Production Technology

Henan OPA Industrial Robotics Co., Ltd., Henan Zhengzhou Zhong, China

Application of intelligent manufacturing in the packaging line of AAC blocks

Loading...The production of AAC products differs from traditional labor-intensive building materials industries such as sintered bricks. It features a highly industrialized and automated production mode, with high levels of automation in both process technology and production equipment. However, some enterprises, due to initial insufficient funding or lack of foresight in planning, have outdated equipment. As new technologies are continually adopted and customer requirements for products increase, the old production methods, due to their inefficiency and high production costs, gradually lose market competitiveness.

To enhance product competitiveness and ensure long-term development, outdated production lines can be upgraded with intelligent manufacturing technology to reach industry-leading levels. This paper uses the example of a digital and intelligent transformation of the finished product packaging line in an AAC block enterprise to illustrate the application of intelligent manufacturing in the packaging line.

Background overview

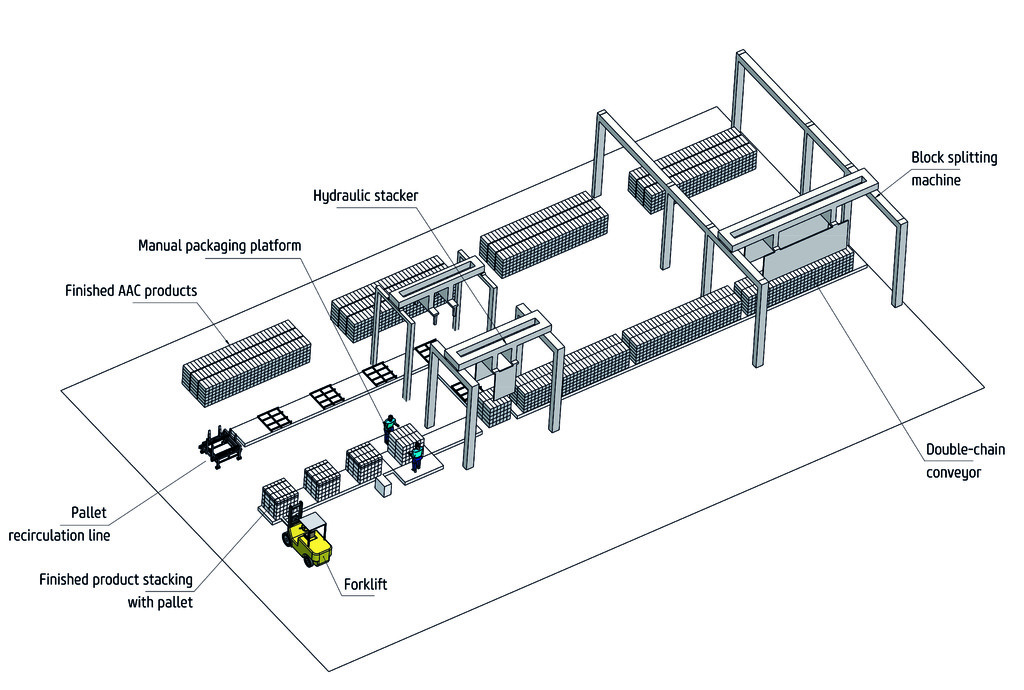

The client is a professional manufacturer of AAC blocks in western Henan, established in 2013, with an annual production capacity of 500,000 m³ of AAC blocks. The original equipment in the finished product section included a splitting machine, a double-chain conveyor, an automatic pallet feeder, a hydraulic stacking machine, a finished product conveyor, and a manual packaging platform. The layout of the production line prior to the transformation is shown in Fig. 1.

