News & Markets

AVL METAL POWDERS n.v., 8500 Kortrijk, Belgium

Together we make the circular economy possible

Loading...The production process at the plant in Kortrijk, Belgium is completely waste free. No traces of solvents are present and can interfere or create disturbing side-reactions in the AAC production. This way of producing is quite unique and allows an extremely narrow and precise particle size distribution of the aluminium powders.

AVL is known worldwide to deliver superior aluminium powders and dust-free pastes which are always within narrow specs, enabling a stable production outcome for its customers. Which is a big advantage in case an AAC production plant faces production challenges, they can focus on the other aspects.

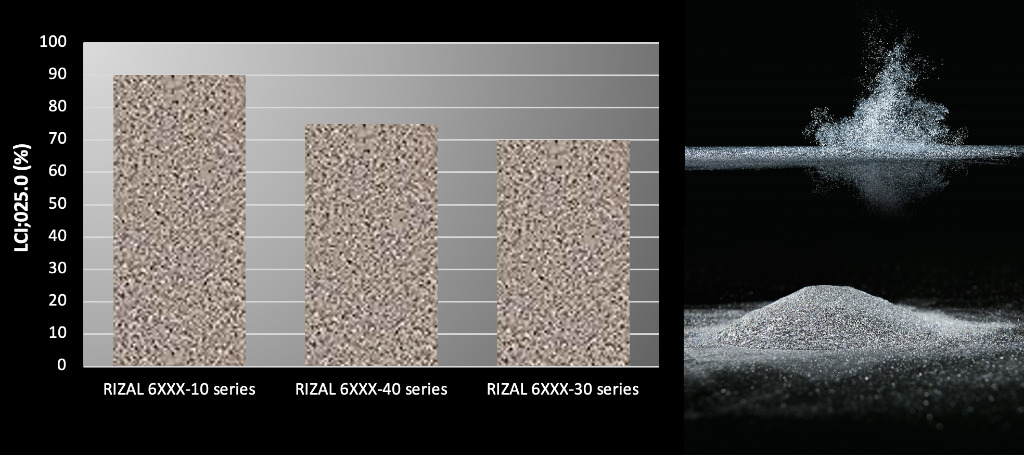

A major benefit of AVL's own designed machines & production process is that a wide range of additives becomes possible. This results in products which can be easily pre dispersed in the customer process. Pre dispersion speed rates of aluminium powders in water have improved with 40% with recent products leading to more homogeneous dispersion of aluminium powder in water. Fig. 1 shows an overview of the pre dispersion speed rate of our high-quality grades.

Since a decade at AVL Metal Powders n.v. we are using raw materials with the same final gas formation. The family company invests highly in R&D and QA as our team consists out of employees with over 30 years of experience in the business and are always focused to assist customers to deliver the ideal product according their wishes and needs for the process, to solve production problems, etc. This leads to excellence and close cooperation with the customer where we work together on the development of fantastic products.

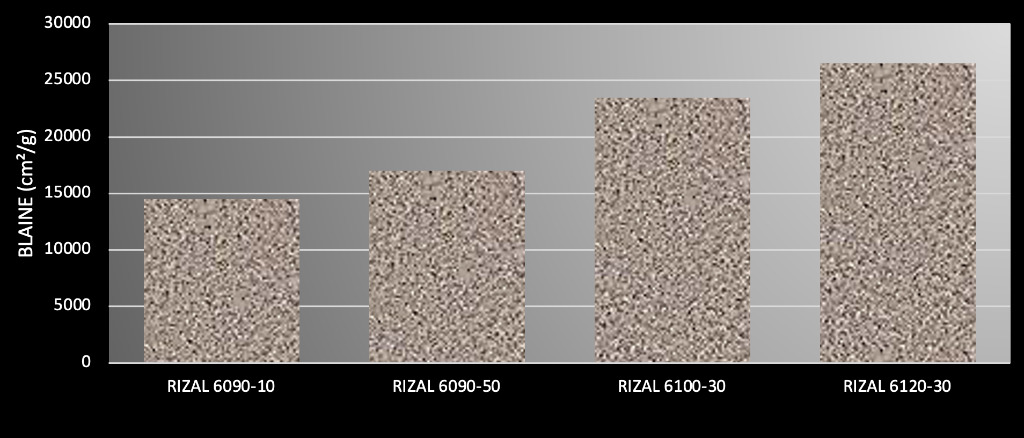

Over the past 50 years, a professional laboratory has been established with all the necessary measuring instruments so that everything can be carried out flexibly and in-house. AVL´s analysing techniques include particle size distribution, BET, Blaine, Hydrogen analysis and mass flow equipment.

