Science & Innovation

Waste utilization

Environmentally friendly material solutions in the technology of autoclaved aerated concrete

Loading...

Prof. Waldemar Pichór, is an employee of the Department of Building Materials Technology of the Faculty of Materials Science and Ceramics of the AGH University of Science and Technology in Krakow, Poland. His interests focus primarily on the technology of advanced building materials including smart materials, 3D concrete printing, and using the waste by-products from various processes in the building materials technology. He is the author of several dozen articles in major scientific journals in the world, over a dozen patents and protected technological solutions, as well as the author of a scientific monograph and co-author of several academic handbooks. pichor@agh.edu.pl

AAC is a material that is appreciated by users, because of its functional values. The favourable relationship between the operational properties, above all a very low value of the thermal conductivity coefficient in relation to other construction materials, with an acceptable strength allowing for free erection of walls, contribute to the willingness to reach for this solution. The lightest varieties of autoclaved aerated concrete have very favourable results in the material balance and the demand for process energy in relation to alternative materials, especially per cubic meter of the product. Minimizing the use of both process energy and the amount of raw materials used is one of the most frequently raised advantages in terms of the environment, in line with the general trends and assumptions of sustainable development, the Green Deal and the broadly understood reduction of CO2 emissions and environmental protection [1, 2]. Also, until recently, an often emphasized feature of the material produced in one of the variants of this technology was the fact that it is made of “pure” natural raw materials sand and lime, probably encourages clients to choose this material. This is a totally understandable action from the point of view of competitive advantage, however, we are slowly losing this comfort, and the use of natural resources, not only because of the environmental aspect, but because of the changing public perception, may no longer be seen in a positive light. From the point of view of the environmental effect, the high-energy process of grinding sand, and in particular the burning of lime, can be reduced by seeking material substitution, preferably by by-products from other technologies and processes. This technology has been going on for decades. The most popular solution is the use of fly ash from the power industry and the development of the so-called ash variants [3-5]. An overview of the current state of the art in autoclaved aerated concrete production can be found in the paper [6]. As an aside, it is worth mentioning that, by using ash as a raw material, it is possible to obtain AAC with better thermal insulation properties, in relation to the so-called sand variant. This, of course, is not the only example of using combustion by-products or post-process waste, as a component of the raw material mix. The partial replacement of traditional raw materials, also concerns the search for an alternative to a binder in the form of lime and a replacement for aluminum powder, used to foam the mass.

The impact of technology on the environment is a complex issue. Often, such an analysis is limited to the assessment of the impact of the production process itself, from the extraction of raw materials - including their necessary processing, especially important when using high-energy processes such as drying, burning, milling, the synthesis of the material itself, to the formation of the final product. More and more often, this analysis takes into account, in addition to the production phase, the product life cycle and, the more importantly, recycling after its end. In this context, the use of autoclaved, aerated concrete with a low thermal conductivity coefficient of less than 0.1 W/(m·K) is part of the strategy of reducing energy consumption by reducing the heat losses in the facilities used. It is worth mentioning that autoclaved, aerated concrete, as one of the few materials, allows the construction of walls, that meet the current high thermal insulating criteria, for buildings in a single-layer system [7]. Autoclaved aerated concrete can be successfully used for the construction of zero-energy, zero-emission, passive buildings and, regardless of what they will be called in the future, those with the best energy performance. The environmental impact after the life cycle of the material, is in the simplest variant the effect of safe storage, but a more attractive variant is a second chance for a new “life” of the material, i.e. material recycling. In this case, used products made of autoclaved aerated concrete, can also be seen as a valuable raw material for reuse in the production of various building materials or, after appropriate processing, as a completely new material, e.g., granules for agricultural use - fertilizer carrier or a substrate for hydroponic cultivation. Another example is the use of properly processed aerated, autoclaved concrete waste, with high porosity, as sorbents. This form of recycling, apart from the possibilities of the production plants themselves, is possible with the development of selective collection of construction waste. Effective implementation of this scenario, requires not only the development or modification of the existing infrastructure for collecting and sorting construction waste, but also legislative changes, e.g. excluding a separate subgroup of AAC aggregate, out of the group of recycled aggregates - Rc type, of course with the adaptation of the minimum quality requirements to its specifics.

AAC waste, regardless of where it is generated - production waste, selective collection of elements from demolition of buildings can be easily i.e. with little energy expenditure - processed into a product/material, with new properties. Grinding is most often used, and thanks to the porous microstructure and the resulting good grindability of the waste, the energy input in the grinding process is much lower, than for ash or sand. The obtained material, ground to the appropriate grain size, thanks to which its porosity is significantly reduced, can be used as a supplementary cementitious material for concrete.

The paper presents selected examples of the use of alternative raw materials, mainly by-products from other technologies, in manufacturing of autoclaved aerated concrete, as well as the issue of recycling of used AAC elements, from the demolition of buildings.

