Production Technology

Hefei Sunrise Aluminium Pigments Co., Ltd., Shuangfeng Development Zone, Hefei, Anhui, China

Selection of aluminium powder for the production of lightweight and high strength AAC products

Loading...Taking AAC products with bulk densities of 400 and 600 kg/m3 as an example, from the raw material analysis, AAC products with a bulk density of 400 kg/m3 can save about 20 - 30% of raw material consumption compared to AAC products that have a bulk density of 600 kg/m3. In relation to the thermal performance of the material, the thermal conductivity of AAC products with a bulk density of 400 kg/m3 is 30 - 40% lower than that of AAC products with a bulk density of 600 kg/m3. From the perspective of the entire built structure, the amount of structural building materials can be reduced when adopting the use of AAC products with a density of 400 kg/m3. In comparison to AAC products with a density of 600 kg/m3, the weight of the wall filling material is reduced by 100 - 200 kg/m³, and the overall weight of the building is reduced. Therefore, the pursuit of light-weight and high-strength AAC production processes and application technology is of great significance for the saving of resources and energy, as well as the improvement of environmental protection. This approach of low bulk density and high strength has become a common pursuit of AAC producers, but the strength reduction related to reduced product weight has also become a problem that needs to be addressed.

The challenges in producing high strength AAC with low density

In theory, the lower the bulk density of AAC, the lower its strength. Therefore, the aim of achieving a low bulk density without reducing the strength is related to a certain degree of difficulty in the production processes. The combination of low density and sufficient strength is also a common goal that AAC producers have been pursuing. Under theoretical conditions it can be assumed that, as long as the raw materials and processes are stable, the products can meet the requirements of the customers. But in reality, in the environment of increasingly scarce resources, the available raw materials are limited and the waste materials to be used are also variable. In addition, products of low bulk density and high strength are also related to very high requirements for process technology and production operation standards, because the production of AAC with low bulk density needs to improve the slurry water to material ratio. The higher the slurry water to material ratio, the lower the stability of the slurry expansion volume in the process of gas generation. The lower the absolute dry bulk density of the aerated concrete product, the larger the volume expansion ratio of the slurry during the pre-curing and gas generation processes, the higher the porosity in the plastic slurry, and the thinner the material thickness surrounding the pores. If the strength of the material surrounding the pores, which supports the overall structure, is insufficiently compatible with the expansion of the slurry and cannot bear the weight of the slurry itself, collapse of the mould can occur. Such poor stability of the slurry can result in low quality of the finished product. Therefore, most AAC producers need to select high-quality sand with a high silicon content, high-strength cement, high-quality quicklime and gypsum, and appropriate water/material and calcium/silicon ratios in the production process to achieve the combined effects of light weight and high strength.

The influences of pore size and pore structure

Is it possible to achieve the combined requirement of low density and sufficient strength through some other controllable measures? To answer this question requires us to further explore the key reasons for high strength. Whether it is a low bulk density or a high bulk density, we need to pay more attention to the air pore structure if we want to make the strength higher at the same bulk density level, and the importance of this element in practice is often ignored by producers. The author and his team have done a lot of testing, analysis and concept demonstration, and found that if the pores are in a closed state, or if the integrity of the shape of the pores is improved, then the strength will be higher. In addition, the higher the number of pores at a constant pore volume, the higher the strength of the product. Through research, it was found that aluminium powder plays a crucial role in the quality of the pore structure. The porosity of AAC with low bulk density is relatively high, and the overall porosity as well as the distribution of gas pore sizes directly affect the strength of AAC. The higher the porosity, the smaller the pore sizes and the higher the number of pores, the rounder the pore shapes and the higher the strength. However, in the actual production, continuous pores are usually produced, so that the actual pores are non-circular, resulting in a strength reduction of AAC. For different hydration products, even if the porosity is the same, the strength may be very different. When the overall porosity is the same, the strength increases with a decrease of the size of the pore. Therefore, the improvement of the volume stability of the slurry during the gas generation process and the reduction of the pore size during the gas generation pores are the prerequisites for the production of low bulk density AAC. Aluminium powder, as the most critical gas generating agent, has an important influence on the volume stability and gas generating porosity of the slurry. Therefore, the control variable method was adopted to control other conditions and change the type of aluminium powder in the production of low bulk density AAC. This was done to explore the influence of aluminium powder with different particle sizes on the gas generation curve and slurry pore diameter in the production of low bulk density AAC.

