Production Technology

Aircrete Europe, 7575 EJ Oldenzaal, The Netherlands

State-of-the-Art Vacuum Pump System for AAC Autoclaves

Loading...The autoclaving process is one of the most critical stages in AAC manufacturing. Achieving the correct vacuum level before introducing steam is essential to ensure uniform curing, product quality, and long-term durability. Traditional, aged vacuum systems often struggle to reach stable deep vacuum levels quickly, leading to longer cycle times, uneven pressure distribution, and increased energy consumption. To address these inefficiencies, Aircrete Europe developed a new Vacuum Pump System that combines precise process control with robust mechanical design.

System Overview

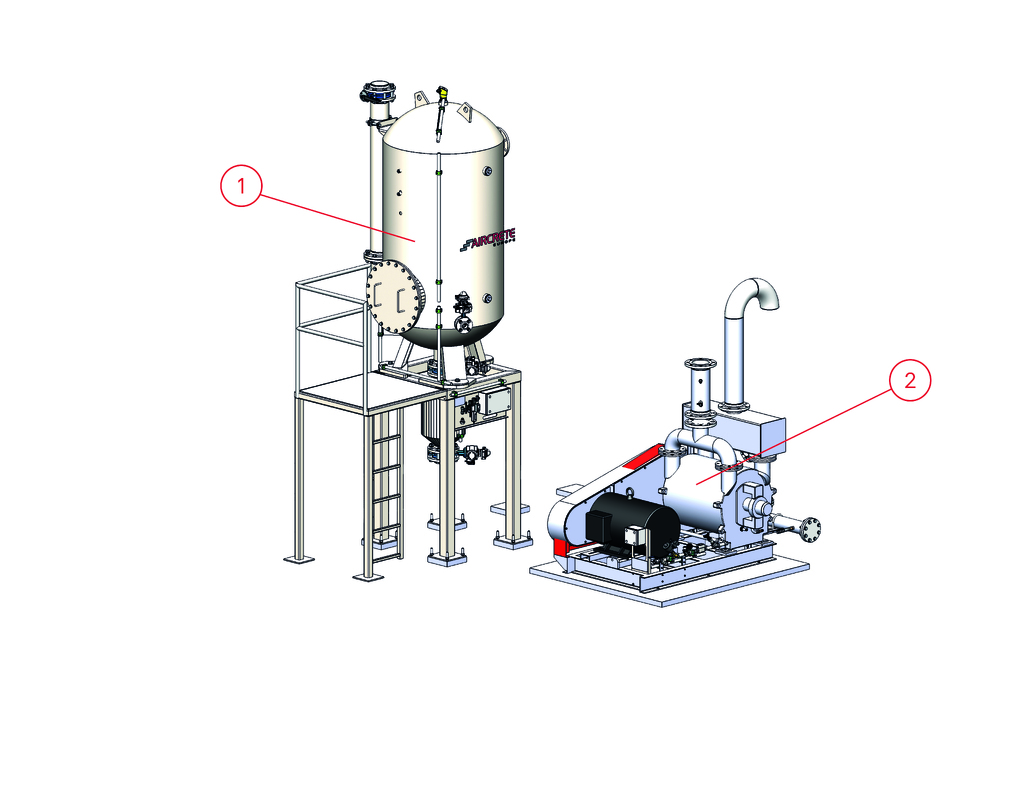

The Aircrete Vacuum Pump System (Fig. 1) is a stand-alone liquid ring vacuum pump unit with a nominal capacity of 2,250 m³/hr and a maximum working vacuum of -0.8 bar. The vacuum pump itself is equipped with a 55-kW drive, frequency inverted. The unit includes a 2m³ cooling and filtration tank, which ensures stable operation, prevents overheating, and filters the extracted air before discharge. With its own control cabinet (MCC + LCP), the system can be easily integrated into any new or existing AAC plant configuration. The system is available as stand-alone solution for any AAC factory, regardless of technology and equipment supplier.

