Production Technology

Aircrete Europe, 7575 EJ Oldenzaal, The Netherlands

Added value in AAC: New U-block and lintel production line for efficient manufacturing of high-value products

Loading...What are AAC U-blocks and why do they matter?

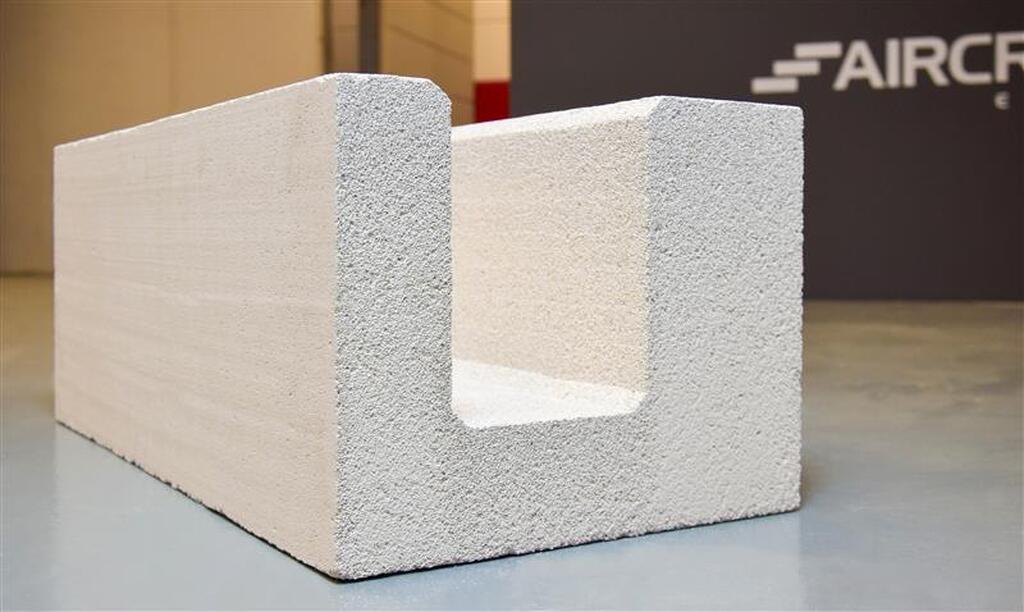

U-blocks are special AAC units characterized by a longitudinal cavity in the shape of a “U,” designed to accommodate reinforcement bars and in-situ concrete. In essence, they combine the thermal and lightweight properties of AAC with the mechanical strength of reinforced concrete. The application of U-blocks in AAC wall systems simplifies construction processes by eliminating the need for external formwork and ensures continuity between structural reinforcement and masonry. Their versatility makes them suitable for multiple structural functions, including lintels and reinforcement belts (ring beams), both of which are critical for the stability and performance of modern buildings.

