News & Markets

20 years of Xella Italia

A story of vision, resilience, and progress

Loading...The company’s beginnings could best be described as a dream come true. With only a handful of people, it felt like embarking on an adventure similar to the characters in “Pirates of the Caribbean”, first trying to understand the market environment and then fighting to conquer it. At the time, operations were lean. Customer Service and Administration were located in France, and all goods were imported from other Xella plants abroad. Over the years, however, the company transformed dramatically. In two decades, turnover grew from less than five million euros to more than eighty million euros. Two production plants were opened, now serving about 2,000 customers across Italy. It has been a long path, but ultimately a remarkable story of team success – one that would not have been possible without the commitment of its people.

The first plant was acquired in 2011

A milestone came in 2011 with the acquisition of the Hebel plant in Pontenure. Before then, logistics had been costly and unsustainable, relying on imports from four different countries. The purchase of the plant changed everything. Despite the economic recession that was severely affecting businesses at the time, Xella Italia managed to grow substantially and build a truly organized company with administration, production, and sales under one roof. Specialized professionals joined the organization, and the team had to learn quickly – sometimes by making mistakes, but always turning them into lessons.

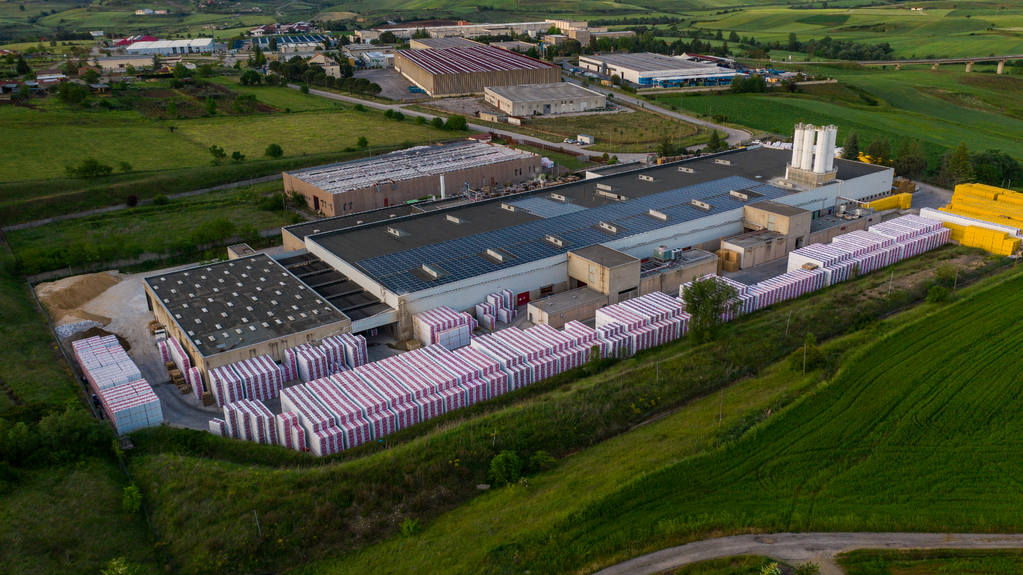

One such mistake occurred during the financial crisis of 2011–2012. Without a proper credit management system or dedicated staff, the company suddenly doubled its turnover and customer base in the middle of an economic downturn. The solution was to establish a new Credit Department with specialized resources, which soon became one of the strongest in the industry. The need for structure increased again with the opening of the second AAC plant in Atella in 2020, which began producing under the Ytong brand.

Important strategic steps

Strategically, Xella Italia focused early on developing business for external walls. While this was standard practice in other countries, in Italy the discussion around energy-efficient housing was only just beginning. With strong support from Product Management and Marketing, the company invested in this niche and actively contributed to the growing acceptance of energy efficiency in construction. Over time, the product portfolio expanded beyond AAC blocks to include glue for blocks, Multipor, plasters, and renders – always with the aim of offering customers and building partners complete solutions rather than isolated products.

For Marco Paolini, the story of Xella Italia is also deeply personal. He joined the company in 2006, when his children were still young. Taking charge of a small, plant-less team in Italy was not easy, but the acquisition of Pontenure brought stability and opened the way for growth. Looking back, he sees how the challenges faced in those early years built resilience for the future. Watching the team develop and grow together has been one of the most rewarding parts of the journey.