Examples of the use of by-products and waste from other technologies

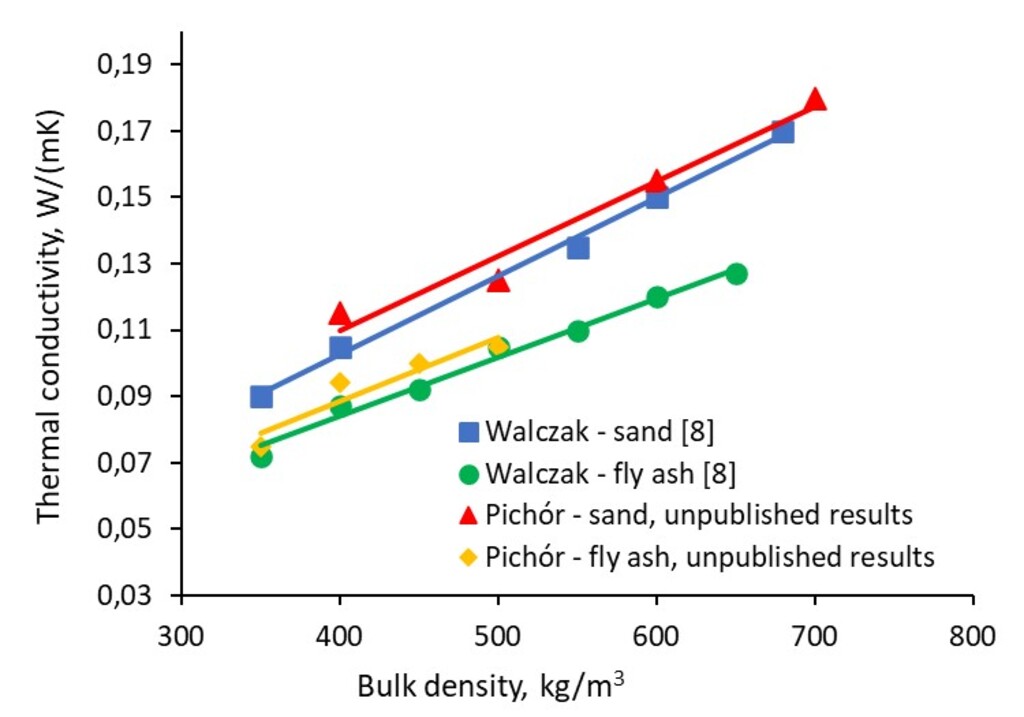

An well-recognized and used example of the use of combustion by-products is the application of fly ash from commercial power plants, as the silica carrier [4]. The use of the ashes has a long tradition, which is also related to the historical tradition of the location of AAC production plants near power plants and combined heat and power plants. This location had the great advantages, starting from the possibility of receiving high-pressure steam, the immediate vicinity of a large amount of ash, and also due to the well-developed technical infrastructure of the power plant. The issue of using fly ash is well documented in the literature. The properties of autoclaved, aerated concrete containing fly ash, are well known [4, 5, 8, 9]. It is also known that AAC made of fly ash is determined by a lower thermal conductivity coefficient compared to AAC based on quartz sand and having the similar volume density.

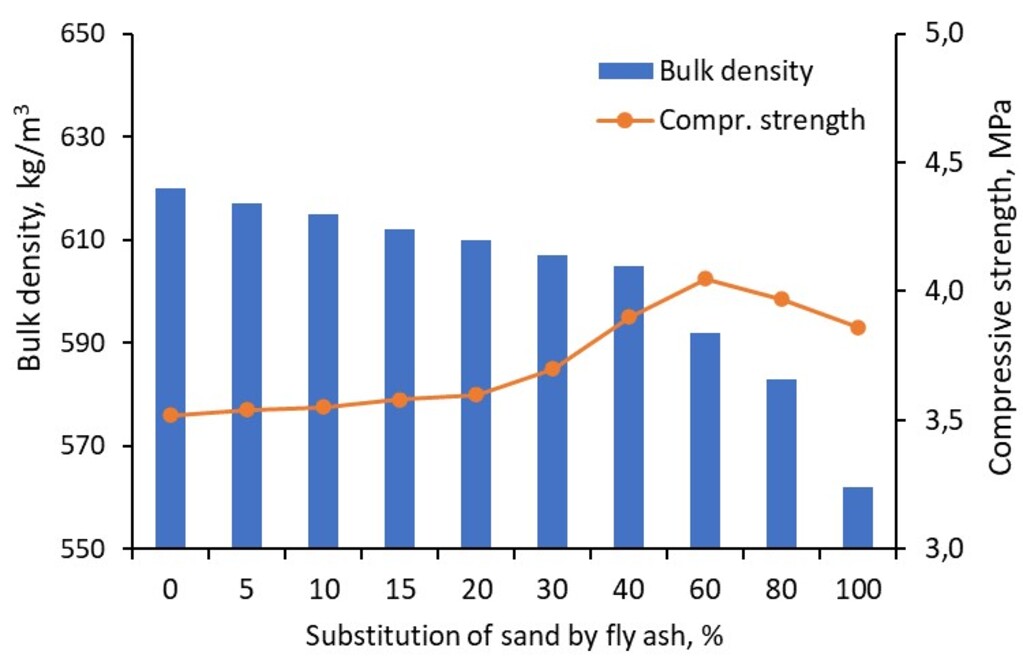

The value of the thermal conductivity coefficient is influenced by many factors, including, first of all, porosity and pore size distribution, but also the composition and properties of the solid phases. In the pores, convection is the main factor responsible for heat transport, so reducing the size of the pores is a beneficial treatment, reducing its value. The refinement of pores sizes depends of many factors: grain size distribution, mass homogenization, properties of aluminum powder and mass rising conditions. These are mainly technological factors. The solid phase, at least in macroscopic terms, is also defined by microporosity, mainly between the crystallites, and here also the convection plays minor, but noticeable role in the total heat transport. On the other hand, assuming a similar pore distribution in concrete produced with the fly ash in relation to sand, an important factor is the heat transport mechanism in hydration products principally by C-S-H, and, more importantly, unreacted grains of the silica source. And here the influence of the crystallinity of this material is noticeable, because the heat transport in the aluminosilicate amorphous phase of the ash grains is much smaller than in the case of crystalline quartz. In addition, some of the ash grains are defined by internal closed porosity, up to and including the form of microspheres, which additionally has a positive effect on the thermal conductivity coefficient. An additional factor may be the presence of aluminum ions, which promote the formation of tobermorite, and therefore increase the degree of quartz reaction [10, 11]. From the point of view of strength, the substitution of fly ash instead of quartz sand in the grinding process, results in a greater fineness of the components and therefore also in an increased reactivity of the silica source with calcium ions. The effect may be the increase of the AAC strength, however, one should be careful in generalizing this phenomenon, as this effect is often masked by the influence of many other factors. With the high degree of replacement, the effect of the difference in the strength of the unreacted micro-aggregate, in favor of sand is marked.

