News & Markets

34rd world's leading trade fair for construction machinery, building material machinery, mining machinery, construction vehicles and equipment

Welcome to the bauma 2025!

Loading...The bauma offers the world's largest overview of the complete construction, building materials and mining machines industries and international leading machine manufacturing companies from the autoclaved aerated concrete industry will also be represented at the bauma.

On the following pages in this issue of AAC Worldwide, you will find up-to-date information from exhibiting companies from our industry, who have sent us their individual news for self-promotion. Short and compact, sorted alphabetically, with details of the companies and references to their respective booths at the bauma 2025!

ad-media Guide

ad-media is the publishing house of AAC Worldwide. The ad-media Guide for the entire concrete industry contains, in a handy waistcoat-pocket format, selected information about the suppliers to the AAC industry who will be present at bauma 2025. The ad-media Guide will be distributed at the AAC Worldwide exhibition booth B1.138 to all those interested in this industry. We look forward to your visit.

bauma news

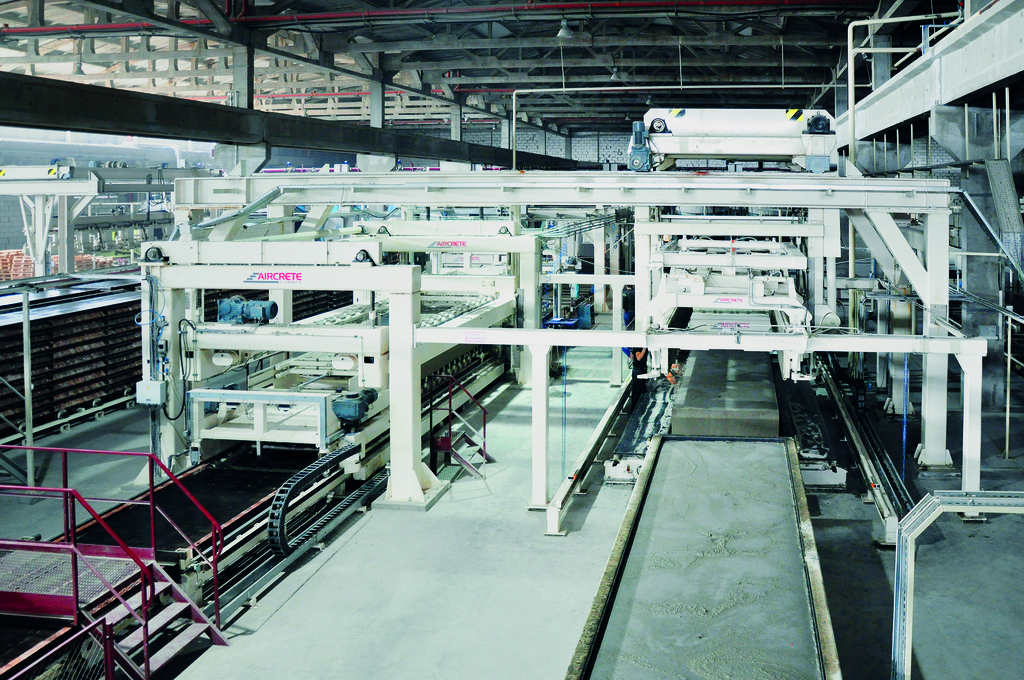

Revolutionizing AAC & CSU Production – Visit Us at bauma 2025

Aircrete Europe is shaping the future of Autoclaved Aerated Concrete (AAC) and Calcium Silicate Units (CSU). At bauma 2025, we’ll introduce Calsitec, our CSU-dedicated brand, and showcase turnkey CSU production solutions following the acquisition of WKB Systems' intellectual property.

In our AAC plants, our cutting-edge SUPER SMOOTH flat-cake cutting, advanced autoclaving control and In Control 4.0 software, optimize efficiency, precision and sustainability. Now, we also offer tilt-cake solutions with green separation, enhancing AAC plant capabilities.

See our next-gen aluminium paste dosing system, designed for maximum safety, precision, and efficiency, along with a high-accuracy slurry density measurement device, delivering cost-effective investment and maintenance.

