Production Technology

Keda Suremaker, Maanshan City, Anhui Province, China

Equipment Trends in the Era of Globalization and Carbon Neutrality

Loading...At Keda Suremaker, four distinct trends have been identified as shaping the next generation of AAC production:

· Smart Manufacturing,

· Green Manufacturing,

· Customization,

· and Large-Scale Production.

Here is an in-depth look at how specific equipment innovations are redefining the industry.

Smart Manufacturing: From General Automation to Specific Solutions

The traditional AAC plant is evolving into a smart, data-driven ecosystem. Intelligence is no longer just about automated buttons; it is about specific machines taking over complex, repetitive tasks to ensure consistency and safety.

Smart Raw Material Preparation

Keda Suremaker has moved beyond manual adjustments. Modern systems now feature Automatic Grinding Media Replenishment Systems and intelligent batching systems. These systems automatically calculate and adjust recipes based on real-time density detection and temperature collection, ensuring the slurry is optimal before the process even begins.

The End of Manual Cleaning

A prime example of targeted automation is the Automatic Mold Cleaning Machine. Positioned on the return track, this equipment automatically clears and collects waste residue from the molds. This innovation eliminates one of the most labor-intensive and messy tasks in the plant, ensuring a pristine mold for the next cycle without human intervention.

Automated Reinforcement

Efficiency is also evident in the Automatic Mesh Assembly System. Capable of handling various specifications (50/75/100/125/150mm/200mm, etc.), this system achieves a production rhythm of just 2.5 to 4 minutes per mold, significantly outpacing traditional manual assembly methods.

AI-Driven Safety

The integration of AI vision is revolutionizing safety management. Systems can now automatically detect personnel in dangerous zones or verify safety gear usage, triggering immediate alarms to prevent accidents.

Green Manufacturing: Energy Efficiency as a Standard

"Green Solution, Greener Life" is not just a slogan at Keda Suremaker – it is an engineering mandate focused on reducing consumption and utilizing renewable resources.

Steam Management & Heat Recovery

The autoclave section is typically the largest energy consumer in each AAC plant. Through automatic gas distribution, waste heat recovery, and automatic hydrophobic systems, modern plants can achieve up to 20% energy savings. Keda Suremaker is also actively tackling emissions by implementing systems that eliminate "white smoke", noise, and odors.

Servo Hydraulic Applications

Replacing traditional hydraulics with Servo Hydraulic Systems offers faster response times and significantly lower energy consumption. In recent case studies, such as the Chinese Maanshan Hengda project, this shift saved approximately $10000 USD annually in electricity and hydraulic oil costs alone.

Photovoltaic (PV) Integration

A major trend is utilizing the vast roof space of AAC plants for Building Applied Photovoltaics (BAPV). This not only generates green electricity to offset plant consumption but also protects the roof, extending its lifespan.

Customization: Adapting to Diverse Market Needs

One size no longer fits all. As the global market shifts from standard blocks to panels, and towards higher precision products, equipment must be flexible.

Thin Panel Solutions

To meet the rising demand for thin AAC panels, Keda Suremaker has introduced the "Flat Cake Autoclaving + Green Cake Separation" technology into its portfolio. This method significantly reduces breakage rates and allows for a 1-2mm gap during separation, which improves autoclaving efficiency and product quality.

Specialized Processing

Innovations like the Specialized Grooving Station and Lintel Production Systems allow producers to offer high-value, application-specific products to their customers.

Flexible Packaging

The market requires versatility in logistics. Advanced packaging lines can now seamlessly switch between palletized and pallet-free packaging modes, adapting to different transportation requirements without stopping production.

Large-Scale Production: Engineering for Speed

To meet global infrastructure demands, capacity is a key to success. Keda Suremaker has engineered specific machines to break previous speed limits and support large-scale output.

Breaking the Cycle Time Barrier

Keda Suremaker is pushing the limits of physics in the plant to achieve a 45-second cycle per mold in critical sections.