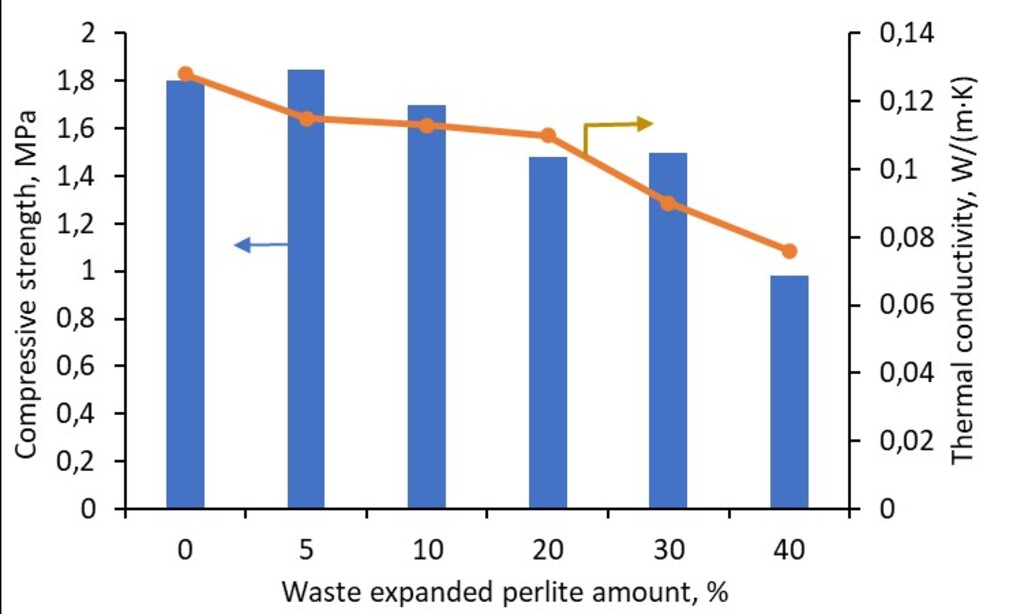

The situation in the raw materials market is constantly changing, in particular the availability of high-quality fly ash, which is widely used in the production of CEM II and CEM IV-VI cements. This tendency, due to the increasing share of supplementary cementitious materials in cement and also due to environmental considerations, will probably not change in the future. We are looking for other raw materials that are a source of silica, in AAC technology. An example is the use of waste, formed during production of expanded perlite [12]. The worldwide production of perlite exceeds 3 million tons. The amount of waste, dust with grain size below 200 μm is estimated to be approximately 5%-10%, depending on the construction of the fluidized bed furnace, in which the process is carried out [13]. Expanded perlite grains are composed of the amorphous aluminosilicate phase, containing about 70% SiO2, 10-15% Al2O3, and approximately 10% alkali expressed as CaO, K2O and Na2O oxides. It is a waste that is difficult to process and manage due to its low bulk density, and thus high dusting and high porosity. However, if it is a substitute for sand and is dosed to a wet mill in a moist form or even slurry, the problem of dusting ceases to be significant. In the grinding process, the expanded perlite grains easily grind into the form of single plates of expanded perlite, thanks to which this component has a much greater surface area, compared to co-ground quartz sand. This results in high reactivity of perlite with calcium ions.

Macroscopically, this effect is manifested by the possibility of obtaining a significant improvement in the thermal conductivity coefficient, while maintaining a similar strength level, up to 30% of quartz sand substitution. This is a very promising result, but the availability of perlite dust in a sufficient quantity, must be taken into account. There are no raw perlite rock deposits in Poland, and plants are looking for other solutions, for this waste developing.

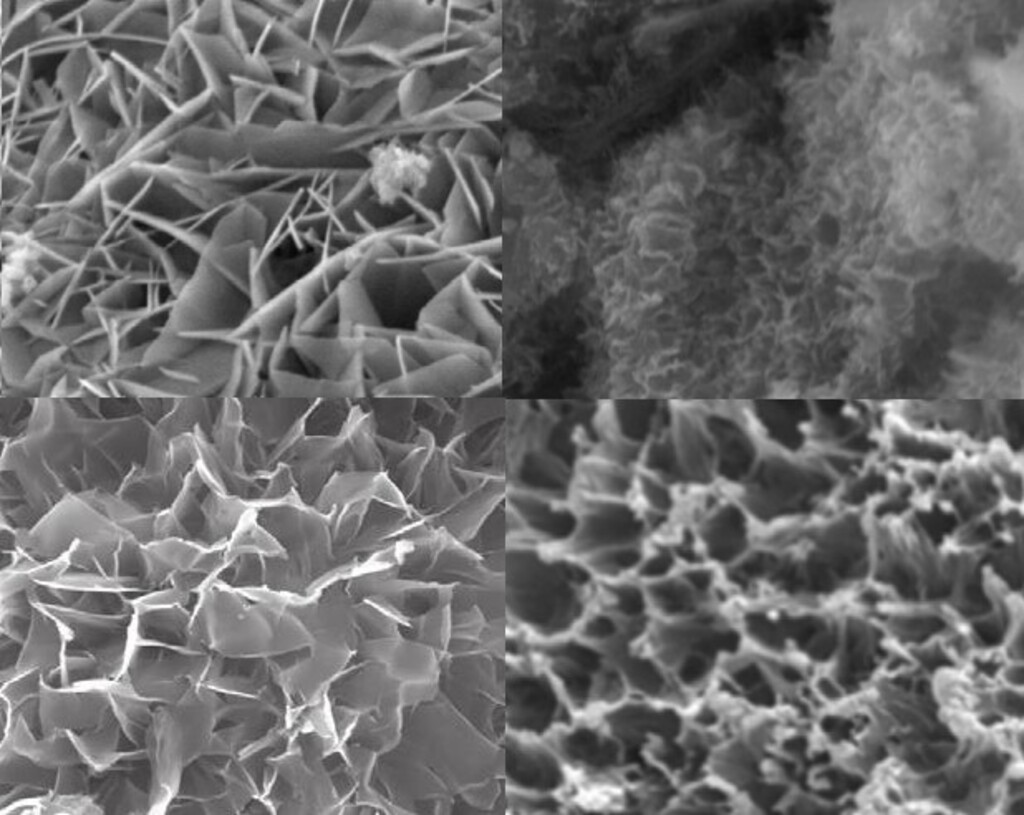

The use of various mineral additives affects the microstructure of the cellular concrete matrix. Most of the published works show very well-formed tobermorite crystals, but such agglomerations are not the average image of the microstructure. The clearly visible tobermorite peaks in the XRD patterns, are usually associated with products crystallizing on the inner surfaces of the pores, generated by hydrogen. A common form of mass microstructure is the fibrous or ribbon forms of the C-S-H phase, partially transformed into tobermorite. Scawtite was also observed in samples containing carbonate additives. In the study [14] an attempt was made to replace gypsum, with limestone meal in AAC. Although the aim of the authors was to replace gypsum due to the potential possibility of leaching sulphate ions from landfilled AAC wastes, the work is interesting due to the change of the phase composition of the products after autoclaving. The possibility of increasing quartz conversion in such a system is promising thanks to the formation of scawtite [Ca7[Si6O18](CO3)·2H2O], which has the potential to form rosette-like structures. Although, according to the work of Matsui [15], the sulphate ions accelerates the conversion of C-S-H to tobermorite. The presence of fi ne grains of limestone may also potentially have such an effect, and certainly a hetero-nuclei formation effect.

