Production Technology

WKB Systems GmbH, 48477 Hörstel, Germany

Sustainable manufacturing from one source

Loading...The sustainability of an autoclaved aerated concrete plant largely depends on the material and energy intensity of the production process. The usage of secondary resources, disposal of wastes, energy recovery and minimum environmental impact are the main components of the resource-friendly technologies.

Thanks to long-term experience accompanied by tried-and-tested solutions for the efficient usage of resources, a German AAC equipment manufacturer WKB Systems GmbH offers innovative machinery and reliable technologies for the sustainable AAC production at high technical and economic indicators.

Effective mixing plant

In order to improve the efficiency of an AAC plant, the engineers of WKB Systems GmbH analysed the complete production process to find out plant areas that could be optimised.

In due course a new generation of the mixing unit was developed. All components are made of high quality stainless steel to improve the longevity as well as the operational availability of the mixing unit. Furthermore, the agitator can be easily removed from the tank for maintenance purposes. The mixing speed depends on the density of AAC being produced at the moment that results in significant energy savings.

All in all the mixing unit is designed in accordance with the latest sustainability requirements so the complete mixing cycle ends up with a homogeneous mixture at the lowest energy and raw material consumption.

Tailored to the customer requirements it can be designed with two mixing tanks. Each tank is equipped with an agitator and a frequency-regulated motor. The working cycles of tanks are matched to each other in such a way that two moulds are filled with AAC mixture at the same time.

Waste heat recovery

The hardening of the AAC material in autoclaves is the main energy consuming production step. While planning the autoclave section of a plant, the engineers of WKB Systems set a high value on waste heat recovery. Usually AAC plants are equipped with 6 autoclaves of a total capacity of 1200 m³ /day. This allows to apply the efficient steam reusage system, where several autoclaves are operated in a staggered manner. So the return steam is forwarded via piping system from an autoclave that has finished its working cycle to another one for the pre-heating before a new autoclaving process starts. This results in significant fuel savings.

The control system of autoclaves provides steam bypass, with the ability to adjust the steam release time.

Additionally, the heat of the condensate that appears during the autoclaving process can also be recovered. It is used with a heat exchanger to heat the building or preheat the process water. This also leads to fuel savings.

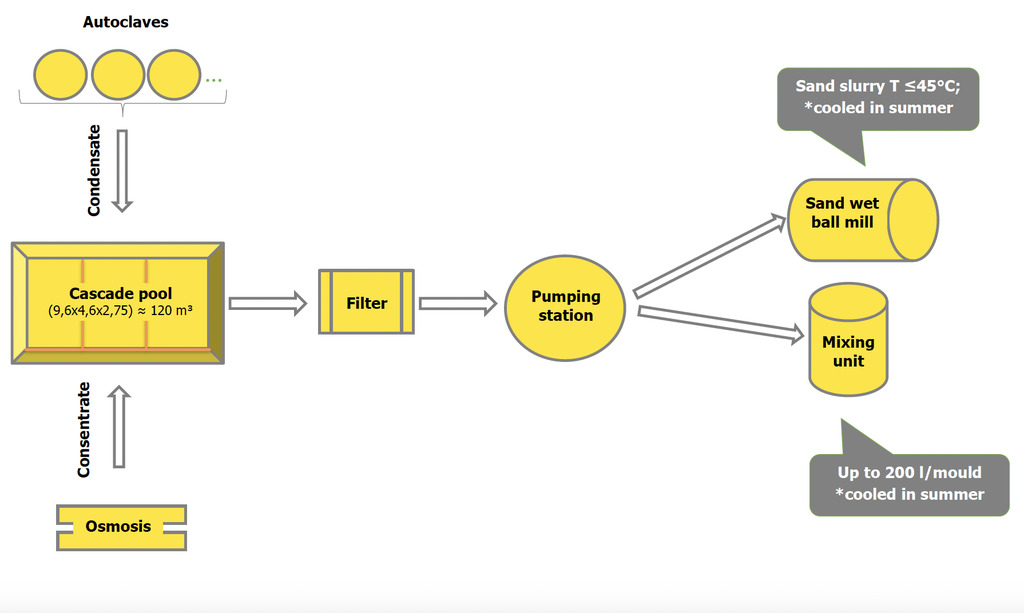

Condensate return system

The utilisation of the collected condensate from the autoclaves and concentrate after reverse osmosis pays an important role towards energy efficiency of the production process. Using WKB technology, the condensate from autoclaves can be used, e.g. in the mixing unit or in the sand wet ball mill.

