News & Markets

Xella International GmbH, 47259 Duisburg, Germany

Why the future belongs to autoclaved aerated concrete

Loading...In many countries around the world, people are not only wondering where to find affordable housing and how to respond to rising energy prices. Across generations, they are also questioning the sustainability of their homes. That's because the pressure to reduce the world's carbon footprint has never been greater. Climate change has become a daily reality.

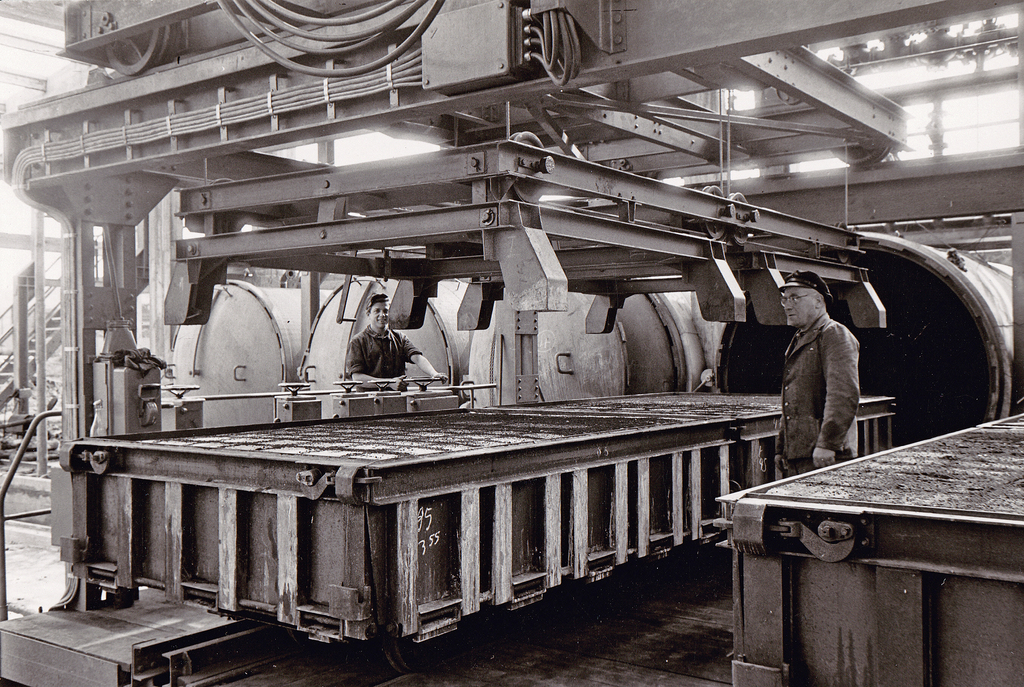

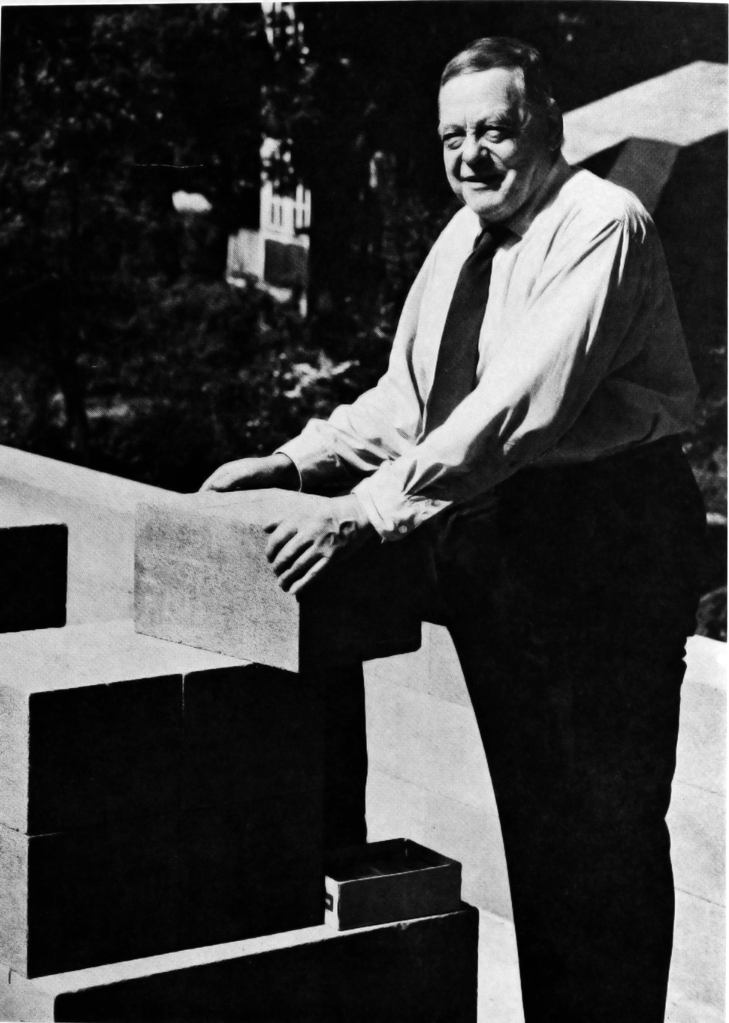

100 years ago, things were no different in Sweden. Shortly before that, in 1922, an architect named Axel Eriksson was driven to ingenuity by hardship. After World War I, his country suffered severe energy shortages and the government increased the requirements for housing construction. Better insulation was required from now on. Eriksson, a young assistant professor of construction techniques at the Royal Institute of Technology in Stockholm, conducted research on aerated concrete samples. He knew that such blocks would not only be ideal for building faster than before and alleviating the housing shortage. They would also insulate interiors much better than wood, which was popular at the time. He accelerated the hardening process of the porous mass of baked shale lime, water, and aluminum powder by placing the sample in a laboratory autoclave. The resulting hardened brick was stronger than ever and had a stronger crystalline composition. The heat and pressure of steam curing had fused the silica and lime components into a form of calcium silicate hydrate crystal. Eriksson patented his invention one year later in 1924 and found in his compatriot Carl August Carlén the merchant who brought the new building material Ytong to the world.

Continuous development

This was the beginning of a well-known success story. Not only because Ytong was already giving a boost to progress on the building sites and was meeting the needs of the building owners. But also because Xella and its predecessor companies continued to develop the material over the decades. Production became more sustainable and planning more digital. Cécile Fages, Xella's Chief Sustainability & Communications Officer, describes this continuous commitment as follows: „At Xella, we work hard to make sure that the dream of comfortable, sustainable places to live and work can come true for as many people as possible. However, our ambition goes even further. Indeed, our vision states that We are building a sustainable world”.

The European Commission has set the policy framework with its European Green Deal. By 2050, member states are to achieve zero net greenhouse gas emissions. In addition, economic growth is to be decoupled from resource consumption. Two ambitious goals. "Our industry, the construction sector, can and must play a key role in achieving these goals. Even though the current global economic context is already impacting the construction industry.“

Social responsibility

Even in this challenging environment, the sector must remain a viable industry, a valued business partner, and a part of society that contributes with conviction to the Paris climate goals. Especially, as it has recently been criticized by the World Economic Forum in being “a latecomer*” with regards to decarbonization.

For Xella, this means, according to Cécile Fages: "Step by step, we are realizing our very ambitious vision in terms of CO2 emissions. This is part of our business strategy. That is why we are committed to science-based targets. This is our contribution to a net-zero building industry“. This means that these targets are in line with what the latest climate science deems necessary to meet the goals of the Paris Agreement – limiting global warming to 1.5°C.

