Production Technology

Signode Denmark ApS, Sønderborg, Denmark

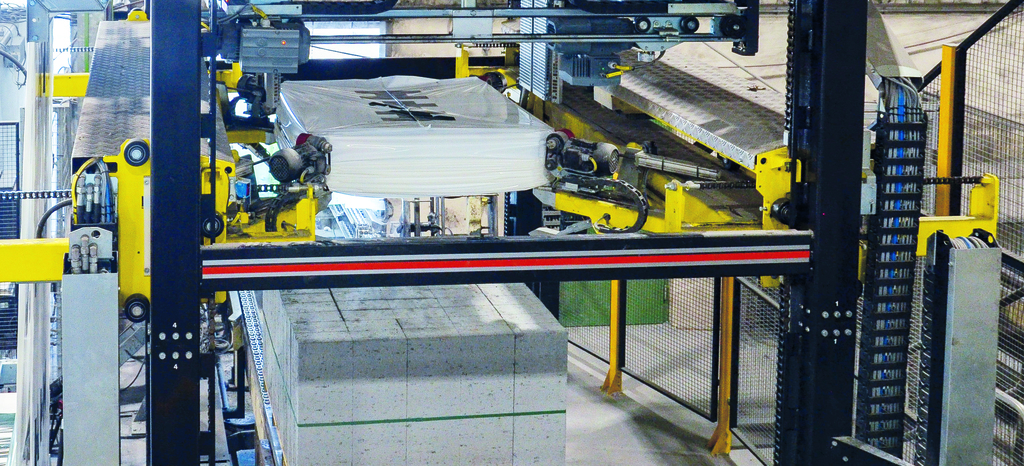

Implementing state of the art packaging at H+H Pollington, UK

Loading...As Leyton Austin – H+H’s Continuous Improvement Manager states, “We were in the market for a low maintenance, high performance, fully automatic stretch system capable of hooding a high number of banded packs with minimal intervention from ourselves”.

“We recognised that the Multi FleX1 Stretch Hooder was key to achieving the higher speeds as well as meeting some of our key site sustainability targets - lower energy and low film consumption. We needed a commitment from Signode that the Multi FleX1 would be capable of stretching and applying stretch hoods with a thickness of only 50 microns without tares, rips, or holes”.

Leyton added “Our previous shrink system operated with a very low film thickness when compared to the industry norm, so we know that downgauging the thickness was a big ask but the Signode team were confident in their analysis, a confidence that continued throughout the life of this particular project”.

Signode’s Construction Key Account Manager Tony Butler commented, “We don’t just pluck film thicknesses and high-speed cycle times out of the air; we make initial judgments and predictions based on over 35 years of product and film knowledge. Then more importantly, we test to validate those initial judgements in our “state-of-the-art” test center in Soenderborg, Denmark". Testing allows you, the customer to make real time valued judgments on the optimised pack solution for your particular product, along with an indication of the basic costs involved, whether it be “Wrap, Strap or Hood”.

Tony continued, “In order for us to apply thin films onto sharp uneven surfaces, without holes, we have developed (through years of testing) a film unwinding system that allows us to wind film off the grippers during the initial stretch cycle. This has the effect of increasing the length of the “stretch sweet spot” reducing film thinning considerably which is the difference between holes and no holes”.

Tony added, “If we look at this from a sustainability point of view, a film thickness reduction of just 10 microns for a typical AAC, Paver, Brick or Tile plant working 16 hours a day, 7 days a week 50 weeks a year would result in an overall film reduction of 15.5 tons/annum. Multiply this up to a 20-, 30-, 40- or 50-micron reduction, over multiple Stretch systems, over multiple sites and the film reductions just keep increasing and the direct material costs fall”.

One of the features of the Multi FleX1 is the inclusion of a “Logo Registration System” feature. During the manufacture of the hood a colour sensitive sensor picks up the start of the first “H” of the H+H logo (coloured green) and starts an encoded measurement equaling the exact amount of film required for that particular product. This ensures that all the logos are aligned when stacked in the stock yards for maximum marketing impact.

From a routine maintenance point of view a patented “top-down” system allows floor level access to the film sealing/cutting systems for easier and faster servicing. Film replacement is also completed at floor level to increase machine up time.

It’s probably good to note at this stage that this was not a new line being commissioned stage by stage, slowly ramping up to full production. There was a small window of opportunity where production was temporarily suspended to allow the install and commissioning to take place.

Leyton recalls “This was not the simplest of installations, the old bagging/ shrink system had to be taken out leaving the existing transport conveyor/lifting device in situ. The Lachenmeier hooder was disassembled, manipulated into position, and re-assembled with precision, against the backdrop of production pressure and a re-start date that could not be missed”. Signode, being a total solutions company and leading manufacturer of packaging equipment, tools, and consumables, not only had the resources to assist, but also the skills, developed within the Signode PackagingPlus™ Team, required to operate within the restrictions presented by this task. “Given the heavy demands we place on any equipment in an operation like ours, I am always sceptical about the engineering quality of new equipment. But our experience with Signode and the Lachenmeier equipment specifically is that the system is robust and simple to operate with complete reliability” concluded Leyton Austin.