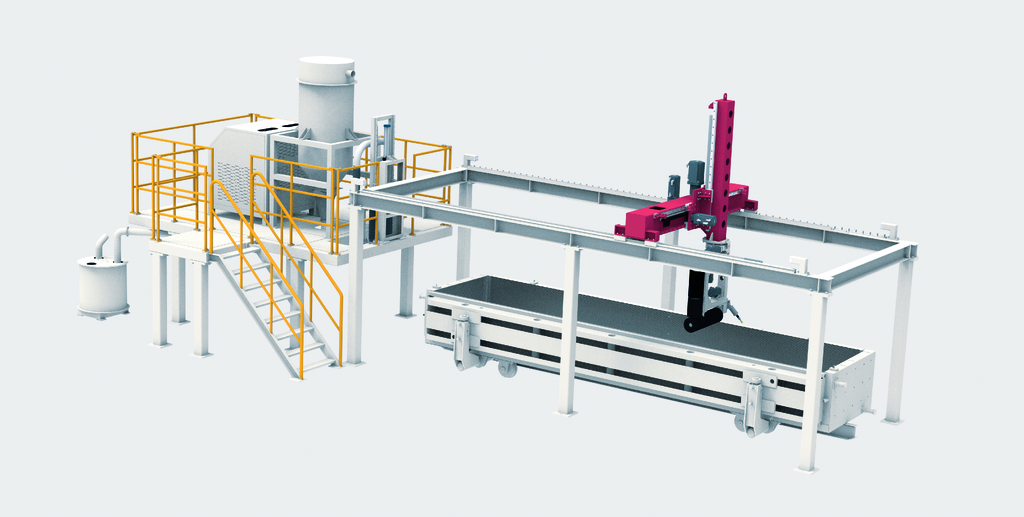

Double-Station Overhead Trimming Machine

In order to support high-speed production, a double-station trimming machine has been introduced. Its suspended, hollow structure prevents material accumulation and reduces civil engineering costs, ensuring continuous high-speed operation with minimal maintenance. The Double-Station Overhead Trimming Machine is designed to quickly tilting and peeling the bottom layer off the green cake using a cost-effective, overhead system that stays clean automatically.

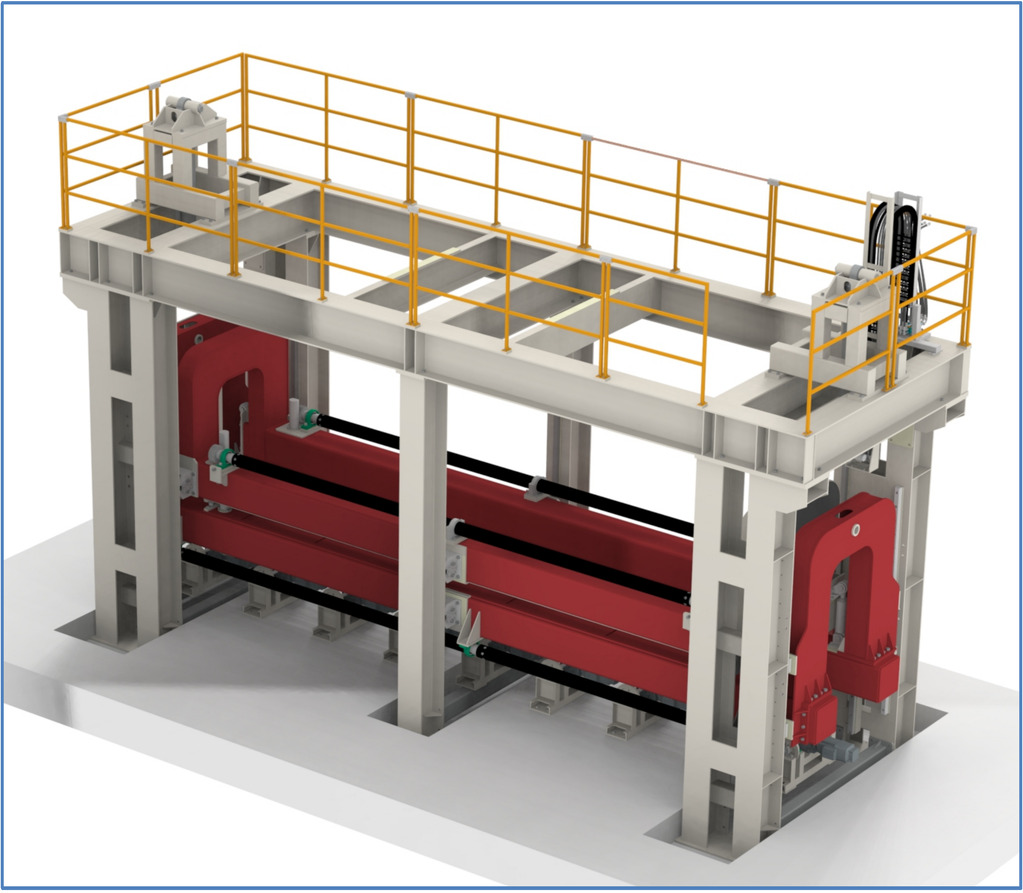

High-Capacity Clamp-Type Separator

Traditional separators often bottleneck production with slower cycles. Keda´s updated clamp-type separator has considerably cut the operation time to under 90 seconds (200mm product, down from traditional 2.5 minutes), ensuring that the separation process keeps pace with the fastest production lines.

High-Speed Mixing

New high-speed mixers running at 1500 rpm ensure that slurry preparation never lags behind the casting schedule, supporting high-volume output.

The Future: The "Lights-Out Factory"

Where do these trends lead? They converge at the concept of the "Lights-Out Factory" (or Dark Factory) – a production environment driven by big data and AI that requires minimal human intervention.

This evolution represents a fundamental shift in the nature of AAC manufacturing. Keda Suremaker believes that the entire industry is committed to making this vision a reality, moving away from traditional labor-intensive processes toward a future defined by precision, safety, and continuous optimization.

This changeover is not just about modernising and upgrading the machinery, but rather about collectively transforming the AAC plants into sophisticated technology hubs that will define the standards for sustainable construction for decades to come.