Production Technology

PMX Labs Sp. z o.o., 60-750 Poznan, Poland

Heat in the Production Process – An Often-Overlooked Optimization Opportunity

Loading...PMX Labs produces and distributes Poromix Additives, a modern tool for optimizing production. As AAC experts, technical and technological aspects of AAC are also consulted. With over 30 years of combined industry experience and numerous factory visits, the most common production issues have been identified. One key issue is the neglect of energy considerations in various aspects of AAC production.

Heat is Energy, Energy is Money

Some factories precisely control heat intake by monitoring the temperature of slurries and water, while others neglect this factor and continue operating regardless.

Every raw material has a cost. Just as excessive use of cement or lime is avoided, heat should also be preserved. Heat losses in the factory, such as through open doors, drafts, or uninsulated tanks, require compensation in the form of additional energy consumption of binders.

Achieving Balance

For an optimized and efficient recipe, two critical conditions must be met:

· Mineral balance

· Thermal balance

Thermal balance is just as crucial as mineral balance. Even with the best raw materials and the most advanced mixer, improper thermal treatment – such as insufficiently warm molds or suboptimal autoclaving – results in inefficiencies.

More Water = Less Heat

Water is essential for facilitating critical chemical reactions in the production process, but its use should be optimized. Overuse negatively impacts energy consumption during autoclaving and affects product quality.

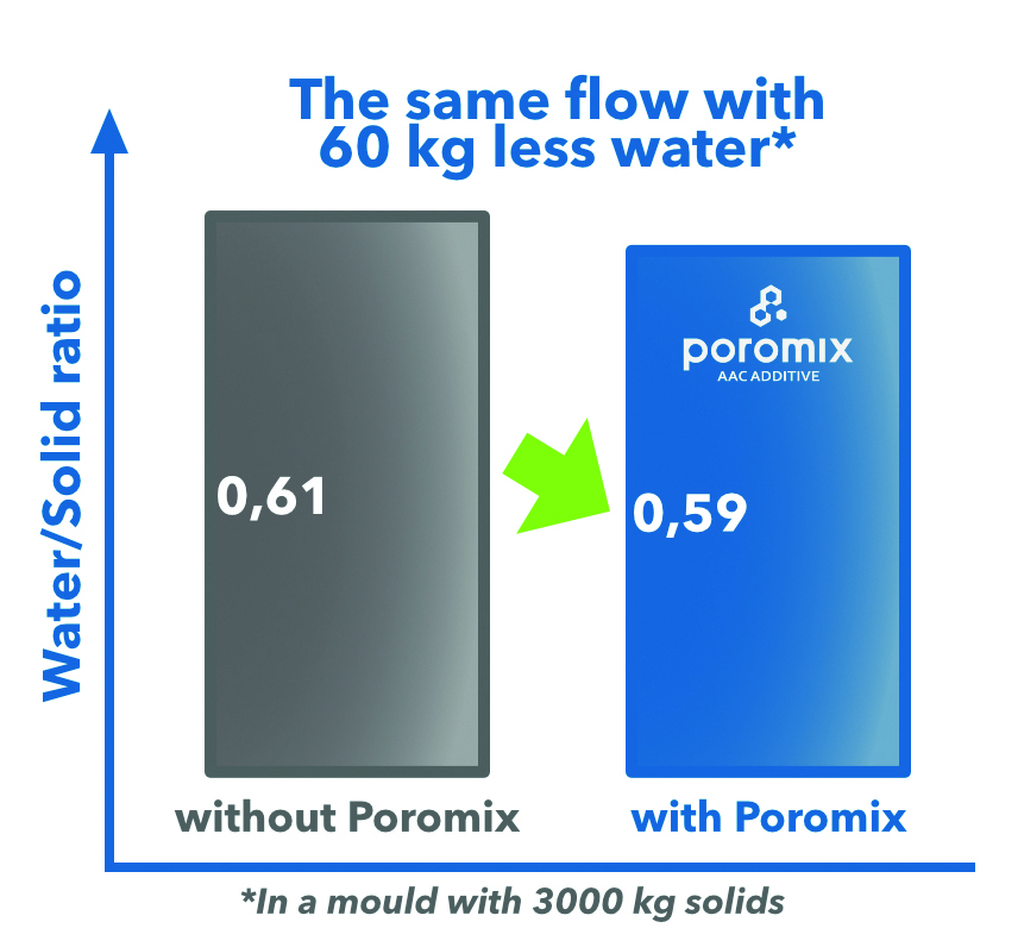

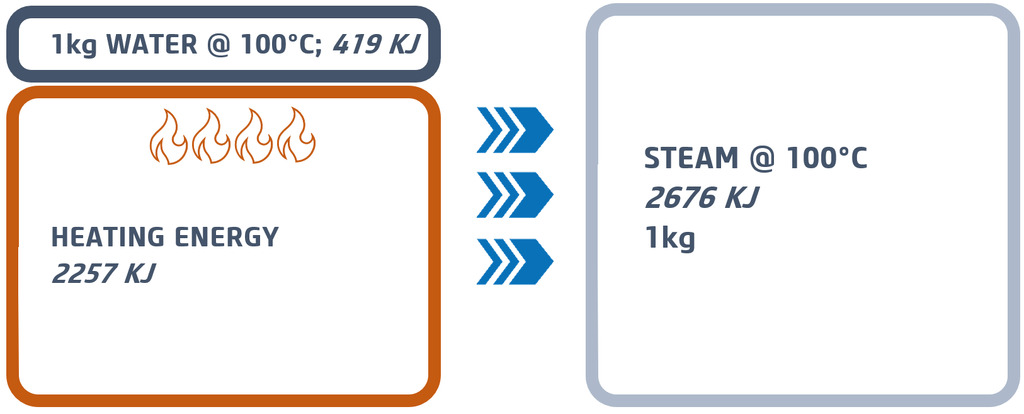

One fundamental parameter in AAC production control is the Water to Solids (W/S) ratio. This ratio represents the total amount of water in the mix – including water from sand, return slurries, aluminum suspension, and both hot and cold water dosed into the mixer – relative to the total amount of dry solids. Water has the highest heat capacity of all substances, requiring 2257 kJ to convert 1 kg of water into steam. This energy demand must be supplied by the boiler. (Figs. 1 and 2)