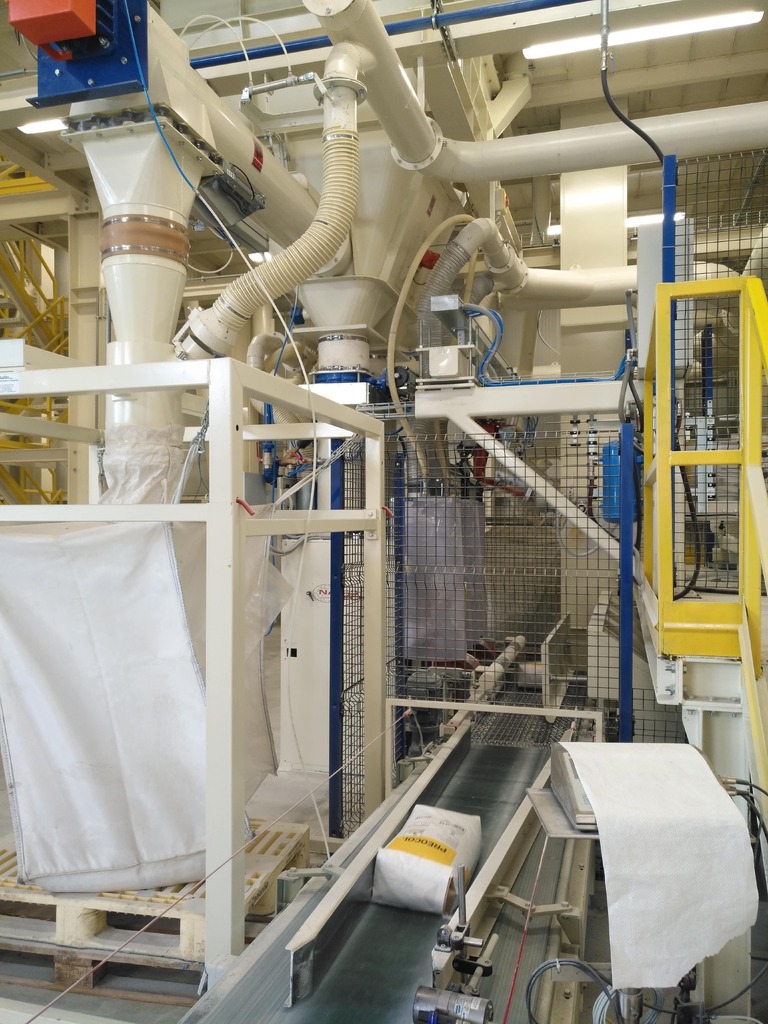

In 2019, Xella opened a new plant in Pontenure, thereby expanding its production of mortar and interior wall plaster. Covering an area of more than 100,000 square metres and built to Industry 4.0 standards, the facility met and still meets the highest energy and environmental requirements. Xella's solutions were sustainable, recyclable and designed to create a healthy indoor climate from the outset – further strengthening the company's role as a leading provider of integrated system solutions.

Combining sustainability and profitability

Sustainability has also been a central theme in recent years. In 2021, a photovoltaic system was installed at the Atella plant, resulting in significant energy and CO₂ savings. Two years later, the same was implemented in Pontenure, reducing energy costs further and making better use of renewable energy. Other environmental measures, such as minimizing heat gas emissions, have also been adopted – continuing a process of improvement that began when the plant was first built in 2008.

Collaboration within the Xella Group has played an essential role in the company’s success. Initially integrated into the French organization, Xella Italia benefited greatly from international cooperation and the exchange of knowledge. Over time, the Italian team was able not only to adopt best practices from abroad but also to contribute back – supplying sister companies with plasters and glue. The potential for greater knowledge-sharing across the group remains an important opportunity.

The future of Xella Italy

Looking to the future, Marco Paolini sees both challenges and opportunities. With a market share close to 10 percent, there is still room for growth, provided the company continues to recognize and seize opportunities. Maintaining the spirit of innovation that defined the first 20 years will be crucial. This means anticipating customer needs, digitalizing processes, and supplying products that are less labor-intensive while ensuring sufficient production capacity. Equally important will be sustaining team spirit in a changing world, where motivation, engagement, and satisfaction are key to future success.