Visit Hall B1-Booth #247, our team will be available to discuss tailored solutions, provide insights, and showcase live demonstrations of our advanced AAC and CSU technologies.

Booth B1.247

KEDA SUREMAKER to Showcase AAC Innovations

Keda Suremaker, a leading name in the autoclaved aerated concrete (AAC) industry, is thrilled to announce its participation in bauma 2025, the world’s largest construction trade fair.

What to Expect at Keda Suremaker Booth

Keda Suremaker will present several exciting products and solutions:

Advanced AAC Production Equipment: Featuring the latest innovation in AAC machinery technologies, like Keda Suremaker Green Cake Separation Machine and Mould Cleaning Machine.

Smart Energy-Saving Solutions: Integrated with automatic steam distribution, automatic condensate drainage, and waste heat recovery, maximizing the utilization of thermal energy in the AAC production line.

High-Capacity AAC Production Line: Comprehensive adjustments and upgrades have been made to the equipment configuration and production line layout to meet customers’ demand for intensive, high-capacity production.

Our team will be available to discuss how these innovations can benefit your business and help you stay ahead in a competitive AAC market.

Booth C1.508

Experience Masa WhiteHUB at bauma 2025!

Masa WhiteHUB, as part of the Masa family, will be showcasing analogue and digital milestones at the Masa booth in hall B1.347, covering aspects of quality assurance in the production of building materials. Visitors are invited to explore exhibits, innovations, and information related to the production of AAC and sand lime bricks, and to engage with experts from Porta Westfalica and Enschede.

Making its debut at bauma is the Production Reporting System. This tool connects the information worlds of plant operators and management, and makes products traceable based on their production data. Furthermore, Masa WhiteHUB is showcasing a device for determining the fermentation state of AAC mass and presenting new solutions for reinforced AAC elements as well as cutting lintels. Additionally, possibilities for the efficient production of prefabricated sand-lime brickwork will be shown. Masa WhiteHUB – the best of two worlds.

Booth B1.347

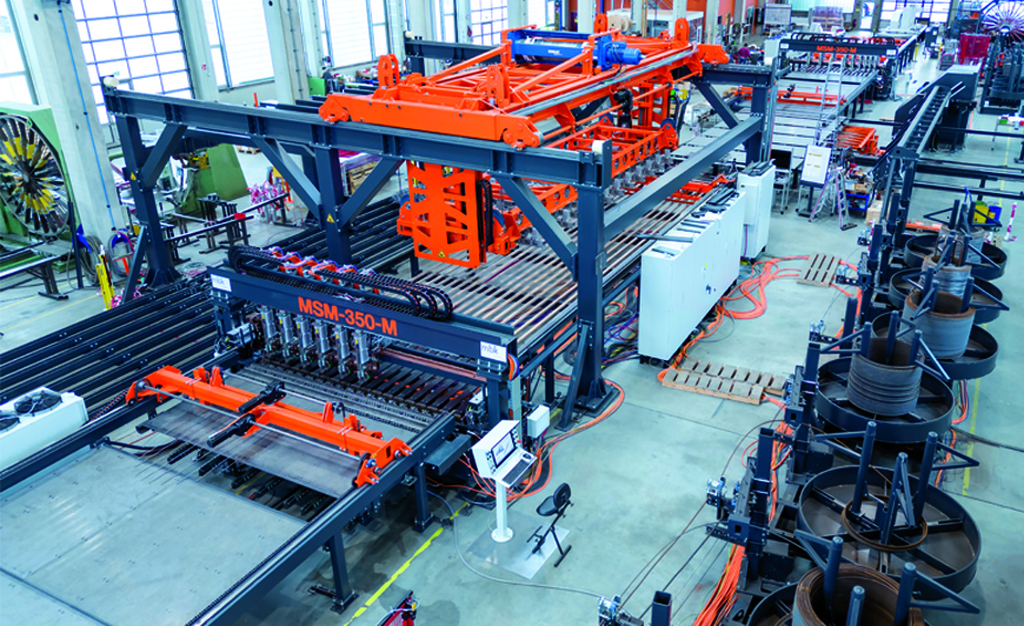

mbk – mesh welding machines and systems for the AAC industry

As a leading manufacturer of welding machines and systems for the concrete, construction, and precast industries, we oversee the entire process – from initial planning to installation. Whether standard machines, customer-specific adaptations, or special constructions, our experienced team meets every challenge. Since 1961, we have been producing in Kisslegg, with our machines operating in over 60 countries worldwide.