There was a slight increase in the volume density while maintaining a similar strength, however, due to the complex nature of the interactions, the system requires further research, especially in the context of the influence of the contents of limestone, on the mass rising and thermal conductivity of AAC.

The decrease in leaching of the sulphate ions from the waste AAC, can be achieved by introducing calcined clay into the concrete matrix [19]. In such a variant, it is possible to obtain similar functional properties of concrete, i.e. strength, thermal conductivity and shrinkage, at a level similar to that of the reference samples. Particularly from the point of view of reducing the energy demand expended in the sand grinding process, the use of various waste mineral dusts, e.g. granite dust [17], dust, or rather sediments formed during the cutting of rock blocks [20], seems to be interesting.

According to available estimates, the amount of dust generated during granite processing, exceeds 50% of the granite stone content, offered as the final product [22]. During many stages of its treatment, significant amounts of fi ne dust are produced, with a dominant particle size of several dozen micrometers. The dust contains approximately 65% SiO2, 20-25% of the sum of Al2O3 and Fe2O3 and up to 10% alkali. Therefore, it can be an attractive replacement for sand, limiting the need to grind it, to the large surface area. In work [17] on AAC with a relatively high volume density - higher than 1000 kg/m3, a favorable effect on strength was demonstrated, which was due to the matrix compaction and the increase in the bulk density of concrete, with dust. A linear increase in the thermal conductivity coefficient, as a function of the amount of dust introduced, was also observed. In the case of varieties with a much lower bulk density, this effect will probably be less visible, because of the dense matrix, but one should not expect an improvement in insulation in this system. Similarly, the waste generated when cutting rock blocks, not only granite ones, is characterized by a high content of silica, despite the obvious differences in the mineralogical composition, excluding carbonate rocks. It is estimated that when cutting blocks, the amount of waste in the form of dust, is up to 10% of the mass of the cut rock [23]. In the work of Wan et al. [20], attention was paid to technological contamination with phosphates and coolant, of water additives to the cutting waste, but it was of the little importance for further processing. The grain size of the cutting dust is slightly coarser than that of the granite polishing, but in most cases it does not exceed 100 μm. It is advantageous that the waste does not need to be dried, when introduced in the form of a slurry together with the wet-milled sand slurry, as a partial substitute for it. It was showed that there was practically no significant influence on the mass rising process, the bulk density, the compressive strength after autoclaving, as well as on the value of the thermal conductivity coefficient of the obtained concrete samples, even with complete replacement of sand with the dust, from cutting rock blocks. From an environmental point of view, this is a very attractive solution, not only in terms of saving energy used to grind sand but also in potentially drying of the slurry, for use in other technologies.

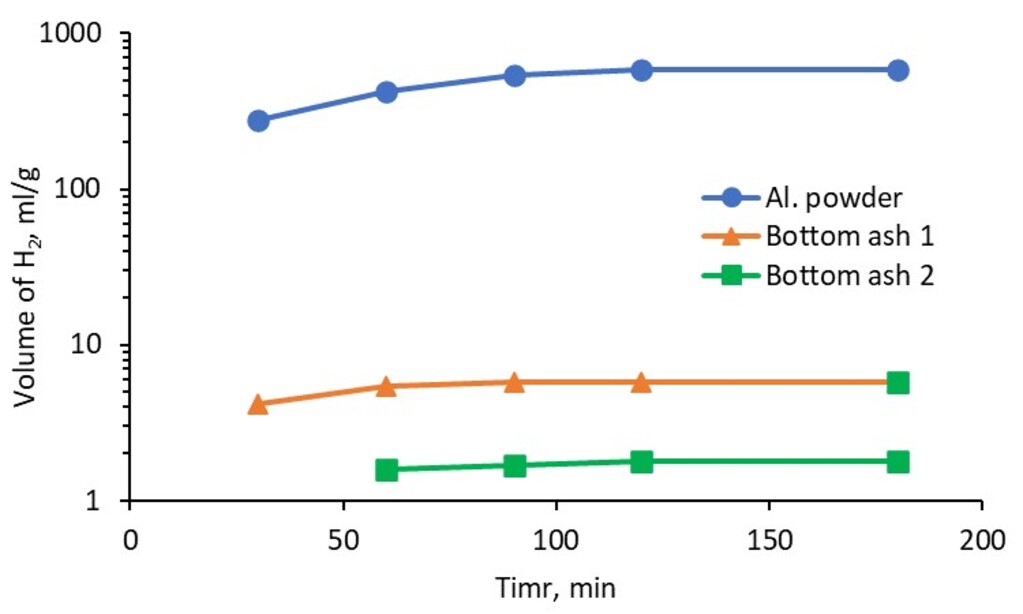

The source of silica can also be various other materials, e.g. burnt coal shale [16], glass cullet [24], metallurgical slag and municipal waste ash [25]. Especially the latter are more and more often the subject of research, due to the constantly increasing amount of waste generated, especially in large cities, and the problems with its disposal. According to the data of the Statistics Poland [GUS], in 2020, 13.1 million tons of municipal waste was collected in Poland, of which 20.3% was directed to thermal conversion with energy recovery - over 2.6 million tons. On average, there is about 380 kg of waste per one inhabitant of Poland, which is much less than in Europe about 500 kg [26]. After incineration of municipal waste, fly ash is obtained, as well as bottom ash, which is more interesting due to, among others, lower content of heavy metals [27]. Bottom waste constitutes about 80% of ashes from incineration of municipal waste [28]. These wastes usually contain, apart from silica, high CaO content, even 30%, and a few percent of P2O5. The presence of phosphorus compounds disqualifies, or significantly reduces the possibility of direct use of bottom waste in cement-based composites, due to their negative effect on cement hydration. However, in the case of autoclaved aerated concrete, the benefits are seen in the simultaneous replacement of both - part of the quartz sand and part of burnt lime. These ashes may also contain metallic aluminum [29]. The results of the work of Song et al. [25] indicate the possibility of using bottom ash both as a partial replacement for quartz sand, but more interesting, as a replacement for aluminum powder. Although the amount of hydrogen formed in the reaction of Al with calcium hydroxide, is about 100 times lower than when using Al powder, however, due to the very small amounts of aluminum powder introduced into the mixture, nothing prevents introducing many times greater amounts of ashes.