The importance of AAC lintels as a high-margin product

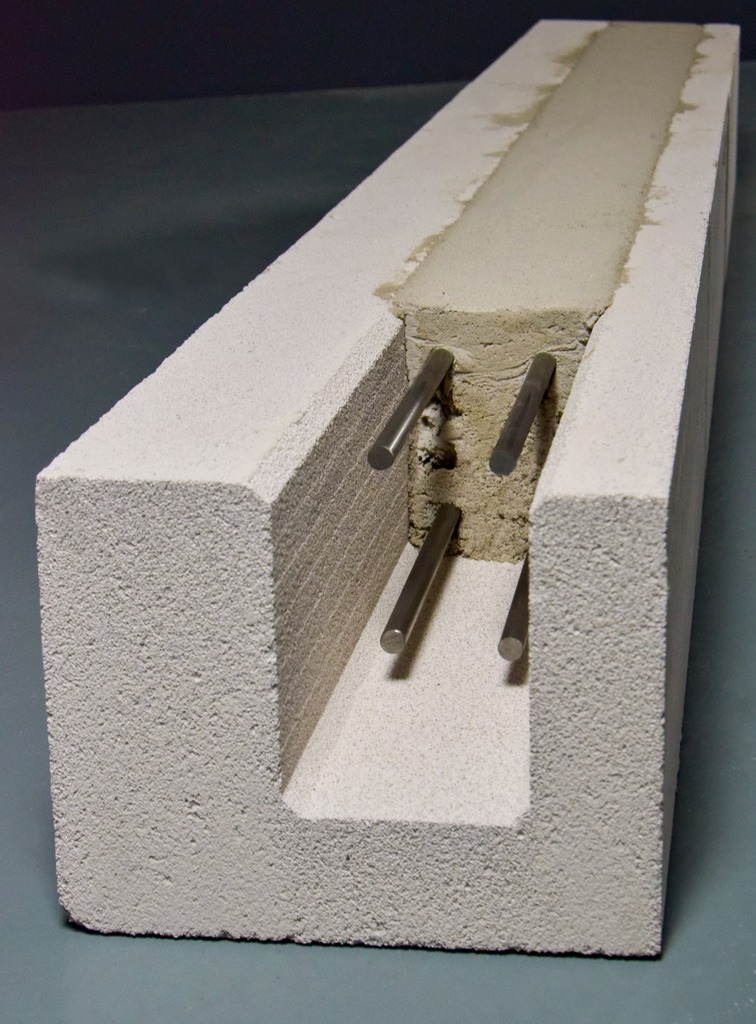

Among all possible applications of U-blocks, lintels stand out as the most commercially and technically significant. Lintels are positioned above window and door openings and must safely transfer loads from the masonry above. Traditionally, lintels have required prefabricated reinforced concrete elements, which not only added cost but also disrupted the thermal continuity of AAC walls, so called heat bridges. By manufacturing lintels directly from AAC U-blocks filled with reinforcement and concrete, builders achieve structural reliability while preserving the insulating and lightweight qualities of AAC construction. This dual advantage has made lintels one of the most sought-after AAC products. Importantly, lintels sell for significantly higher prices than regular blocks, typically between 15 and 30 percent more, providing AAC producers with an excellent opportunity to capture additional margin.

Reinforcement belts and seismic safety

In addition to lintels, U-blocks are widely used to create reinforcement belts, also known as ring beams. These elements form a continuous band of reinforcement around the perimeter of a building, significantly improving seismic resistance and enhancing load distribution across the structure. Particularly in earthquake-prone regions, reinforcement belts are mandatory to ensure building safety. AAC U-blocks provide an efficient way to create these belts while maintaining consistent material properties across the building envelope, ensuring that structural strength does not come at the cost of energy efficiency.

Challenges in U-block manufacturing today

Historically, the manufacturing of U-blocks has been approached in two ways. One method is to assemble them by gluing two or three AAC blocks together. While this avoids material waste, it requires special pre-cut blocks and industrial glue, which adds considerable cost and complexity. The second approach is to saw, or mill hardened AAC blocks to form the U-shape. This technique provides greater flexibility in terms of dimensions, but conventional milling technologies have often been slow, labor-intensive and inefficient in dust control, limiting their economic feasibility.

As a result, many AAC producers have been left without a robust or economically viable solution for U-block manufacturing, despite the clear market potential of these products.

Existing U-block machines and their limitations

The range of existing U-block machines on the market illustrates the challenges faced by producers. Some rely on basic manual milling tools, which are affordable but can be inconsistent in quality. The other more common solution is to saw slices into the blocks, either manually or with a semi-automated saw and then break out these slices. This, however, can not only lead to inconsistent quality, but also leaves the producer with larger pieces of AAC waste that need to be disposed of or crushed in order to be reused in the production. As a result, despite their importance, U-block production has not always been optimized, creating a gap between market demand and technological capability of the AAC producer.

Aircrete’s new U-block concept

To address this gap, Aircrete Europe has developed a new U-block manufacturing concept that combines innovation with practicality. The design focuses on transforming customer challenges into opportunities: turning surplus and waste AAC blocks into profitable products, reducing inefficiencies, and supporting a more circular production cycle. This innovation represents a fresh perspective on U-block manufacturing, directly addressing the long-standing concerns of AAC producers worldwide.

