Production Technology

WKB Systems GmbH, 48477 Hörstel, Germany

Optimised aluminium dosing and mixing process

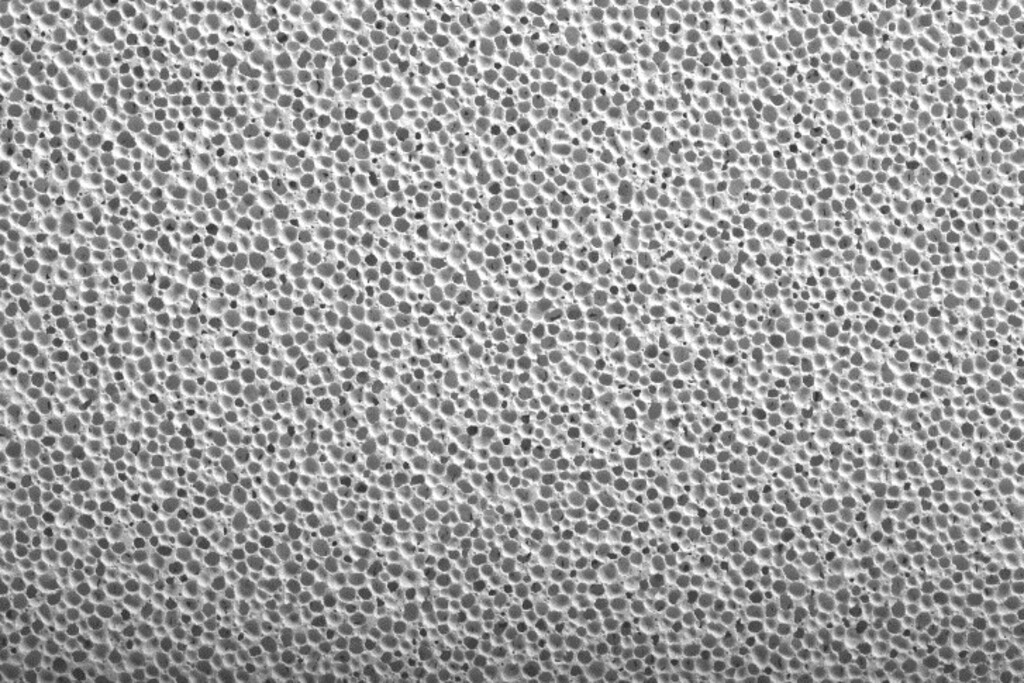

Loading...Pores are the main structural element of AAC that forms constructional and technical characteristics of the end product. Types of pores, their forms and sizes are the basis of the microscopic structure of the material. One of the main challenges in the production of AAC is to manufacture products with a high-quality microscopic structure based on the formation of pores with a spherical shape and a diameter of D<2 mm, which are the signs of structural stability (see Fig.1). Furthermore, it influences the strength and durability characteristics of AAC.

Hydrogen (Н2), that extricates during the chemical interaction of aluminium with calcium hydroxide in AAC mixture, forms the pore structure of the material. That is why it is of great importance to choose the right sort of aluminium paste with a good activity.

2Al + Ca(OH)2+6H2O → CaO•Al2O3•4H2O+3H2↑

On the other hand, it is to pay attention to the dosing and mixing process itself. The preparation of aluminium dispersion influences directly the whole production process and to the great extent the quality of manufactured AAC products. The German manufacturer of machineries, equipment and complete production lines for AAC industry – WKB Systems – supplies its customers with a smart aluminium dosing and mixing unit.

This stand-alone facility on a steel frame consists of:

- two storage tanks with tension sensors and slow-motion mixers

- dosing screw conveyors of special construction

- mixer tank

- pressure vessel for pneumatic sending

The aluminium dosing and mixing unit operates batchwise in a fully automated mode. The dosing of aluminium paste and water occurs strictly according to parameters set in the recipe. A tact cycle for dosing and mixing processes lasts 3 - 4 minutes. At the end of the cycle, the ready-to-use aluminium dispersion is forwarded under the high-pressure air to the main mixing plant, where AAC mixture is getting ready for one casting mould. The batchwise kind of operation means the preparation of aluminium dispersion only for one casting mould per cycle tact that guarantees the stable quality of the aluminium mixture. The longer aluminium reacts with water, the sooner it looses its activity.