Process Description

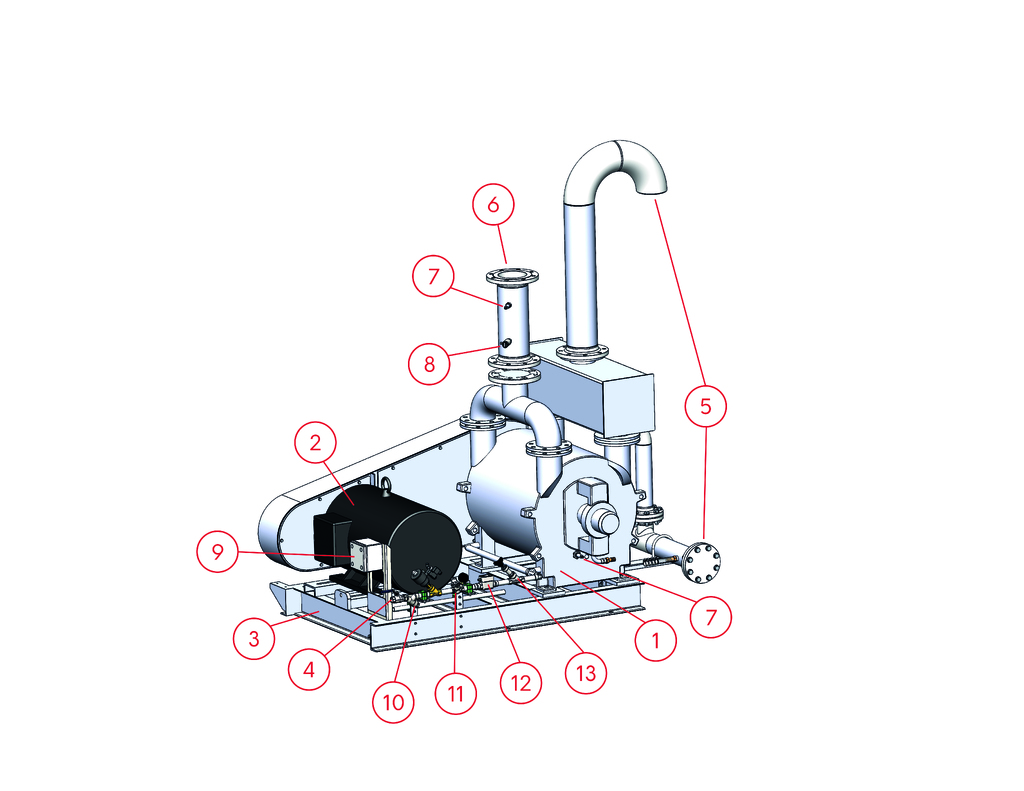

During the vacuum cycle, the system extracts air from the loaded autoclave to achieve the required negative pressure prior to steam injection. The Vacuum System consists of two main assemblies, the Vacuum Pump and the Tank Assembly, which operate together to ensure stable and efficient vacuum generation throughout the curing process.

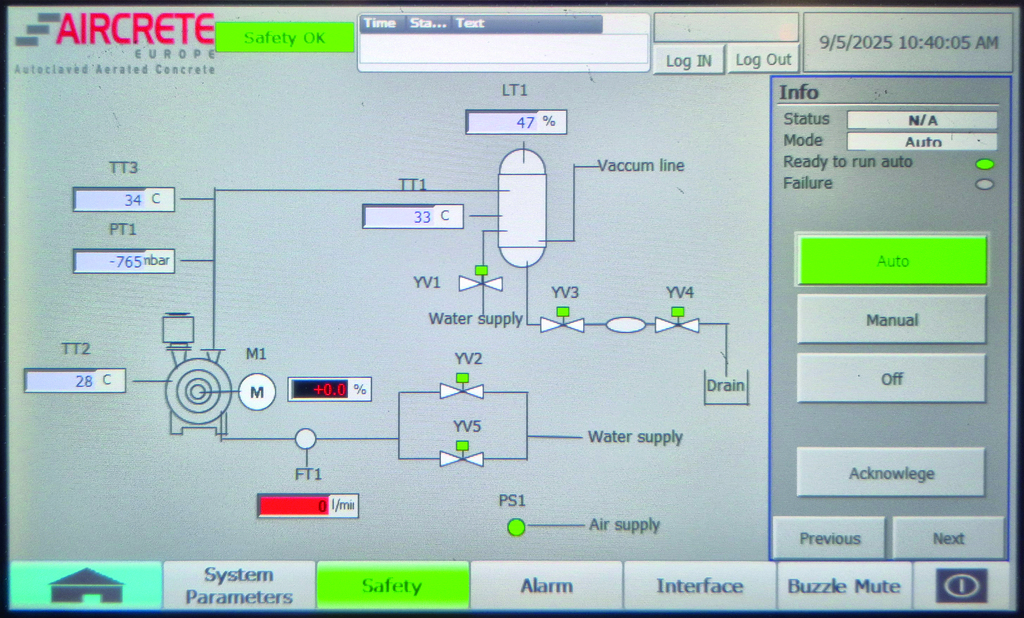

To maintain optimal performance, the system automatically regulates the water flow in accordance with the operating speed of the Vacuum Pump.