Evaluating the influence of aluminium powder properties

Anhui Sunrise group is a professional R&D and production organization dedicated to aluminium paste and aluminium powder. It is also the largest manufacturer of aluminium pigment and aluminium powder in China. Sunrise has been established for more than 20 years, and its products are exported to more than 50 countries and regions worldwide, including Europe, the Middle East and Southeast Asia. Sunrise has completed in-depth, detailed and comprehensive research on aluminium powder processing, surface treatments and surface coatings, and has accumulated rich experience, based on which it produces special aluminium powder for the special needs of the autoclaved aerated concrete industry.

Laboratory investigations

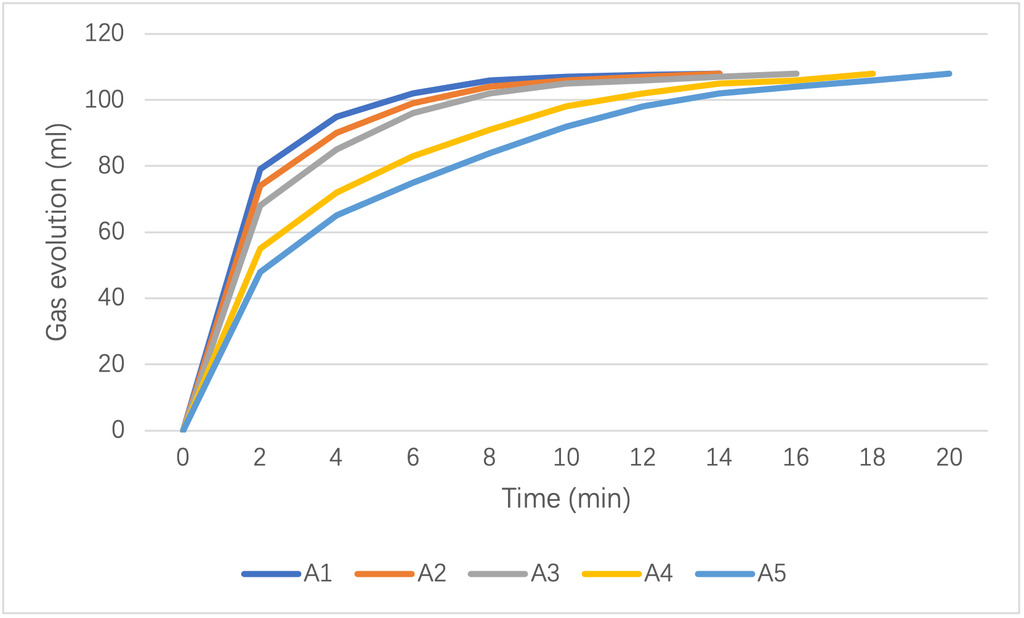

Aluminium powder with special particle sizes produced by the Anhui Sunrise group was selected for the experiments in this research. First, the aluminium was tested in the laboratory. For the experiments, 0.07 g of aluminium powder was mixed with a calcium hydroxide solution (12 g of calcium hydroxide, 50 ml of water) for 15 s, and the gas generation data was measured at a constant temperature of 45℃ (Table 1). The laboratory gas evolution curve is shown in Figure 1. The figure shows that under laboratory test conditions, the gas evolution curve gradually flattens with the increase of aluminium powder particle size.

Table 1: Laboratory-obtained gas test data of aluminium powder with different particle sizes.

