Production Technology

Jiangsu Teeyer Intelligent Equipment Co.,Ltd, Changzhou City, Jiangsu Province, China

Improvement and innovation in production equipment

Loading...On the basis of this epochal background, through the application of 5G+ industrial Internet technology, Teeyer achieves extensive linking of each production unit, deep integration of operational information, and full optimization of data elements, making a great effort to build an advanced plant with high efficiency and capacity.

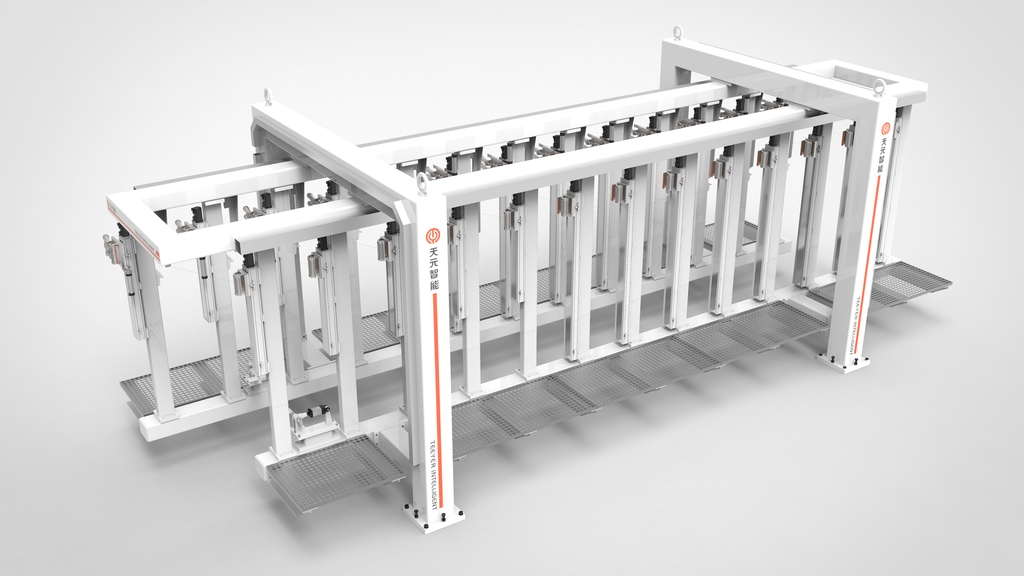

Intelligent servo side cutter

Teeyer develops the intelligent servo side cutting machine, which is controlled by the servo cylinder. Through this system, the feed quantities for each cutter can be precisely adjusted, to ensure that cutting surfaces are clean and smooth. The groove cutter system is equipped with four kinds of mortising groove cutters in order to meet the needs of various plate specifications. Product specifications are determined through RFID data acquisition, and cutting specifications are automatically adjusted according to the finished-product information.

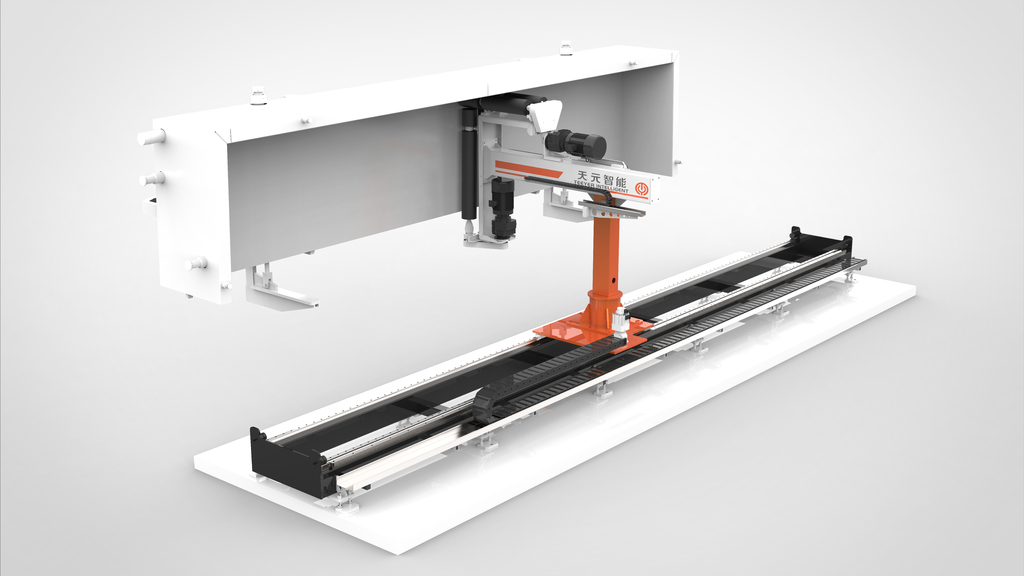

Intelligent servo horizontal cutting machine

Similar to the servo side cutting machine, the horizontal cutting machine is also driven by a servo system and uses product specifications based on the RFID data acquisition. It can automatically adjust the cutting position of each cutting wire, and set the wire diameter compensation, which greatly increases the product dimensional accuracy. In addition, the system is suitable for different requirements and specifications and is able to switch automatically between block and panel production. This improvement makes a significant contribution to faster production cycles and, correspondingly, it reduces the size deviation of cutting wires caused by manual operation. At the same time, the alarm system for damaged cutting wires and the system for auto cleaning are also taken into consideration.

Mould cleaning machine

The mould cleaning machine cleans the sticky material and waste residue inside the mould with the help of a visual identification system. As designed, the waste residue falls into the cutting pit after cleaning, which facilitates recycling of production waste and provides an optimized working environment while requiring less labor force.

The RFID data acquisition and equipment operation share data with each other. The data can be used throughout the whole production process, such as steel mesh preparation and circulation section, finished products separating, as well as at the packing section. This application aims at providing a fully automated operation system without manual intervention and offers full production data traceability.

Conclusions

‘Pragmatic, professional, innovation and win-win’ is Teeyer´s business philosophy. Looking into the future, as a leading company in the AAC industry, Teeyer’s staff has a global vision and will continue to make every effort, stay true to the company’s original aspiration and forge ahead to transform the national brand ‘Teeyer intelligent’ into an outstanding global brand.