Production Technology

UKeyer Intelligent Equipment (Zhejiang) Co., Ltd, Changxing County, Huzhou, China

Energy-saving technologies and practices in the thermal system of AAC plants

Loading...With the increasingly stringent global requirements for environmental protection, energy conservation and emission reduction, the AAC industry is facing enormous challenges. This paper aims to propose effective energy-saving measures and related technical solutions based on an analysis of the current operating conditions of the steam-driven thermal systems in AAC factories. These measures are intended to reduce production costs, improve product quality and promote the industry’s development towards low carbon manufacturing technologies.

Industry status quo and energy consumption analysis

Energy consumption

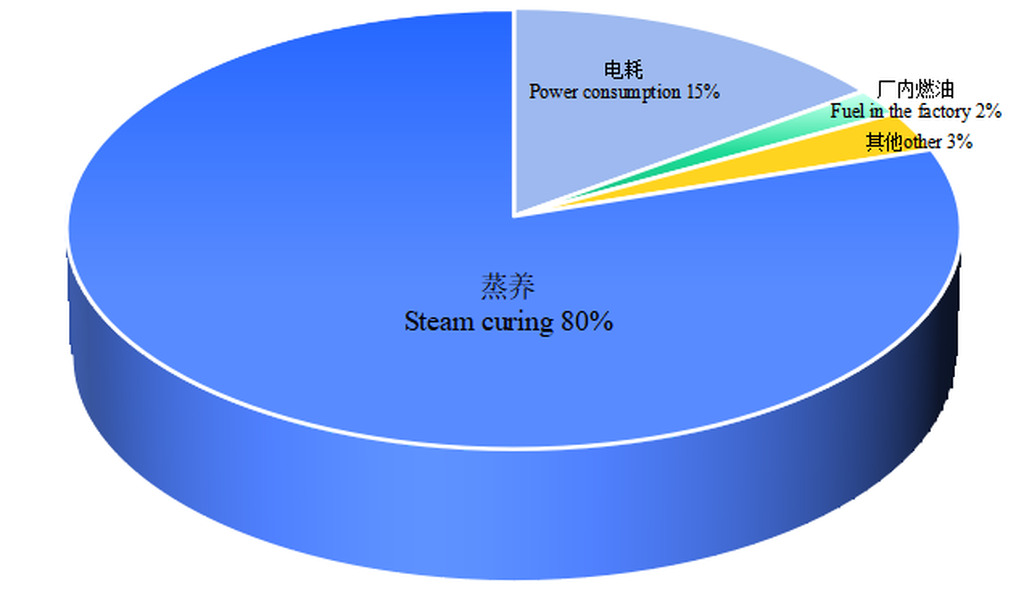

Energy consumption in AAC production can be related to the following aspects:

- Steam curing (autoclaving): 80%

- Electricity consumption: 15%

- On-site fuel and oil consumption: 2%

- Others: 3%

Steam sources

Steam sources include self-supplied steam from internal boilers (70%), with fuels including coal, natural gas and biomass fuels, as well as steam supplied externally by thermal power plants (30%).

