Production Technology

UKeyer Intelligent Equipment (Zhejiang) Co., Ltd, Changxing County, Huzhou, China

Efficient and eco-friendly packing system for AAC blocks

Loading...UKeyer Intelligent Equipment Co., Ltd. (hereinafter referred to as "UKeyer") is a subsidiary of the UBlok Group and has relied on the technological advances of the group's products for more than 20 years. It specializes in research and development of AAC equipment, AAC factory engineering, equipment manufacturing, technological transformation and system upgrading, adhering to the business philosophy of "originating from practice, serving the industry", and providing technology, equipment, and services to the entire industry.

Most of UKeyer’s technology originates from actual technology requirements, as well as experience with processes and equipment from 12 AAC production bases with single and double production lines (including panel production lines) of the UBlok Group, which had an output of 5.1 million cubic meters in 2023. In recent years, it has independently developed solutions such as the "Three 30s" one-stop AAC production line solution (i.e., equal design capacity combined with 30% reduction in land area, 30% reduction in comprehensive investment and 30% reduction in operating costs), as well as AAC factory technological upgrade solutions, which include the AAC product packing and logistics system, the AAC steam energy-saving system, the AAC product waste recycling system, the AAC factory intelligent security system, the AAC production line transformation and upgrading system, and more.

This article discusses technical aspects of the widely used efficient and eco-friendly packing and logistics system for AAC products in the Chinese market.

