Production Technology

Hefei Sunrise Aluminium Pigments Co., Ltd., Shuangfeng Development Zone, Hefei, Anhui, China

The effect of aluminum powder on the performance characteristics of AAC

Loading...A previous article published in AAC Worldwide 1/2022 discussed the effect of aluminum powder on the pore structure of AAC. The current article presents an overview on the various ways in which the pore structure in turn affects the performance characteristics of AAC members and products.

How does the pore structure of AAC influence its performance?

Effect of the pore structure on the strength of AAC

The porosity and pore size distribution of AAC directly affects the strength of the material. AAC with ideal properties has a high porosity, small pore sizes, spherical pore shapes and high strength. However, in the actual production, pore connectivity may result in non-spherical pore shapes, which negatively affects strength and other properties. Further, for different hydration products, even if the porosity is the same, the strength may be very different. With the same porosity, the strength increases with a decreasing pore size.

Effect of the pore structure on water absorption of AAC

The porous nature of AAC facilitates a continuous moisture exchange with the surrounding environment. Together with water, corrosive substances can enter the interior of the concrete, which has an adverse effect on the performance of AAC. The water absorption capacity of AAC is directly related to the pore structure. There are three transport modes of liquids in AAC: diffusion in the saturated pore solution, capillary adsorption, and permeation under a pressure gradient. When the material is in an unsaturated state, capillary suction plays a leading role in water transport. However, when the capillary adsorbed water reaches the saturation state, the air pore network becomes the transmission channel for water, and water is transmitted in the pore network under the actions of pressure and gravity. The smaller the pores and the higher the number of pores, the more uniform the structure of AAC products and the better the water seepage resistance.

Effect of the pore structure on drying shrinkage of AAC

AAC has the characteristics of high porosity and large specific surface area. The material can easily store a large amount of adsorbed water, and it can also easily lose adsorbed water and thus experience drying shrinkage. There are many open pores on the surface of AAC. When in contact with water, the voids on the surface are saturated with water. With the further diffusion of water, more capillary channels are filled with water. In response to environmental influences and temperature changes, the adsorbed water content may decrease, which decreases the volume of the material and causes drying shrinkage, possible consequences of which may relate to poor adhesion of AAC and the cracking of wall joints. When the relative humidity is greater than 43%, the drying shrinkage of AAC is caused by the loss of adsorbed water and condensed water, and the drying shrinkage value is determined by the amount and size of pore capillaries. The smaller the pore diameter, the lower the drying shrinkage value and the better the drying shrinkage resistance.

Effect of the pore structure on thermal conductivity of AAC

The thermal conductivity of materials is affected by porosity, apparent density, humidity, temperature, and air flow direction. AAC is characterized by low thermal conductivity due to its high porosity. Usually, after water enters the pores, water diffuses in the pores and acts as a heat conduction medium, increasing the thermal conductivity of the material. However, for AAC, closed and isolated pores are dominant, which reduces the diffusion of water. Therefore, the appropriate pore structure will enable AAC to obtain good thermal insulation performance. Studies have shown that the smaller the pore size, the higher the number of pores and the more uniform the structure, the smaller the diffusion coefficient of water and the smaller the thermal conductivity.

Effect of the pore structure on durability of AAC

The main hydration product of AAC is tobermorite, which has better durability compared to conventional concrete. However, because tobermorite is porous, external liquids and gases can enter with relative ease, which can have an adverse impact on durability. The durability of AAC with regards to frost resistance and carbonation is uniform, which is closely related to its pore structure. The porosity of AAC is beneficial to its frost resistance. When the temperature of the AAC surface drops below zero degrees Celsius, the water on the surface freezes. A portion of the frozen water is pressed into the pores, which alleviates the frost damage to the cementitious matrix.

In addition, AAC can easily come into contact with carbon dioxide in the air, resulting in carbonation. Results show that with the increase of the number of pores, the porosity of the system increases, and the degree of carbonation increases. The strength of AAC is slightly improved after natural carbonation, which also improves the durability.

Considering the influence of pore structure on various properties of AAC, it can be seen that the smaller the pore diameter of AAC, the higher the number of pores and the higher the porosity. If the pore structure is more uniform, the various properties of AAC will improve.

Factors affecting the structure of air pores in AAC

The raw materials and their ratio, the nature of the aluminum powder, and the production process parameters of AAC directly affect the pore structure of AAC. The calcium to silicon ratio is usually controlled within an appropriate range. An appropriate calcium to silicon ratio improves the strength at early ages, which can reduce the damage caused by early stresses and make the pore structure more stable. The control of the water to solid ratio is also very important in the production. When the water to solid ratio is relatively low, the thickening speed of the slurry is accelerated, resulting in suffocation, insufficient gas generation and prevention of a uniform pore structure. When the water to solid ratio is relatively high, the slurry has a large fluidity, the viscosity is low, the gas generation speed is accelerated, the pore structure is poor, and in serious cases the mold may collapse.