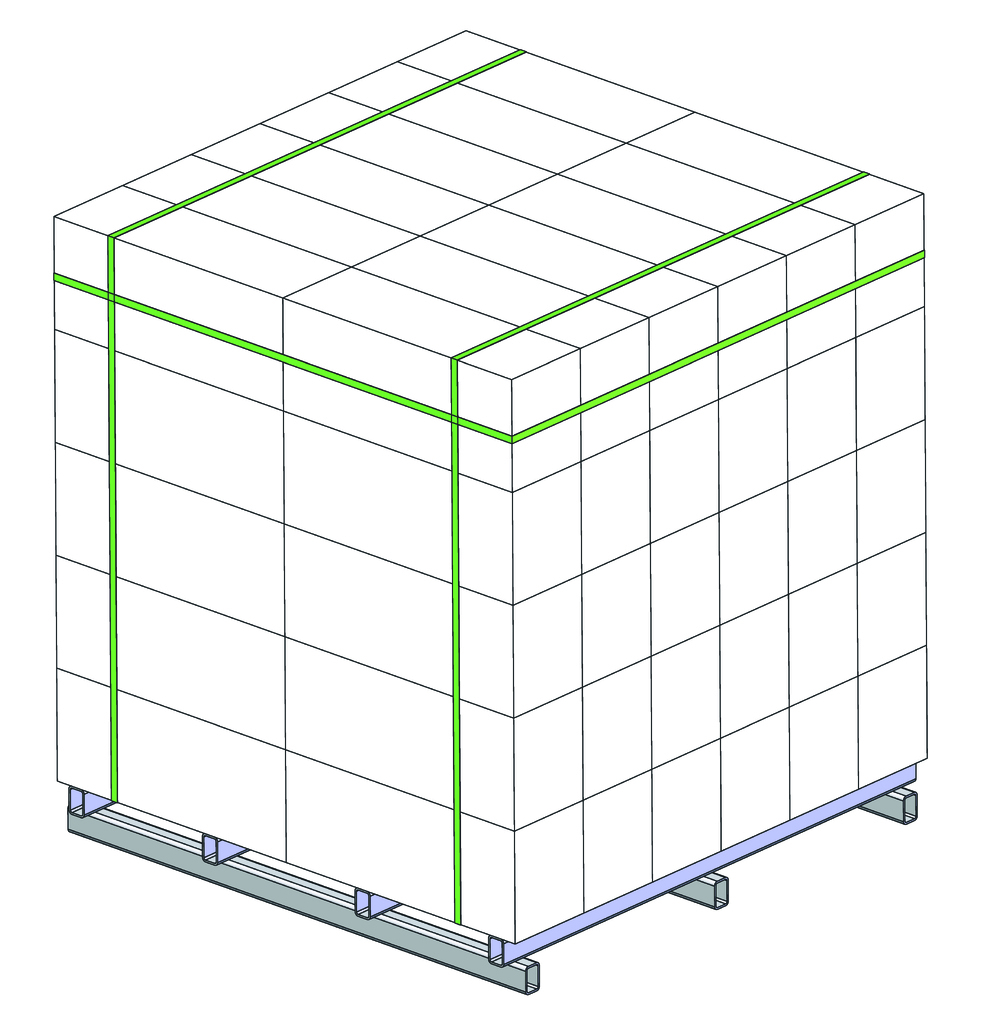

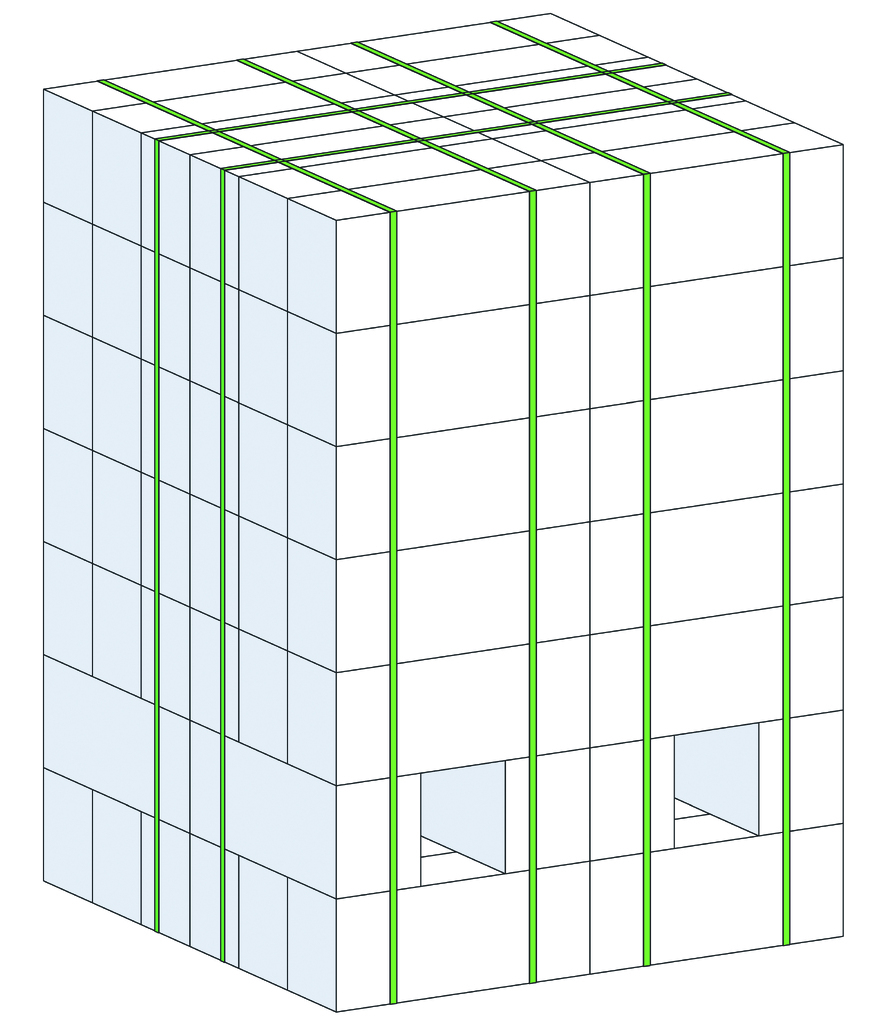

After autoclaving, each cake measures 6 m × 0.6 m × 1.2 m. The cakes are aligned and then split into 1.2 m × 1.2 m × 1.2 m blocks for packaging. For convenient handling and transportation, each finished AAC unit is equipped with a steel pallet at the bottom.

The original packaging process involved the following steps: after autoclaving, the AAC blocks were split by the splitting machine, lifted onto the double-chain conveyor, aligned under the hydraulic stacking machine, and placed on a steel pallet by the stacking machine. The blocks were then manually packaged on the manual packaging platform, transported to the finished product area, and then moved to the storage area by forklift.

As the production line was not initially equipped with automatic packaging equipment, manual packaging involved several drawbacks:

· Manual packaging is slow, causing upstream processes to frequently require manual intervention and shutdowns, leading to unstable production rhythms and low overall efficiency.

· Manual tensioning of the packaging straps relies on personal feel and experience, resulting in either damage to the blocks due to excessive tension or instability of the stacks due to insufficient tension.

· The hydraulic stacking machine could not stack upwards, limiting the height of the finished product stacks to 1.2 m, resulting in wasted transportation capacity.

· Manual positioning of the packaging straps is inconsistent, affecting product competitiveness.

· Manual packaging wastes packaging straps, increasing unnecessary costs.

· This packaging method requires steel pallets for forklift handling, leading to additional investment, long turnaround times, and the need for dedicated storage space. Pallets can also be lost or damaged during transport and handling, requiring periodic replacement and maintenance, thus incurring significant expenses.

Given these issues, the user wanted to retain the existing palletized packaging line while adding a new pallet-free automated packaging line to reduce manual operations.