Cakes with excessive water content require longer autoclaving cycles, as additional energy is needed to convert excess water into steam. Reducing water content directly decreases energy consumption, leading to cost savings. Additionally, if autoclave capacity is a production bottleneck, shortening the autoclaving cycle can increase overall production capacity.

Water's high heat capacity allows it to absorb energy from binder reactions immediately after casting. A higher water content results in cooler cakes, causing an energy imbalance. Insufficient cake temperature due to excessive water negatively affects reaction efficiency and reduces compressive strength. Practical implementation of additives has demonstrated that reducing water content alone can enhance compressive strength due to this mechanism.

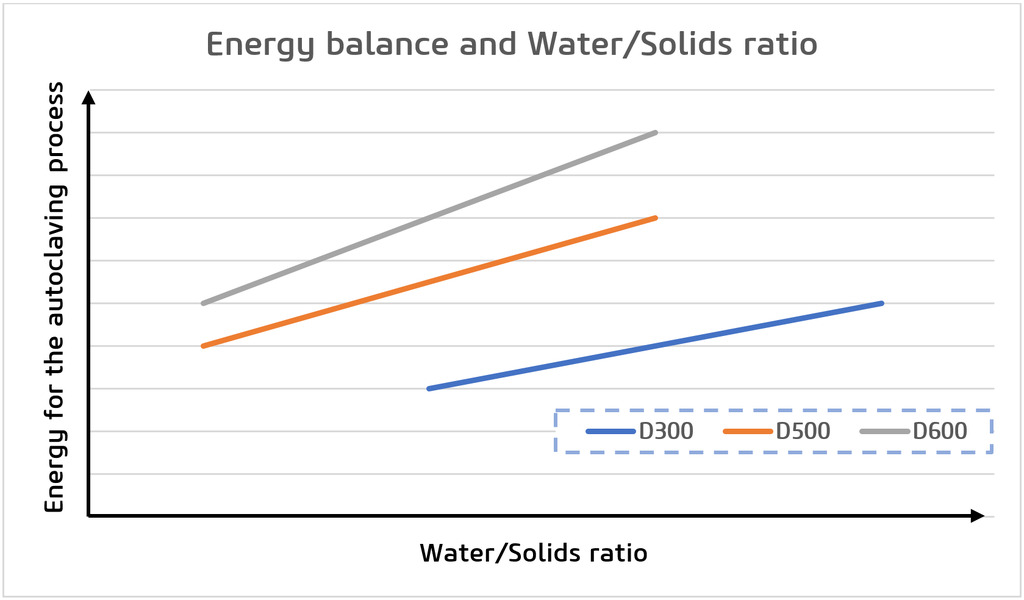

Energy Balance and the W/S Ratio

According to energy balance theory, a higher W/S ratio requires more energy to surpass the activation barrier. The correlation between W/S ratio and energy consumption is evident across different densities (300 kg/m³, 500 kg/m³, and 600 kg/m³) – see Fig. 3.

Excess water can also cause sticking and difficulties in evaporating water from the cakes, increasing the risk of "soft patches" (unautoclaved areas) or autoclaving cracks. More water in the autoclave leads to unnecessary condensate generation and potentially higher final product moisture levels.

Reducing water content is essential for maintaining the thermal balance of the cake. Mixing tower operators should be aware of this before adding extra water to improve mass flow or mitigate cracks – an issue frequently encountered in production facilities.

Strategies for Reducing Water Content

Poromix additives are designed to enhance both energy and mineral balance by:

· Preventing coagulation: Allowing better hydration and dispersion of particles.

· Reducing water surface tension: Using surfactants to optimize water efficiency in the mix.

Coagulation Prevention

By preventing coagulation, Poromix maximizes the effectiveness of binders, reducing the required quantity while increasing reaction efficiency. More hydrated cement and lime contribute to increased heat generation from these reactions.

Water Surface Tension Reduction

Modern chemicals can replace excess water. Poromix functions as a surfactant, reducing water surface tension and allowing for greater hydration of raw material particles (Fig. 2). This effect enables similar hydration levels with reduced water content. From an energy perspective, this approach maintains mass flow (viscosity) while increasing mix temperature.

Curing Chambers

Most factories utilize curing chambers, but implementation varies. These chambers provide stable thermal conditions for rising cakes.

Some plants merely cover molds to prevent drafts and heat loss, while others install heated tunnels (40-60°C). In addition to retaining heat in the cakes, curing chambers also keep unused molds warm, ensuring readiness for the next production cycle.

After curing, cakes are transferred to the cutting machine. Ideally, cut cakes should be loaded directly into an autoclave or stored in pre-autoclave chambers, preventing excessive energy loss before the next production phase.

Conclusion

Heat is just as important to the production recipe as the quality of cement or lime. Energy optimization leads to cost savings and greater production stability by ensuring consistent thermal conditions.