News & Markets

Consistent industry growth

AAC – the sunrise segment in India's building materials industry

Loading...India is the second largest block manufacturer in the world after China. The Indian block producing industry is almost entirely unorganized and characterized by large number of small players competing at regional level. In total, India has around 150 - 180 plants for AAC block production.

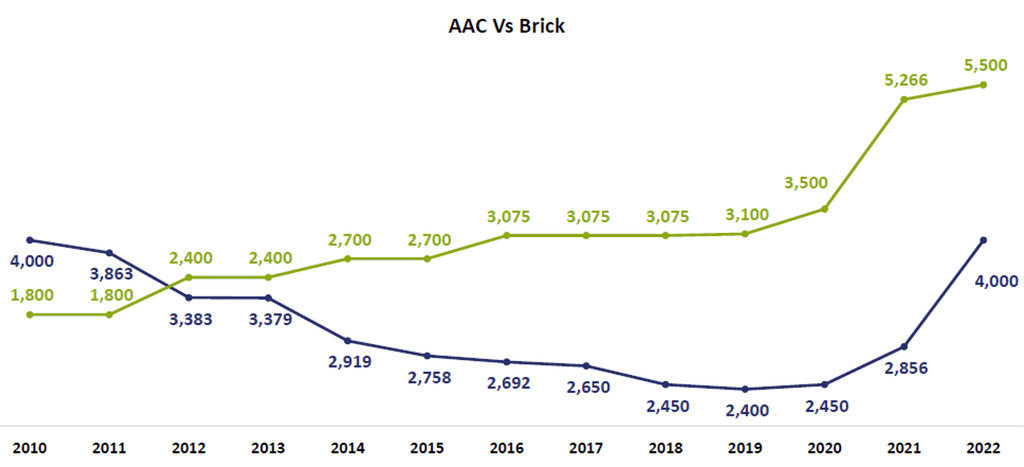

Despite the significant increase in the use of AAC blocks in the building industry during the last decade, the material only covers about 7 - 8% of the market, while 85 - 90% of the industry are still dominated by red clay bricks. This means that there is a huge market potential for the years to come. The global AAC market is expected to witness a Compound Annual Growth Rate (CAGR) of 7.5% and reach around 15 billion Euros by 2027. According to a recent report, the Indian AAC block market is anticipated to register a CAGR of 14.3% from 2020 – 2027.

AAC block manufacturing is gaining prominence in the Indian market and many plants are currently established across the country, especially in Western India. A large number of current projects make extensive use of AAC blocks, including large urban developments, mass housing projects (for affordable housing, slum rehabilitation, etc.), IT/ITES (Information Technology Enabled Services) park developments, high rise constructions and commercial developments. The associated growth in the segment is expected to increase exponentially in the years to come.

AAC blocks are well accepted by the Indian market and their use will grow significantly owing to the increased awareness amongst industry professionals, including builders and architects, who appreciate the many beneficial attributes of AAC blocks over red clay and fly ash bricks. The shortage of urban labour and a high interest in cost savings have forced developers and construction companies to look for faster and more efficient building materials.

In addition to the inherent technical benefits, AAC compliments the project management in terms of speed, consistency, and quality of construction. In the domestic market, several primary factors drive the growth of the AAC industry, including accumulated demand for infrastructure, the government’s impetus through numerous infrastructure and housing projects, as well as regulations supporting the use of eco-friendly construction materials in combination with attempts to achieve the goal of net-zero carbon emissions.

BigBloc is the only listed company in the AAC block sector in India and the largest producer of AAC in Western India. For the future, the company plans to launch new products including ALC panels, tile adhesives and gypsum plaster, as well as other construction chemicals. The company has the vision to become the largest manufacturer of AAC blocks and panels in India in the next 2 - 3 years.

With an increase in regional government projects and an expansion of the real-estate industry, the demand for AAC is expected to see a sharp growth. The Indian government’s ‘Housing for All by 2024’ is also a major game changer for the industry. Projects such as Pradhan Mantri Awas Yojana, Police Housing, Kanya Shiksha Parishar, etc. are prominent examples, for which the Government has made it mandatory to use AAC. In addition, India is likely to see an investment of around 1.3 trillion Euros into the housing market over the next seven years, during which it is likely to witness the construction of 60 million new homes.

Green solutions for the growing urbanization

Growth in the infrastructure sector, growing preferences for low-cost houses, and an ever-increasing focus on green and soundproof buildings are the factors driving the AAC market. AAC blocks, owing to their energy-efficient properties along with being fire resistant, termite or pest resistant, seismic resistant, lightweight, sustainable, as well as quick and easy in application have emerged as a preferred choice.

The construction industry has traditionally been dominated by red clay bricks. The fundamental issue, however, is that it has used red soil for mass production, which reduces forest areas. AAC is a natural and non-toxic construction material that saves energy and provides eco-friendly solutions for the environment. Additionally, the thermal insulation properties of AAC blocks reduce the energy consumption and help fight global warming, which results in savings during the lifetime of buildings.

BigBloc Construction Ltd is the only company in this segment generating carbon credits. The increasing carbon footprint on the environment is of growing concern. The company has a commitment towards the production of green building products and solutions. The ultimate vision of the company is to help the construction and infrastructure industry to build green and sustainable habitats. With the aim to conserve soil, NXTBLOC, which is a green product for the industry, was launched by the company. The carbon footprint of these AAC blocks is considerably less compared to traditional walling materials. Aiding further, the low weight of NXTBLOC AAC blocks reduces the carbon emission as higher product volumes can be transported per truck load, compared to traditional walling material.

Economic considerations and construction speed also drive the growth

AAC blocks help by building homes better, faster, and cheaper. The costs of raw materials, such as lime, cement, petroleum coke and aluminium powder also currently favour the use of AAC blocks, compared to clay bricks.

Fly ash is one of the key raw materials for AAC blocks. In India there are many thermal power plants which generate lot of coal waste (fly ash). AAC blocks use this as a raw material and provide green solutions to India’s brick industry. In addition, over the last decade, prices of bricks have risen considerably as compared to AAC blocks, which further provides a competitive advantage over traditional bricks.