Background

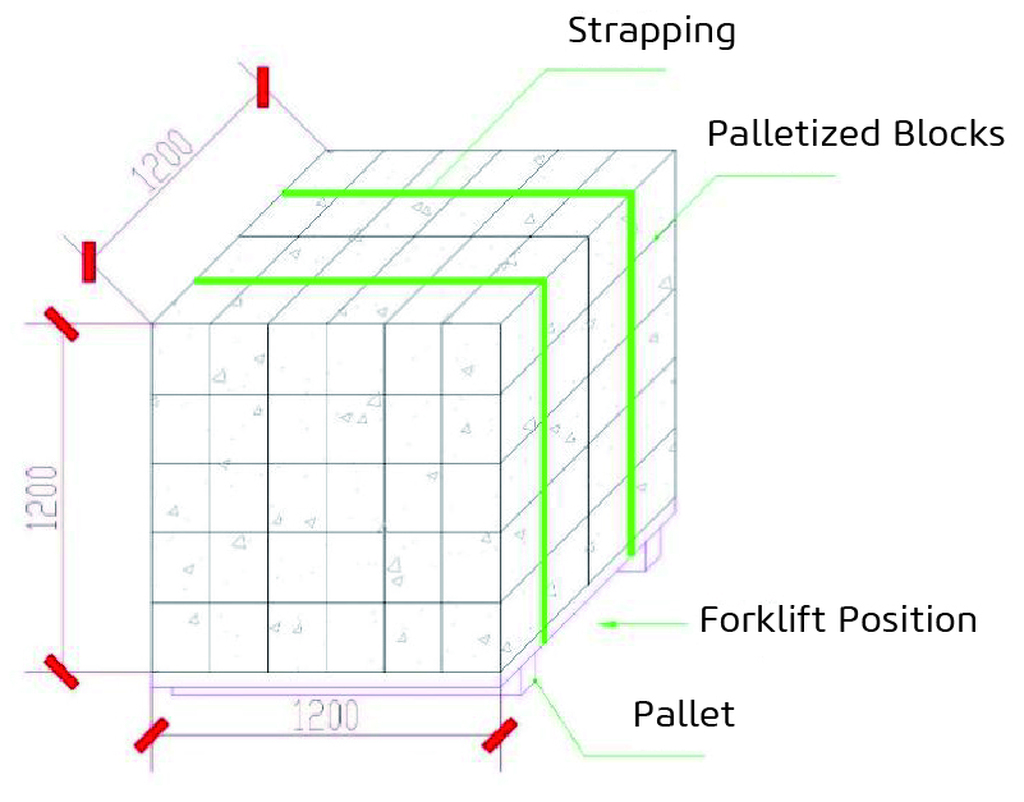

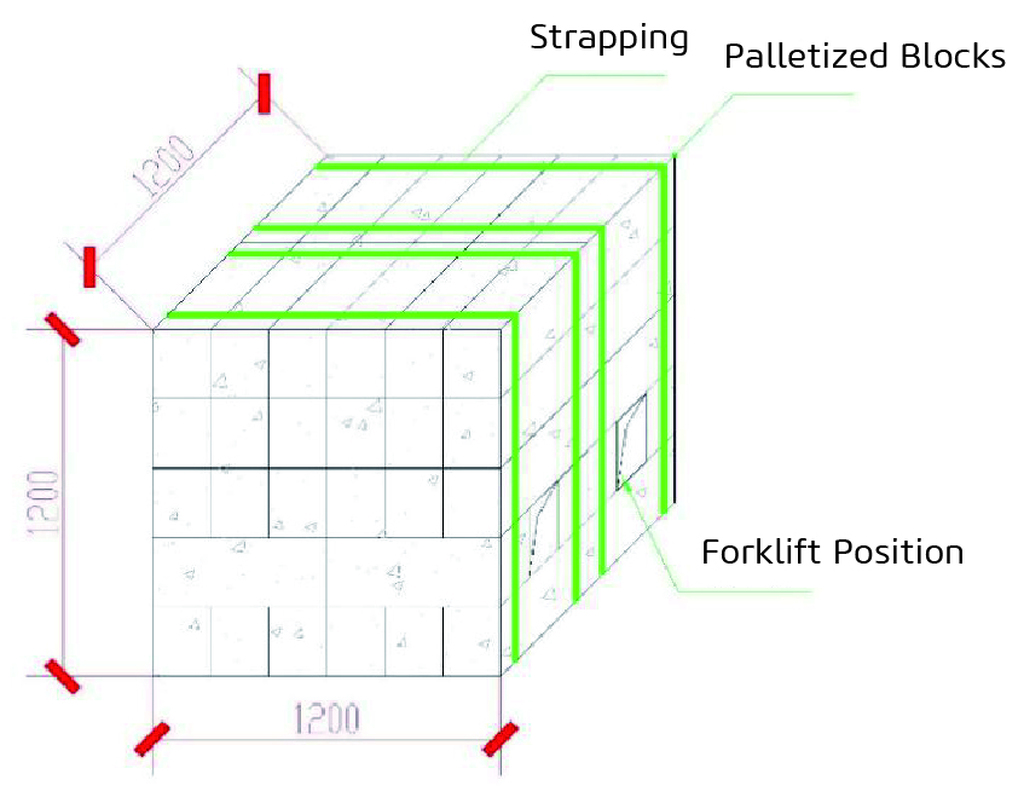

In the traditional AAC industry in China, the standard size for packaged blocks is generally a whole stack of 1200 mm × 1200 mm × 1200 mm. In the block production line, pallets need to be placed on the conveyor and then the finished blocks are placed on the pallets for packing (Fig. 1, 2).

The main considerations for the traditional AAC block packing system can be summarized as follows:

1. Pallets accumulate on construction sites, requiring long turnover cycles and a large stock, resulting in high production investment costs (Fig. 1).

2. Pallets are inevitably lost or damaged during transportation and handling, requiring periodic replacement and maintenance, resulting in high production and operation costs.

3. The higher the production capacity, the higher the number of pallets required and the larger the area required for pallet stacking.

4. Transport logistics require deposits on pallets, which are disadvantageous for product sales. Claims for lost pallets affect the customer experience and increase the risk of customer loss.

5. Repeatedly used pallets may deform, leading to product damage during transportation.

Currently, there is a pallet-less packing method for blocks on the market. Intelligent robots are used to layer the whole stack of blocks, forming forklift holes through mechanical operations when stacking the second layer. After the whole batch of blocks is stacked, it is provided with packing (Fig. 3).

Through research, it was found that the main disadvantages of the traditional pallet-less packing process for blocks are as follows:

