Production Technology

Pmx Labs sp. z o.o., 60-758 Poznan, Poland

Practical guide on conducting additive trials at an AAC plant.

Loading...Why factories test Poromix?

In these crucial times of pursuing Carbon Neutrality of AAC production and necessity of keeping low competitive production costs, many factories are discovering Poromix Additive as a tool to help in these major strategies.

Each AAC factory is different, with partially locally sourced raw materials, and various technologies of production. Yet main objectives are the same – to supply the market with a final product that meets the requirements and is produced cost-efficiently.

Many AAC factories around the world use various kinds of chemical additives in production – mostly soaps and stabilizers. Every plant using any of those experience some benefits.

Regardless, if an AAC plant is very experienced with high automation or is newly build – each plant can benefit from trials and exploring opportunities for optimizations.

The trials

PMX Labs (Poland) offer trials of Poromix to experience first-hand the possibility of optimization. In most cases a personal on-site visit is organized to maximize the efforts and steepen the learning curve. Remote trials (so with online support from Poromix team) are also offered in some cases and often results from those are base for the on-site visit.

No dosing system is required to be present for the trials as they are made using a 25 kg sample and manual dosing. Application is done directly into mixer or to sand/fly-ash slurry. Whether conducted remotely or during on-site visit, trials are always focused on reaching undisturbed production (keeping viscosity stable, keeping cycle times, etc.) and exploring potential for reductions of raw materials.

A visit of PMX Labs experts is always a great opportunity to share industry know-how and experience in recipe optimizations with the local team. Often an open discussion with management and quality teams leads to finding ways of simplifying a part of production or economizing the use of raw material/consumables/energy.