Achieving highest standards

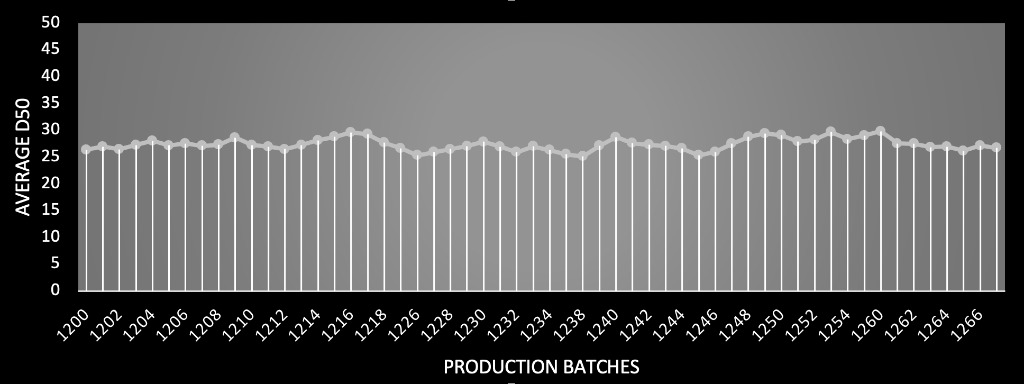

Recently an integrated quality control system has been implemented in the production site which enables a full traceability of all produced batches and has severely decreased production fluctuations leading to a stabilized product outcome (fig. 2).

Beside aluminium powders AVL can also supply a wide range of stabilized solvent based aluminium pastes for the AAC industry. One of the newest developments are water-based aluminium pastes with water as main solvent with the advantage of being non-hazardous for transport. These are the RIZAL 7XXX-YY/70WB21 series. In case customers wish and need aluminium pastes with another main carrier, such as diethylene glycol AVL’s tailor-made products are still offered and further developed.

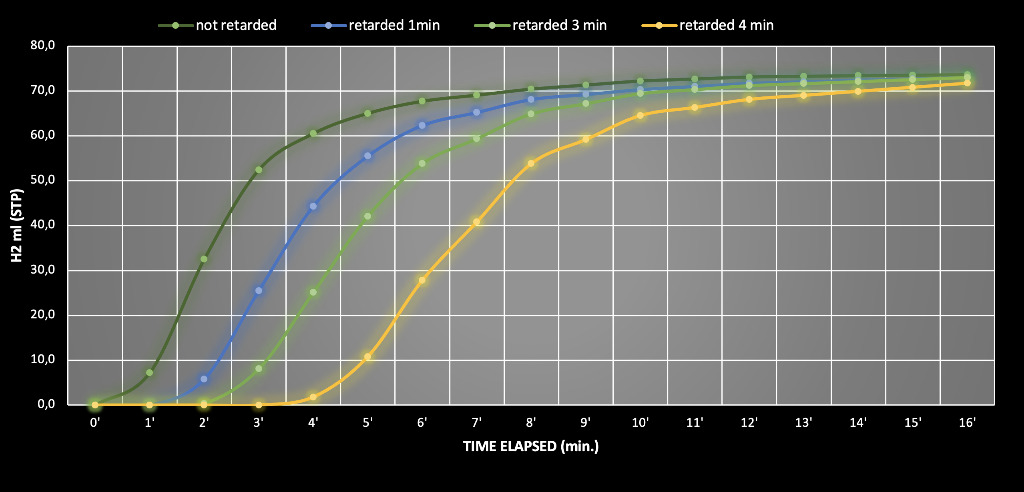

In close collaboration with certain customers, AVL is very proud to introduce aluminium pastes with a retarded and/or postponed reaction. A whole range of pastes are developed and can be custom made upon request. These types of aluminium pastes facilitate the pre dispersion of aluminium with water in the case this is one of the demands of the AAC process.

Rising cracks are a severe issue in the AAC production which explains the focus of AVL’s experts regarding this issue. Thanks to a fully equipped lab AVL is terminating the tests allowing to launch soon new high-quality grades that can tackle in an efficient way rising cracks via controlled gas-formation.

This will allow the individual production to have fewer production failures and tonnages of own production that have to be re-introduced into the process. In that way construction waste can be revalorised at higher speed.

AVL has a wide range of products for the AAC market, from delayed to retarded to extremely postponed in time to powders with an exceptionally high Blaine value, see fig. 4.

This way AVL can offer customers all types of products, covering demands all over the market.

Customer satisfaction is the key for AVL Metal Powders n.v. This results in supplying customers who have a partnership with AVL for more than 30 years.