Projects

The Budget House

A family dream made real with Ytong

Loading...

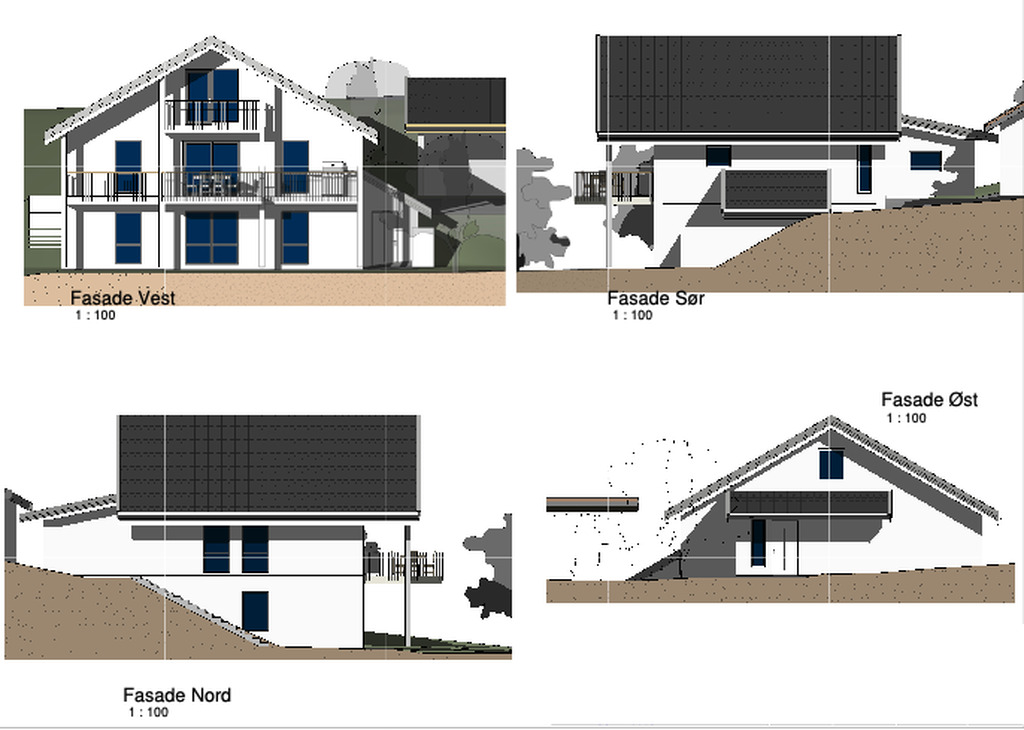

The housing project is situated in Granli, Norway, dubbed “Budsjetthuset” (English translation: Budget House), and is the family's first building project with its own Instagram account. Xella Norway has supplied Ytong AAC blocks, both in outer walls, internal load-bearing walls, and panels floor structures, which have laid an important foundation for the family home.

“We were aware that building a house could put pressure on family relationships, so we had many discussions before taking the plunge when we agreed that there is a special soul in something the family has built together. The dream has been to create a family home without ending up with too much debt. With a journeyman's certificate in surface treatment and a great dedication to acquiring as much knowledge as possible to make the most economical choices, we decided that this was realistic”, says Ljungquist, continuing:

“A crucial factor was that we found a building material that allowed us to do much of the work ourselves. By choosing Ytong autoclaved aerated concrete, we could focus on the larger tasks and get started quickly with surface treatment. Ytong allowed for easy assembly without the use of mortar or the need for extra layers like vapor barriers or plasterboard, while still meeting all the technical building requirements. It was a cost-effective material that saved us a lot of time.”

Building in a difficult time

In addition to a building project, both parents have been working full-time, as well as part-time jobs on weekends in the field of mental health and as a surveyor.

“Our goal with Budget House was to minimize debt as much as possible. We have achieved this by working a lot alongside the building project, personal effort in the building process, and choosing economically smart materials, in addition to good help from >Grandpa Tom<," says Ljungquist.

The last three years have been an internationally turbulent time that has greatly affected the construction industry. Here, AAC proved to be a wise choice.

“We managed to choose a material that was not affected by market turmoil. While the price of steel and wood skyrocketed, the supply of Ytong blocks we had received from Xella Norway remained stable. This was of great importance when other expenses and challenges, such as a lack of available craftsmen due to layoffs, arose”, reflects Ljungquist.

100% Trim-Free

As operations manager at Ljungquist AS, Ljungquist is familiar with housing trends, and one thing he wanted to achieve himself was a truly trim-free home.

“We wanted to prove that it was actually possible to have a 100% trim-free house. This was achieved through knowledge, as well as aesthetic solutions with plastering, painting, and flooring. By avoiding trim, we have also saved costs associated with this building material. It's a bit amusing to think about”, elaborates Ljungquist.

A crazy learning curve

No one in the family had experience with AAC, but that was not a problem.

“There was a crazy learning curve with Ytong – the first floor took three months to build, but with the accumulated knowledge, we managed to erect the next floor in just three days! We also plan to use Ytong for the future garage and annex, with Ytong roofs in addition to walls. It is safe to say that we are very satisfied with the result - where both children have handprints on the ring wall that the house stands on!” explains Ljungquist.

In conclusion, Ljungquist has good advice for those considering building their dream home:

“Preparation is key: Read, discuss thoroughly, and explore all possibilities before starting. By listing everything that annoys you in everyday life, you can effectively discuss and be well-prepared when the time comes. And as in life in general - you pull the load together and help each other towards the goal.”