Projects

The versatility of autoclaved aerated concrete

Building a Tibetan Stupa in AAC Block

Loading...

Michael Baron: College of San Mateo, California & Western Washington University, Washington. Pietrasanta, Italy: Studied architecture, marble sculpture, bronze casting, mold making, pantograph & plaster enlarging work. Director: Lindisfarne Institute - Kairos Architectural & Geometry Lecture series, foreman of building construction. Designer/builder: use of alternative building materials including, AAC, CLC, SIPS, timberfarme, adobe, ICF, rastra. Currently, Director of Aerblock Enterprises, LLC. Distributor of Hebel AAC. www.aerblock.com

The traditional Stupa stems back to ancient times. It evolved from a simple earthen mound into a complex religious monument to honor the living, while incorporating various symbolic shapes to represent the body and teachings of the Buddha.

Before the project could start however, a Feng Shui practitioner was summoned to determine the best location for the Stupa and a series of Tibetan Buddhist rituals were performed to consecrate the site.

Only then could the plan of the structure be laid out, followed by the casting of a sturdy concrete foundation. Now it was time for our team to step up and initiate the AAC work, starting with a leveling base course of 10 cm AAC-4 block.

After the base course, we began constructing the cubic pedestal and stepped terraces of the building. We were to learn, as we proceeded with the work, that each step and level of the Stupa is charged with Buddhist wisdom and symbolic significance.

Upon completion of the base plinth, whose form stepped in, then up and then out again, work stopped. Then a specific Buddhist ritual was performed to consecrate this particular phase of the monument, which represents the ‘Earth’ element. Various artifacts were to be permanently invested inside the core of the space and then the entire chamber was sealed up.

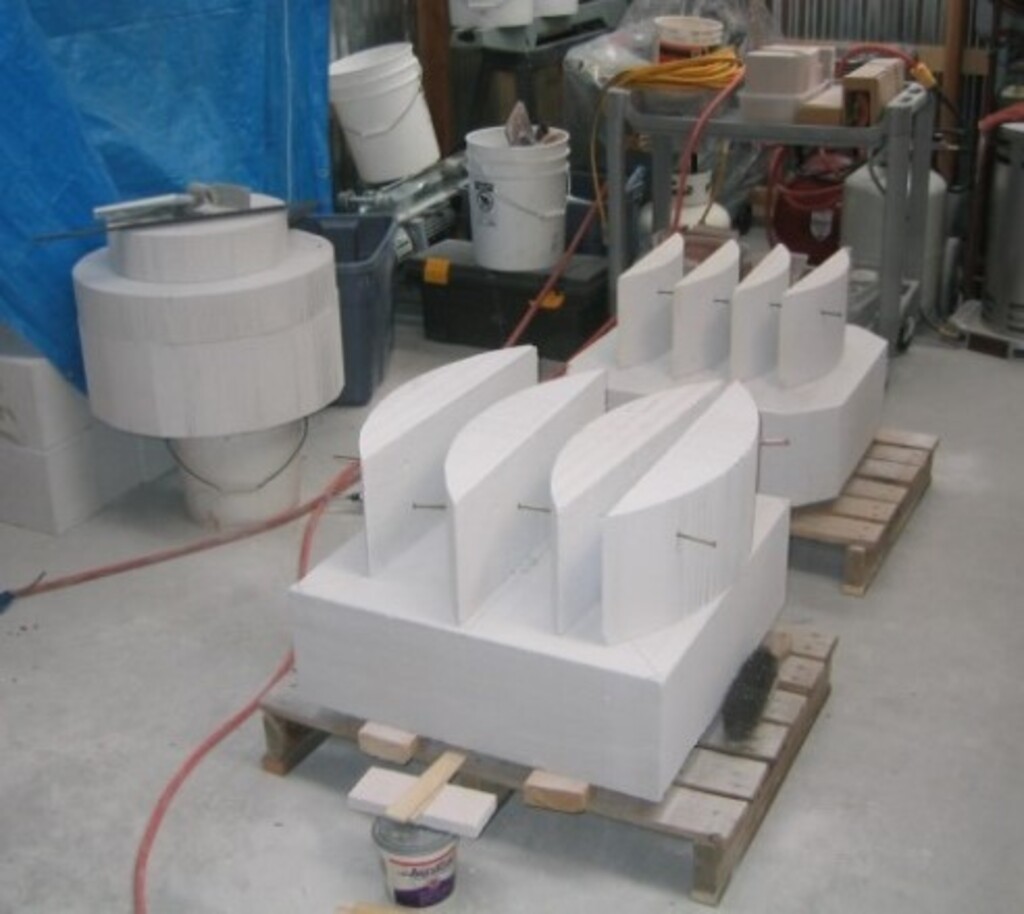

We then came to a point in the architecture where we had to construct a hemispheric feature called the ‘Bumpa’, representing the ‘Water’ element. This domical shape was laid out in rings on the ground and from multiple AAC wedge blocks. Thanks to our Lissmac band saw, which tiresly assisted us, we were able to cut complex angles and puzzel together the curved block parts to form the dome.

After fabricating a final small cubic transition element, the basic shell-body of the Stupa was complete. It took us about 8 weeks to construct the project up to this point, including setting the reinforcing steel and the grouting of each section.

The last structural feature was a tall 13-step cone or spire, representing the element of ‘Fire’. There were early discussions about making this piece in cast bronze, but that was ruled out because of cost. Plan-B was to build the cone out of AAC. This would prove to be a bit of a challenge as it involved the cutting of AAC jumbo blocks into various sizes, gluing them together and machining them into tapered discs. The milling operation was accomplished by converting a local potter’s wheel into an AAC lathe, and then routing in the angled profile and the 13 rings of the cone.

Having spent time in Italy years before, pursuing studies in bronze casting and marble sculpture, I had watched the lathe-machining of large marble column bases. Surely I thought, the milling of AAC would be easier than marble. Everything was going to plan until one disc, all of a sudden took on a bit of a wobble, and before I could shut down the motor, it took off across the studio, spinning and smashing everything in its way before finally coming to a stop. Having been spared being nearly crushed by this event, there was no doubt a Buddhist lesson in ‘balance’ I needed to learn.

The day came when the crane arrived for the setting of the completed ornamental crown of the Stupa. A number of prominent Tibetan Rinpoche’s came to observe the final assembly and placement, while we builders kept fingers crossed that everything would actually fit together as intended. The Umbrella element, representing ‘Wind’, along with the “Moon, Sun and Jewel’ elements, representing ‘Space’, were then interlocked, anchored to the top of the cone-spire and then hoisted up into the sky.

To our good fortune, all went well, and everything came together ‘like a glove’. As if to confirm our efforts, we were treated to a surprise reflection of beautiful prismatic colors that, to this day, emanates from the cut-glass crystal that tops the Stupa.