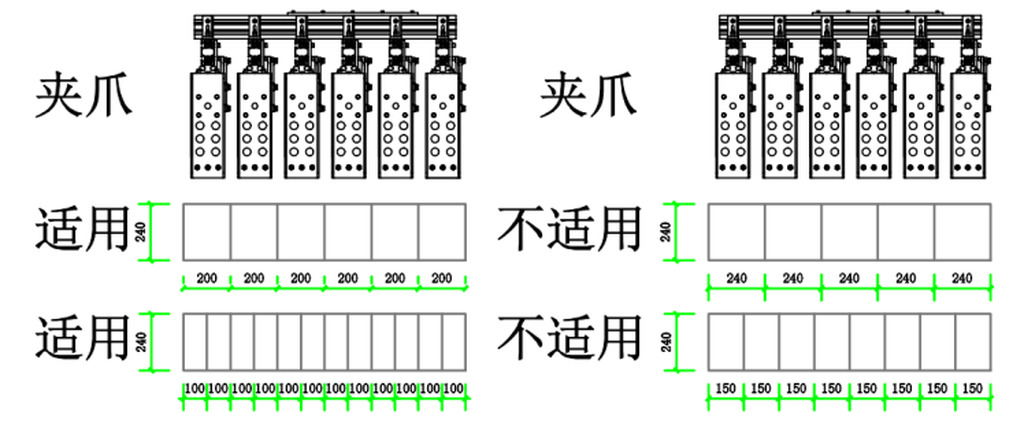

· Robots need to stack layer by layer. For example, the stacking of standard blocks of 600 mm × 240 mm × 200 mm requires five iterations of the stacking process (Fig. 4) to provide packing to the whole batch, which is inefficient and consumes a lot of energy.

· The gripper of such robots has certain requirements for block specifications and cannot meet the pallet-less packing of special block models. It cannot adapt to the production mode of two sizes of blocks with one mold (Fig. 5), which has certain limitations.

· The robots need to extract 4 blocks from the second layer and rotate them by 90°. The extracted blocks need to be manually sorted and processed, resulting in high labor costs.

· The number of packing belts is 4 (Fig. 3), which cannot firmly secure the blocks. If the belts are too tight, they will damage the bottom layer of blocks; if they are too loose, they will cause the forklift holes to deviate, and the bottom blocks will become loose.

· Specific chain conveyors are required, which cannot be combined with the traditional pallet packing process.

· The loading of finished products is generally done on 28 stacks, which results in low loading efficiency and a large workload for forklifts.

· The level of intelligence is relatively underdeveloped, and there is a low degree of automation.

The solution

Through investigation and research on the production of AAC blocks, it is not difficult to see that the main technical problems that need to be solved relate to improving the efficiency of the block production line, adapting to various production modes connected to multiple specifications and models, and simultaneously meeting the requirements of both pallet packing and pallet-less packing in one system. This pallet-less packing system has an overall independence. Through practice and demonstration, the independently developed version 1.0 AAC block pallet-less packing system has been implemented in UBlok (Hancheng) New Building Materials Co., Ltd. The layout of the production line is illustrated in Figure 6.