Steam consumption

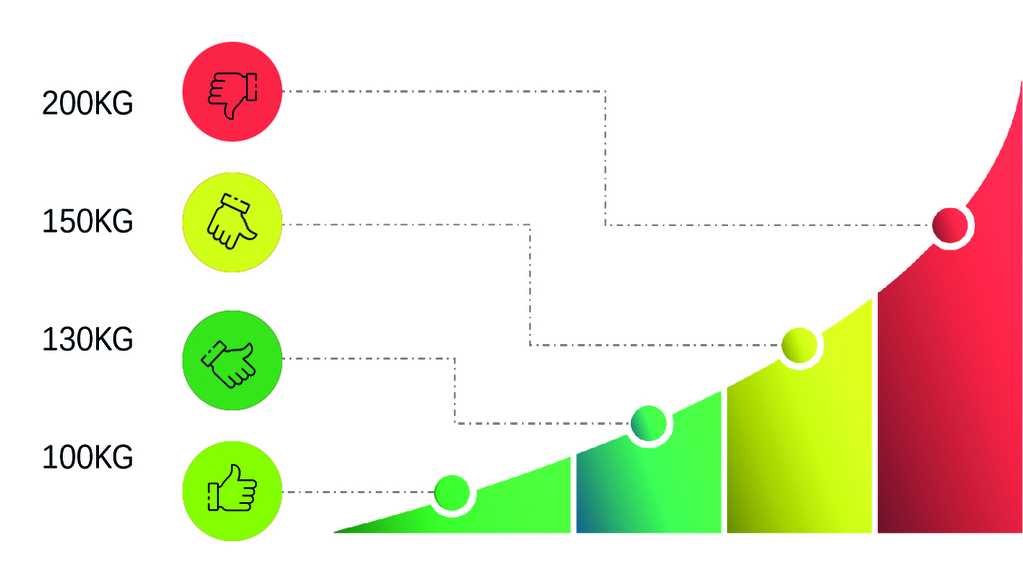

According to the research, the industry's steam unit consumption can be divided into four levels:

· Around 100 kg/m³: The steam system is reasonably well designed, with fully automatic or semi - automatic gas distribution, advanced steam traps, good thermal insulation performance, full steam inversion, and exhaust pressure below 0.2Mpa.

· Around 130 kg/m³ The system is equipped with automatic steam traps, waste heat recovery, etc., and the exhaust pressure is around 0.3Mpa.

· Around 150 kg/m³: The system provides partial steam inversion and common steam traps. Fresh steam is used for the pre-curing, drying and pouring processes.

· Around 200 kg/m³: The system does not provide any steam inversion, has poor thermal insulation, and is characterized by serious leakage of steam traps. The steam replenishment results in frequent pressure reductions when operating at constant temperatures, creating unreasonable steam curing cycles.

Problems associated with steam application

The main problems associated with improper steam applications include, i) product quality issues, such as cracking, uncooked cores, watermarks, sticking, and colour differences in autoclaved products, ii) low turnover rates of the autoclaves and low production efficiency due to high and unstable steam unit consumption, frequent pressure replenishment, limited steam inversion times and low waste heat utilization rates, iii) environmental impacts related to unnecessary discharge of exhaust steam, high temperature in the workshop, poor working environments in the factory area and the workshop, bad odour from condensate water, and severe corrosion of the autoclave body and insulation elements, and iv) high equipment failure rates due to valve damage, blockage and water hammer.

The causes for these problems are related to i) system design flaws associated with manual control of the heating and cooling curves and the inability to accurately control the flow curve, resulting in cracking during steam curing, as well as incorrect pipeline design, the selection of the wrong valves, and unreasonable steam metering, ii) insulation defects related to unreasonable insulation design, which is associated with improper insulation thickness, improper selection of materials and inefficient construction layouts, iii) poor steam quality due to unstable pressure and temperature, excessive non-condensable gas content and steam impurities, and iv) wrong perceptions about steam application and energy conservation, which relates to a lack of emphasis on energy use, uninformed implementation of waste heat recovery systems, unreasonable energy management and dispatching systems, as well as a lack of systematic control of the front-to-end processes.

Table 1: Losses and problems caused by unreasonable steam applications (the unit price of steam varies due to regional differences in energy prices. However, the quantity of steam loss provided can be used as a reference).

Statistics on economic losses and carbon emissions caused by unreasonable steam utilization | ||||||

Quality loss | Energy consumption loss | Costs(USD) | Average price per cubic meter(USD) | Steam flow rate(t) | Remark | |

Annual output | 200,000 m³ | Autoclave tail gas | 600,000 | 30 | 20,000 | The steam is not reused for a second time |

Defect rate | 5% | Steam trap leakage | 78,000 | 30 | 2,600 | According to ten steam trap points |

Economic loss | 300 | Poor thermal insulation | 63,000 | 30 | 2,100 | Six autoclaves |