Why milling is the core strategy

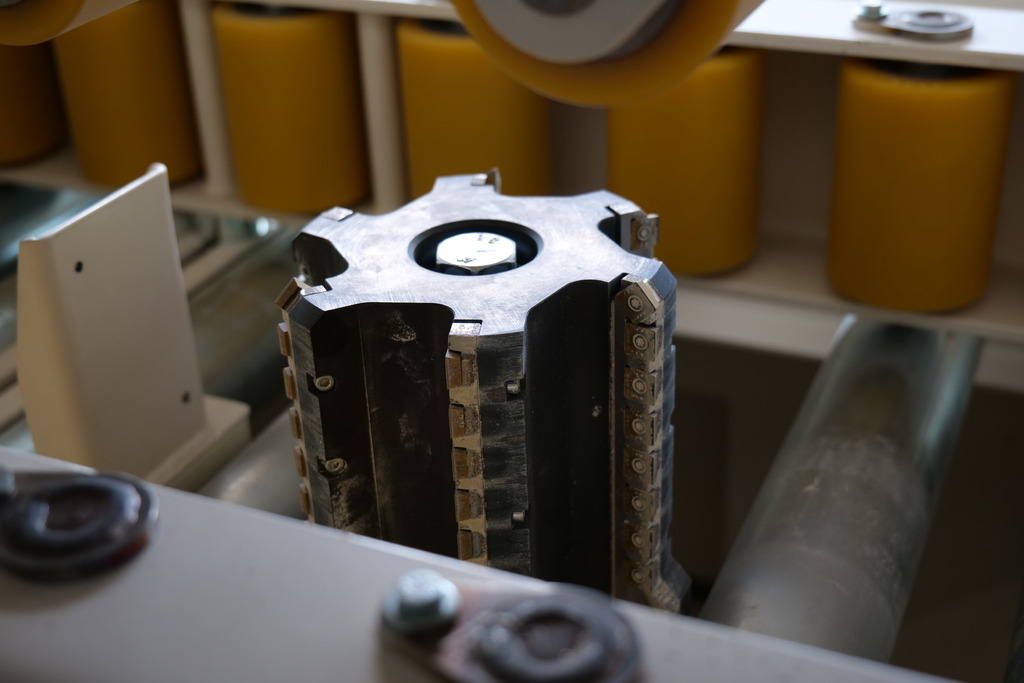

The heart of this new concept lies in milling technology. Milling offers unmatched flexibility because it allows any block, whether standard, oversized, or considered waste, to be repurposed into a U-block. Aircrete’s solution not only ensures precision in shaping the cavity but also features an advanced cyclone-based system to capture fine dust generated during the process. Far from being a waste product, this dust can be easily reintegrated into the production process, where its water-absorbing properties can help reduce rising time and improve viscosity. In this way, the system transforms a potential by-product into a process enhancer, perfectly aligning with the principles of circular economy and sustainable AAC production.

