Production Technology

PMX Labs Sp. z o.o., 60-750 Poznan, Poland

Addressing sticking issues in AAC manufacturing

Loading...While visiting AAC plants around the world (more than 100 over the years so far), PMX Labs experts consult and discuss with Production Managers and Quality Control Teams the challenges and difficulties in daily operation. This is a unique and invaluable insight into the industry’s best practices and a broad exchange of experiences. Over the years it has become very clear that many of the challenges the factories have to cope with are common around the globe, regardless of the country, type of raw materials or the technology of production.

Currently the AAC industry, much like the whole building materials industry, is in the stage of optimization. There are:

legislation demands (for instance lambda coefficient of walls in buildings built in European Union),

environmental conditions (reducing the CO2e (equivalent) emissions),

the market is increasingly competitive.

Reaching ways to optimize the production of AAC, in many plants has become an important part of maintaining the position on the respective markets.

Waste control

Reduction of raw materials consumption is an obvious cost optimization often brought up during consulting. The next way is less apparent but brings direct results: strict waste reduction.

Production Management and Quality Control must be aware that every waste, whether in the green or white phase, is a result of some error. While some aspects like volatility of raw materials or pure human error are impossible to control, there are many that can be: machines setup and maintenance, clear Standard Operating Procedures, process and quality control – starting with raw materials and finishing with ready product.

To improve in the area of waste reduction a waste classification method is recommended. Noticing, categorizing and reporting waste allows to quantify it and solve it consequentially.

For some plants, reusing return slurry into the process acts like a justification for having high amount of waste in the first place. It is important to remember, that the return slurry is fed by the cut-out parts after cutting machines – by design. Every waste above this level is a missed opportunity to generate sellable benefit from the raw materials making the cake.

Mechanical vs Process waste

Waste is mainly generated through cracks and adhesion. Either during a green phase or after autoclaving, this leads to parts of cake having to be discarded. To better understand how it is created, and most importantly how a factory can reduce these effects, a close look into specific processes will be given.

Generally, waste origins can be categorized in two groups:

Mechanical waste

Process-related waste

Mechanical reasons are the scope for machinery producers and engineers maintaining the equipment. Often factories have damaged/fatigued moulds, uneven rails, cranes with not enough tolerances – all that leading to mechanical cracks, broken corners, etc. Solutions here are maintenance or replacement of machinery but that is not the scope of this article.

Process-related sources of cracks and sticking is the subject for technologists and quality control, as it ties these fields together. It can be further categorized:

Raw materials quality

Effectiveness of mixing

Recipe composition

Rising and cutting conditions

Autoclaving process

Raw materials quality

Sand plays a key role in AAC production. As it is sourced locally, some factories on a daily basis have to deal with sands that are far from perfect, and still it is possible to produce good quality end products. Suitability of sand for a high-quality AAC production with less problems is a major topic. Sands with higher silica content will create environment for less sticking in the cakes. Plants often use blends of different sands to stabilize quality, but there are limits to such improvement.

Recipe composition

Recipe is plant-specific, as the combination of raw materials characteristic is very particular. It depends on the quality of sand available, cement and lime used, and finally on the technology present in the plant.

Water content is the most important factor that is easily adjustable and has major role in preventing sticking. Water-to-solids ratio should be as low as possible, while hydrating binders and creating flow of the mass.

In many factories the intake of water is underrated, as it is loosely added whenever there are troubles with the flow of mass, or rise height (to some point). How then they experience intensive sticking after such procedure – is no mystery at this point.

Superplasticizers are chemical additives aiding lowering water content without disturbing the performance of the green cake. With lowering the water surface tension, they are enhancing the effectiveness of hydrating binders. The additive replaces some parts of water, enabling to lower down the water content in the cake.

Mixing

Quality of mixing raw materials plays an important role in adhesion prevention. It is typical for mixing dry materials with liquid for coagulation to occur. However, when the mixing is perfected and the raw materials are not overdosed, this is omittable. On the other hand, if the lumps of unreacted binders occur a lot, this will lead to hydrolyzation in the autoclave. This will happen on the surface of the blocks – thus sticking the elements togethers – the adhesion.