WKB Systems developed and applies in AAC plants the following condensate return system.

The condensate is forwarded through a pipeline system to a three-section cascade pool with a volume of 120 m³. Here the concentrate is additionally discharged (water that must be disposed of after reverse osmosis). Large particles settle in the cascade pool and condensate is averaged. Settled particles are later removed during planned production shutdowns, but at least once a year.

A mechanical cleaning filter and a pumping station are installed behind the pool, where one of the pumps supplies condensate to the storage tank of the mixing plant, and the other pump supplies condensate to the sand wet ball mill.

In the event of any failure of one of the pumps, a reserve pump is provided. So, if necessary, all main pumps can be switched.

If the averaged condensate satisfies all the requirements of water specifications, the whole amount of condensate can be used for the production of autoclaved aerated concrete. For this purpose, a cooling system for the condensate is provided. This way of condensate implementation definitely lead to economic and environmental advantages.

Here is a sample of the averaged condensate composition from one of AAC plants equipped with WKB Systems machinery.

Table 1: Averaged condensate composition

Ingredients | unit | Water requirements | Concentrate from osmosis facility | Condensate from autoclaves | Averaged condensate (approx. 35%) + water (approx. 65%) |

pH | рН | 4-12,5 | 6,2±0,2 | 11,9 | 6,8±0,2 |

Ka | mg/dm³ | ˂ 500 | - | ˂ 2 | - |

Na | mg/dm³ | - | 86±12 | - | |

Cl⁻ | mg/dm³ | ˂ 350 | - | 18±2 | - |

SO4²⁻ | mg/dm³ | ˂ 600 | 695±104 | 571±86 | 380±57 |

Fe | mg/dm³ | - | 0,093±0,022 | 0,6±0,09 | 0,41±0,10 |

petrochemicals | mg/dm³ | traces | ˂ 0,05 | 0,101±0,034 | 0,24±0,08 |

settled particles | mg/dm³ | Not more 200 | 4,5±0,8 | 4,0±0,7 | 21±3 |

Based on the results of the data obtained, it was found that the condensate has a strongly alkaline environment, and the concentrate from osmosis is neutral.

Using the averaged condensate (concentrate + condensate) and water, we obtain production water that meets all the requirements and does not adversely affect the AAC mixture.

For example, it is known that sulfate (SO4²⁻) slows down the slaking of lime during preparation of the aerated concrete mixture and fermentation of the cake. However in practice, the condensate additionally introduces into the composition about 50 grams of sulfate per 1 m³ of the mixture that does not give such an effect and plays a secondary role.

Summarising the facts above, it is to state that the concentrations of ingredients given in the table are insignificant and do not have any effect on the composition of the aerated concrete mixture.

The complete recycling of the averaged condensate results in:

- Water savings up to 35%

- Reduced heating expenditures

- Elimination of waste water fees

- Lower environmental impact

Return slurry circulation

The cutting lines of WKB Systems operate under „no-wastes“ approach. All cutting rests (cake sides, bottom and top layers) are forwarded with a conveyor to a return slurry tank to be reused in the production process.

Based on its impact on the technological process, the return slurry can be seen as an additive of the crystalline seed group. The hydration products of the binders contained in the slurry are the centres of crystallisation of the hydrosilicate binder.

The usage of return slurry in the AAC mixture contributes to an increase in the plastic strength of the cake (faster pore building process) before autoclaving. Furthermore, it improves the sedimentation stability and the quality of autoclaved aerated concrete products.

The return slurry contains CaO, and it should be taken into account while defining the composition of the AAC mixture. It results in optimised consumption of binders in the recipe. The average consumption of return slurry in production lines by WKB Systems is 17-20% by weight of solids.

