Production Technology

Ersel, 41420 Çayirova-Kocaeli, Turkey

Grinding circuits for AAC plants

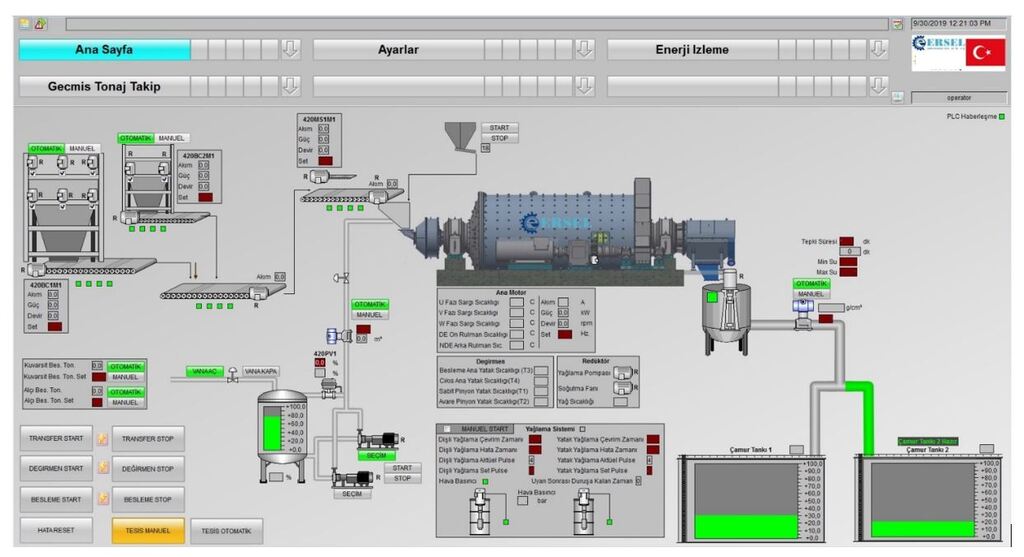

Loading...Wet ball mill

Ball mills provide grinding at the required capacity according to the size reduction ratio, grading curve and sand slurry density required by the processes of sand and gypsum preparation, which form part of the preparation of raw materials in AAC production. Mill designs begin with the bond index test, which is a test of the grindability of the material to be processed.

The design of the mills takes various factors into account, including the required capacity, fill level, lining design, grinding ball selection, the most suitable mill size, and milling speed. Since mills represent equipment with some of the highest power consumptions in AAC plants, the most ideal designs are made to reduce energy consumption.

The mill rotation speed, which is one of the critical parameters for grinding efficiency, can be adjusted with a frequency converter as a precaution for the variations that may occur in the feed raw material. Stable and uninterrupted feeding is important in the feeding process of the mills. Feeding is done with the mill feeding belt, using belts with weighing systems located under the sand and gypsum bunkers. These conveyors are equipped with all necessary safety features.

Consistent slurry quality is obtained by accurately dosing the water to be used in mill grinding. By measuring the flow rate continuously in the dosing system, the desired amount of water is automatically adjusted by means of proportional valves. In addition, the mills are equipped with an automatic lubrication system.

Since the balls used in grinding are subjected to wear, balls are fed to the mill automatically at intervals determined by the ball feeding machine, taking into account the optimum product size distribution and motor current. Ball feeding is controlled and automated. Mill linings and lifter bars are designed to provide the best grinding efficiency. The most efficient capacity and liner lifetimes are evaluated in the design. With the trommel screen at the discharge of the mill, worn small grinding balls and oversize materials are extracted by the sieve. The slurry passes through the sieve and is poured into the tank at the discharge.

The submersible pump on the tank pushes the slurry into the sludge silos. In this process, the grinding system communicates with the level sensors on the slurry silos.

The grinding plant has a user-friendly interface that provides easy control and use. By providing full-time communication with the plant's main control centre, all data can be recorded and monitored. With the unique design of the mills, they provide minimum installation and commissioning time. The equipment is easy to maintain and offers advantages such as fast and reliable service opportunities, remote support, and readily available spare parts.

Vertical roller mill

Grinding is provided to meet the requirements for burnt lime in AAC plants and to bring AAC production waste back into the system.

The crushed AAC material is fed into the mill grinding table and moves to the corners of the flat table and under the conical grinding rollers by centrifugal force. The material is held and ground between the rollers and the grinding table. In order to optimize the grinding efficiency, the grinding force on the rollers can be adjusted via the hydraulic loading system. Depending on the selected air flow rate and the separator rotation speed, the desired grain size product will be extracted from the mill. The classifier sends large-grained materials back to the mill for re-grinding.

Mechanical stops in the mill prevent the rollers and table from being damaged, and also prevent the rollers from physically contacting the grinding table. Vertical roller mills have low energy consumption and are easy to maintain and operate. Vertical roller mills are designed as compact plants.

The rotary feeders at the exit of the silos regularly feed the material to the mill. The material is fed from the silos to the mill with a screw conveyor. Mill feeding air lock is used. A magnetic separator prevents metal parts from being included in the milling process. With the belt scale on the feeding belt, the mill is fed at a stable and determined rate.

After the material has left the mill, the product is pneumatically transported to the cyclone and product filter through the piping system. In the dust filter, the dust filter is fed in such a way that each bag is fed homogeneously. The product is transferred to the pneumatic transfer silo with a screw conveyor under the bag filter. The product collected in the silo is taken to the usage silo with a powder pump, ready for use. Filter outlet air is discharged from the chimney.

In order to dedust the plant, dust extraction is done with a dedusting filter. The material coming out from under the dust filter is given to the collection screw to be transferred to the pneumatic transfer silo with the screw conveyor.

The operation of the plant is fully automated. The plant provides easy maintenance and operates with minimal downtime.