Total economic losses | USD 741,000 | |||||

Increase in carbon emissions | 20,800 t | |||||

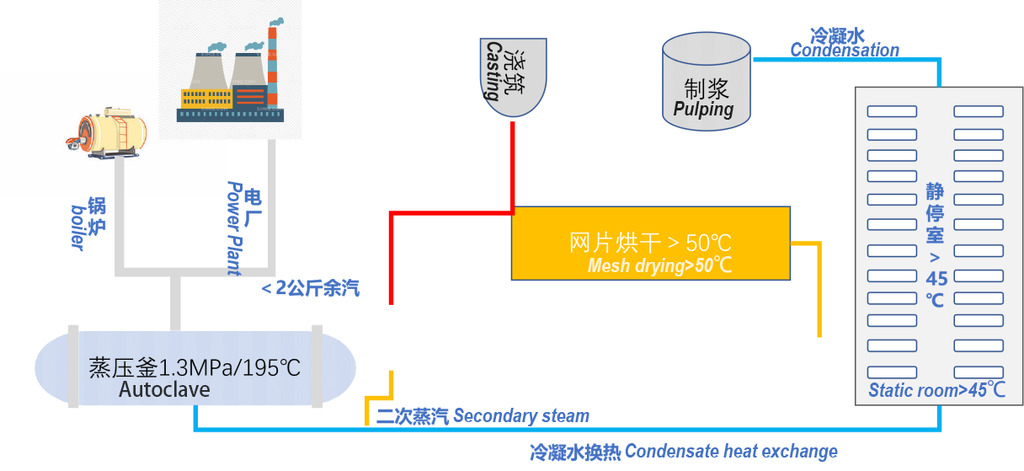

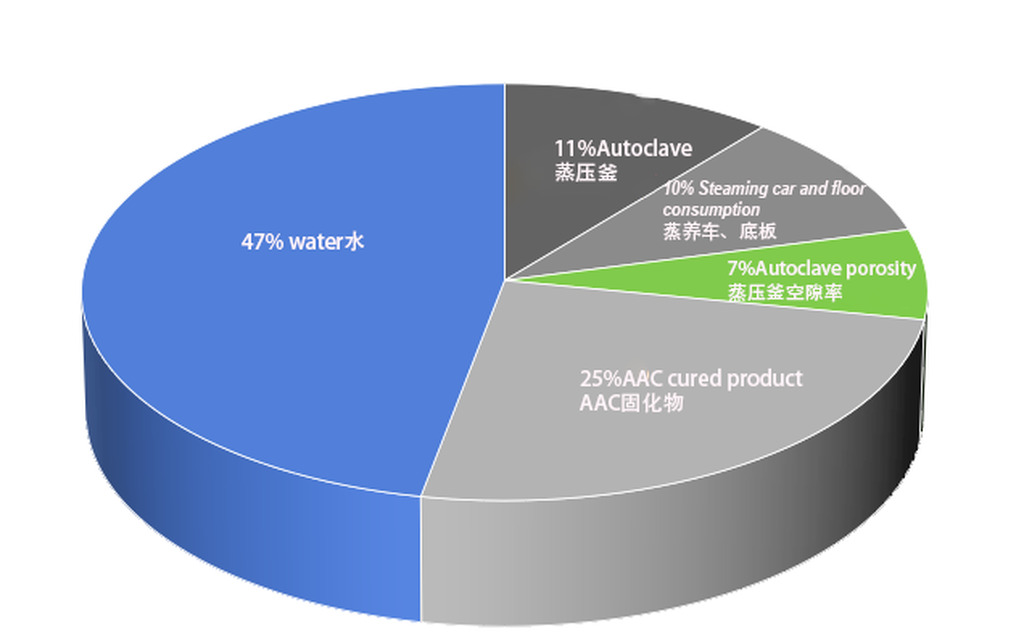

Distribution of steam energy consumption in AAC plants

The steam consumed by the moisture content in AAC accounts for 47%, while the steam consumed by the solids in AAC accounts for 25%. Several factors related to autoclaves also influence steam consumption, accounting for a total of 11%. In addition, steam consumed by the bottom plates of the autoclave curing cars accounts for 10% and steam consumed by the void fraction inside the autoclave accounts for 7%.

