Production Technology

Pmx Labs sp. z o.o., 60-758 Poznan, Poland

The importance of structured data collection in AAC plants

Loading...It is a challenge to obtain consistent results in production considering the often-varying quality of raw materials and the risk of machine malfunctions. On top of this come the needs related to changing raw material suppliers, the calibration of new machines, or the implementation of a requirement related to reducing the intake of water or energy in production by using an additive. These needs pose ever-present challenges for a quality/process manager. While dosing control systems allow setting parameters like dosage levels, the outcome of the same mix design can vary for multiple reasons. Therefore, data collection through the production process is key in understanding the current process conditions and ensuring the stability of production.

Complete production process control is a standard procedure performed by PMX Labs when testing and implementing the Poromix additives. It is conducted with a Quality- or Process Management team and focuses on measurements in various areas of a production plant. Once data is collected in a correct manner, it needs to be interpreted and conclusions can be implemented.

Crucial process areas and test metrics

Crucial process areas and test metrics include:

1. Casting area (mixer outlet)

o Viscosity test

o Temperature control

o Casting height

2. Rising area

o Temperature control

o Gassing time

o Rising height

3. Cutting area

o Temperature control

o Green hardness test

o Measuring the product height

o Visual inspection

4. After leaving the autoclave

o Visual inspection

o Sample collecting

Casting area

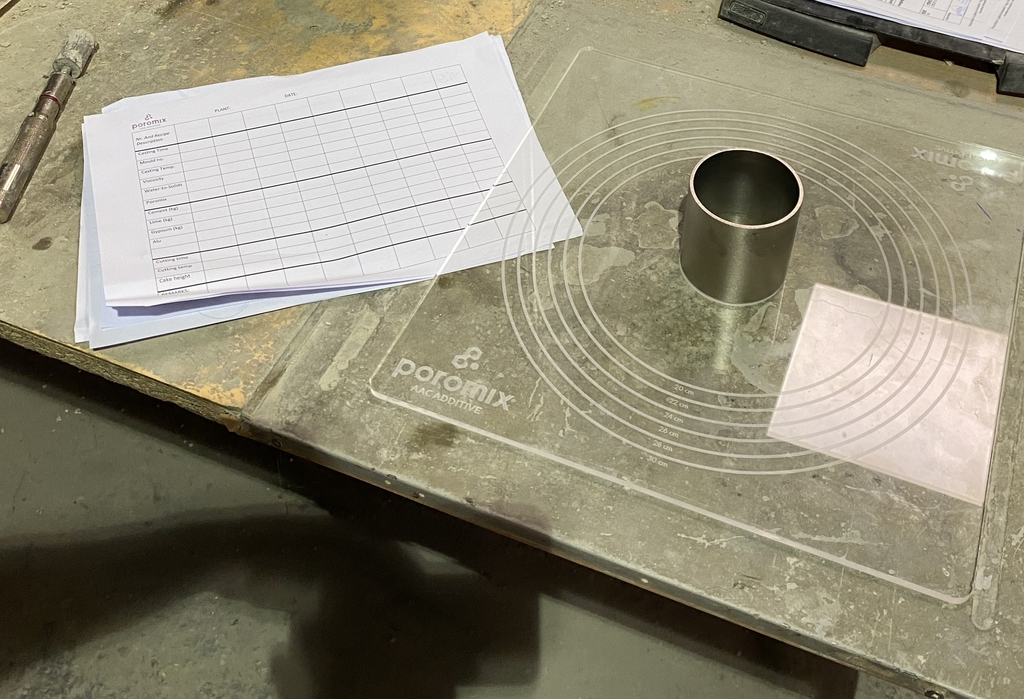

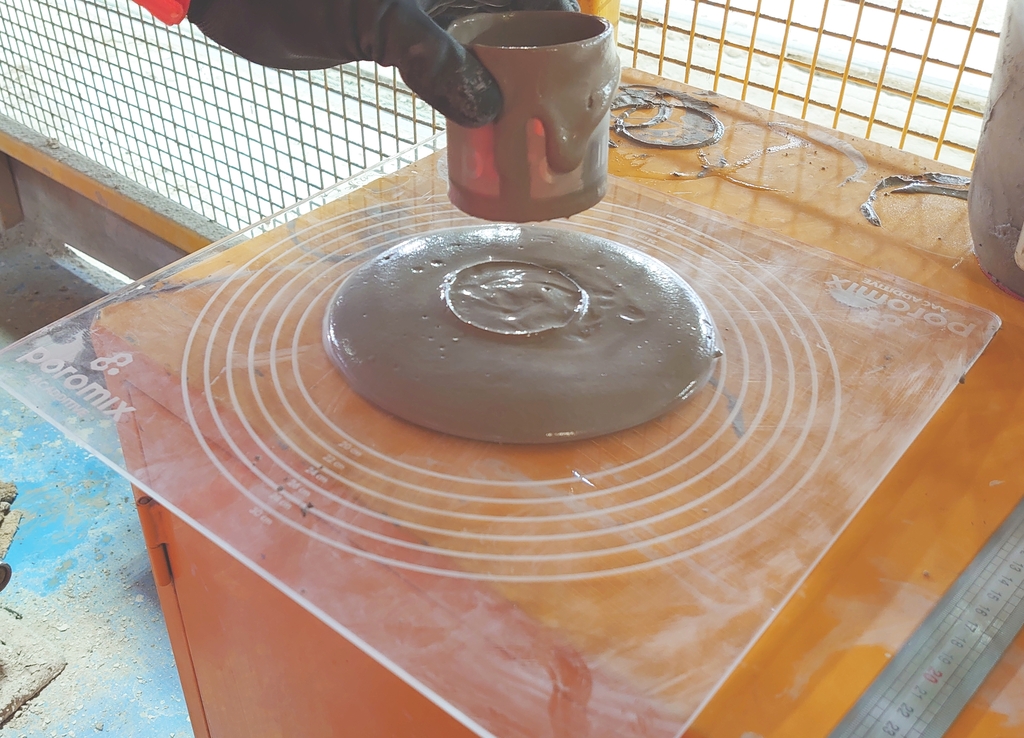

The viscosity test allows for quick flow analysis and fast reaction in case of mix design changes, the development of new mix designs, or periods of unstable raw material supply (Fig. 1-3). The procedure is to collect a sample always at the same time (for example once the mixer discharge stops) and measure its spread on a smooth and dry plate.

In some production plants, access to the mould area is restricted by safety fencing. However, a solution for this measurement can always be found without sacrificing safety (for example a collection bin on a longer stick or a gap in the fence just for sample collection).

The mixer area is also a good location for measuring the temperature of the freshly cast mix to occasionally confirm the functionality of the thermometers.

Rising area

The observations of the gassing process and cake temperature during rising give an insight into the progress of the chemical reactions in the cake (Fig. 4 and 5). AAC reactions are all about timing and they need to be aligned in time for an optimal outcome. Often at this stage, the effect of the viscosity test of each cake can be seen. Lower viscosities tend to produce higher cakes at the same aluminum dose. The influence of water on the temperature can be directly noticed here as well. If a mix recipe with less water is attempted, the temperature reading will be higher.