In the case of introducing up to 30% of bottom ash from combustion, without the use of aluminum powder, AAC with a bulk density of 630 kg/m3 and a compressive strength of 6 MPa, was obtained. In each case, a much more favorable pore size distribution in the bulk was found, in comparison to the samples in which the foaming was carried out, with the use of aluminum powder. Much less work is devoted to find at least a partial substitute for the burnt lime, used in this technology. The properties of burnt lime, especially its reactivity, the maximum temperature achieved in the process and the time of its occurrence, directly affect the process of mass rising, as well as the availability of calcium ions, for the reaction with silica. For this reason, great care should be taken in transferring the results obtained in the laboratory to the industrial practice. Nevertheless, it is a significant issue, due to the possible reduction of the amount of burnt lime, during the production in which large amounts of CO2 are emitted from limestone decomposition and fuel combustion.

An example of burnt lime substitution is its partial replacement with ash, obtained from burning the waste paper [29]. This ash contains large amounts of CaO, even above 40%, due to the commonly used carbonate filler in paper making, but it can also has large content of sulphates. The study attempts to completely replace lime with the ash, from burning paper. Such a possibility was pointed out, but a certain limitation is obtaining the favorable CaO/SiO2 ratio in the mixture and its influence both on the phase composition - hindered formation of tobermorite, but also on strength. According to the authors, the best results that can be applied in industrial practice, were obtained with the CaO/SiO2 ratio in the range of 0.7 to 0.8.

Attempts were also made to use the waste from cleaning flue of gases from waste incineration, with spraying slaked lime slurry [30]. The waste was used in the form in which it is generated in the gas cleaning process, as well as, to activate it, after preliminary thermal treatment at 550°C. According to the authors, such waste can potentially be a partial substitute for lime, despite a slight negative impact on the pore distribution and thus deterioration of the thermal insulation properties of concrete. Nevertheless, it should be noted that gas cleaning wastes contain chlorides, often in large amounts, which may be an obstacle in the use of this material.

ACC recycling

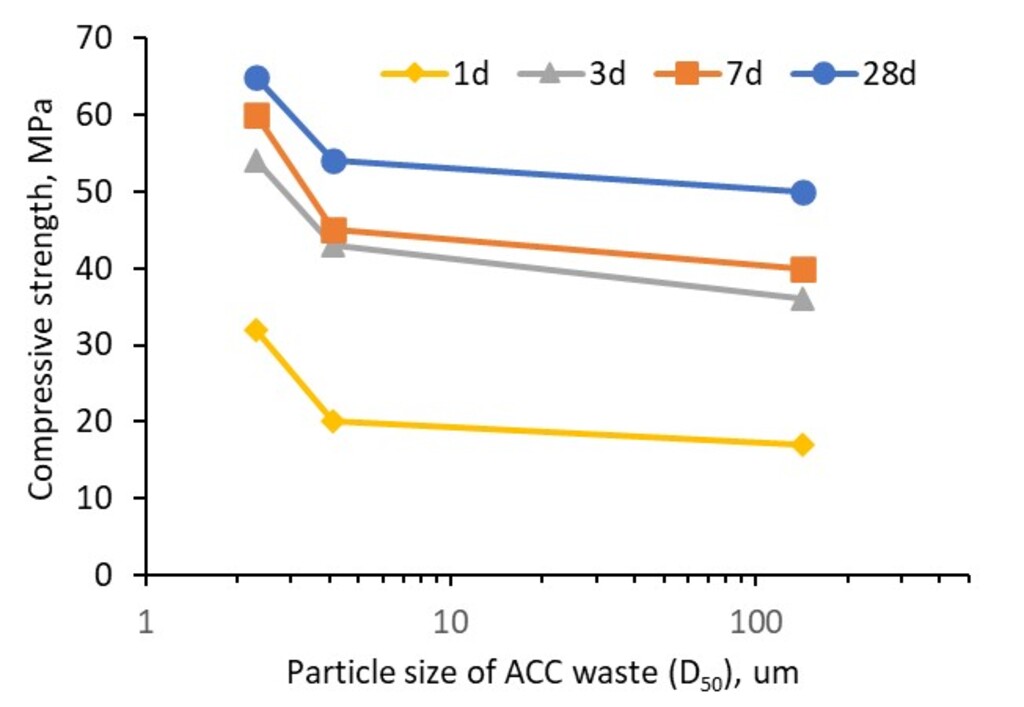

ACC is one of the most popular building materials used for erecting walls. Production in Europe exceeds the level of 16 million m3 per year [31], and the world volume of autoclaved aerated concrete is estimated as 450 million m3 of unreinforced products annually [32]. Over the past decades, ACC has been used to create millions of objects that are demolished over time. After segregation and cleaning, such material can be recycled. Part of the waste can be used directly after crushing, without additional processing - sorbent and agrotechnical applications, however, due to the potential scale of use, attempts to use the waste after grinding as an additive or substitute for cement in mortars and concretes, are valuable. In this context, however, there are two major limitations: the aforementioned level of leaching of sulphate ions from the waste, due to the gypsum used for mix formulation and the porous microstructure, the negative impact of which on the permeability of e.g. chloride ions in concrete may be significant, even with a small amount of the additive used. Therefore, in most cases it is proposed to ground the waste, in some cases even under to the level of a few micrometers. Due to the porous microstructure of AAC, the energy input in this process is many times lower than in the case of other, usually used, supplementary cementitious materials. The impact of waste grinding and the level of cement replacement was analyzed, among others, by He et al. [33]. Increased water demand and an effect on cement setting time, have also been reported. The effective influence on the properties was obtained by using the smallest particle size of the waste. This work also presents an analysis of the energy balance and costs for a 20% share of ground waste in cement, showing a 20% reduction in both CO2 emissions and total process costs, while maintaining similar strength as in the reference sample. A comparison of the effect of ground AAC with other ground mineral waste, on the properties of cement composites can be found by Yang et al. [34].

