Production Technology

Jiangsu Teeyer Intelligent Equipment Co., Ltd, Changzhou City, Jiangsu Province, China

Causes and prevention of defects in AAC slabs

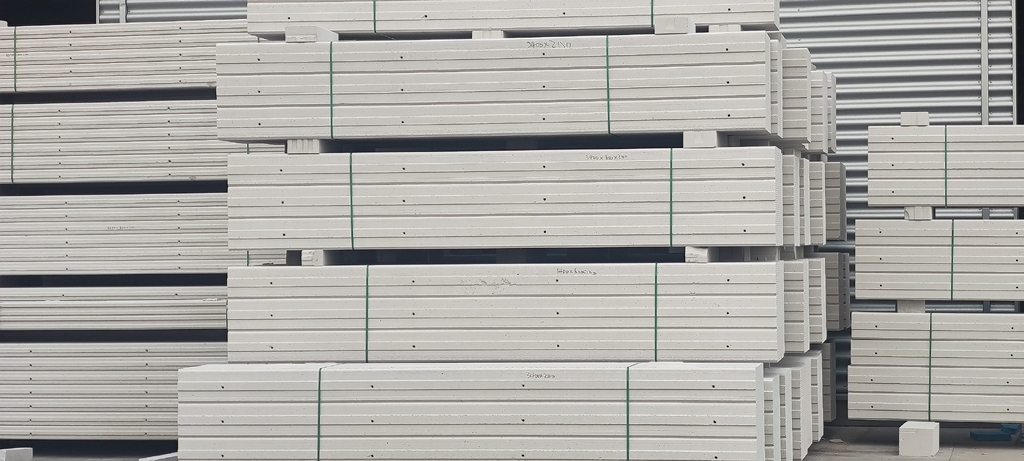

Loading...AAC slabs are construction components with structural properties and made with reinforcement to meet specific requirements. Due to the various advantages of the product, manufacturers will give priority to production expansion with AAC slab equipment or reserve the space required for installation of AAC slab equipment [1]. AAC slabs have numerous advantages including less market competition, wide range of applications, high added value to production, high construction efficiency, significantly low cost, energy saving properties, environmental protection and recycling, etc. [2].

In comparison to AAC blocks, the production of AAC slabs has stricter requirements on raw materials, process ratios and process control. Autoclaved curing is necessary for aerated concrete to obtain strength and other properties, and it is a specific method for achieving hydrothermal synthesis of products. It is not only related to the performance of the products, but also to the improvement of production efficiency and energy consumption of factories. This paper focuses on the optimal autoclave curing system for AAC slabs and presents the main equipment and operational procedures of autoclave curing. Based on field production experience, the author summarizes problems occurring in production to then provide improvements towards increased quality and production stability of AAC slab products.

Thermophysical process of autoclave curing

Heat exchange process

In the autoclave, in addition to heat exchange with the AAC material, the steam also carries out a series of heat exchanges with the kettle, the condensate, the steam car, the bottom plate, etc. The higher the heat transferring efficiency, the faster the heating of the AAC, and the shorter the time to reach a uniform temperature inside and outside the material. In the whole autoclave curing process, the heat transfer inside the AAC is mainly accomplished by the migration of condensate water and the infiltration of steam, so that the air permeability of the AAC cake has a great influence on the heat transfer inside the material. The main factor affecting the air permeability of AAC are the constituent materials used in the mix. For aerated concrete of the same material composition, the fineness of the components affects the air permeability [4]. In addition, the solids content in the raw material and the proportion of waste used in the batching process, to some degree, have an influence on the permeability of the AAC cake.

Thermal equilibrium

In the autoclave curing process, the source of heat in the kettle is generally saturated water steam (a small number of enterprises use a certain degree of superheated steam), and the heat consumption steps are as follows:

1. heating up of the AAC material and the moisture contained in it,

2. heating up of the kettle,

3. heating and steaming base plate and steaming car,

4. residual air in the heating kettle,

5. heating condensate water in the kettle,

6. the kettle body dissipates heat to the environment.

The actual steam consumption is related to the autoclave curing system adopted, the environmental temperature difference, the timeliness of condensate discharge in the kettle, the amount of steam taken out in the process of condensate discharge, the reactivity of raw materials and the thermal insulation measures of the autoclave. The hydrothermal reaction of AAC is of exothermic nature. Theoretically, when autoclave curing reaches constant temperature, the pressure and temperature of the autoclave should not decline, but in fact, due to the heat dissipation of the autoclave kettle body and the leakage from pipes and valves, it is difficult to keep up the pressure and it is often necessary to properly compensate the pressure in the initial stages of constant temperature.

