Science & Innovation

AAC recycling cluster ‘REPOST’

New recycling options for post-demolition AAC

Loading...

Oliver Kreft is a chemist. He completed his PhD at Potsdam University and took up employment at the Xella Technologie- und Forschungsgesellschaft in 2008, where he is now responsible for Circular Economy – from the development of circular products to the transfer of basic research into business models and production processes. Oliver Kreft is author of numerous publications on circularity of Autoclaved Aerated Concrete (AAC), and is engaged in associations and working committees on resource efficiency and circular economy of mineral construction materials.

oliver.kreft@xella.com

Dipl.-Ing. Torsten Schoch is a civil engineer who has worked in the building materials industry since 1992. After holding positions in project development and construction engineering at Ytong AG, he was appointed CEO of the Xella Technologie und Forschungsgesellschaft mbH in Kloster Lehnin, Germany, in 2006. He is involved in various national and European standardization committees, e.g. those related to heat transfer, energy performance of buildings, and structural thermal insulation in high-rise buildings, to name a few. He is chairman of the Verband Bauen in Weiß, a manufacturer’s association which provides architects and civil engineers with information about white building materials (AAC and calcium silicate blocks). He is Board member of the European AAC Association (EAACA) and chairman of the EAACA Technical Committee.

torsten.schoch@xella.com

Introduction – high-quality recycling of AAC

AAC is a building material that has been known and proven for 100 years and is also fully recyclable. The recycling of AAC fresh from production, which occurs as cuttings or breakage during production, has been practiced for decades. During production, broken or residual AAC is either further refined into granulate (oil binder, thermal insulation fills, roof greening substrates or animal bedding), or milled and returned as so-called primary AAC into the ongoing production of AAC. By contrast, post-demolition AAC (pd-AAC or secondary AAC) usually contains foreign matter, which makes high-quality recycling difficult, which is why AAC is usually deposited in landfill after use. Decreasing landfill capacities, legal obligations for the recyclability of products and the protection of primary materials therefore make it essential to find recycling alternatives for this demolition material.

The joint research project REPOST aimed at the reduction of primary raw materials in the production of AAC by recycling pd-AAC at the same or comparable quality level [1]. This concept thus differs from conventional building material recycling. According to statistics, around 90 percent of mineral construction waste was recycled in 2020 in Germany, but mostly as low-value and down-cycling in road construction [2].

In a central work package of REPOST, the existing material cycle for AAC was opened for AAC-waste material. AAC prototypes for masonry constructions were developed from pd-AAC, each of which was to contain the maximum possible quantities of pd-AAC while complying with normative required material properties. AAC contains a large proportion of cement, being produced with high energy input and high CO2 emissions. Where recycling within a closed cycle is not possible, its thermal conversion into dicalcium silicate, a main component of cement clinker, was investigated by the Karlsruhe Institute for Technology, Institute for Chemical Chemistry. The aim was to (partially) replace the primary cement in the production of AAC with a recycled product that causes lower CO2 emissions and energy expenditure during its manufacture.

Another central work package was to prove that closed-loop recycling of AAC via both direct recycling and LT-BCC production is environmentally beneficial compared to landfilling. Therefore, in-depth life-cycle-assessments have been carried out by the Karlsruhe Institute for Technology, Institute for Industrial Production (KIT-IIP).

Secondary AAC (pd-AAC) was provided by Hamburg-based project partner Otto Dörner Entsorgung GmbH.

From 2019 to 2022, Xella took part in a joint research project ‘REPOST – Recycling-Cluster Porenbeton (AAC)’, funded by the German Federal Ministry of Education and Research grant number: 033R249 A-D.

Project participants:

• Xella Technologie- und Forschungsgesellschaft mbH, Germany

• Otto Dörner Entsorgung GmbH, Germany

• Karlsruhe Institute for Technology, Institute for Technical Chemistry (KIT-ITC) , Germany

• Karlsruhe Institute for Technology, Institute for Industrial Production (KIT-IIP) , Germany

Provision of pd-AAC

Post-demolition AAC (pd-AAC) from demolition measures was collected and sorted by trained personnel at Otto Dörner Entsorgung GmbH. Preliminary visual inspections for critical foreign matter did not reveal negative findings. The material was subjected to crushing at Xella’s granulate plant in Rotenburg, Germany. The resulting AAC-powder was free of pollutants according to LAGA M20, TR Boden [3] so that from a chemical point of view there were no application restrictions for its utilization. To ensure sufficient varietal purity on a long term, a requirement profile was defined together with Otto Dörner: Foreign matter must not exceed a total quantity of three per cent by volume. Mineral plasters/adhesives/mortars are unproblematic to produce AAC. Only materials that are free of asbestos and other WHO fibres are accepted.