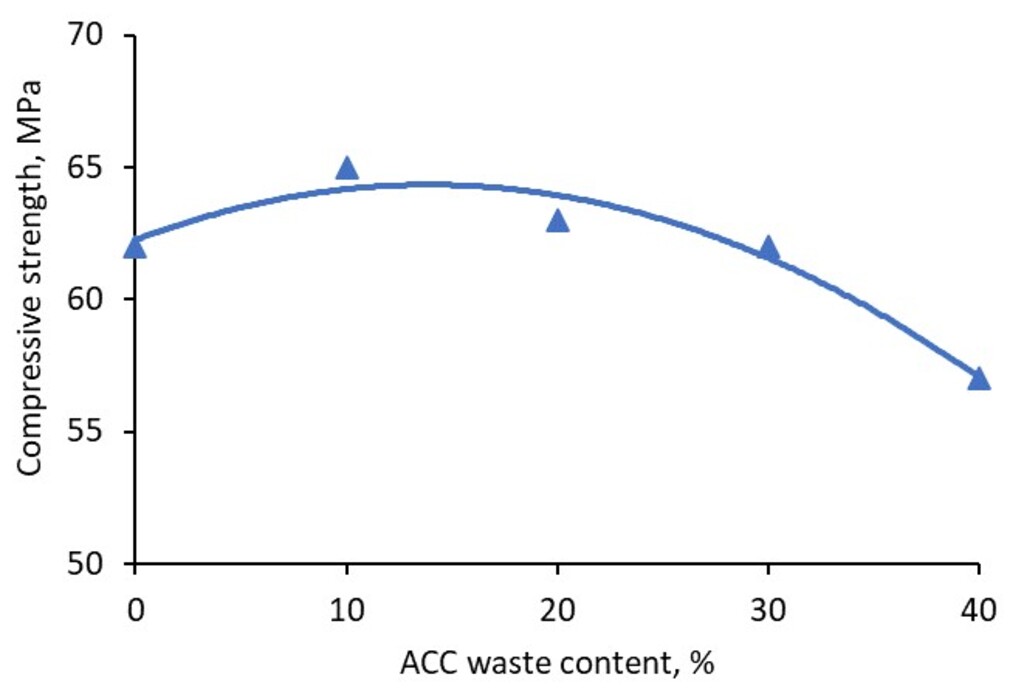

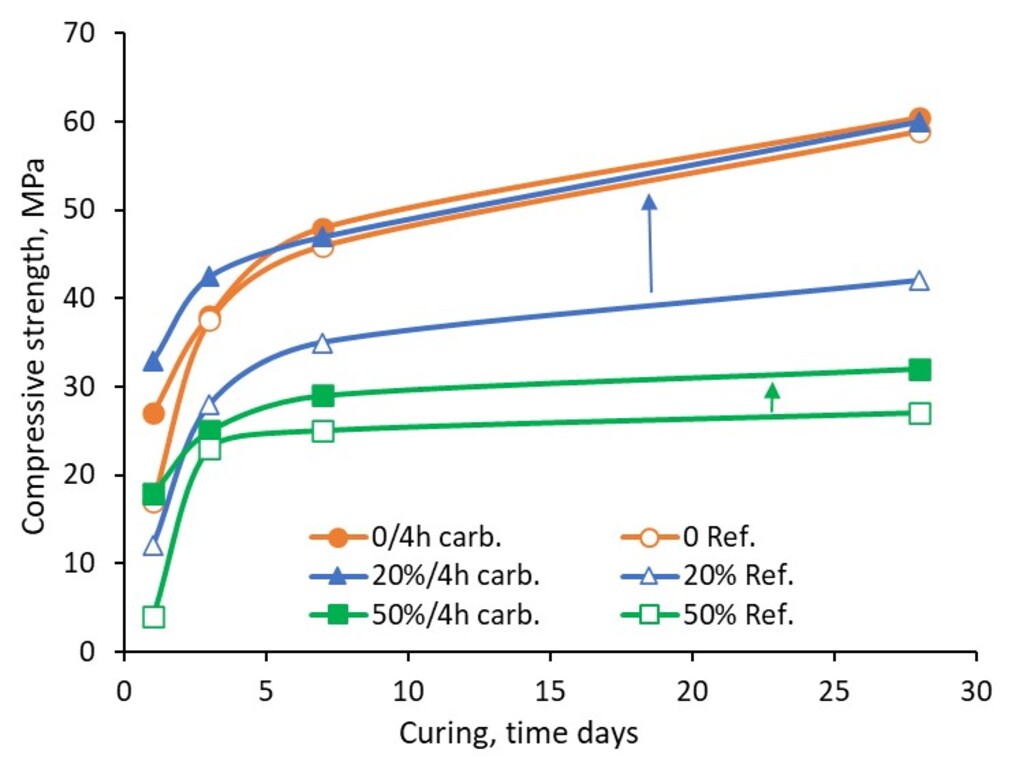

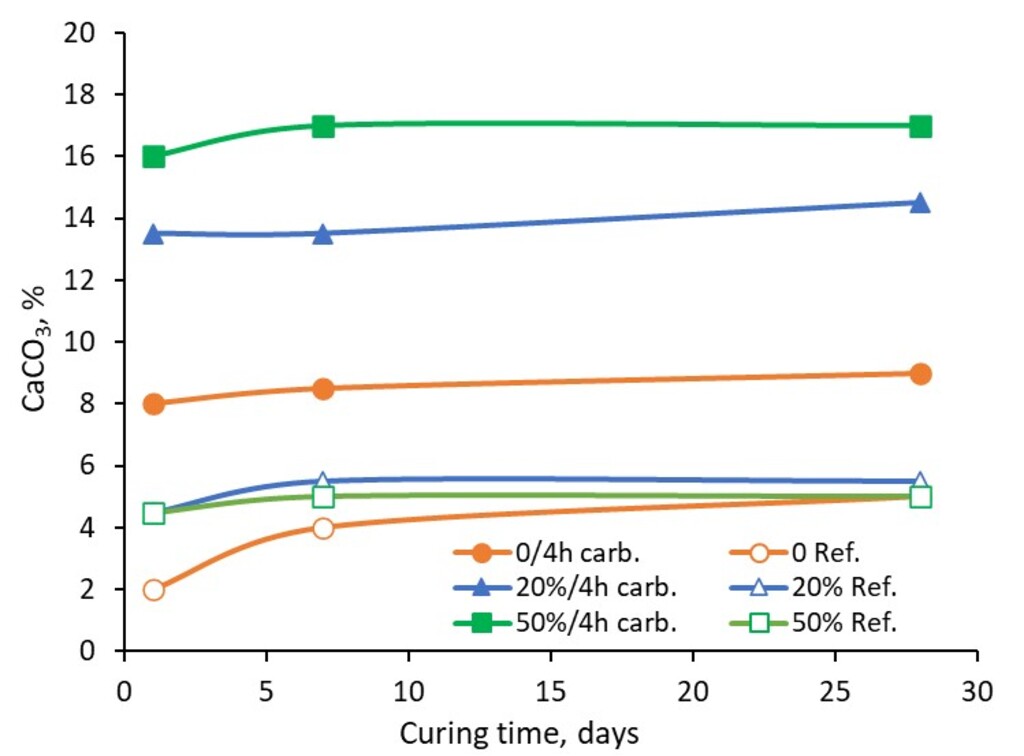

An interesting proposal for the use of the ACC waste was presented in Qin and Gao paper [35]. After the waste ground to the size of several dozen micrometers, it was added as a replacement for Portland cement to composites, which then, after a short maturation, were subjected to accelerated carbonation. It is one of the methods of the CO2 use that is considered more and more frequently and, at the same time, increasing the early strength of concrete precast elements [36, 37].

Increase in strength was found, especially after several hours of carbonation, which started at the early stage of cement mortars curing. The mutual relation between the strength of the mortars and their permeability, and thus also the later durability, limits the amount of ground waste introduced to 20% of the cement mass. It is a promising method both for the utilization of ACC waste and for reducing the amount of CO2. In addition to reducing the content of cement, and therefore the emission related to burning clinker for its production, according to the authors, it is possible to bind a dozen percent of CO2 in the mass of the binder in the composite.

Another way of using AAC waste is its use as an additive to cement-based composites, to reduce autogenic shrinkage [38]. This effect is achieved through the ability to retain water in the pores of the waste of the ACC grains. Then, water is available during cement hydration, reducing the risk of shrinkage cracks, associated with surface drying. With the use of crushed waste, greater efficiency was achieved in reducing shrinkage and internal curing than in the case of expanded perlite. Nevertheless, such results must be related to the influence on other properties, e.g. permeability, and thus the subsequent durability of such materials.

Conclusions

Autoclaved aerated concrete can be seen from many points of view, as an environmentally friendly material. Both the optimized production process itself, including the possibility of using by-products and wastes from other technologies as raw materials, as well as very good thermal insulation properties of final material, and after the end of the life cycle, the easy of recycling and processing of ACC wastes, justify such a perception. Despite the changing face of the world and the change in social priorities, the technology of AAC production is still one of the most environmentally friendly technologies, for the production of building materials in the future.