Thermal expansion and contraction of products

During the autoclave curing process, expansion and contraction of the AAC cake volume will occur due to the temperature changes. The heat deformation of the product is not uniform and in the heating stage, the surface temperature of the product rises first, so the deformation occurs earlier compared to the inside of the product. In contrast, when cooling, the internal temperature of the product decreases at a lower rate than the surface of the product. The uneven temperature distribution results in uneven thermal deformations. If a product is subjected to sharp temperature changes during autoclave curing, it may be damaged because of excessive temperature stress.

In the AAC cake, in addition to solid substances, there is a lot of liquid and gas. The internal pressure of the mass is dependent on whether the water is in a gaseous or liquid stage, which is mainly related to expansion and contraction of steam and air. If the AAC cake has sufficient strength, this does not pose a threat to the product, because the pores in the product are not completely closed, and hence the water and air mixture can move through the connected capillary holes or be expelled. The internal pressure differential is thus alleviated. A destructive effect on the product only occurs when the strength of the product is too low, or if the internal pressure difference increases too fast [5].

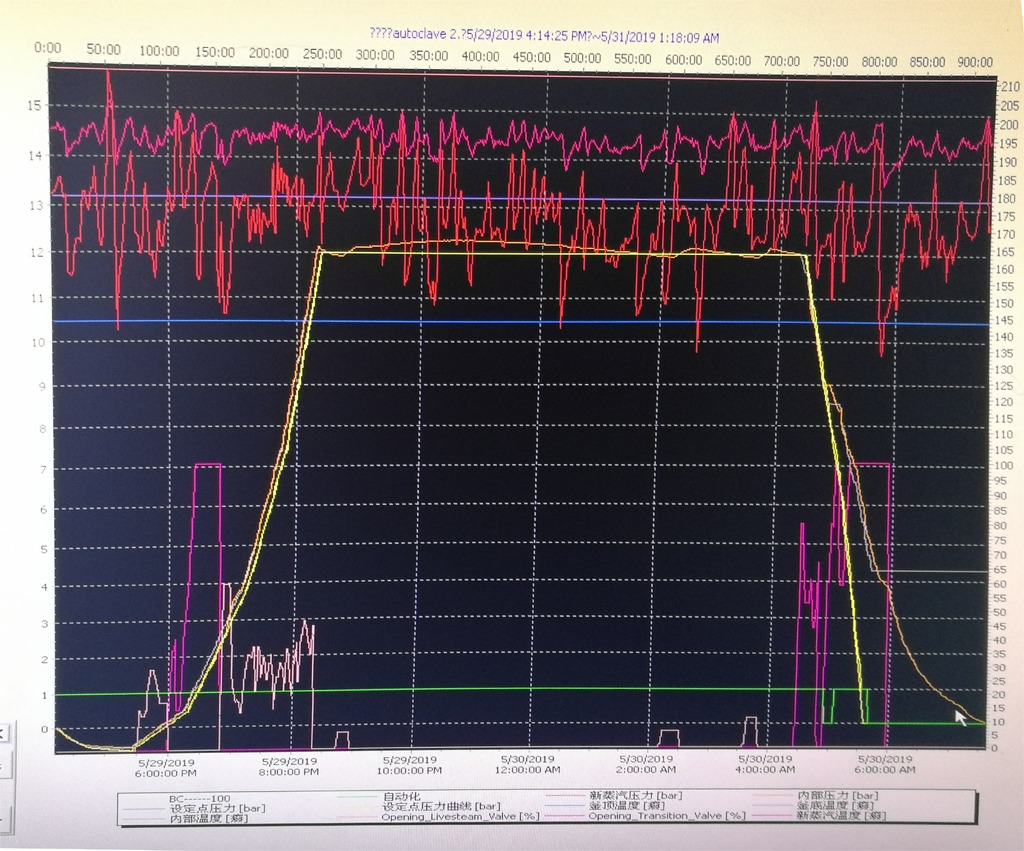

Autoclave curing processes for AAC slabs

Autoclaved curing is an important stage in the formation of hydration products inside the product and therefore directly related to the quality of the final product. The curing process for AAC slabs is more complicated than that for AAC blocks, and non-standard curing operations can easily cause defects. The two main indexes in the steaming stage are the pressure and the temperature of the autoclave kettle [6].

Vacuum stage

When there is a certain amount of air mixed into the steam, the heat exchange efficiency will be greatly affected due to the poor heat conduction capacity of the air. In the autoclave curing process, after first vacuuming, most of the air in the kettle is discharged, and the heat exchange between the steam and the cake is improved. At the same time, due to the negative pressure state formed after the partial gas discharge in the kettle and the product pores, the steam not only condenses and permeates to the surface of the body, but it is also absorbed by the cake layer, which is due to the action of negative pressure inside the material. The AAC material is conducive to heat transfer towards its center, so that the temperature of the whole body rises rapidly, which shortens the heating time. The stress inside the AAC is reduced when the temperature rises.