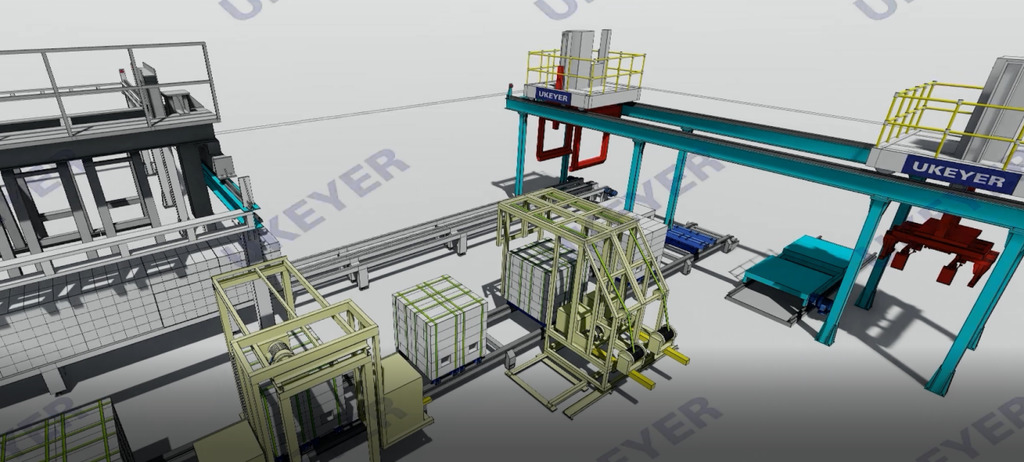

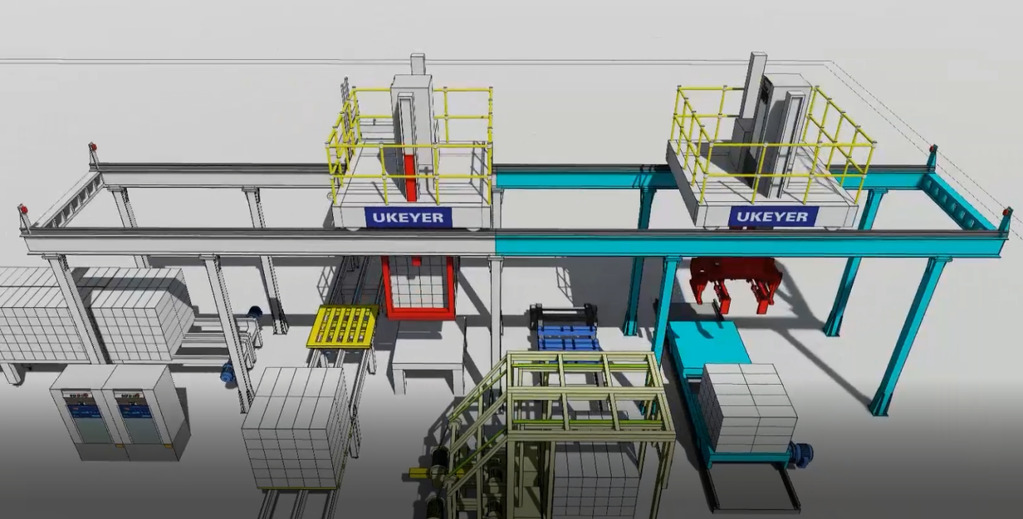

Through the application and research of the version 1.0 pallet-less packing system for AAC blocks, UKeyer found certain drawbacks in using intelligent robots to control the pallet-less automatic packing line. There is still a need to develop new products to replace the stacking by intelligent robots and meet higher capacity requirements. Therefore, this pallet-less packing system for AAC blocks has optimization and upgrade potential. Through internal research and design, the version 2.0 pallet-less packing system for AAC blocks has been implemented by UBlok (Lixin) New Building Materials Co., Ltd. The layout of the production line is illustrated in Figure 7. The implementation is shown in Figures 8 and 9.

Version 2.0 pallet-less packing system for AAC blocks

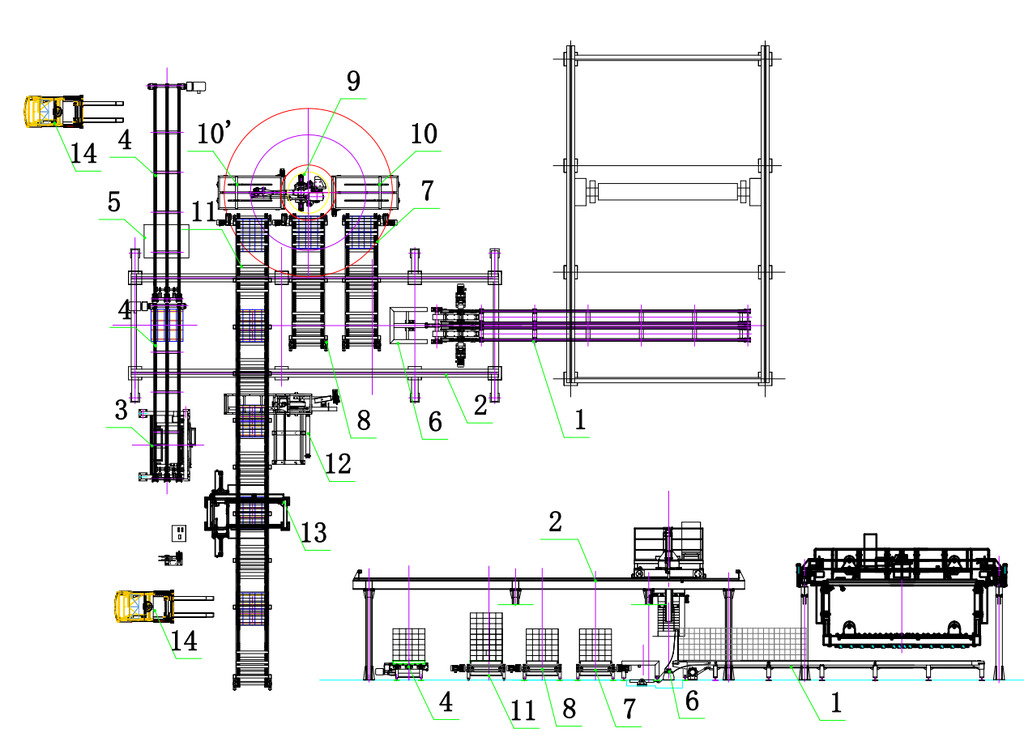

The Version 2.0 pallet-less packing system (Fig. 7) includes the following components:

1. Block gripper: mainly responsible for transporting whole block molds.

2. Finished product chain conveyor: mainly responsible for transporting whole block molds.

3. Block body transverse shift machine: mainly responsible for transporting whole stacks of block molds.

4. Finished product packing conveyor: chain conveyor with tray tube, mainly responsible for conveying whole stacks of blocks.