Grade | D50 (μm) | 2-min gas volume (ml) | Gassing end time (min) | Gas volume (ml) |

A1 | 6 | 79 | 16 | 108 |

A2 | 8 | 74 | 16 | 108 |

A3 | 10 | 68 | 18 | 108 |

A4 | 15 | 55 | 22 | 108 |

A5 | 20 | 48 | 26 | 108 |

Production line experiments

In the actual production line experiments, high-quality raw materials such as sand, quicklime, cement, and gypsum were selected, and the experiment was carried out according to the proportion required for the production processes for AAC products with a density of 400 kg/m3. The water/material ratio for the mortar was set to 0.8, and the mortar fineness was 15% (passing the 200-mesh sieve, the content on the sieve was 15%). The specific ratio is shown in Table 1. The pouring temperature was controlled at 40℃ and testing the actual gas evolution of aluminium powder with different particle sizes was done under constant conditions. The gas evolution curve is shown in Figure 2. In production testing, the gas evolution curve is different from the gas evolution curve detected in the laboratory. 6 μm, 8 μm, and 10 μm aluminium powders have a faster gas evolution rate in the first 15 minutes. The smaller the D50, the faster the gas evolution rate. After 15 minutes, the gas evolution rate gradually decreases. The smaller the D50, the slower the gas evolution rate, and the longer the final gas evolution time. 15 μm and 20 μm aluminium powders have a slower gas evolution rate in the first 10 minutes, and the larger the D50, the slower the gas evolution rate. After 10 minutes, the gas evolution rate gradually accelerated. The larger the D50, the faster the gas evolution rate and the shorter the final gas evolution time.

Table 2: The ratio of raw materials used in the experiments.

Raw material | Sand | Cement | Quick Lime | Gypsum |

Ratio | 60% | 25% | 11% | 4% |

The pore size, absolute dry bulk density and absolute dry strength of finished blocks made of aluminium powder with different particle sizes are compared. The results are shown in Table 3. It can be seen from the data in the table that, under the same process conditions, an increase in the particle size of the aluminium powder results in a gradual increase in the average pore diameter and also a gradual decrease in the absolute strength in the dry state.

Table 3: Comparison of various data obtained on blocks made of aluminium powder with different particle sizes.

Grade | D50 (μm) | Average Pore diameter (mm) | Absolute dry weight (kg/m³) | Absolute dry strength (MPa) |

A1 | 6 | 0.3 | 409 | 3.52 |

A2 | 8 | 0.5 | 412 | 3.46 |

A3 | 10 | 0.7 | 408 | 3.59 |

A4 | 15 | 1.0 | 415 | 3.21 |

A5 | 20 | 1.2 | 425 | 3.18 |

Concluding remarks

In summary, under the above experimental process conditions, at an early stage, a decrease in the D50 of the aluminium powder results in a faster reaction rate, higher production of hydrogen, higher energy, and faster volume expansion of the slurry. At later stages, the gas evolution rate and the hydrogen production decrease, the energy decreases, the slurry gradually thickens and therefore the ultimate shear stress of the slurry gradually increases, the volume expansion is slow, and the gas evolution time is extended. There is no violent bubbling, the final product has small pores and a high strength in the dry state. In contrast, the larger the D50 of the aluminium, the slower the reaction rate in the early stages, the less hydrogen produced, the lower the energy, the slower the volume expansion of the slurry, the faster the gas evolution rate in the later stages, and the higher the energy. In this instance, the speed of slurry thickening is slower than the speed of aluminium powder gassing, the volume expansion of the slurry is relatively fast, the volume stability of the slurry is relatively poor, the gassing time is short, there is violent bubbling, the final product has large pores or even perforations, and the absolute strength in the dry state is low. The production of low bulk density products is related to large slurry water to material ratios and poor slurry stability. Therefore, it is necessary to select aluminium powder with fine particle sizes to delay the gas evolution time of the aluminium powder in the later stages, to match the gas evolution time of aluminium powder with the thickening time of the slurry, and finally produce products with small, uniform pores and high absolute strength in the dry state.

Anhui Sunrise Group is aiming at the field of low bulk density autoclaved aerated concrete. The specially customized high-performance aluminium powder is widely used all over the world and has received unanimous praise from customers. It has subverted the traditional production and processing technology of AAC in China, reshaped the technical performance of the products, and opened up broader opportunities for developing the autoclaved aerated concrete industry.