Science & Innovation

A look into the future

AI helps to increase workplace safety at the Xella Hrušovany plant

Loading...

"Sometimes the effort to address a seemingly unsolvable problem can lead us to the discovery of completely new possibilities. This is exactly what happened with the use of smart vision in our plant. When the technical assessment project started in 2021, I did not foresee where it would lead us in Hrušovany as a result," says Zdeněk Ovečka, Head of the Hrušovany plant near Brno.

At the plant in Hrušovany, health and safety have always been the highest priority and have for several years been subject to regular and systematic improvements. Despite these efforts, a technical audit indicated processes that were no longer satisfactory and needed to be improved. One of the points highlighted by the audit was the need to better secure outdoor areas where empty pallets are prepared for the packaging line and pallets with finished products are stored.

In the past, attempts were made to secure these areas with light barriers, which often failed due to flying insects, falling leaves, rain, and even strong sunlight. In addition, forklift drivers needed to enter the area on a regular basis and the subsequent process of re-establishing the barrier, which required them to exit the vehicle, significantly slowed down traffic. When the plant manager approached their regular service providers for a solution, the efforts were fruitless.

It wasn't until the Amper Trade Fair in Brno that a solution was finally identified. There the plant managers met the innovative young company Invanta, which specializes in using "smart vision" technology to ensure safety in industrial operations. Based on Xella’s immediate interest in the technology and since the company was also from Brno, a meeting at the production plant was arranged only two weeks later. After the site visit, Invanta proposed a solution that could be implemented with the support of Xella’s safety department. "For innovative projects like this one, I greatly appreciate the support of the production team. It is this cooperation that is the key to the success with which we realize our projects in Hrušovany", emphasizes Zdeněk Ovečka.

