidden behind internal fitments or internal lightweight partition walls. Each pod is wired for power and electric lighting in the factory so final assembly is a matter of simply connecting the electrical services between pods.

Current Status and Future Developments for Transportable AAC Structures

A number of single-story homes have already been built in Australia using this method, proving the solid, transportable, AAC prefabricated housing concept competitive and reliable.

The current design capacity of the modular room pods, with their 200mm AAC wall panels and 150mm AAC floors, can also support the upper level of a two-story home. The upper story pods can be placed directly on top of one another or can span across lower pods in a stepped home design. Design work is already finalized and the construction of a 2-story modular AAC home is planned to be completed in 2023.

This 4-bedroom, 2-level design is also very compact. It can be placed on a site footprint of around 100m2, making this design highly compatible with medium density developments in new and established urban areas. The speed to market and performance benefits of the transportable AAC home system is also aimed at providing faster and higher quality social housing.

In addition, developers have expressed interest in using the transportable AAC room pod model as a method of constructing higher density low-rise accommodation, including hotel and motel type developments.

Preliminary planning and design engineering is underway to explore a transportable high density multi-residential design using the same AAC modular transportable pod system.

This article (as full version) appeared in its original form in the proceedings of ICAAC 2023 (7th International Conference on Autoclaved Aerated Concrete): Puzey A, Balding T. Use of load-bearing AAC panels in transportable, prefabricated, pre-finished, modular housing. ce papers.2023;6;174-182. https://doi.org/10.1002/cepa.1974

Correspondence

Adrian Puzey, Category Manager Hebel – CSR Ltd, Australia

Tony Balding, Director – Building Supply Company Pty Ltd, Australia