This article has been previously published in Cement Wapno Beton: W. Pichór, 27(3) (2022), 166-177 doi: https://doi.org/10.32047/CWB.2022.27.3.2

References

[1] A. Hinc, Transformacja gospodarki w kierunku niskoemisyjnym. Studia BAS 29, 109-136 (2012).

[2] “Fit for 55” package [part of the European Green Deal], adopted by the European Commission on July 14, 2021.

[3] B.G. Hellers, R. Schmidt, Autoclaved Aerated Concrete (AAC) – the story of low-weight material. Proc. V Int. Conf. of Autoclaved Aerated Concrete, Bydgoszcz 2011.

[4] G. Zapotoczna-Sytek, S. Balkovic, Autoclaved aerated concrete. PWN, Warszawa 2013 (in Polish).

[5] N. Narayanan, K. Ramamurthy, Microstructural investigations on aerated concrete. Cem. Concr. Res. 30, 457-464 (2000). https://doi.org/10.1016/S0008-8846(00)00199-X

[6] X. Qu, X. Zhao, Previous and present investigations on the components, microstructure and main properties of autoclaved aerated concrete – A review. Constr. Build. Mater. 135, 505-516 (2017). https://doi.org/10.1016/j.conbuildmat.2016.12.208

[7] Announcement of the Minister of Investment and Development Of Poland of April 8, 2019 on the announcement of the uniform text of the ordinance of the Minister of Infrastructure on technical conditions to be met by buildings and their location. Journal of Laws of The Republic of Poland 2019, item 1065.

[8] P. Walczak, P. Szymański, A. Różycka, Autoclaved Aerated Concrete based on fly ash in density 350 kg/m3 as an environmentally friendly material for energy – efficient constructions. Proc. Eng. 122, 39–46 (2015). https://doi.org/10.1016/j.proeng.2015.10.005

[9] N.N. Lam, Influence of fly ash and recycled AAC waste for replacement of natural sand in manufacture of Autoclaved Aerated Concrete. 2020 IOP Conf. Ser.: Earth Environ. Sci. 505 012001 (2020). https://doi.org/10.1088/1755-1315/505/1/012001

[10] W. Nocuń-Wczelik, Efect of Na and Al on the phase composition and morphology of autoclaved calcium silicate hydrates. Cem. Concr. Res. 29, 1759-1767 (1999). https://doi.org/10.1016/S0008-8846(99)00166-0

[11] N.Y. Mostafa, A.A. Shaoult, H. Omar, S.A. Abo-El-Enim, Hydrothermal synthesis and characterization of aluminum and sulphate substituted 1.1 nm tobermorites. J. Alloys Compd. 467, 332-337 (2009). https://doi.org/10.1016/j.jallcom.2007.11.130

[12] A. Różycka, W. Pichór, Effect of perlite waste addition on the properties of autoclaved aerated Concrete. Constr. Build. Mater. 120, 65–71 (2016). https://doi.org/10.1016/j.conbuildmat.2016.05.019

[13] Perlite and Vermiculite: 2014 Market Review and Forecast, Merchant Research & Consulting Report, 2014.

