News & Markets

Keda Suremaker, Ma’anshan, Anhui Prov., China

Building the future: differentiation strategy for the global AAC market

Loading...China and Indonesia: Driven by scale and capacity

In Asia and indeed globally, China and Indonesia represent the most vibrant markets for AAC. In China, prefabricated construction is becoming increasingly popular due to its efficiency, environmental friendliness, and energy-saving benefits. AAC panels, known for their unique properties, have become an essential component of prefabricated buildings. More and more construction projects are adopting AAC panels for walls, partitions and roofs to achieve efficient insulation, thermal resistance and energy savings. Additionally, the fire resistance and durability of AAC panels meet modern construction standards for safety and longevity.

Meanwhile, Indonesia, a rapidly developing nation, has seen an explosive increase in construction demand, especially with the government's recent announcement of a capital relocation plan. This move is expected to trigger a surge in infrastructure and residential projects, providing significant opportunities for AAC panel applications in the Indonesian market. The relocation is expected to boost the usage of AAC panels significantly, further stimulating the growth of the AAC market.

As a comprehensive AAC system supplier, Keda Suremaker has keenly observed these market trends. An increasing number of customers are seeking to build high-capacity production lines to balance raw material costs, energy costs, inventory management, operational profits, and labor costs effectively. In response, Keda Suremaker has introduced several technical innovations and optimizations.

For instance, Keda´s new pallet-free packaging technology for blocks significantly reduces packaging materials and labor costs while enhancing the transport efficiency and safety of products. This innovation not only provides economic benefits to the clients but also strengthens the company’s competitiveness in the market. Addressing the competitive packaging costs in the AAC product market, the new pallet-free packaging process adapts to both pallet-free and pallet-required scenarios. When using the pallet-free option, clients save substantially on packaging and labor costs.

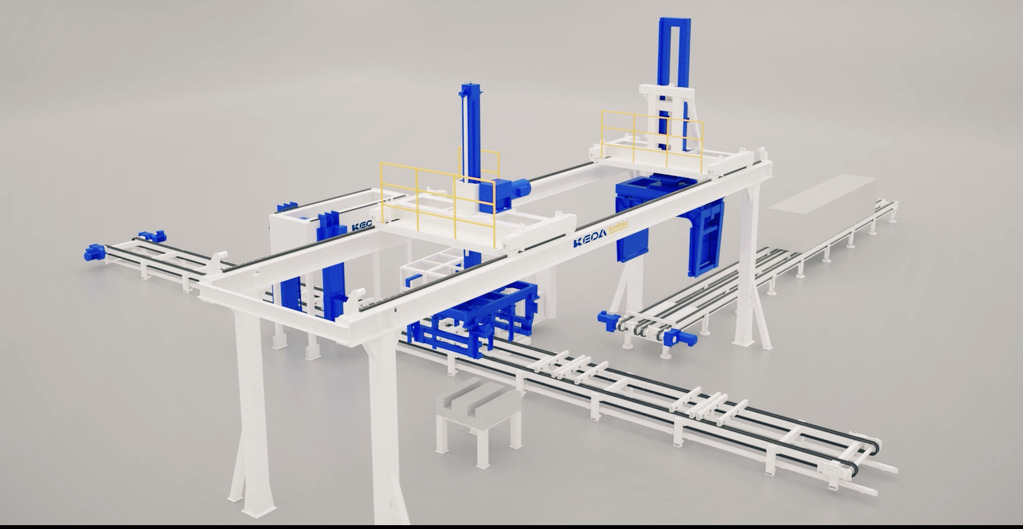

The system utilizes a dual cake transfer machine mode, where one machine is dedicated to selecting and stacking blocks, replacing the conventional industrial robots, thus significantly reducing maintenance costs. Two cranes work together, selecting blocks based on thickness and creating spaces for forklift holes while reorganizing the selected AAC bricks for packaging. The chain conveyor system, equipped with a recycling station, moves the stacked green cakes through two mobile packaging machines, securing them in both horizontal and vertical bands, ensuring stable and secure transport. Customizable packaging heights are available based on client needs. When using pallets, a pallet dispenser at the end of the chain conveyor issues pallets between two recycling stations, facilitating the stacking and packaging process.

