Production Technology

Zhejiang Yizhou Machinery, 314504 Tongxiang, China

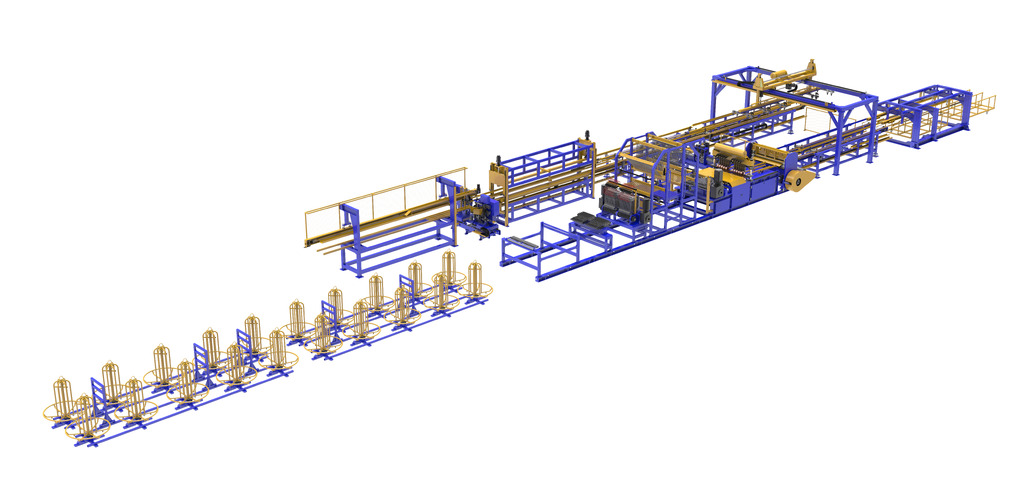

Advancing AAC production through high-performance mesh welding automation

Loading...Automation redefined: from raw material to finished mesh, seamlessly

Gone are the days of labor-dependent, error-prone mesh production. Yizhou’s automated line integrates cutting-edge technology to deliver a fully streamlined process, eliminating human intervention and advancing best practices for consistency.

End-to-end automation

The production line handles every stage autonomously - from vertical bar feeding and straightening to precise welding, cutting, and stacking. Equipped with advanced servo motors and intelligent sensors, it operates 24/7, ensuring uninterrupted production. For instance, the stepping mechanism precisely positions bars at pre-set intervals, while automated welding units execute uniform welds with minimal supervision.

Speed and precision

Boasting a welding speed of up to 20 points per minute - over five times faster than manual methods - the line drastically reduces lead times. High-precision control systems ensure each weld meets strict design specifications, with dimensional tolerances within 4 mm, guaranteeing compliance with global standards.

Smart oversight

An integrated monitoring system tracks real-time data, from material usage to equipment performance. Alerts for material shortages or anomalies enable proactive adjustments, minimizing downtime and maximizing productivity.

Sustainability meets efficiency: designed for the future

Aligning with global “green building” initiatives, Yizhou’s line merges automation with eco-conscious design.

Energy efficiency

Equipped with high-efficiency motors and frequency conversion technology, the system reduces energy consumption by over 30%, lowering operational costs while cutting carbon footprints.

Material optimization

An intelligent nesting algorithm minimizes waste by optimizing steel bar usage, reducing scrap and supporting circular economy principles.

Cleaner production

Low-smoke welding materials and enclosed welding chambers reduce emissions, ensuring compliance with strict environmental regulations and promoting healthier workspaces.

Versatility & adaptability: tailored to diverse needs

Yizhou’s line is engineered to meet the unique demands of varied construction projects, offering advanced flexibility.

Multi-spec compatibility

The system accommodates steel bars of varying diameters and spacings, adapting seamlessly to produce mesh for AAC walls, floors, and roof panels. Whether for high-rise buildings or prefabricated structures, the line delivers consistent quality.

Rapid changeovers

Modular design allows quick adjustments to mesh specifications. Operators can switch between product sizes in minutes, ensuring agility for small batches or customized orders.

Smart integration

The line’s compatibility with digital management systems enables remote monitoring of production metrics, empowering managers to optimize workflows and resource allocation.

Trusted globally: a legacy of innovation

With decades of expertise in resistance welding technology, Yizhou has established itself as a leader in automated solutions. Its production lines are trusted by AAC manufacturers worldwide, and its services are backed by robust engineering and comprehensive technical support.

Robust engineering

Built with industrial-grade components, the line withstands rigorous 24/7 operation, ensuring long-term reliability even in harsh industrial environments.

Comprehensive support

Yizhou provides on-site installation, operator training, and ongoing technical assistance, ensuring seamless integration into existing workflows.

Conclusion

Yizhou’s fully automated AAC mesh welding production line is more than equipment - it promotes the advancement of AAC production technology. By merging automation, precision, and sustainability, it empowers manufacturers to meet growing demands while upholding the highest standards of quality. For those seeking to elevate their production capabilities, Yizhou stands as a partner in progress, driving the future of construction forward.