Transformation plan

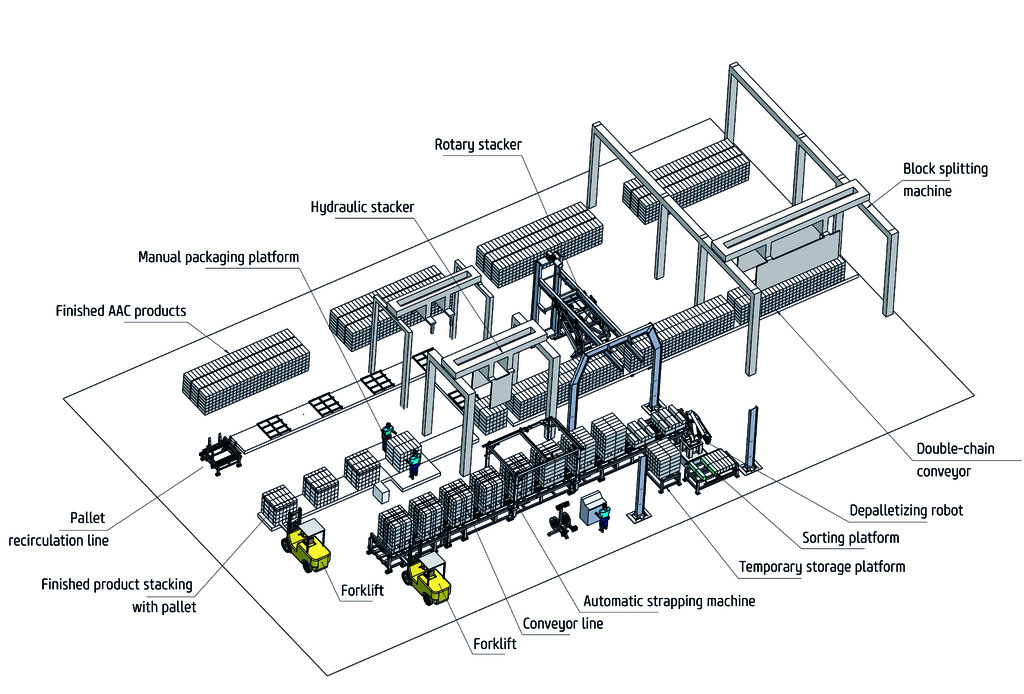

Based on the user’s requirements and site conditions, a parallel pallet-free automated packaging line was added, including an automatic stacking machine, a depalletizing robot, and an automatic strapping machine.

The new automated packaging line employs extensive intelligent manufacturing technology, utilizing various sensors and signal processors for data and signal acquisition and processing. By integrating a visual human/machine interface with digital control, deep human/machine collaboration is achieved, relieving workers from strenuous labor. The layout after the transformation is shown in Fig. 3.

Workflow of pallet-free packaging

Taking the production of 600 mm × 240 mm × 200 mm blocks as an example, the workflow is as follows:

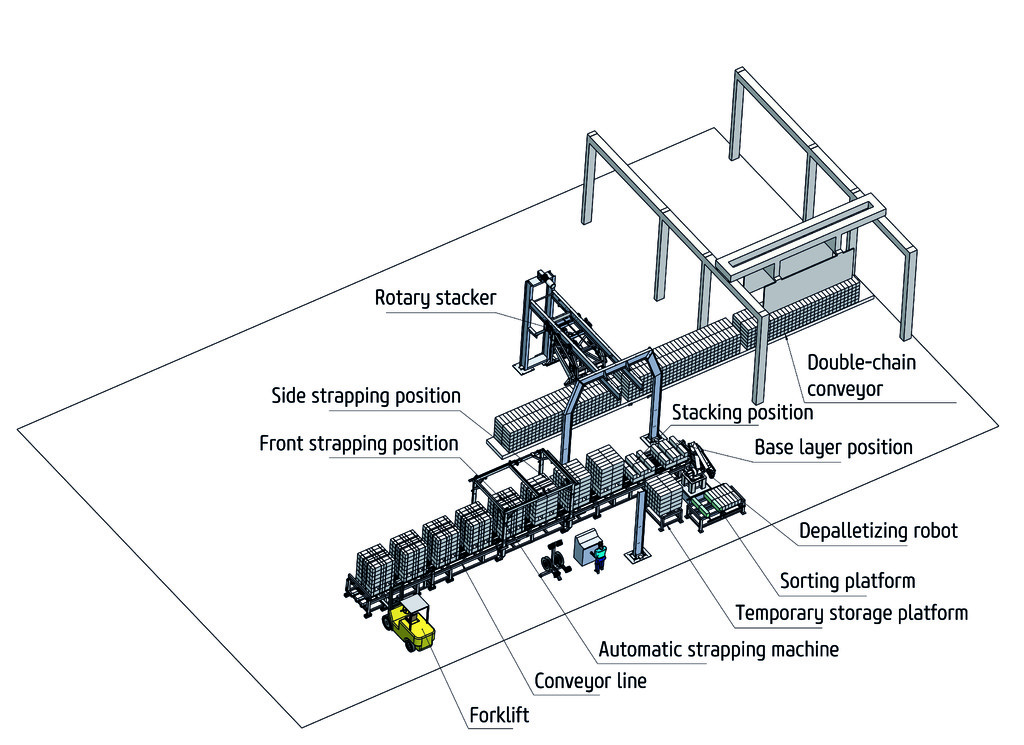

1. Sensors added to the original chain conveyor detect the arrival of the entire board of AAC blocks, triggering the rotary stacker to transport the specified blocks to the temporary storage platform and send a depalletizing instruction to the robot.

2. The depalletizing robot, based on the pre-set stacking method from the human/machine interface, sequentially removes the blocks from the temporary storage platform and places them on the packaging conveyor as the base for the pallet-free stack. During this process, the robot automatically determines whether the blocks are for the base layer or fork hole layer and places the blocks for the fork holes on the sorting platform.

3. The robot places the pallet-free base on the conveyor. When the stack reaches the stacking position, the rotary stacker places a new stack on the base, forming a taller stack. The stacking height can be adjusted according to different vehicle transport requirements by inputting parameters into the control system via the human-machine interface.

4. The stacked blocks are conveyed to the strapping position. The automatic strapping machine completes the strapping process based on digital settings for strapping force and stack parameters. The strapped blocks are then transported to the end of the conveyor for forklift transport to the finished product area.

Analysis of the advantages

Comparing the new and old finished product lines, the pallet-free automated packaging line with intelligent control offers several advantages:

· The entire system uses digital control, precise positioning, and high automation.

· Automatic equipment operation ensures stable production rhythm and higher overall output.

· The strapping force, strap length, and strapping position can be digitally adjusted, preventing block damage, ensuring stable stacks, reducing strap waste, and enhancing product appearance and competitiveness.

· Pallet-free packaging reduces various costs associated with pallets.

· Multiple stacking heights can be achieved, increasing transport capacity by approximately 20% under the same transport conditions, thus reducing transportation costs.

Conclusion

This transformation involved extensive use of intelligent manufacturing technologies, such as new sensors for data and signal acquisition and processing, digital programming for coordinated equipment operation, and visual operation interfaces. These technologies significantly improved equipment utilization and reliability, enhanced product quality and competitiveness, reduced labor and labor intensity, and lowered operational costs.

For the promotion and application of pallet-free packaging, the following aspects need attention:

1. Ensuring the quality of autoclaved products.

2. Higher requirements for logistics vehicles and construction site storage areas.

3. Safety measures for hoisting.

4. Efficiency, stability, and cost-effectiveness of the packaging machine and consumables.

5. Diversity in packaging line design to meet different user requirements.

6. Increasing the localization rate of supporting equipment to reduce the cost of technological upgrades.

Developers of pallet-free packaging technology and equipment for autoclaved aerated concrete blocks include Henan OPA Industrial Robotics Co., Ltd. and UKeyer Intelligent Equipment (Zhejiang) Co., Ltd.