Based on the steam consumption in the production process, one can understand the heat energy requirements of different areas of the production line and the proportion of steam consumption in each link of the autoclave curing process. This enables a more purposeful utilization of heat energy as well as an improvement of the production processes, the equipment, and the facilities overall. As a result, steam energy consumption can be reduced and losses in production quantity and quality caused by the irrational utilization of steam can be minimized.

Approaches and practices of steam utilization and energy conservation

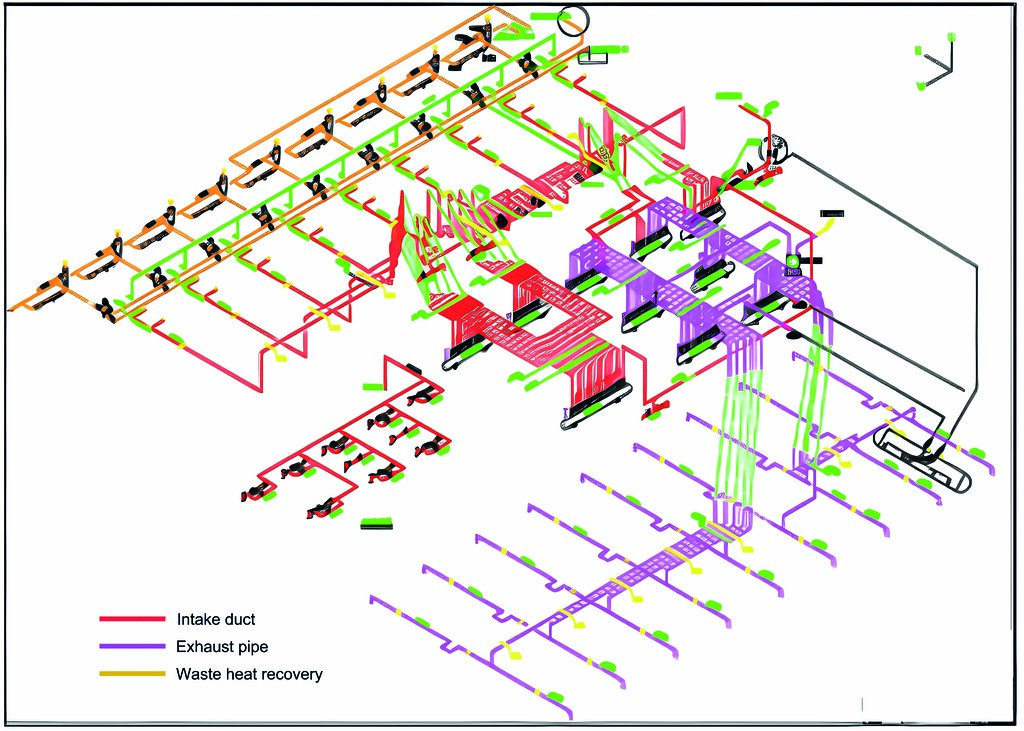

Automatic autoclaved curing system

Only through an automatic autoclave system can the optimal autoclaved curing curve be achieved, which is demonstrated using the Ubinox Changxing factory as an example. This factory operates 9 autoclaves with dimensions of 2.72 × 38 meters in its first production line, where the exhaust gas has a pressure of around 2 bar and the unit consumption is approximately 110 kg/m³. For the second production line, there are 12 autoclaves with dimensions of 2.68 × 38 meters, with a gas exhaust pressure of around 1 bar and a unit consumption of approximately 100 kg/m³. In this factory, the fully automatic autoclaved curing system adopts flow control, precisely controlling the flow curve according to the set autoclaved curing formula. Compared with other domestic automatic autoclaves that use pressure control, the advantage of flow control is that it is an active control method, while the pressure control is passive. When the pressure signal is fed back to the regulating valve, the steam flow has already exceeded the amount required at this stage, thus leading to risks in the autoclaved curing process. The fully automatic autoclaved curing system can achieve fully automatic control of heating, which results in constant temperature and consistent steam transfer and cooling, eliminating fluctuations caused by manual operations. Moreover, it facilitates the traceability and analysis of quality defects.

