Production Technology

WKB Systems GmbH, 48477 Hörstel, Germany

Process automation and robotics in the AAC industry

Loading...The building materials‘ industry has seen remarkable technological advancements in recent years. One of the areas that has particularly benefited from these innovations is the production of autoclaved aerated concrete (AAC). The integration of automations and robotics into the AAC manufacturing process has further elevated its efficiency, flexibility and sustainability.

The benefits that robot applications bring to the AAC industry are:

product quality improvement

reduced production time

better safety standards

higher productivity level

accuracy and flexibility

savings in production costs

image positive impact

Meanwhile, a number of robotised solutions are successfully used in the AAC production technology by WKB Systems GmbH.

Smart facility for more automation

WKB Systems widely uses linear robots for pins stacking and removing during loading/unloading of hardening cars in a completely automated way. These robots or so-called manipulators are rail‐bound and designed as a portal.

The manipulator is equipped with additional fine adjustment units to make an automated process possible. It sets itself directly to a respective stacking/removing position so that pins can be handled.

A pneumatic impulse device is also installed, which gives an impulse beat from several directions on a stable pin so that it is loosened before the pulling process begins.

The overall control panel is responsible for a complete process of starting or stopping of the manipulator. It is also possible to operate the facility manually. So there is a separate control panel can be placed close to it (usually in the area of the packing unit).

Technical data:

max. tolerance of hardening cars and grates of ±10 mm

max. weight of pins of 10 kg

6 pins per hardening grate (3 per side)

max. 3 hardening grates per a hardening car (on top of each other)

stacking/removing of pins in the same direction

Sorting/packing and pallet orientation robot system

AAC insulation board is a mineral insulation system with the following key characteristics:

dimensional stability

vapour permeability

incombustibility

average density of 120 kg/m³

certified lambda (±) 0.045 W/mK

thermal resistance (R) of (±) 4m²

This type of AAC products cannot be packed, sorted, transported in production lines manually or by other types of hydraulic mechanical grippers due to their low density. Only robots with vacuum grippers will be the right industrial solution for these tasks.

The engineering team of WKB Systems designed and developed a special robotics line for sorting and packing of AAC insulation boards using five different types of robots, each of them performing specific tasks, incl. empty pallet handling.