Cutting line

This is a standard procedure in AAC factories to check the hardness of the cake, ensuring the right conditions for the cutting machine. Hardness is measured with dedicated penetrometers that PMX Labs supplies as well (Fig. 6). There is no universal correct value of hardness, as each plant has its own requirements and conditions. What is universal, is that the same mix composition should be generating the same hardness at the same time, to support the stability of production. If the hardness increases or decreases, a reason needs to be identified, as it can lead to a loss of cakes.

It is good practice to measure temperature and height as well as to control repeatability of the process within a day, a week and a month. It is important to do measurements in a standardized non-random location, as depending on the measuring spot, the readings can be different (for example, the area near the mould wall always has a lower temperature compared to the middle of the mould). As parameters change in time, it is also important to note the time of measurement so that the information can be interpreted with full understanding.

After autoclaving

Samples for laboratory testing are collected at this stage so that strength and density can be determined. One method to reduce the variance in quality results is to collect blocks from the same area in the cake. The heat distribution differs within the cake; therefore, it is normal to observe a variance in strength results across a single cake.

Once the white cake leaves the autoclave it is important to look for any cracks or problems with quality (Fig. 8). The faster a problem can be noticed and diagnosed, the faster it can be resolved. Damage to blocks may be related to machine handling or operators’ mistakes. Other causes may be associated with the mix recipe and production processes, which need to be closely monitored.

In advanced AAC plants, a classification of quality problems is introduced, so that problems can be minimized or avoided based on their causes.

Conclusion

Production process control requires attention from quality management and operators, but the importance of the information it provides cannot be overstated. Proper data collection and its interpretation enables crucial production decisions and facilitates process optimization. A high standard of quality management will lead to higher production stability, better product quality and, in the long-term, reduced production costs.

Besides delivering Poromix additives, PMX Labs can assist AAC plants with data collection procedures, interpretation of results and the derivation of practical lessons for optimization.