Production Technology

Aircrete Europe, 7575 ED Oldenzaal, The Netherlands

Xella engages Aircrete Europe to implement large quality and reliability improvement project in the Netherlands

Loading...

With an increasing demand for AAC products, particularly for the super smooth partition panels, process reliability has never been more important, which was also a major consideration for the decision to upgrade the first section of the cutting line with the new generation Aircrete Cross Cutter. Besides an increased reliability, the new cross cutter also ensures a higher product quality and reduced energy consumption, thereby hitting the ground running for Xella in 2022.

Project background

As part of continuous drive to improve the process and product quality, Xella decided in 2021 to upgrade the first section of its cutting line with a replacement of the cross cutter (used for the cut of the AAC product in the longitudinal direction, meaning block height or panel length). This upgrade increases the quality of the cut product, reduces wire breakage (leading to production interruptions, production capacity loss and waste reduction) and reduces energy consumption. The cross cutter of the cutting line is not a standalone part of equipment, but an integral part of the overall cutting line. This makes an upgrade more challenging from an engineering point of view to ensure the upgrade would continue to interact smoothly with the existing electrical control and safety circuits. Also from installation point of view, these types of projects are more challenging. As the cutting line is a fundamental part of the factory and the production process, the required downtime for installation would have to be minimized as much as possible to avoid excessive production loss.

Technical description and advantages

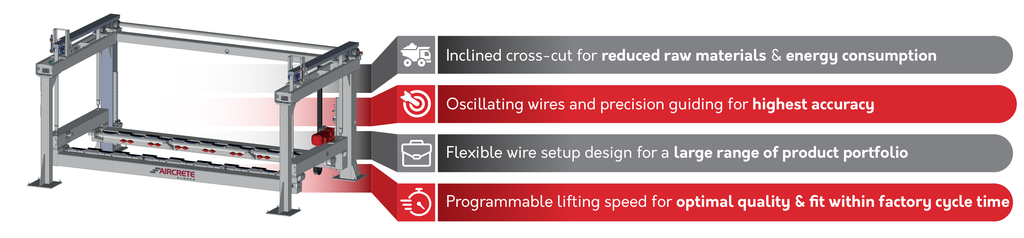

The latest design of the Aircrete Cross Cutter ensures higher cut precision whereby TLMB (Thin Layer Mortar category B) standards can be easily met. The cross cutter is characterized by an inclined frame with oscillating wires. By creating an inclined crosscut, the wires leave the cake at an angle, minimizing the sling effect and damage to the cake caused by it. This results in an optimal top crust removal process.

Another beneficial side effect is that the thickness of the top crust can also be reduced. This allows for less raw materials consumption for casting and less return slurry during the production process, and therefore, less energy consumption. Furthermore, with the option of a variable and programmable lifting speed of the frame, the speed of the wires at the end of the crosscut cycle (i.e., when the wires leave the cake) can be reduced, which minimizes the top crust damage without compromising cycle times. Finally, with the use of A-quality brands and components, the quality, reliability, and lifetime of the equipment are ensured as well.

The Aircrete Cross Cutter allows for large flexibility when it comes to product dimensions in Xella’s product portfolio. The wires of the cross cutter can be positioned on any position from 0 to 6 meters, with increments as short as 5mm (Fig. 2). All crosscut wires oscillate back and forth, and the wire tensioners are designed in a way that no more than two consecutive wires move in the same direction, neutralizing lateral forces and avoiding the cake to ‘rock’. The wire oscillation ‘stroke’ is adjustable, and the wires oscillate within the rigid crosscut frame, where two reciprocating moving cutting shafts support the alternate wires. The wires are held by air-tensioned holders on precision grooved segments to ensure optimal accuracy of the crosscut (i.e. height of the block or the length of the panel) (Fig. 3).

Project preparation and implementation

Being the global expert of flat-cake cutting technology, Aircrete Europe has great experience of designing complex modernization projects, which need to be implemented with minimized downtimes. The engineering of this important project, for which Aircrete Europe was engaged as the technology partner, started in the summer of 2021. During the engineering and manufacturing of the cross cutter, Xella and Aircrete teams have worked intensively together to prepare thoroughly for the installation and commissioning phases. Clear scope divisions and responsibilities were defined, and a detailed installation preparation plan was worked out by both teams. The installation was realized in the winter of 2021/2022 (Fig. 4). Due to comprehensive planning and cooperation between the teams, the actual dismantling of the old equipment and installation of the new Aircrete Cross Cutter was realized ahead of the schedule, reducing the downtime of 14 days with multiple days.

Peter van Doorn, plant manager at Xella Vuren, commented: “We engaged Aircrete Europe for this project as they are known for being the go-to party for these type of challenging projects with custom made solutions. Their reputation with implementing complex modernization projects in combination with their design and thorough planning made us decide to engage them as our technology partner for this project. The fact that they beat their own installation planning and reduced the actual factory downtime with multiple days is a big bonus and I am very happy about that.”

About Xella

Xella Netherlands is a part of the Xella Group, one of the world’s largest producers of autoclaved aerated concrete and the only producer of AAC products in the Netherlands with three factories. Xella distinguishes itself in the building world as a specialist of supplying high-quality building materials for both the residential and non-residential construction. Within its AAC segment, Xella produces AAC panels and blocks under the Hebel, Ytong and Multipor brands.

Hinweis Company Channel

Check out the advantages of the Aircrete Inclined Cross Cutter in this video