Heating stage

The precured AAC cake is heated to the highest temperature for steaming. The heating stage has both positive and negative effects on the strength of the product. On the one hand, the steam condenses on the surface of the product, continuously penetrates into the product through the fine hole, fuses with the original water in the material, dissolves calcium hydroxide and other soluble substances, forms a new structure, and increases the strength. On the other hand, physical phenomena such as volume expansion, water migration and stresses due to internal and external temperature difference occur during the heating process, which may damage the solid structure. Therefore, to achieve a balance between the positive and negative effects so that the strength of the material can resist the structural damage caused by temperature rise, the heating rate should not be too fast.

Constant temperature

The AAC cake in the autoclave remains at a constant maximum temperature for a period of time, which is the main stage for the hardening reaction and strength growth of AAC products. Constant temperature and time directly affect the strength and durability of the product. The time of constant temperature should not be excessively extended while meeting the strength and durability requirement of the product.

Cooling period

During the cooling period, the steam supply stops, and the temperature decreases until the product can be removed from the autoclave. If the temperature decreases too fast, the liquid water will boil in the high-temperature and low-pressure environment, forming intense evaporation, resulting in strong water flow and air flow, which may cause cracks in the product.

Common defects of AAC slabs after autoclaving

Adhesion

A typical adhesion failure is shown in Figure 3. Reducing the water-solid ratio and appropriately increasing the cutting hardness of the product can effectively solve the issue of poor adhesion [7].

Chamfering and cracking

The cracking of AAC slabs is generally controlled by two aspects: production raw materials and aeration system [8]. Figure 4 shows typical signs of cracking.

Watermarks

The main factors leading to watermark include poor reactivity of raw materials, large water to material ratios, poor drainage, etc. [9].

Conclusion and prevention measures

The autoclave curing system controls curing temperature and time so that the AAC cake can react fully and effectively. In order to obtain the required strength in a short period of time, and to avoid possible damage as much as possible, the following must be considered:

1) Good steam supply (saturated steam or slightly superheated steam at appropriate pressure). For maximum effective heat exchange, it is required to try to avoid carrying liquid water in the steam or using highly superheated steam.

2) Create a good heat exchange environment. In addition to good autoclave tightness, it is necessary to discharge the air remaining in the free space of the autoclave and ensure smooth condensate drainage.

3) Appropriate heating rate. The rate at which the cake is heated depends on the degree to which the product is subjected to internal stress. When the strength of the AAC cake in the kettle is high and the temperature is high, and the ability to resist the internal stress is strong, then the temperature can be increased at higher rates.

4) Sufficiently high temperature and constant temperature time. The inside of the AAC cake can fully complete the hydration reaction in the curing stage and generate the necessary hydration products.

5) Appropriate cooling speed. In the process of depressurization, in addition to the contraction of the product itself, the volume expansion due to vaporization of liquid water inside the product can also damage the product. An appropriate exhaust speed is maintained to ensure that the internal stresses during the cooling process will not cause damage to the product.

References

(original literature in Chinese language)

[1] PENG Junzhi, PENG Xiaoqin. Research progress on the structure and properties of aerated concrete[J]. Materials Herald, 2011, (1):89-92

[2] LIU Yanjun, CHEN Botian, CHEN Yu. Review on the development of aerated concrete at home and abroad[J].2013,41(3),30 -36

[3] State Administration of Market Supervision and Administration, National Standardization Administration of China. GB157-2020 Autoclaved Aerated Concrete Board [S], Beijing: China Standard Press, 2020

[4] Chen Youzhi, Li Fangxian, Fu Tianquan, et al. Experimental study on silica-containing stone chip-lime aerated concrete[J]. Journal of Wuhan University of Technology, 2005,27(3):27.

[5] GONG Wei, DING Xiangqun, JI Yanliang, et al. Effect of autoclave system on the strength of iron tailings aerated concrete[J]. Silicate Bulletin, 2013, 33(1):43-48.

[6] FANG Ye. Technical transformation of autoclaved aerated concrete block production line[J]. Wall material innovation and building energy conservation, 2014, (2):57-59.

[7] LIU Jiadi. Research on the production of aerated concrete blocks from stone processing powder waste[J]. Nonmetallic Mining,2014, 37(4):50-53.

[8] ZHANG Ji-Neng, GU Tong-Zeng. Production process of aerated concrete[M]. Wuhan University of Technology Press. 1992.6.

[9] Yu J, Li Z, Wang CH. Analysis of quality problems of aerated concrete block walls and proposals for prevention and control measures[J]. Building blocks and block construction, 2014, (2):50-54.