At present, practice has proven that the adoption of an automatic autoclaved curing system is the optimal solution for controlling the autoclaved curing quality in AAC production. Considering the high cost of imported autoclaved curing systems, the AAC producer Ublok Intelligence has optimized the control logic based on the imported autoclaved curing system of Changxing's first production line. The flow control valves are of imported brands, while the electric on-off valves are of domestic brands. This not only achieves the same effect but also reduces costs by approximately 50%.

Semi-automatic autoclaved curing

The technical innovation concept of this system aims to control the autoclaved curing quality while reducing the system cost. It adopts the traditional steam manifold gas distribution mode, combined with the group control logic of pipeline-type automatic autoclaves. Automatic control valves are used in each group to control the heating curve, and domestic manual stop valves are used as on-off valves. The advantages of this system are that the heating curve can be automatically controlled and that the autoclaved curing quality is not affected by fluctuations in manual operation. The cost is significantly lower than that of a fully automatic gas distribution system. However, the shortcoming is that the workload related to autoclaved curing operations cannot be reduced.

Optimization of the thermal insulation plan

According to statistics, the annual steam loss caused by heat dissipation from a DN100 valve is approximately 10 tons. Autoclave rings, bottom supports, etc. all need to be insulated. The static curing room and pre-curing kiln require improvement of thermal insulation measures.

The insulation thickness of the autoclave body should be no less than 150 mm. An additional 30 mm of insulation should be added to the upper third of the autoclave body. The insulation thickness of the main steam pipe should also be no less than 150 mm. Also, heat dissipating areas such as autoclave rings and supports need to be insulated. Practice has proven that before adding a 50 mm layer of aluminium silicate, a layer of nano-reflective film and a 0.6 mm layer of aluminium sheet to the original 100 mm of insulation, steam supplement was required 3 to 4 times during the original constant temperature stage. After the transformation, steam supplement is no longer needed, and a pressure increase can be observed. The steam loss caused by the thermal insulation defects of the green body is approximately 3,000 tons per year.

Proper selection of steam trap devices

If the steam trap is selected incorrectly, approximately 260 tons of steam may be wasted each year due to leakage.

Through nearly three years of practical application and optimization, UKeyer Intelligence has developed a dedicated steam trap system for autoclaves in AAC factories. This system addresses the issues of untimely drainage of large-volume low-pressure water and leakage of small-volume high-pressure steam. Its unique control mode eliminates the problem of steam leakage and temperature drainage during high pressure conditions. The steam trap device not only affects product quality but also energy consumption, and it is one of the key components of the entire steam system.

Steam quality as a key factor

The conditions for stable steam include a stable steam volume, controllable pressure and temperature, low contents of air and non-condensable gases, and a clean and dry production environment.

Incomplete curing, watermarks, and colour differences are all caused by the formation of non-condensable gases and water, which affect steam heat transfer. In addition, calcium and magnesium ions in the water are some of the factors causing colour differences on the surface of products.

For steam with entrained water from internal boilers and during steam-reversing operations, the dryness of the steam can be improved by installing a steam-water separation device before the steam enters the autoclave.

It is advisable to install air-release valves at the end of the pipeline and on the upper and lower parts of the autoclave body to discharge the residual air and non-condensable gases inside the autoclave. On the premise of ensuring product quality, this can maximize the reuse value of the steam, truly achieving rational energy utilization and energy reduction.

Another tool for efficiency improvement is digital empowerment. Utilizing the EMS Energy and Carbon Dual Digitization System to monitor and manage energy usage in real-time further enhances energy efficiency.

Conclusion

From the industry analysis presented in this paper, many problems may exist in the operation of the steam thermal system in AAC plants. However, by implementing reasonable energy-saving measures and technological transformations, energy consumption can be significantly reduced, product quality can be improved, and environmental pollution can be decreased. In the future, UKeyer will continue to focus on further optimizing the technology and management of the steam system, and work together with customers to promote the low-carbon and sustainable development of the industry.