Digital future

But it is not only the sustainability of autoclaved aerated concrete that will determine its future. According to Andreas Radischewski, Digital Building Solution and Transformation Manager at Xella, 2023 will be a landmark year for the use of artificial intelligence (AI) in the construction industry. "The big advance is better analysis of all the business data that has been collected over the years. Now we will be able to use it in a more targeted and comprehensive way. Artificial intelligence helps us interpret the data sets so that we can plan and build even more economically," says Radischewski. “More and more customers are asking about the certifications of building materials. Advanced Analytics (AA) is a big help here. Using data from a building model, the carbon footprint of the entire building can be calculated with just one click.”

AI can also optimize internal processes, warehousing, and business models. "This kind of analysis helps you make connections that you can't make in your head or by hand," says Radischewski. Xella's openness to new technologies drives further evolution and encourages the exploration of opportunities to make construction less labor-intensive and healthier. As an example, Xella is currently conducting tests on newly developed exoskeletons designed to assist construction workers in carrying heavy loads. These exoskeletons provide back support and offer workers the stability they need.

An international network

Xella has been pushing ahead with offering digital building solutions, like its service blue.sprint, for its customers for several years now. In 2022, they realized nearly 1750 blue.sprint-supported projects in Europe (where both clients and Xella planned digitally ---> read a report on this topic starting on page 62). Fewer mistakes, less material, fewer labor hours and a high degree of planning security are the benefits for everyone who builds with AAC and BIM. But there is still a lot of convincing to be done at European level. While in countries like Denmark the way is clear for 3D planning, other countries are still reluctant to adapt. As a result, digitalization naturally becomes a decentralized topic for Xella. “In this context, it is our perpetual exchange that keeps us ahead as Group. For instance, when we provide support to customers in the digital planning process in the Netherlands and Belgium, we incorporate this valuable experience into the processes of other countries. Collaboration is key”, says Andreas Radischewski.

7th International Conference on Autoclaved Aerated Concrete

Sustainable production and recycling, energy-efficient construction, and the implementation of digital tools to promote the respectful use of labor and resources - there are many promising areas in which to discuss the prospects for autoclaved aerated concrete in a dynamic construction industry. These aspects serve as a good prerequisite for the 7th International Conference on Autoclaved Aerated Concrete (https://icaac2023.com/info) in Prague. From September 6-8, 2023, the European Autoclaved Aerated Concrete Association (EAACA), supported by the Polish Concrete Producers Association (SPB), invites international experts from scientific institutes, AAC manufacturers, raw material suppliers, and associations to come together, connect, network, and discuss the future of building with AAC.