The gases extracted from the autoclave first pass upward through the Water Tank, entering from the bottom where they are initially cooled before reaching the Vacuum Pump. A check valve prevents any backflow into the autoclave, while a manual shut-off valve allows operators to isolate the line when required. As the gases move through the Water Tank, they undergo further cooling and the condensate is separated and collected at the bottom. This sequence ensures that the gas stream supplied to the Vacuum Pump is cleaner, drier, and at a lower temperature, thereby supporting reliable and consistent long-term pump operation.

Throughout the cycle, the system continuously monitors the vacuum pressure and automatically adjusts Vacuum Pump parameters as necessary to maintain the desired operating conditions.

Automatic Water Level Regulation

The water level in the Water Tank is automatically controlled by the system. When the water reaches the predefined high-level threshold, a discharge valve at the bottom of the tank opens, releasing the accumulated water into the Water Discharge Reservoir. Once this reservoir reaches its maximum level, a secondary valve opens to route the water to the drain through a controlled outlet. Importantly, this discharge sequence can occur while the Vacuum Pump remains in operation, ensuring uninterrupted system performance. If the water level in the Water Tank drops below the required setpoint, fresh water is automatically supplied to restore it to the specified operating range.

This self-regulating process guarantees consistent, safe, and stable vacuum generation during every cycle, minimizes the need for operator intervention, and protects the integrity of the curing process. Moreover, the reduced maintenance requirements of this innovation contribute to a marked increase in operational efficiency across the plant.

Performance and Efficiency

Field results show that the Aircrete Vacuum Pump System reliably reaches a -0.65 bar vacuum within 12 minutes for a standard autoclave loaded with 18 cakes of 5.4 m³ each. Average energy consumption per cycle is between 18-25 kWh, assuming a maximum infeed water temperature of 25 °C and a vacuum of -0.7 bar. This offers a substantial improvement in both energy efficiency and process time in most of the existing plants.

Stand-alone Integration

The system’s modular design allows it to operate independently or be seamlessly integrated into existing plant control systems. The dedicated control cabinet ensures synchronized operation with autoclave cycles while providing real-time data on pressure, temperature, and water flow. Installation requires minimal downtime, as the skid-mounted layout enables quick connection to autoclave vacuum lines and utilities. This stand-alone flexibility makes the system an attractive upgrade for both new and modernized AAC plants.

Key Highlights

The Aircrete Vacuum Pump System delivers multiple benefits to AAC producers:

· Faster and deeper vacuum formation, enabling optimal curing conditions and shorter autoclave preparation times.

· Stable and precise process control, supporting consistent product quality across every cycle.

· Reduced energy consumption and maintenance, achieved through efficient cooling and condensate separation that protect the Vacuum Pump and prolong component life.

· Compact, modular design suitable for both retrofit projects and new plant installations.

· Fully automated monitoring and control, ensuring safe, reliable, and hands-free operation of the entire vacuum sequence (Fig. 4).

Sustainability and Long-term Value

By improving the efficiency of the curing process, the system directly contributes to reduced energy usage and water consumption across the production line. The ability to achieve stable vacuum levels faster not only saves electricity but also increases autoclave throughput, resulting in a lower carbon footprint per cubic meter of AAC produced. These improvements align with Aircrete Europe’s broader commitment to delivering sustainable and high-performance solutions for the global AAC industry.

Conclusion

The new Aircrete Vacuum Pump System demonstrates how targeted engineering innovation can generate immediate and measurable benefits in AAC production. By combining deeper vacuum performance, efficient cooling, and stand-alone automation, the system enhances both process reliability and energy efficiency. It represents another step in Aircrete Europe’s ongoing mission to optimize every stage of AAC manufacturing – ensuring greener, faster, and smarter construction technologies for the world of tomorrow.