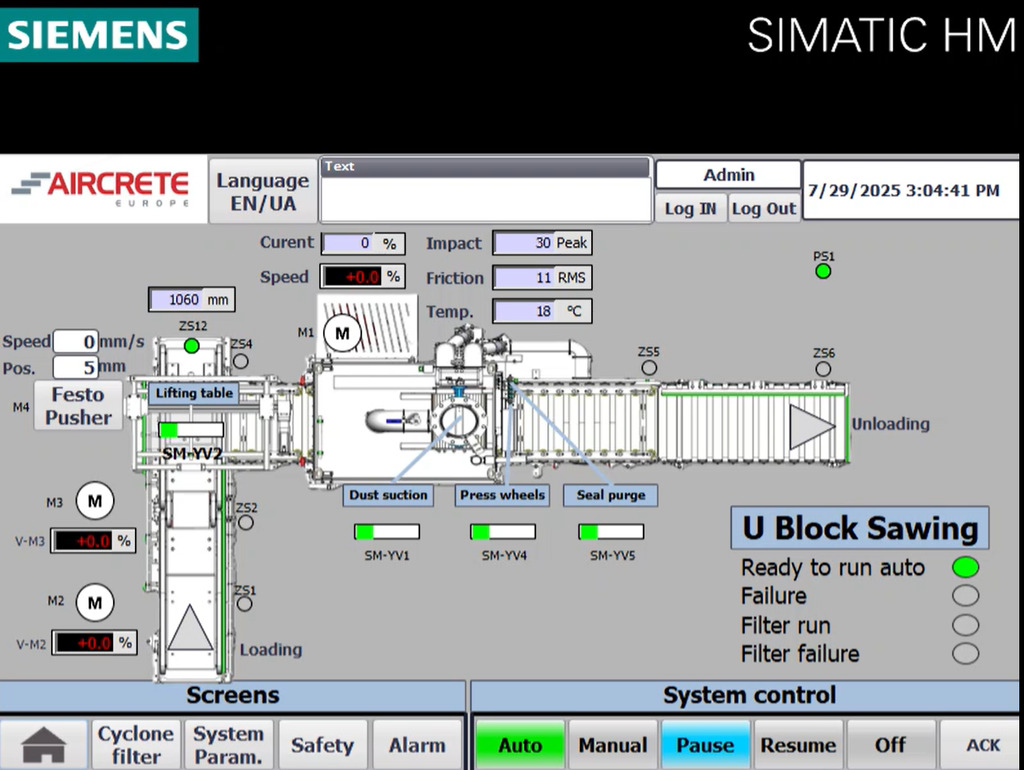

Semi-automatic operation for cost efficiency

Another key aspect of the Aircrete U-block machine is its semi-automatic design. By combining manual infeed and outfeed with fully automated milling, the machine strikes the ideal balance between cost-efficiency and operational reliability. This approach avoids the complexity and expense of fully automated systems while ensuring consistent product quality and productivity. For AAC producers, this means an easy-to-operate, user-friendly machine that integrates seamlessly into existing production setups without requiring large-scale modifications. Aircrete does however also offer an option to fully automate the process, by installing a robot to load the blocks and to unload and palletize the U-blocks.