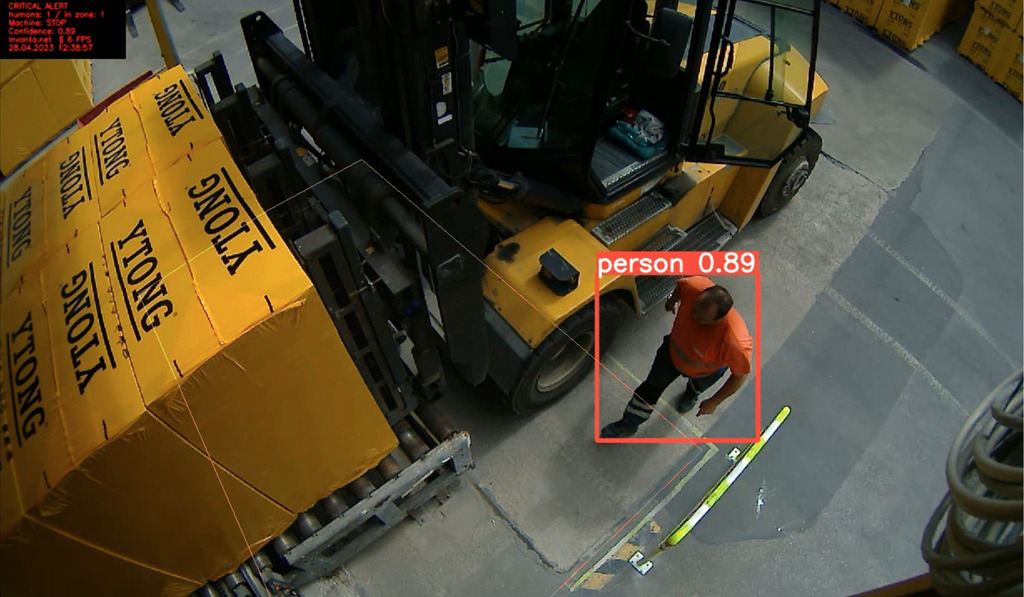

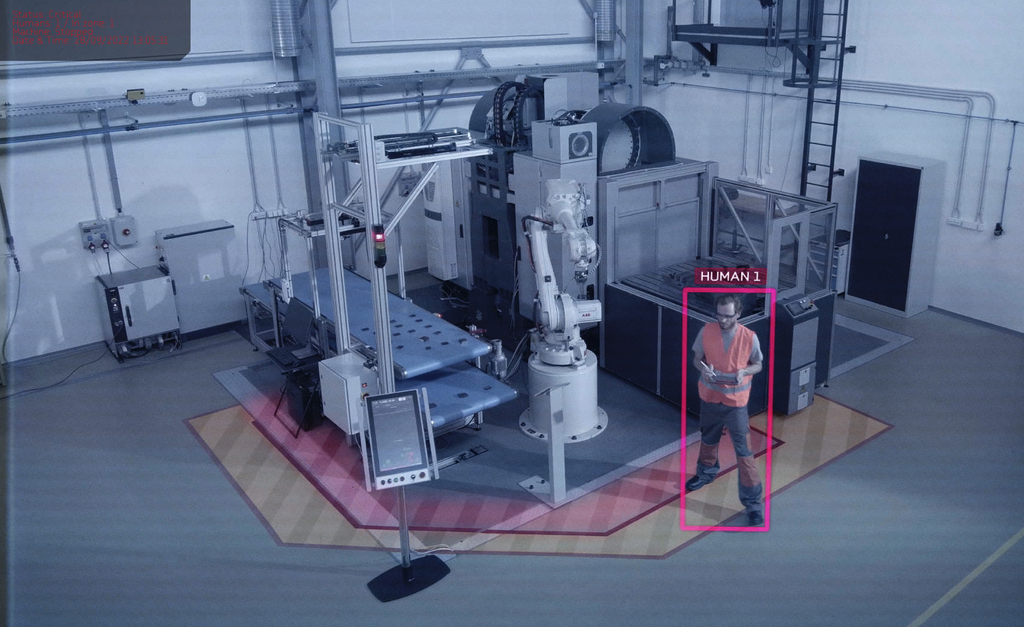

Invanta's solution is part of a new generation of industrial safety systems driven by artificial intelligence. Using "smart vision" technology, the system is able to identify potential hazards in real time and autonomously actively stop the machinery to prevent accidents. The system can detect a variety of potential hazards, including people or objects. Using machine learning, the system can also adapt and improve over time, becoming more accurate and effective at detecting potential hazards. This type of technology is rapidly advancing the field of industrial safety and Xella in Hrušovany is happy to be a part of it. The implementation in the plant is a pilot project with strictly defined and monitored framework conditions.

Invanta has developed a highly innovative solution based on machine vision and artificial intelligence that can bring a new level of industrial safety. This solution is able to prevent injuries or fatalities to workers by recognizing dangerous situations and reacting accordingly (e.g. stopping machinery completely). It is the vision of the company to make the industrial environment exceptionally safe for all workers.

Developed as an all-in-one box, the system contains everything that is needed for the fast video analysis, recognition of dangerous situations and fast reaction. The safety system consists of an interface between the processor and the control system of the guarded machine.

· Wide angle camera – the embedded camera ensures fast and clear video stream and perfect coverage.

· Computing unit – small and high-performing, optimized for AI functions and image processing.

· Artificial Intelligence – the neural network provides reliable real-time video analysis and image recognition.

The advantage over traditional solutions such as fencing or laser optical barriers is the ability to distinguish people or human body parts from the material being processed. This capability is a major competitive advantage. Other and equally important advantages include space saving, recognition of human presence not only at the boundaries but inside the entire area, elimination of human error and other extensions such as face recognition, fainting or fall detection, presence of personal protective equipment, etc.

Technology

The digital camera signal is fed to a specialized processor running a Neural Network (NN). The NN evaluates the monitored area in case a person is detected. The system works in two modes - when the yellow zone is violated, the machine is slowed down, and when the red zone is violated, the machine is stopped and thus a safe state is established.

Solution

As part of the project "Safety of the outdoor pallet areas of the packaging line with an artificial intelligence system", the workplace of the production plant of Xella CZ s.r.o. in Hrušovany u Brna was secured with the Invanta s.r.o. safety system.

After a technical audit, additional safety was deemed necessary for two outdoor areas. These included the pallet workplace, where the packaging line receives empty pallets, and the picking point, where pallets with finished products are removed. In the past, there had been attempts to secure these areas with light barriers, which often did not work due to the reasons mentioned earlier.

In both mentioned areas the system uses two sensors with cameras to monitor the pallet workplace and a defined surrounding area. The acquired image is processed through artificial intelligence-based software and recognizes human objects.

A protection zone is defined around this workplace. In the event that a person enters the zone, the AI system will transmit a signal via the PLC to the packing line control system and stop the movement of the packing line conveyor immediatelly.

The system does not react when the critical zone is disturbed by the forklift truck during the managing of pallets. However, it reacts immediatelly when a person is detected in the zone.

The workplace operates on a continuous basis and so does the safety system.