Direct material recycling of pd-AAC into new AAC

Prototype development

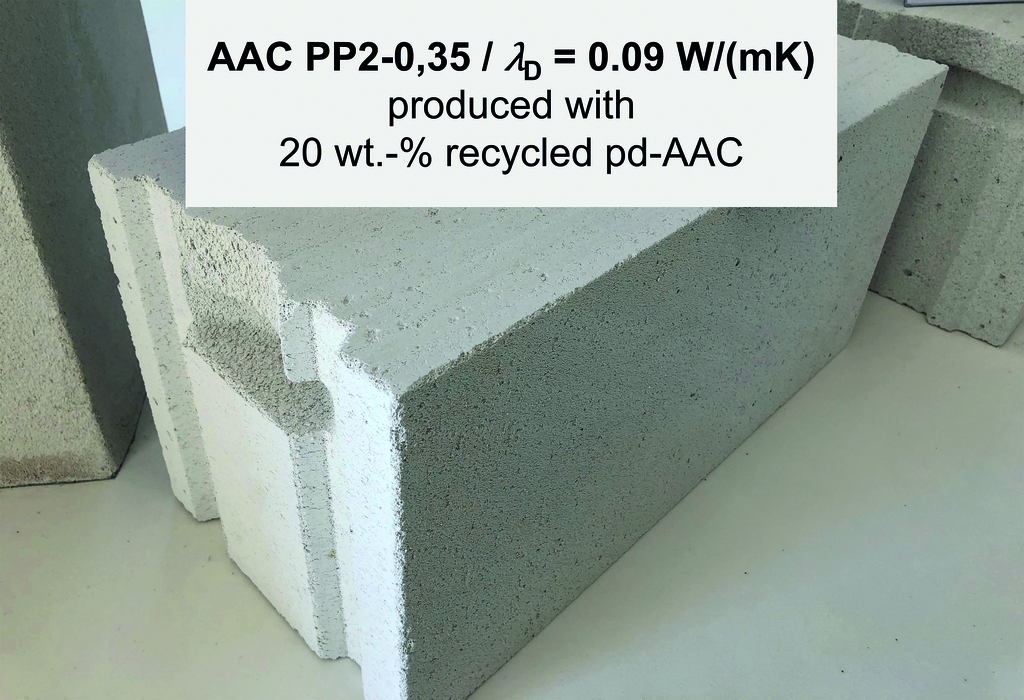

The use of AAC powder (regardless of whether it is primary or secondary powder) must (1) be realizable without production-related disruptions and (2) without violating normative specifications or Xella's internal quality requirements. To ensure this, prototypes were developed on small-scale-level. Primary raw materials (except for primary powder) were replaced by powder from pd-AAC according to their proportion in the recipe (the higher their proportion, the more was substituted by powder). Only the highest sorting quality was used for recipe development. Three AAC quality classes were investigated: Ytong PP2-0,35 (mean dry density > 0,30 to 0,35 kg/dm3), PP4-0,50 (> 0,45 to 0,50 kg/dm3) and PP4-0,55 (> 0,50 to 0,55 kg/dm3) [4][5]. The development of Ytong PP2-0,35 and PP4-0,50 with a powder content of 20 wt.-% and Ytong PP4-0,55 with a powder content of 30 wt.-% was successfully completed. All formulations were successfully validated by up-scaling to a production-typical casting volume of 5 m3. The increased powder shares did not have negative impacts on product properties [4][5][6]: The compressive strength requirements were achieved without any objections. Equilibrium moisture content at 23 °C / 80 % RH [7] and the drying shrinkage ɛcs,tot [8] were below the normative and/or Xella internal limit values. Fig. 2 exemplary shows an Ytong block PP2-0,35 with 20 wt.-% pd-AAC-powder.

Impact on carbon emissions

Our research aimed to address a critical gap in the literature concerning the environmental assessment of closed-loop recycling options for demolished AAC in construction materials. The study also intended to compare the developed pd-AAC recycling methods and their environmental impacts, which has not been explored in existing literature, yet.

According to ISO 14040 [9], life cycle assessment is defined as a tool to assess environmental impacts and resources used throughout the product life cycle – from supply and processing of raw materials to product manufacture, dissemination, usage, maintenance and repair, and finally waste-management including disposal and/or processing for recycling (secondary material production). This life cycle definition is often referred to as “cradle-to-grave” methodology. However, to evaluate the environmental impact of our recycling strategies this linear methodology had to be expanded beyond waste-management. One way for such a “system expansion” is the “avoided burden” approach. The input (waste and/or recycled product) per se enters the assessed system without any burdens (“zero-burden”) and serves as a functional unit for the evaluation and comparison of possible after-use scenarios [10]. The “avoided burden” method assumes that the recycled product replaces competing primary raw materials of the product. Consequently, environmental burdens from the replaced primary materials are subtracted from the investigated system.