5. Intelligent sorting machine: mainly responsible for rotating blocks and picking out forklift holes.

6. Mobile cart: mainly responsible for storing blocks picked out by the intelligent sorting machine and stacking them into whole stacks.

7. Mobile sword-type strapping machine 1: mainly responsible for strapping 4 horizontal strapping belts along the forklift holes.

8. Mobile sword-type strapping machine 2: mainly responsible for strapping 4 vertical strapping belts perpendicular to the forklift holes.

9. Forklift.

10. Finished product chain conveyor: mainly responsible for transporting whole block molds.

11. Horizontal strapping machine: mainly responsible for horizontal strapping of whole stacks of blocks when pallet packing is used.

12. Finished product chain conveyor: mainly responsible for transporting whole stacks of block molds and pallets when pallet packing is used.

Innovation and advantages

The following advantages are provided by the version 2.0 pallet-less packing system:

· It meets both pallet packing and pallet-less packing methods, reducing the need for pallets and minimizing investment costs.

· It reduces the steps required for the stacking process, improves the efficiency of stacking and saves time and energy costs.

· The intelligent sorting machine is used instead of robots to extract blocks to form forklift holes and stack them, which improves the efficiency of stacking, saves installation space and reduces investment costs.

· It can perform pallet-less packing when there are two different sizes of whole block molds.

· The use of mobile carts to stack extracted blocks realizes block reuse and reduces labor.

· The pallet-less packing system uses 8 strapping belts to pack whole stacks of blocks, making the packing structure more stable, reducing wear and tear on the blocks during packing and transportation and improving the pass rate.

· Products packed with this process are more favored by the market, with wider sales channels.

Further development

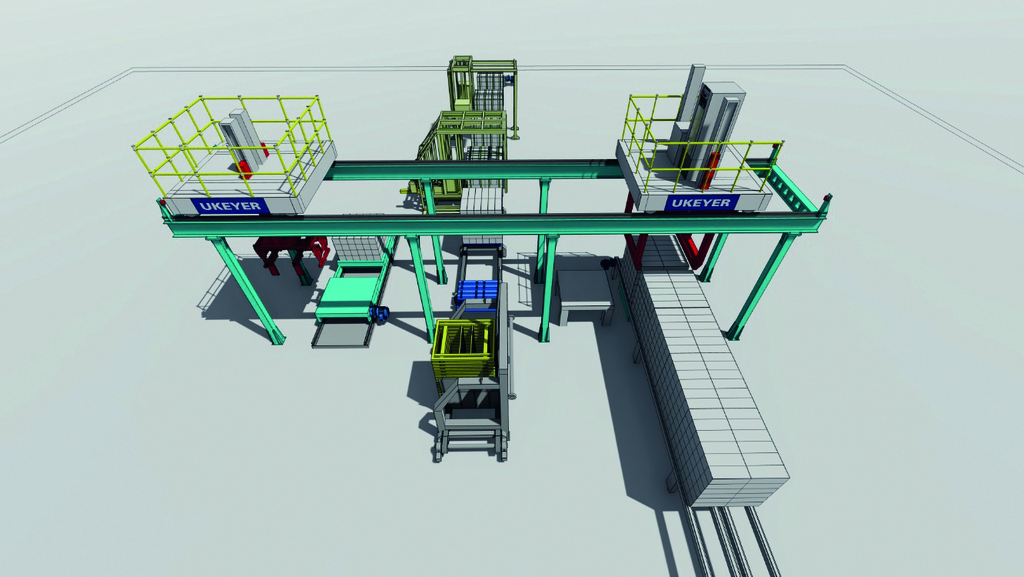

After commissioning and use of the version 2.0 pallet-less packing system for AAC blocks, through production and practical experience accumulation, UKeyer has developed the version 3.0 pallet-less packing system for AAC blocks (Fig. 10 - 13) and further improved and optimized the pallet-less packing system to better meet the needs of production.