Classifying, sorting and distributing

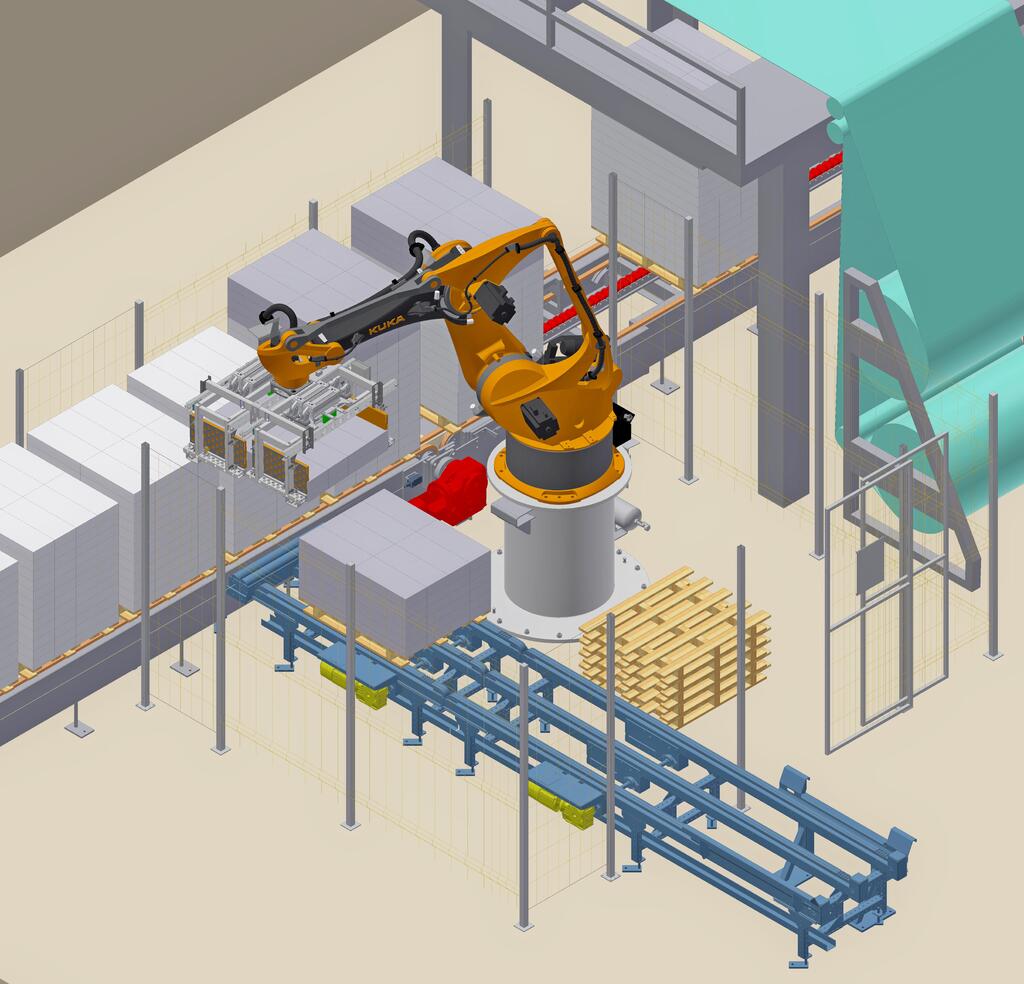

For manufacturers of a wide range of blocks in one AAC cake and small production capacities, a 6‐axis robot application is offered by WKB Systems. It is used for the rapid classification and sorting of all types of AAC blocks according to their size and density, as well as distribution according to the customised orders for shipment with automated stacking of additional rows of AAC blocks on a pallet. The robot sets small packages on a Euro pallet for retail sale or dispatch packages of same-format AAC blocks.

Sample function sequence

A hardening car with two hardened cakes each on a grid on top of each other is forwarded to an unloading crane. This grabs the upper grate with a cake, lifts it and drives to the packing area. Here the crane places the grate on one of the feeding trolleys. Furthermore, the process is repeated with the second grate (bottom layer). The unloaded hardening car is picked up, lifted and placed on a return track by the same crane.

The feeding trolley drives the grates with AAC blocks into the unloading area of the robot. Afterwards the empty grate is moved back to the unloading crane which places it on a hardening car provided.

An industrial robot with a manipulation force of approx. 700 kg and the radius of action of min. 3000 mm is equipped with a parallel gripper. Depending on the product, its format, position of blocks in the cake, package height and so forth, the robot simultaneously removes two rows of blocks of 1200 × 600 × 199/249/499 (max. 180 kg) from the grate, turns them by 90° into the upright position and places them on a shuttle frame.

If necessary, flanking stones or other additional elements are then removed (sorted out) to build up new packages. At the same time, the package height can be increased by further formats. For these purposes, several storage spaces and a chain conveyor are provided inside the robot area. As far as new packages with supplementary formats have been created, they are also fed into further packing process.

On request by an operator, the robot ejects blocks so that manual sorting takes place without any interruption of the complete process. The blocks are then reintroduced for further processing.

Pallet orientation and handling system

In the production of AAC products, not only the main production steps but some supporting processes can be completely automated. The main reason here is to increase the efficiency of the manufacturing and moreover the profitability of the plant.

The feeding of pallets in the packing line is one of those backup processes in the production that can be also automated. Usually, it is done by an operator who is responsible for destacking and upturning of interlaced pallets. So, he manually places a ready‐to‐be‐loaded pallet on a chain conveyor of the packing line.

To make a step towards automation and to improve the plant operating performance ratio, the experts of WKB Systems advise equipping the packing area with an industrial robot.

The robot with 6 axes ensures a very high level of flexibility. It is fitted with a special pneumatic gripper to take a pallet from the storage area and place it on a conveyor of the packing line. The gripper is suited for standard and non-standard pallets.

While starting the process, the robot recognises with special sensors, if a pallet is interlaced or not. Then the gripper takes every single pallet, turns it at 180°, if needed, and feeds the chain conveyor with it. Furthermore, the robot uses special centring device to place the pallet right in the middle of the conveyor, so the packing process occurs with no interruption. The complete working cycle is 45 seconds per pallet.

One of the main distinctive features of the robot gripper is its ability to handle a wide range of pallet sizes, as it is usually needed while packing different AAC block formats in a flow.

Hybrid system for handling and packing – multitasking gripper

The flexibility of an industrial robot not only automates but also optimises the packing processes. A robot used in a hybrid system for handling and packing is equipped with a special gripper. It is able to grip AAC blocks, sand lime bricks and pallets, clean the top surface of the block layer and form customised packages.

One part of this system is an upstream compacter. In order to minimise the gaps between blocks, the upstream compacter pushes them together on a hardening car right before they are picked up with the robot.

The robot takes blocks from a hardening car according to a previously set scheme and places them on different pallets depending on the block size. The surplus blocks are placed on a temporary storage pallet to be packed as far as the production of blocks with the same dimensions starts.

So, there is no need to take any manual action after the production start of a new block format.

A noticeable increase in productivity and product quality, as well as the highest efficiency and precision, are the obvious advantages of this hybrid packet assembling line.

Future perspectives

The introduction of robotics into AAC manufacturing technology is a relatively recent phenomenon. However, there are some indications of a rapid increase in the numbers of robots employed in AAC industry, especially in the area of product handling and packing. Contributing to this process the German manufacturer of equipment and complete production lines, WKB Systems GmbH, has been at the forefront of integrating robotics and automation into AAC manufacturing and expects to develop even more innovative solutions to further optimise AAC production process and redefine the possibilities within the industry.