The main distinctive feature of the aluminium dosing and mixing unit by WKB Systems is that different aluminium pastes can be mixed and their proportion can be easily adopted during the whole mixing process:

- through simple changes on the ratio of aluminium fragments with different sizes, the aluminium mixture can be fitted to AAC density that is being manufactured at the moment

- through mixing of pastes with various activity indexes, the consumption of aluminium can be reduced

The usage of any strong blowing agent can result in the formation mainly of large odd-shaped pores and poor microstructure of the material, while the application of finely dispersed types of aluminium causes crack formations (see Fig. 2). The main reason for those defects is a mismatch of blowing and stiffening processes inside the cake. The cracks or so-called cake deformations are one of the common problems for many AAC manufactures to deal with.

Possible ways to minimise or to avoid cracks is to mix coarse-grained and fine aluminium pastes, pastes with specials agents or pastes of different activity indexes and concentration levels. In such a way, it is possible to control the reaction process to some extent.

The WKB aluminium dosing and mixing unit is able to exactly match aluminium pastes with different characteristics in a completely automated way in order to adopt the aluminium dispersion to the current production of AAC products with pre-determined properties.

The next issue to pay attention is the agglomeration of aluminium, in other words, the sticking of aluminium particles in a clump (see Fig. 3). This usually occurs during long storage periods. The particles separate while mixing only if friction force is stronger than adhesive strength between them. Agglomeration properties of the aluminium paste depend on a chemical agent used.

((Fig. 3)) Fig. 3: Aluminium pastes partially agglomerated (by Marat Bikbulatov)

The preliminary preparation of aluminium paste in small-sized storage tanks with slow motion mixers facilitates the destroying of agglomerates.

The mixer tank of 0.09 m³ makes the usage of aluminium pastes with unstable quality and low activity possible. Here, the aluminium consumption can reach 5 kg per casting mould with 6.768 m³ volume. With the application of WKB aluminium dosing and mixing unit, the Al/H2O ratio can reach the variables of 1/15 or a higher consumption of aluminium at the Al/H2O ratio of 1/10.

It is to emphasise the flexibility of WKB aluminium dosing and mixing unit while testing new types of aluminium paste. There are no additional measures needed. The testing can be done with no intervention into the main AAC production process.

The testing of new aluminium pastes in large tanks with volume of ≈1m³ results in residues of the mixture at the bottom of the tank, so-called bottom heel. It means approx. 100-200 kg of dispersion or ≈5-20 kg aluminium at Al/H2O ratio of 1/20…1/10. In order to receive consistent results after testing of one sort of aluminium paste, the facility must be cleaned completely, incl. those residues. The tank must be also emptied at every stop of the production process.

In this respect, the ease of maintenance and technical servicing of WKB aluminium dosing and mixing unit is another advantage for the end user. For example, the special construction of screw conveyors allows fast and simple cleaning process by one operator as they can be dragged out of the main body, positioned on special guide frames and washed off.

Furthermore, the construction of the base frame allows an operator to unload bags with aluminium paste with a forklift directly near to the storage tanks. In this way, any delivery of the raw material is easily done with no physical efforts by an operator.

The control and operating system of WKB aluminium dosing and mixing unit is completely automated, so the human factor is eliminated, and any failure is minimised. It significantly contributes to the duration and quality of the production process as a whole.

Thanks to its compactness and self-sufficiency, WKB facility can be easily integrated into any AAC plant, already operating or just being erected.

Based on the direct access to AAC production processes worldwide, the engineers of WKB Systems GmbH modernise and customise the aluminium dosing and mixing unit on a steady basis. The practical experience of many years allows them to achieve significant results, such as a short tact cycle of 3 - 4 minutes or a dosing accuracy of ± 10 g.