Aluminum powder is a commonly used gassing agent in AAC production. The pores of AAC are mainly produced by the chemical reaction of aluminum powder in an alkaline environment. The gas forms bubbles under the action of pressure to expand the slurry. The pores produced affect the performance of AAC. In the actual production of AAC, the calcium to silicon ratio is usually controlled within a certain range. To adjust the pore structure of AAC, the water to solid ratio needs to be adjusted and the correct aluminum powder needs to be selected. Therefore, the control variable method is adopted to control other conditions in the production and change the type of aluminum powder to test its gas generation efficiency and the gas generation characteristics of the final product.

Experimental investigation, Test 1

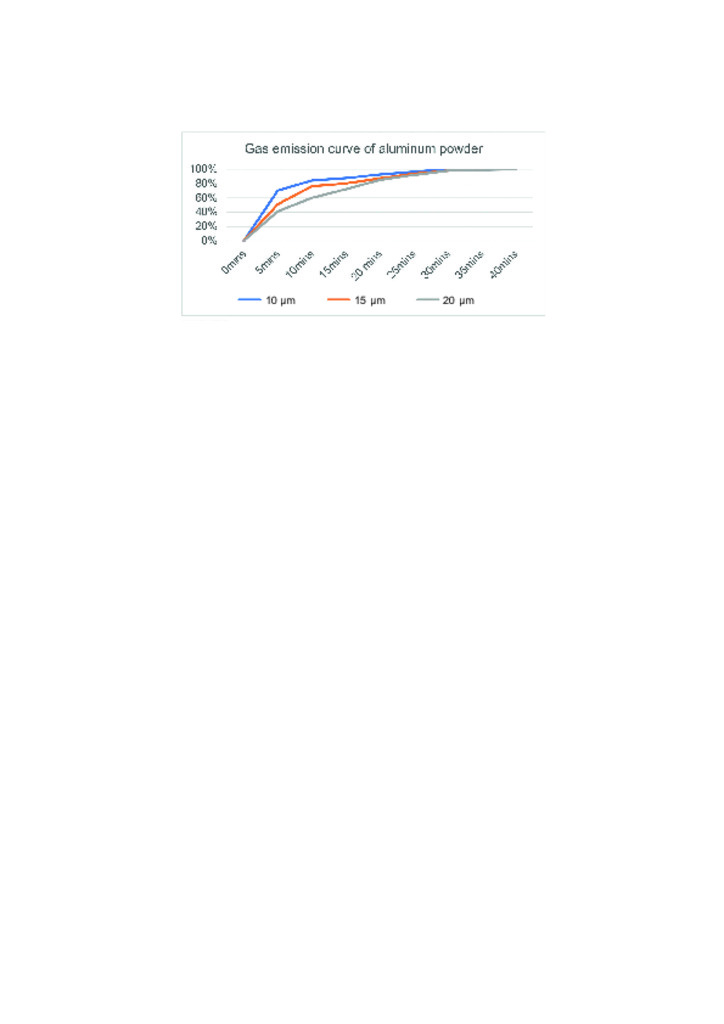

Taking sand aeration as an example, aluminum powders with different particle sizes of 10 μm, 15 μm and 20 μm were tested with a slurry water to solid ratio of 0.64, a slurry fineness of 20% (passing the 200-mesh sieve), a slurry specific gravity of 1.58, a calcium to silicon ratio of 0.52 and a pouring temperature of 46 ℃. The gas generation of aluminum powder with different particle sizes was tested under this condition. The gas generation curves are shown in Figure 1. It can be seen from the figure that the 10 μm aluminum powder gasses rapidly in the first 5 minutes. Within 5 - 10 minutes, 15 μm aluminum powder gasses rapidly, within 10 - 30 minutes, 20 μm aluminum powder produces gas quickly, and after 10 minutes, the gas evolution curve of 10 μm aluminum powder tends to be gentler, compared to that of the other two aluminum powders.

The comparison of pore size, bulk density and strength of the finished products made with the three kinds of aluminum powder is shown in Table 1.

Table 1: Comparison of porosity, bulk density and strength of finished products made with different aluminum powders under the same process conditions.