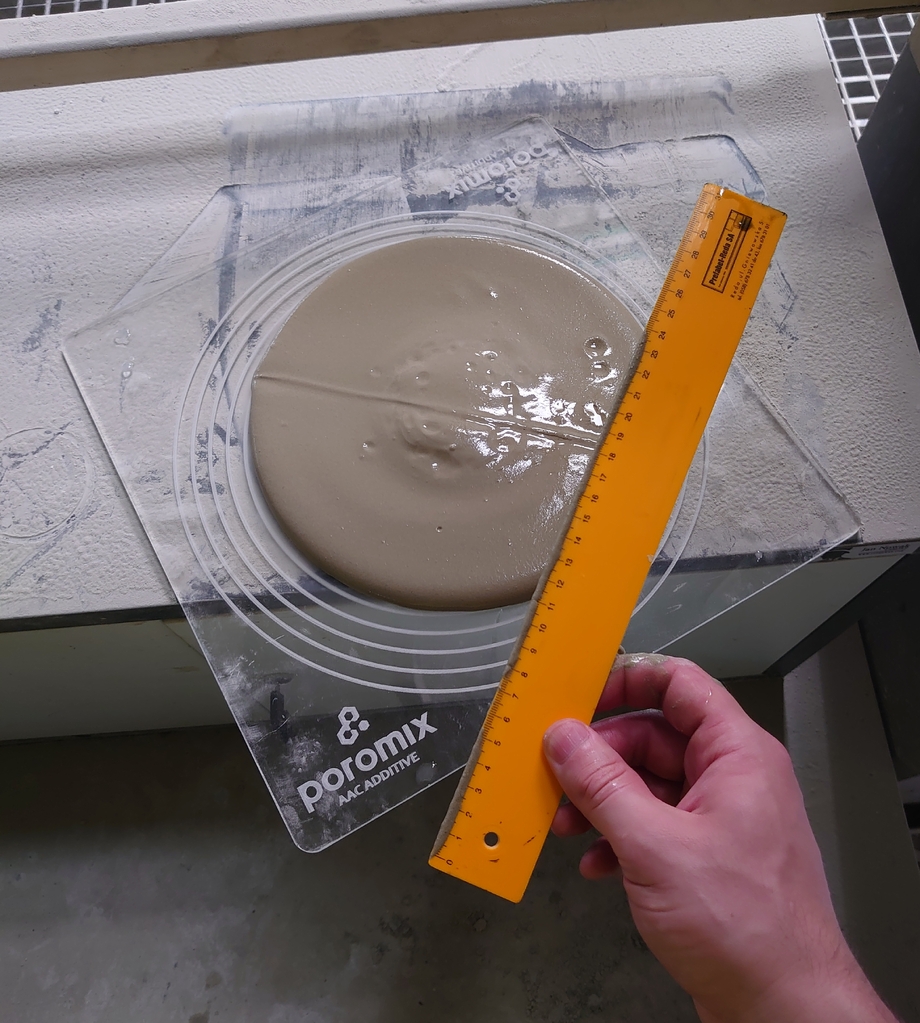

Another benefit of an on-site visit is to jointly measure variables, standardize the testing methods or often introduce new procedures based on Poromix experts’ recommendations.

The first step in any optimization and before trials is to understand the current state and conditions of production. Here a personal visit has the most advantage over a remote trial, as production and quality control is discussed directly. After analyzing the raw materials, recipe and production objectives, the plan for trials is created.

The trials visit usually lasts 2 days. During the first day a lot of focus is put on understanding the plant and objectives with first few cakes casted, the second day is repeating best results from previous day and making larger reductions in longer series. The total of 10-16 casts are made during the trials – enough to be covered by the 25 kg sample.

· First round consists of 3-5 cakes made without and with Poromix, but without any reduction of binders. In this step the team observes if the AAC mix reacts as expected to introduction of the additive. This step builds confidence in the additive.

· Second round introduces Poromix with an optimized recipe – that is lowered amount of binders and water. Various scenarios are tested along with “reference” cakes where no changes to normal recipe are made. Examples of reductions:

o 50 kg less water and 20 kg less cement per mould

o 60 kg less water, 15 kg less lime and 15 kg less cement with 30 kg of dry sand added.

Production process variables control is a must in a plant with ambitions for reliable production. Testing and implementing the Poromix also requires reliable data to capture if and how Poromix affects the mix and the process. PMX Labs team believes that one can only manage what one has measured, therefore all data collected in trials is analyzed.

Crucial areas and metrics to observe during trials – the objective is to see any changes in the process and react:

· Casting area: Viscosity test, Temperature control, Casting height

· Rising area: Temperature control, Gassing time, Rising height

· Cutting area: Temperature control, Green hardness test, Height measuring, Visual inspection

· After leaving autoclave: Visual inspection, Quality check (cracks, sticking, damage types), Sample collecting for density and compressive strength check

It is conducted with a Quality- or Process Management team. Once the strength results are available, the data is complete, and it needs to be interpreted and furthermore conclusions can be drawn.

Trials are concluded with an in-depth report indicating possible further directions and recommendations. The report always consists of two parts:

A) Poromix trials – trial description and results,

B) General plant observations – here based on observations Poromix experts share opinions and tips on what and how could be improved in overall production landscape.

Full production implementation

Often after trials with 25 kg sample a factory wants to continue with a couple-day long production with Poromix. For this a 1000-liter IBC is provided. After confirming the benefits of the additive, a consistent implementation starts. Poromix for bulk orders is delivered in such IBCs – usually 10 or 21 units. At this stage a dosing system is necessary for smooth operation. Some plants modify their existing mixing tower software to include an additive dosing, other plants have independent systems.

PMX Labs specialists are always available for Poromix customers to assist and advise on how to make use of the additive in an optimal way.

Poromix additive

The additive is a blend of five-components, based on polycarboxylate-ethers (PCE). It is designed by PMX Labs specifically to suit and catalyze AAC chemical reactions in a controlled way.

The additive enhances the quality of chemical reactions, creating potential to reduce lime and/or cement. What is crucial, the source of silica and calcium is irrelevant – the additive works with sand, fly ash, and less carbon-intensive alternative binders. It can be used in production of both AAC blocks and panels. Using it is beneficial from economic point of view, as the price for a dose of the additive is lower than the cost of reduced raw materials.

Addition of Poromix lowers consumption of water. This by itself causes lower requirement for steam in autoclaves, hence lower fuel consumption.

With better quality of the green cake – that is more homogenous, less sticking and less prone to cracks – lower occurrence of various cracks is observed. This directly leads to less AAC waste, further adding to enhanced optimization.