Bangladesh: Emphasizing process and application

In emerging markets, the solution to production line equipment is just the beginning. It is crucial to help clients streamline and optimize AAC production processes. For clients new to AAC, Keda Suremaker provides more than just advanced AAC production equipment; it offers detailed process guidance and optimization.

During the construction of Bangladesh's first AAC production line, Keda´s process team worked closely with the client to understand their needs and challenges, conducting extensive raw material tests to ensure the materials used met production standards, preventing issues that could affect the stability of the production line. Additionally, the material formulations based on local characteristics were tailored, to ensure the stability and market suitability of the AAC products produced.

The on-site process guidance service involves Keda´s process team working alongside the client's technicians to strictly control every aspect of the production line, providing detailed process flows and operational guides and training operators to ensure they master the skills necessary for stable production line operation.

As the local AAC production factory is relatively new, the market's awareness of AAC materials is not yet ideal. Together with the client, Keda addresses this by sharing international experiences with AAC applications, inviting clients to visit China to observe AAC applications firsthand, and discussing how AAC can be integrated into Bangladesh's building system. Moreover, the active participation in local exhibitions enhances the influence of AAC in the local market.

"We are delighted that the Bangladeshi market is starting to accept and embrace AAC, and we are also very willing to share our accumulated experience in AAC applications. Through various forms of promotion and communication, we believe that the Bangladeshi AAC market will see more AAC factories and AAC application examples emerge, which is what everyone wants to see," said James Lee, the overseas marketing director of Keda Suremaker.

“These efforts are set to further expand the AAC industry in Bangladesh, and we believe that more AAC factories will be established in the region”, Lee continues.

African market: Promoting the potential of AAC materials

On the distant continent of Africa, Keda positions itself as a faithful companion to the urbanization development of African towns and cities. Although the current application rate of AAC in the African market has not reached the desired level, the unprecedented rapid development of numerous major cities across the continent does not go unnoticed. As urbanization accelerates in African countries, the flourishing and upgrading of the construction industry have become inevitable trends.

AAC, as an advanced building material, fits perfectly with the construction needs of these cities due to its superior performance and broad application prospects.

By participating in the industry trade fair and conference ICCX West Africa 2024, Keda showcased the significant advantages of AAC in enhancing building quality and reducing costs to the African market. This not only established a good reputation in the African market but also laid a solid foundation for further promoting AAC in the region.

Keda will continue to deepen its engagement in the African market, committed to fully demonstrating the advantages of AAC materials to more customers. The company will also keep a close eye on market dynamics and technological trends, continually innovating and optimizing the production processes and application technologies of AAC materials to meet the growing demands of the African market. This is based on the belief that in the near future, AAC will become an indispensable material in the construction industry across Africa.

Keda Suremaker can provide a complete project service roadmap for the project, which is divided into four parts as follows:

Part I: Raw material and planning design

a) Assemble an expert team to visit the project site and design the plant layout based on the land conditions and raw material resources.

b) Select the appropriate range of equipment and provide a feasibility study on investment according to the expected capacity and level of automation.

Part 2: Production and logistics

a) Create a production plan that ensures the required delivery timeline.

b) Offer various packaging and logistics solutions tailored to the project’s specific needs.

c) Commission all major equipment at the factory to guarantee reliable quality.

Part 3: On-site installation and commissioning

a) Deploy an experienced project service team to the local site before the equipment arrives. Collaborate with the on-site construction team to facilitate the smooth progress of the project.

b) Provide extensive support for plant planning, equipment installation, electrical commissioning and process solutions. In addition to the local service team, offer 24-hour online remote service.

Part 4: After-sales service and training

a) Furnish training and consulting services for customers throughout the project lifecycle, including but not limited to equipment operation, safety instructions, equipment maintenance, and process FAQs.

b) The Keda Suremaker Engineering Service Center is responsible for providing spare parts and after-sales support to ensure that all after-sales requirements are promptly met.

Bitte auch hier den Hinweis zum Company Channel einfügen.