Aluminum powder type | Air pore average diameter (mm) | Dry bulk density (kg/m3) | Dry strength (MPa) |

10 μm | 0.3 | 545 | 4.5 |

15 μm | 0.5 | 553 | 4.1 |

20 μm | 0.8 | 562 | 3.9 |

Experimental investigation, Test 2

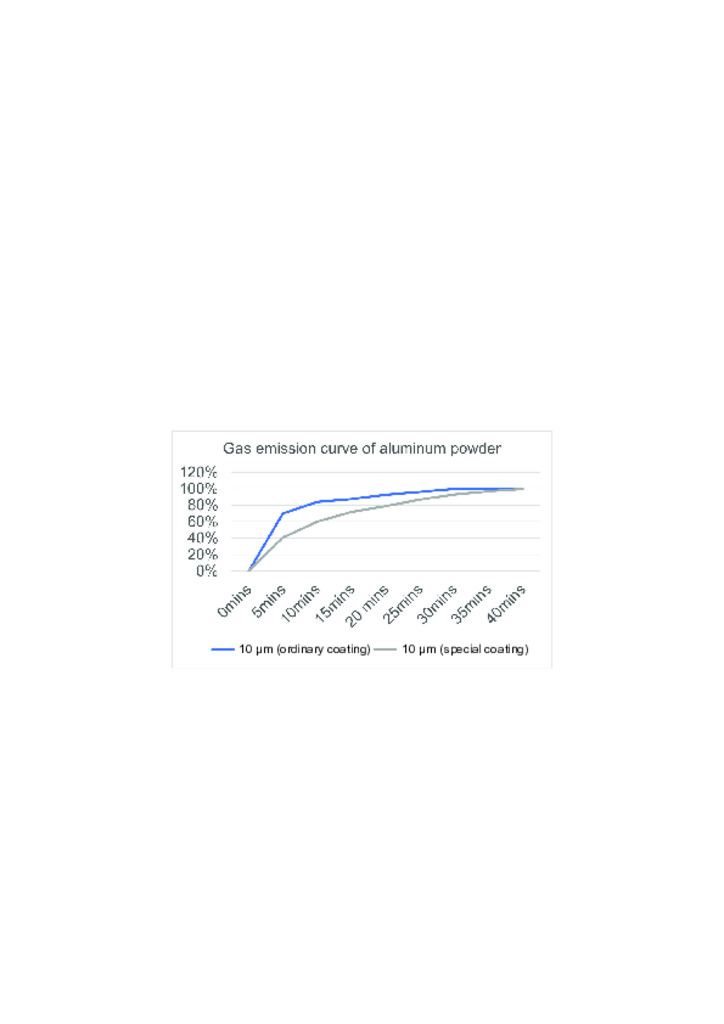

Again taking sand aeration as an example, two different aluminum powders of 10 μm (special coating) and 10 μm (ordinary coating) were tested with a slurry water to solid ratio of 0.64, a slurry fineness of 20% (passing the 200-mesh screen), a slurry specific gravity of 1.58, a calcium to silicon ratio of 0.52 and a pouring temperature of 46 ℃. The gas generation of different aluminum powders was tested under this condition and the gas generation curves are shown in Figure 3. According to the gas evolution curves, it can be seen that the gas evolution rate of aluminum powder with special coating treatment decreases significantly in the first five minutes, the whole gas evolution process tends to be gentle, and the gas evolution rate is uniform.

Comparing the size, bulk density and strength of the finished products made of the two kinds of aluminum powder, it can be seen that the final strength of the samples made with aluminum powder with a special coating treatment is higher, as shown in Table 2.

Table 2: Comparison of porosity, bulk density and strength of finished products made with different aluminum powders, using the same process conditions.

Aluminum powder type | Air pore average diameter (mm) | Dry bulk density(kg/m3)

| Dry strength (MPa)

|

10 μm (ordinary coating) | 0.3 | 545 | 4.6 |

10 μm (special coating ) | 0.2 | 558 | 5.1 |

Summary and conclusions

To summarize, under the same process conditions, aluminum powders with different particle sizes and different surface coating treatments will make the gas evolution curve of AAC products develop differently, which has an important impact on the pore structure. AAC blocks and panels made of aluminum powder with finer particle size will have denser pores, smaller pore sizes, a more uniform arrangement and distribution of pores, and less perforation. The excellent performance of this pore structure greatly improves the strength of AAC finished products.

With the continuous shortage of resources, the demand for high-precision blocks and panels with low bulk density and high strength has increasingly grown and will continue to do so in future, which puts forward higher requirements for the performance of aluminum powders in the gas generation process. In order to better comply with the developments of the industry, Anhui Sunrise Group S-Series and E-Series aerated aluminum powders were developed. Anhui Sunrise Group is a large manufacturer specializing in the production of aluminum pigment and spherical aluminum powder. It has become the industry leader in these two fields in China. With more than 20 years of experience in aluminum surface coating treatment, the self-developed S-Series and E-Series aerated aluminum powders have since their launch won unanimous praise from customers. At present, the superior performance has been successfully verified by more than 200 customers in China and abroad.

In today's world, the global energy crisis is becoming more and more serious. Producers have been contemplating solutions for better energy conservation in the manufacturing processes in the construction industry. In addition, energy conservation properties of the buildings themselves have become a problem of concern. The autoclaved aerated concrete industry should continuously develop and improve, in line with the goals of energy-saving and resource-saving. Upstream and downstream enterprises in the AAC industry should shoulder a sense of mission and work together to make the world a better place.

Hinweis Company Channel