Hard waste free AAC production

Because of the nature of some raw material mixtures, the aerated concrete blocks tend to stick to each other during autoclaving process. This can often create a significant amount of hard wastes (or so-called white wastes).

The engineers of WKB Systems developed a Green Cake Separating Machine (GSM) in order to prevent this phenomenon. The state-of-the-art facility is used after the cake cutting process but before autoclaving. During separating process, complete rows of AAC blocks are moved from each other so small gaps arise between them. The GSM is suitable for all AAC formats and can be tailored to a customer AAC cake size. Mixing of formats inside one AAC cake is also possible. Thanks to GSM application, the production wastes are considerably reduced (< 1%) alongside with a significant rise in production output.

On the other hand, the separating process brings a vast improvement in the quality of AAC blocks. The steam has no hold-ups and can easily spread between single rows and penetrate inside AAC blocks. This leads to better physical and chemical properties of AAC products.

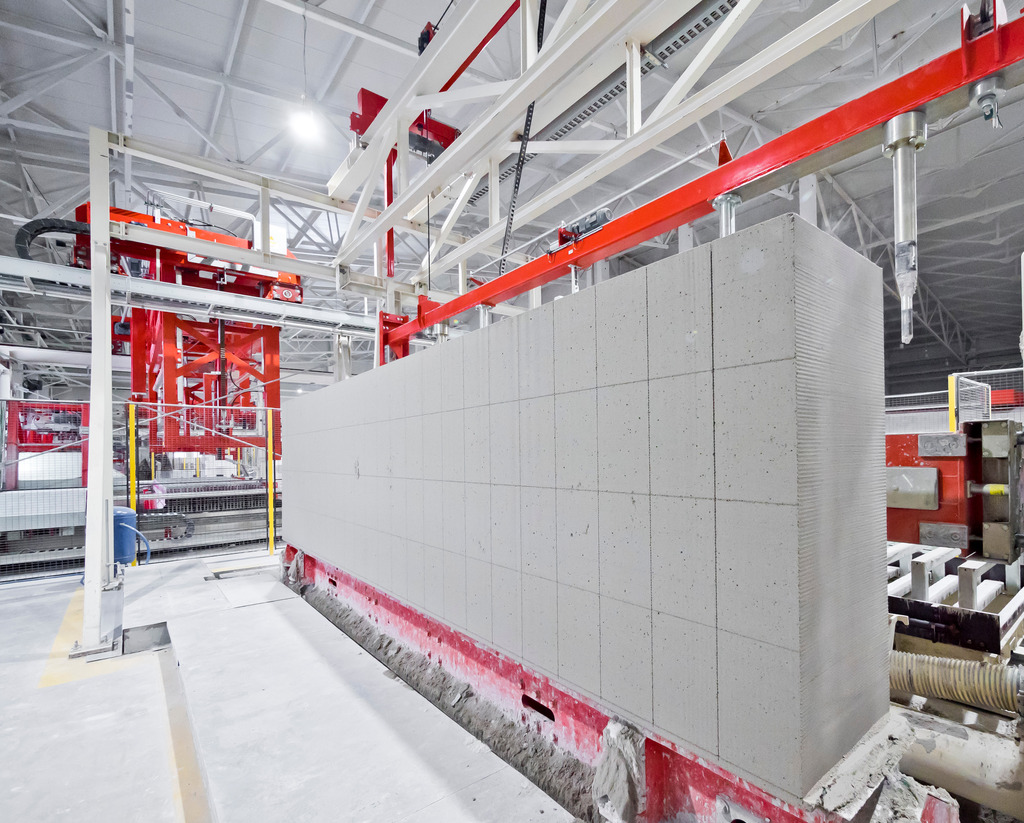

Closed manufacturing process

Nowadays AAC production technology by WKB Systems can be identified as a closed production, i.e. the possibility of wastes recycling is generated directly during manufacturing process. The main achievement is the waste-free and environment-friendly production of autoclaved aerated concrete.

WKB Systems also has on offer customised resource-saving solutions for plant modernisations. Based on the latest engineering developments, the specialists work out innovative concepts to improve production process indicators in order to achieve sustainable manufacturing.