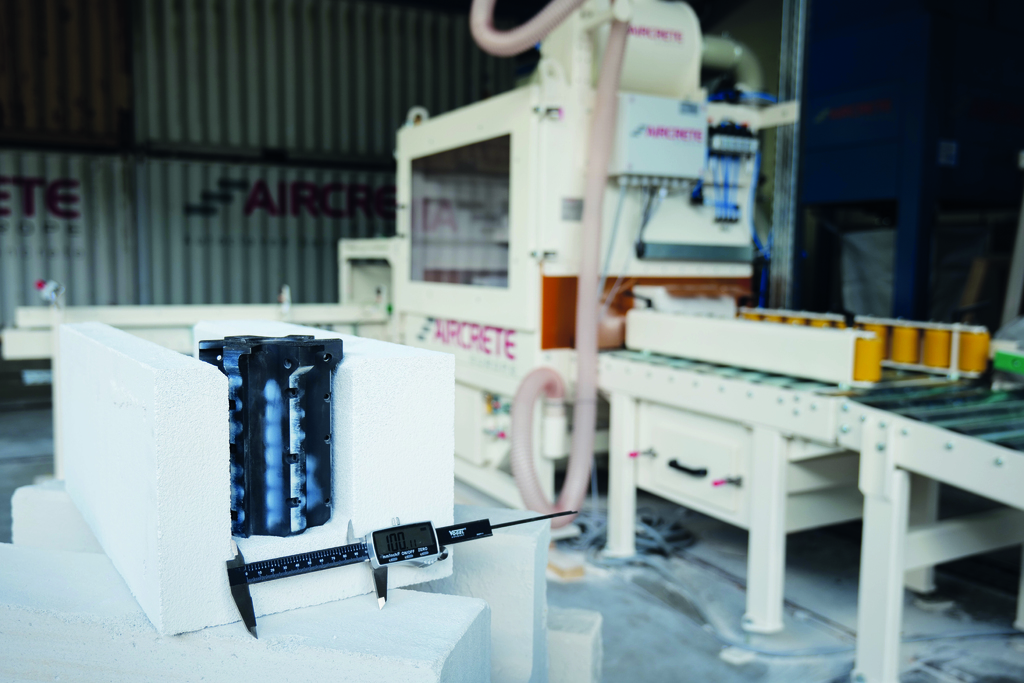

Inside the Aircrete U-block machine

The machine itself comprises several well-engineered subsystems. Blocks are loaded via infeed conveyors and positioned precisely using a pusher mechanism. They then enter the milling area, where interchangeable cutters shape the desired U-profile with high accuracy. The dust created during milling is immediately collected by the cyclone system and stored for reuse, ensuring a clean and efficient operation. Finished U-blocks are then smoothly discharged via outfeed rollers, ready for reinforcement or delivery to customers. The entire system is stand-alone and self-contained, requiring minimal downtime to install and commission within existing AAC plants.

Flexibility and market responsiveness

One of the most notable advantages of the Aircrete U-block machine is its flexibility. By simply changing the milling cutter, producers can create U-blocks with different cavity shapes and dimensions, adapting to various lintel and reinforcement requirements. This feature enables factories to respond rapidly to changing market conditions or customer specifications without costly tooling investments or extended lead times. It ensures that AAC producers remain competitive in a dynamic construction industry.

From U-blocks to lintels: Leveraging WKB expertise with the Lintel Production Line

As part of the acquisition of WKB Systems GmbH’s intellectual property in September 2024, Aircrete Europe has incorporated additional technologies that extend its ability to deliver comprehensive AAC solutions. Among these, the Lintel Production Line stands out as a proven and highly automated concept that can be tailored to AAC production. Originally designed for sand lime brick applications, this technology has now been refined and adapted by Aircrete to complement the U-block Machine, enabling producers to establish a direct and efficient pathway from U-block milling to large-scale lintel manufacturing.

The Lintel Production Line is engineered as a continuous, automated process that minimizes manual handling and ensures consistent quality. Pallets of U-blocks are automatically fed into the line, rotated and positioned with precision. Alternatively, the blocks can be fed directly from the U-block machine to the lintel production line. Reinforcement and spacers are placed before the units enter the concrete pouring station, where a controlled filling system guarantees dimensional accuracy and homogeneity. The lintels then pass through a curing chamber under stable conditions until the required strength is achieved, after which they are efficiently unloaded and prepared for dispatch. This systematic approach ensures high productivity, uniform results and operational reliability. A simplified semi-automated version is also available.

By integrating the U-block Machine with the Lintel Production Line, AAC producers can extend their product range with a reinforced structural element that is consistently in demand. The ability to scale lintel production within the plant environment not only increases utilization of existing resources but also strengthens competitiveness by offering an added-value solution. Supported by Aircrete’s engineering expertise and the inherited know-how of WKB, the Lintel Production Line represents a strategic opportunity for producers aiming to achieve higher efficiency, process stability and market responsiveness in AAC production.

Conclusion: U-blocks as the future of added-value AAC

In conclusion, U-blocks are a cornerstone of added-value AAC products, and lintels derived from them represent a particularly lucrative market opportunity. By enabling the transformation of waste and surplus blocks into U-blocks, Aircrete Europe’s new U-block machine not only increases profitability but also reinforces sustainable production practices. With its innovative milling concept, advanced dust recycling, and semi-automatic operation, the machine offers AAC producers a reliable, flexible, and highly efficient solution to expand their product portfolios. As the construction industry continues to demand stronger, more efficient, and sustainable building materials, Aircrete Europe remains committed to delivering technologies that combine innovation with experience, empowering producers worldwide to unlock new value in AAC manufacturing.