This aspect is easier to change than choosing sand for production. Optimized intake of binders and chemical superplasticizers helping with homogenous mix are important factors in preventing sticking. Moreover, such additives give higher elasticity to the green cake, thus making it more prone to cracking from mechanical shaking, as mentioned above.

Rising and cutting conditions

Process between casting and autoclaving is important for the end product, as during this time the gassing occurs, which gives the final height and structure of the cake. The cake must develop the right hardness in adequate time for cutting, depending on type of technology used.

Development of hardness must be related to releasing hydrogen, which makes for the rise of height. Production managers know the consequences of failing in meeting those two processes too well: if the cake rises too fast in relation to hardness, the hydrogen will be released before the structure is strong enough. The cake will collapse. If the cake hydrogen is released not fast enough, the cake will not rise enough, and the trapped hydrogen will cause lateral cracks after autoclaving.

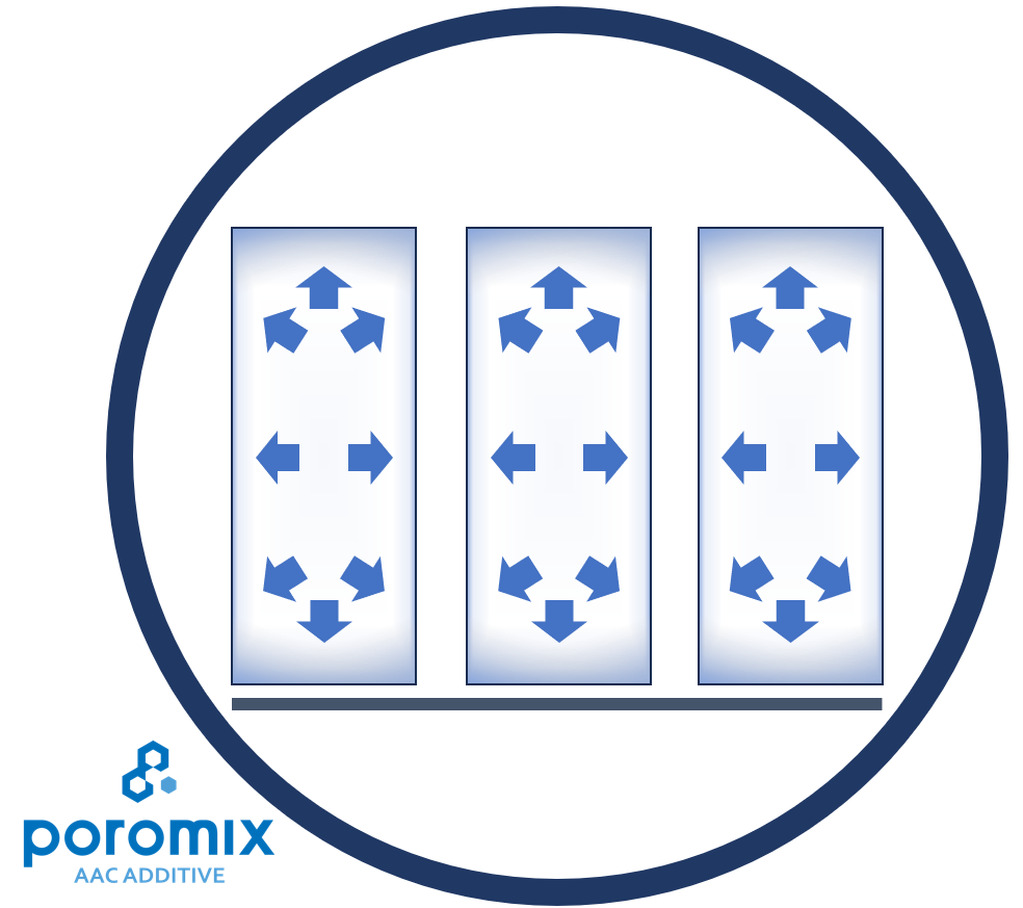

During this process the temperature rises steadily. When preserved correctly, in an environment preventing drafts and excessive airflow, the cake will get to an autoclave without drops in temperature. Moreover, if the cakes are cured in the chambers, the difference in temperatures of the corners and the middle of the cake will be minimal. Such condition is an optimal state in which the cake is ready for the next stage.

Autoclaving process

This is the most important part of the production process of AAC. During this stage the phase transition occurs, and the internal crystal structure is created. The quality of this process affects the characteristic of the final end product in the greatest way.