[14] W. Kurdowski, J. Pawluk, Limestone meal as active mineral additive for production of aerated autoclaved concrete. Cem. Wapno Beton 24(2) 154-160 (2019).

[15] K. Matsui, A. Ogawa, J. Kikuma, M. Tsunashima, T. Ishikawa, S. Matsuno, Influence of addition of AI compound and gypsum on tobermorite formation in autoclaved aerated concrete studied by in situ X-ray diffraction. Cem. Wapno Beton, 16(special issue), 3-6 (2011).

[16] R.D. Wu, S.B. Dai, S.W. Jian, J. Huang, H.B. Tan, B.D. Li, Utilization of solid waste high-volume calcium coal gangue in autoclaved aerated concrete: Physico-mechanical properties, hydration products and economic costs. J. Clean. Prod. 278, 123416 (2021). https://doi.org/10.1016/j.jclepro.2020.123416

[17] M.S. Zafar, U. Javed, R.A. Khushnood, A. Nawaz, T. Zafar, Sustainable incorporation of waste granite dust as partial replacement of sand in autoclaved aerated concrete. Constr. Build. Mater. 250, 118878 (2020). https://doi.org/10.1016/j.conbuildmat.2020.118878

[18] W. Pichór, Properties of autoclaved aerated concretes with cenospheres from coal ash. Cem. Wapno Beton 17, 32-36 (2012).

[19] C. Chucholowski, H. Müller, K.-Ch. Thienel, Low-sulfate autoclaved aerated concrete (AAC): A recyclable AAC with calcined clay. Constr. Build. Mater. 342, 127984 (2022). https://doi.org/10.1016/j.conbuildmat.2022.127984

[20] H. Wan, Y. Hu, G. Liu, Y. Qu, Study on the structure and properties of autoclaved aerated concrete produced with the stone-sawing mud. Constr. Build. Mater. 184, 20-26 (2018). https://doi.org/10.1016/j.conbuildmat.2018.06.214

[21] J. Mendoza M. Feced, G. Feijoo, A. Josa, X. Gabarrell, J. Rieradevall, Life cycle inventory analysis of granite production from cradle to gate. Int.J. Life Cycle Assess. 19, 153-165 (2014). https://doi.org/10.1007/s11367-013-0637-6

[22] L. Lakhani, R.K. Sharma, P. Tomar, Utilization of stone waste in the development of value added products: a state of the art review. JESTR 7, 180–187 (2014). https://doi.org/ 10.25103/jestr.073.29

[23] P. Torres H.R. Fernandes, S. Olhero, J.M.F. Ferreira, Incorporation of wastes from granite rock cutting and polishing industries to produce roof tiles. J. Eur. Ceram. Soc. 29, 23-30 (2009). https://doi.org/10.1016/j.jeurceramsoc.2008.05.045

[24] W. Szudek, Ł. Gołek, G. Malata, Z. Pytel, Influence of waste glass powder addition on the microstructure and mechanical properties of autoclaved building materials. Materials 15, 434 (2022). https://doi.org/10.3390/ma15020434

[25] Y. Song, Z.L. B. Li, E.-H. Yang, Y. Liu, T. Ding, Feasibility study on utilization of municipal solid waste incineration bottom ash as aerating agent for the production of autoclaved aerated concrete. Cem. Concr. Comp. 56, 51-58 (2015). https://doi.org/10.1016/j.cemconcomp.2014.11.006

[26] Municipal waste generated in 2019. Eurostat report, 2021.

[27] C. Lam, A.W.M. Ip, J.P. Barford, G. McKay, Use of Incineration MSW Ash: A Review. Sustainability 2, 1943-1968 (2010). https://doi.org/10.1016/j.jeurceramsoc.2008.05.045

[28] J.M. Chimenos, M. Segarra, M.A. Fernández, F.Espiell, Characterization of the bottom ash in municipal solid waste incinerator. J. Hazardous Mater. 64, 211-222 (1999). https://doi.org/10.1016/S0304-3894(98)00246-5

[29] A. Hauser, U. Eggenberger, T. Mumenthaler, Fly ash from cellulose industry as secondary raw material in autoclaved aerated concrete. Cem. Concr. Res. 29, 297–302 (1999). https://doi.org/10.1016/S0008-8846(98)00207-5

[30] A. Różycka, Ł. Kotwica, Waste originating from the cleaning of flue gases from the combustion of industrial wastes as a lime partial replacement in autoclaved aerated concrete. Materials 15, 2576 (2022). https://doi.org/10.3390/ma15072576

[31] www.eaaca.org

[32] F.H. Fouad, T. Schoch, AAC in USA – a second look. Ce/Papers - Special Issue: ICAAC - 6th Int. Conf. Autoclaved Aerated Concrete. 2(4) E1-E6 (2018).

[33] X. He, Z. Zheng, J. Yang, Y. Su, T. Wang, B. Strnadel, Feasibility of incorporating autoclaved aerated concrete waste for cement replacement in sustainable building materials. J. Clean. Prod. 250, 119455 (2020). https://doi.org/10.1016/j.jclepro.2019.119455

[34] J. Yang, L. Zheng, Z. Su, X. He, Y. Su, R. Zhao, X. Gan, Wet-milling disposal of autoclaved aerated concrete demolition waste – A comparison study with classical supplementary cementitious. Adv. Powder Techn. 31, 3736-3746 (2020). https://doi.org/10.1016/j.apt.2020.07.016

[35] L. Qin, X. Gao, Recycling of waste autoclaved aerated concrete powder in Portland cement by accelerated carbonation. Waste Manag. 89, 254-264 (2019). https://doi.org/10.1016/j.wasman.2019.04.018