The system offers the following features:

· The latest intelligent sorting machine adopts more advanced bidirectional closing clamps, which improve the packing efficiency and can be used with more product models.

· By adding a mobile lifting device, not only can the 20 mm gap between the two block molds be eliminated, but also the distance between the front and rear blocks can be widened.

· A finished product and blank chain conveyor was developed, which ensures that the block molds are not damaged during transportation.

· The finished product packing conveyor uses 6 square tray tubes at each station, making the blocks more stable during stacking. Each square tray tube adopts a 6-hole design, which provides more packing forms and ensures more secure packing.

· The crane walking mechanism adopts servo motor control, with faster walking speed and more precise positioning.

Through research on multiple pallet-less transformation projects, UKeyer’s R&D team found that a single pallet-less layout cannot adapt to the changing site space and production modes, which makes it difficult to meet the differentiated needs of customers. The pallet-less packing system must provide versatility to adapt to different layouts and characteristics. The system can be mainly divided into the following categories according to different layout methods and their characteristics:

1. "I-shaped" pallet-less packing system (Fig. 14): With a fast production pace, the daily output can reach 1000 m³, meeting the packing requirements for blocks with a height of 1.2 m.

2. "Z/U-shaped" pallet-less packing system (Fig. 15): With a faster production pace, the daily output can reach 1200 m³, meeting the packing requirements for blocks with a height of 1.2 m.

3. "L-shaped" pallet-less packing system (Fig. 16): With the fastest production pace, the daily output can reach 1600 m³, meeting the packing requirements for blocks with a height of 1.2 - 1.8 m.

4. "Splicing" type pallet-less packing system (Fig. 17): The production pace is related to the original equipment, meeting the packing requirements for blocks with a height of 1.2 - 1.8 m.

5. "In-line" pallet-less packing system (Fig. 18): It can meet both pallet packing and pallet-less packing on a single conveyor line, meeting the packing requirements for blocks with a height of 1.2 - 1.8 m, significantly reducing investment costs.

After three years of continuous research and development of the pallet-less packing system for AAC blocks, UKeyer has equipped the system with characteristics such as overall independence, optimization potential, upgradeability and versatility. More AAC factories have been revitalized with the transformation of efficient and low-carbon packing systems, with the following advantages:

· The more efficient pallet-less packing system has increased the product's offline speed, thereby improving production efficiency.

· With lower production and operation costs compared to pallet packing, the pallet-less packing system can bring more profits to enterprises. According to calculations based on actual usage in Chinese factories, a production line with an annual output of 400,000 cubic meters can avoid pallet usage fees of around 1 million RMB (approx. 125,000 €) per year when switching to pallet-less production. Considering an input of 40,000 pallets per factory, using iron pallets as an example, the investment in pallets would require 6 million RMB (approx. 750,000 €). Using the pallet-less system, a significant amount of pallet investment costs are saved.

· Pallet-less packing for blocks is a market trend, beneficial for the circulation of AAC block products in the building materials industry, increasing the market share of AAC blocks in the building materials market, and promoting the expansion and development of the AAC industry.

· Reducing pallet inputs is also a way to reduce carbon emissions. Each cubic meter of tree growth accumulates approximately 1.83 tons of carbon dioxide. The carbon emissions from producing one ton of crude steel are approximately 1.7 tons.

By systematizing production modes, the production system can be better optimized, such as with AAC factory intelligent security systems, AAC production line transformation and upgrading systems, AAC steam energy-saving systems, AAC product waste recycling systems, etc. The use of these new technologies and processes greatly enhances the core competitiveness of enterprises, reduces operating costs and increases the competitiveness of AAC block products in the market, enabling the AAC industry to develop in a healthy and sustainable manner.

UKeyer’s current direction of pallet-less packing system development mainly focuses on the following aspects:

· How to adapt pallet-less packing systems to more types of product packing requirements.

· The application of intelligent warehousing in pallet-less packing for AAC blocks.

· How to adapt the logistics of transportation and stacking yards to pallet-less packing for blocks.

· How to protect the edges and corners of blocks during pallet-less packing.

· Improving the efficiency of supporting equipment to meet the growing production demand.

· Reducing the investment cost of technological upgrades and enhancing the competitiveness of pallet-less packing systems.