Our product range includes mesh welding machines, cage welding machines, wire straightening and cutting machines, a truss welding machine, and various accessories. As market demands evolve, automation solutions are becoming increasingly important. Our offering spans from simple automation accessories to fully automated production lines with buffer solutions and connections to downstream systems.

Booth B1.112

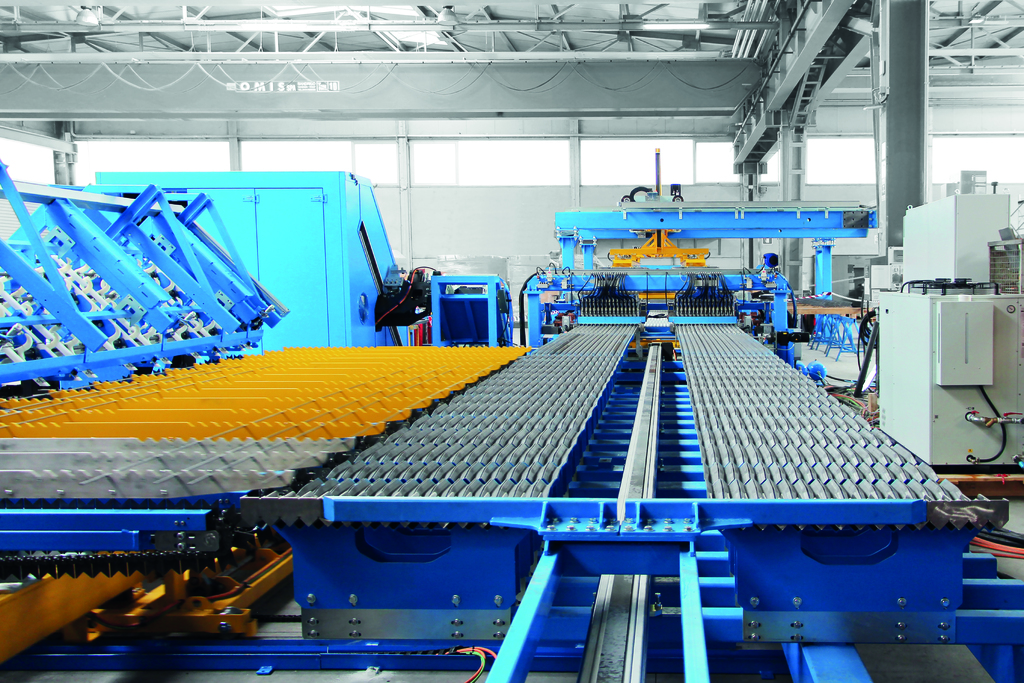

Reinforcement & Software Solutions for AAC Production

Progress Group offers complete AAC solutions that work from design to construction.

Automation in reinforcement and digitalization will take your AAC production to the next level.

Tailor-made automation and digitalization for AAC’s benefits:

greater productivity

ensured flexibility

maximum efficiency

Come and experience our solutions at bauma booth C3.303

Booth C3.303

Speaking of Wehrhahn....

Sometimes the time is ready for a new approach in order to remain fit for the future for the company, customers and employees. That is why we decided to build a new office at our company headquarters.

The old company building was demolished. We erected a new building in two construction phases. The overall result is an innovative office building with an area of 3,300 m². We rely on geothermal and solar energy. At the same time, we have added the new “Development & Technology” department to our expanded R&D and Technology Center. This is where potential is identified, ideas evaluated and implemented in order to develop products for the future that meet global requirements, are energy-efficient and reduce the ecological footprint.

We are ready to meet the challenges of the market. In a completely new design, Wehrhahn offers the proven highest quality in accordance with our objective “Everything from a single source” and continues to be the competent partner for our ambitious customers in the aerated concrete and fibre cement industry.

We are looking forward to your visit: for a first impression at the Wehrhahn bauma stand no. C1.339 and at our headquarters in Delmenhorst!

Booth C1.339