Production Technology

Ecoratio BV, 4251 NK Werkendam, The Netherlands

AAC Demoulding – Release Agent Technology Reimagined

Loading...A striking example of this mindset is the development of a release agent specifically designed for the autoclaved aerated concrete industry. When feedback from AAC producers began to reveal that existing release agents weren’t delivering consistent or satisfactory results, Ecoratio’s R&D team responded swiftly and decisively. Their objective was ambitious but clear: to develop a next-generation release agent that would perform better, align with evolving safety standards, and support the industry's push toward greener practices.

“For us, this is more than just another product development. It’s a reflection of how we work – by listening, asking questions, researching thoroughly, and innovating with purpose,” says Aart-Jan, a chemical specialist at Ecoratio. “This is how we help our customers make their production processes safer, more efficient, and more sustainable.”

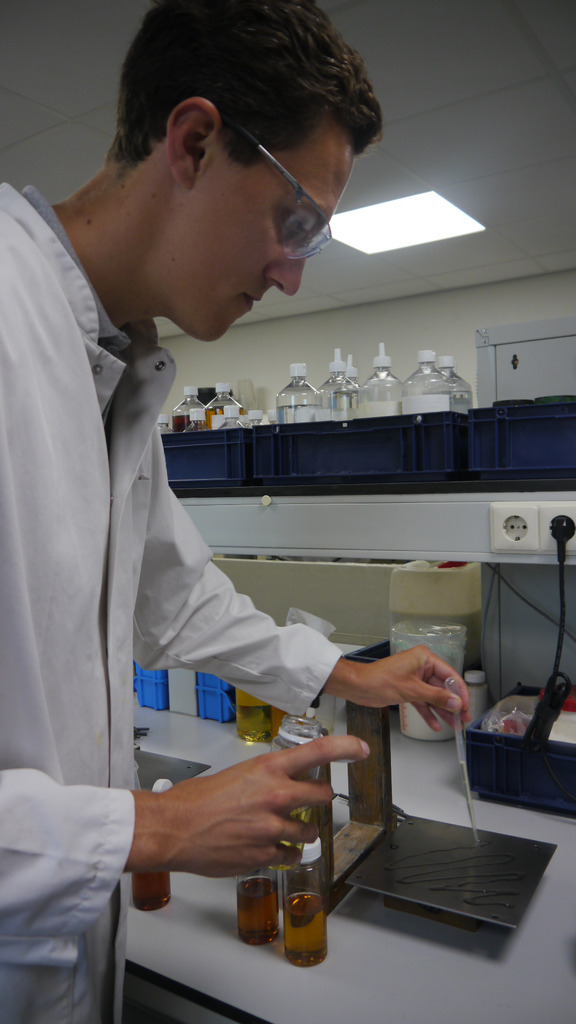

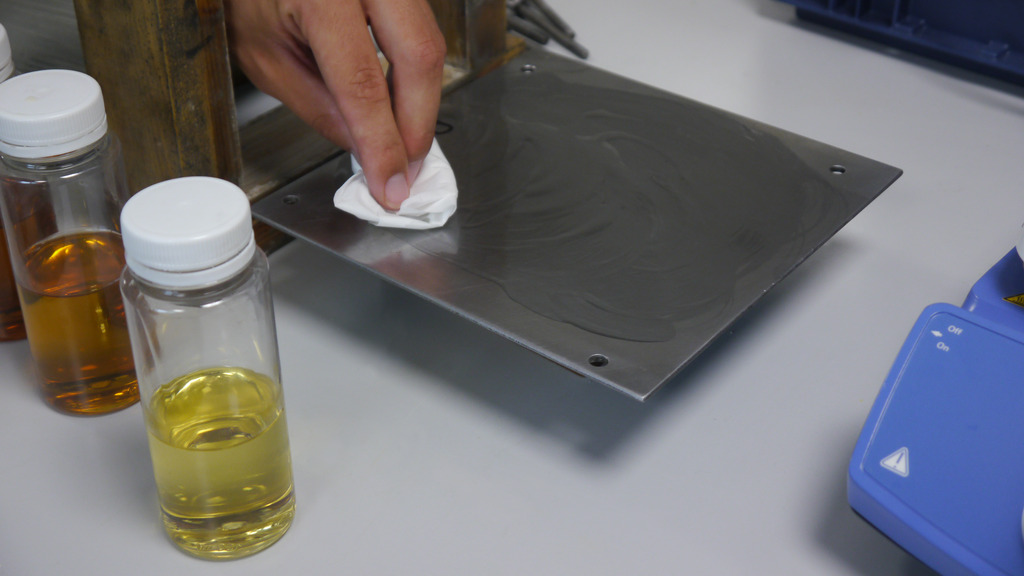

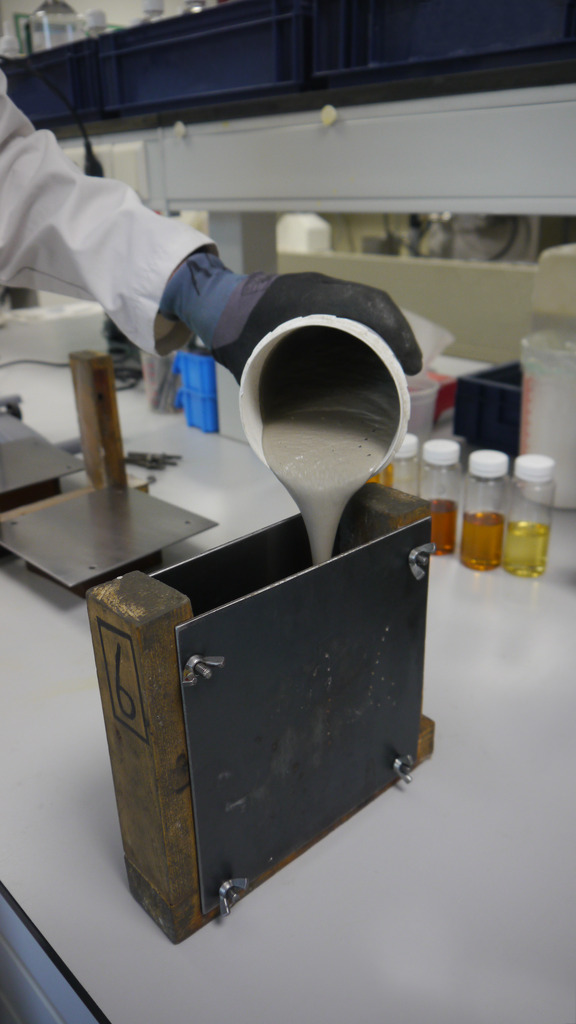

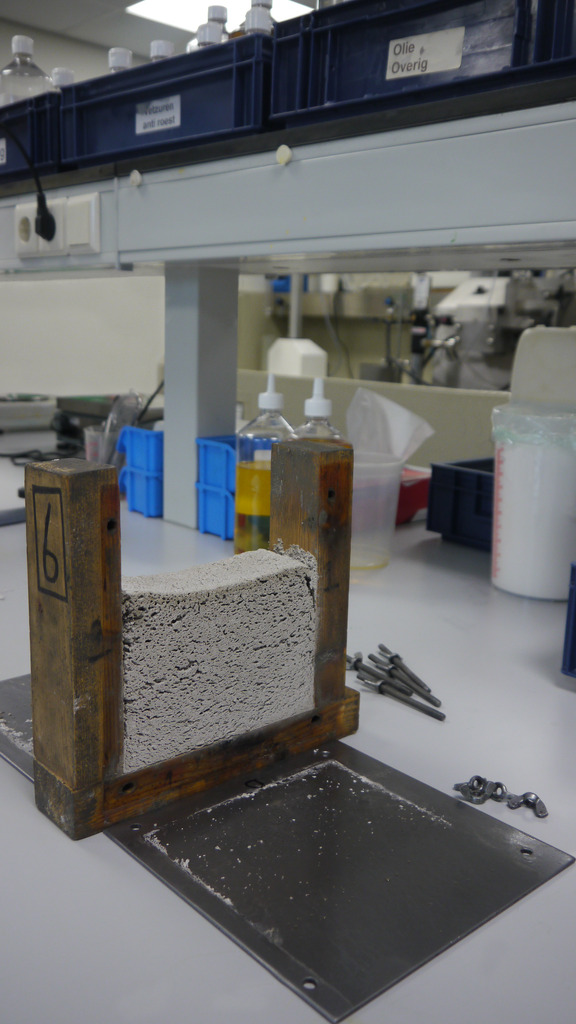

Experimenting, Testing, Refining

Turning that vision into reality required rigorous testing and a willingness to challenge assumptions. Ecoratio launched a comprehensive series of experiments at their in-house test facility, knowing that a solution must not only perform on paper but prove itself in practice.

They tested various release agent formulations under strict criteria, evaluating adhesion, evaporation time, residue behaviour, and potential effects on the surface quality and structural integrity of AAC products. Importantly, these trials were conducted under a wide range of simulated environmental conditions – from hot and dry to cold and humid – mimicking real-life factory settings across different regions.

This hands-on approach combined deep material science with practical field knowledge. Every variation provided fresh insights into how different components interacted. Minor tweaks were made and re-tested with discipline and consistency. Through this iterative process, it became clear which ingredients worked harmoniously and which caused performance issues.

From the Lab to the Production Plant

No two AAC plants are exactly alike. That’s why Ecoratio emphasizes a continuous dialogue between its laboratory team and production partners in the field. Their specialists work side-by-side with customers, gathering real-world data and translating it into actionable insights.

This collaboration ensures the release agent isn’t just theoretically sound – it’s tailored to the everyday challenges of AAC production. In this way, the product evolved as much in factories as it did in the lab. Field feedback led to new test series and refinements, ultimately shaping a solution that’s robust, adaptable, and production-ready.

A Smarter and Safer Greener Choice

The result is a release agent that meets the evolving needs of the AAC industry with improved performance and safety. It’s label-free – making it safer for operators – while delivering consistent results and ease of use across production environments. Just as importantly, it supports a cleaner, more sustainable production process.

By reimagining what a release agent could be, Ecoratio has not only solved a problem but demonstrated how smart innovation, grounded in close industry cooperation, can move construction forward.