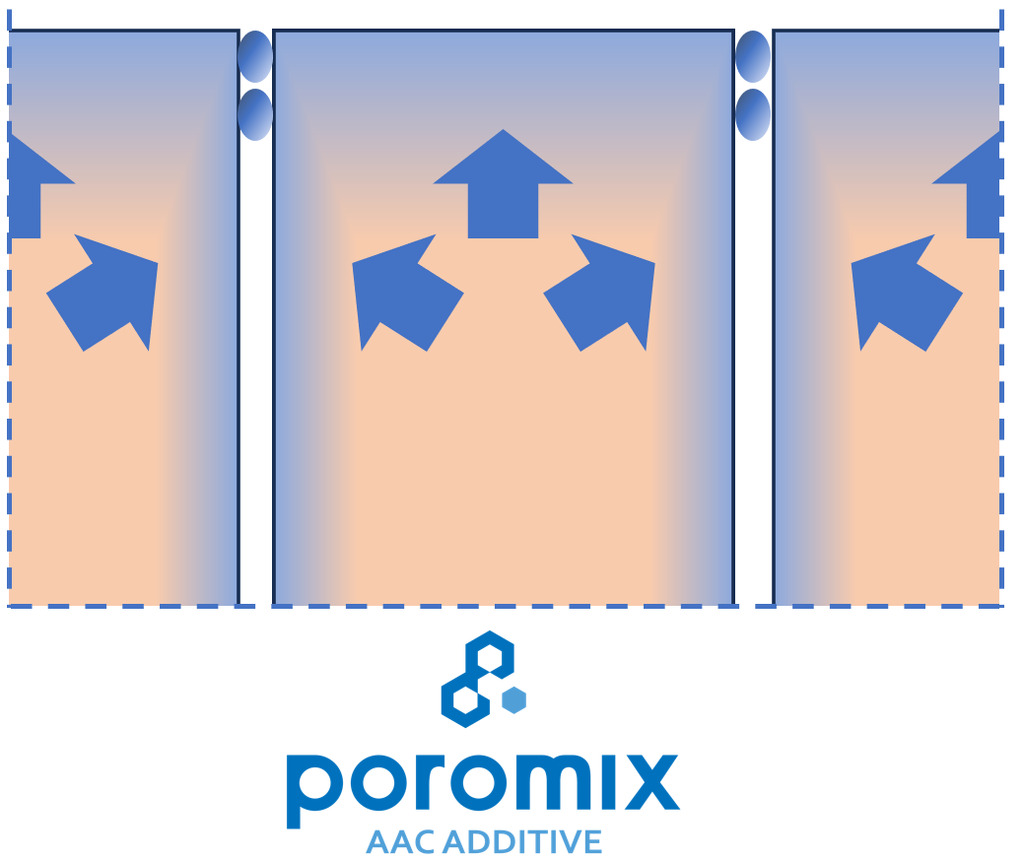

During this stage adhesion can also occur if the loaded green cakes have not been heated properly. If the difference in temperature between the corners and the inside of a cake is substantial, water inside the mass will condensate on the colder surfaces of the cakes (Fig. 4). Instead of evaporating, the water (in form of calcium oxide suspension) under autoclave conditions starts to bind, thus closing the gaps made by the cutting machine. (Fig. 5).

High water content catalyzes this process, as there is simply more water to escape and evaporate from the green mass.

Maintaining the designed top pressure during the process, accounting for leaks and drops by condensate removal with fresh steam will create humid environment inside the tube, enhancing the desired heat transfer.

Conclusions

Keeping waste as low as possible during production process is important, as those percentages directly refer to efficiency of the entire plant – how much of end product is produced with a given amount of raw materials.

Summary of possible solutions to reduce sticking:

Adjusting the recipe precisely to characteristics of available raw materials,

improving the quality of mixing, so the binders are hydrated before autoclaving,

lowering the water content in the cakes getting to the autoclaves,

ensuring the high and even temperature of the green cake before autoclaving,

using possibly fresh steam in the autoclave to enhance the transfer of the heat.

Methods presented in this article are good starting points for the process of improving various aspects of production. They require little-to-no investment, and the results over time can be substantial.