In the present study, the concept of “zero-burden” was applied to pd-AAC from construction and demolition waste (post-demolition AAC, pd-AAC). Thus, resource and energy expenditures during production and use phase were not considered. The functional unit was defined as 1 kg pd-AAC, which enters the assessment without burdens. The system boundaries only comprise the waste-product (pd-AAC).

The ecoinvent 3.6 database was used to assess general processes (crushing, grading, landfilling) and primary production. For substitution, it was assumed that all primary raw materials are replaced according to their input share. The larger the share, the more is substituted by pd-AAC powder. Rewards for substituting primary AAC were based on the dataset "autoclaved aerated concrete block production" considering AAC density class 0.50. The open-source software openLCA was used to model and assess end-of-life options for AAC quality classes PP2-0,35, PP4-0,50 and PP4-0,55.

The substitution credits were highest for Ytong PP2-0,35. In comparison to landfilling, CO2e emissions can be reduced by 0.49 kg CO2e/kg pd-AAC (Tab. 1). Since higher density is associated with a higher sand and a lower cement and lime share, the increase of powder leads to a higher sand and lower cement and lime substitution. Regarding the functional unit of 1 kg pd-AAC, substitution credits decrease as cement and lime account for significantly higher Global Warming Potential (GWP) compared to sand. In result, recycling of pd-AAC in Ytong PP4-0,50 and PP4-0,55 involves substitution credits of 0.42 and 0.34 kg CO2e/kg pd-AAC, respectively (Tab. 1) [11].

Table 1: Impact assessment of a closed-loop recycling of AAC compared to landfilling. Functional unit after system expansion = 1 kg utilized pd-AAC [11]

Environmental impact1 | Landfillling2 | Ytong | Ytong | Ytong |

Climate change, total (CC) [kg CO2-Eq] | 0.01 | -0.49 | -0.42 | -0.34 |

Freshwater and terrestrial | 6.40×10-05 | -9.85×10-04 | -7.66×10-04 | -6.42×10-04 |

Freshwater ecotoxicity | 1.87×10-02 | -3.07×10-02 | -1.95×10-02 | -1.30×10-02 |

Freshwater eutrophication [kg P-Eq] | 8.59×10-07 | -3.24×10-05 | -2.11×10-05 | -1.73×10-05 |

Carcinogenic effects | 8.26×10-11 | -8.94×10-10 | -6.68×10-10 | -5.68×10-10 |

Ozone layer depletion | 3.24×10-09 | -2.15×10-08 | -2.05×10-08 | -1.65×10-08 |

Photochemical ozone creation | 6.84×10-05 | -7.89×10-04 | -6.25×10-04 | -5.26×10-04 |

Resources, fossils (RF) | 0.22 | -2.12 | -1.78 | -1.46 |

Resources, land use (LU) | 0.38 | -1.55 | -1.59 | -1.46 |

1 Crushing, grading and purifying was assessed acc. to ecoinvent 3.6 datasets "rock crushing“, "treatment of waste brick, sorting plant“. Transportation distances of 50 km were assumed for all EoL-scenarios.

2 Landfilling (reference end-of-life option) was assessed using the ecoinvent 3.6 dataset "treatment of inert waste, inert material landfill“. Further landfilling efforts include the construction of the landfill and energy demand for waste handling and landfill management, especially diesel used in landfill machinery.

Research approach for a CO2-reduced binder – low temperature belite cement clinker (LT-BCC) from pd-AAC

Belite cement clinker

Belite is the name for the alpha and beta modifications (α'H-C2S and β-C2S) of the cement clinker mineral dicalcium silicate, which form at high temperatures and remain stable when cooled to room temperature. Belite is a major component of ordinary Portland cement (OPC) [12].

Process to produce LT-BCC from pd-AAC

The process design for the processing of LT-BCC involves several key steps: Raw materials undergo pre-treatment, including crushing, grading, purification, and pre-drying, if necessary. Each component is ground until 50 % of the particles are smaller than 20 μm (d50 = 20 μm) with d95 < 100 μm. The resulting grain size distribution is checked using static light scattering. Based on each sample's CaO and SiO2 content, the addition of CaCO3 is calculated to achieve a starting material with a molar ratio of CaO to SiO2 of two. A small addition of a mineralizer, either Na2CO3 or CaCl2, is added to the mixture. The inclusion of a mineralizer helps enhance the kinetics of the reactions.

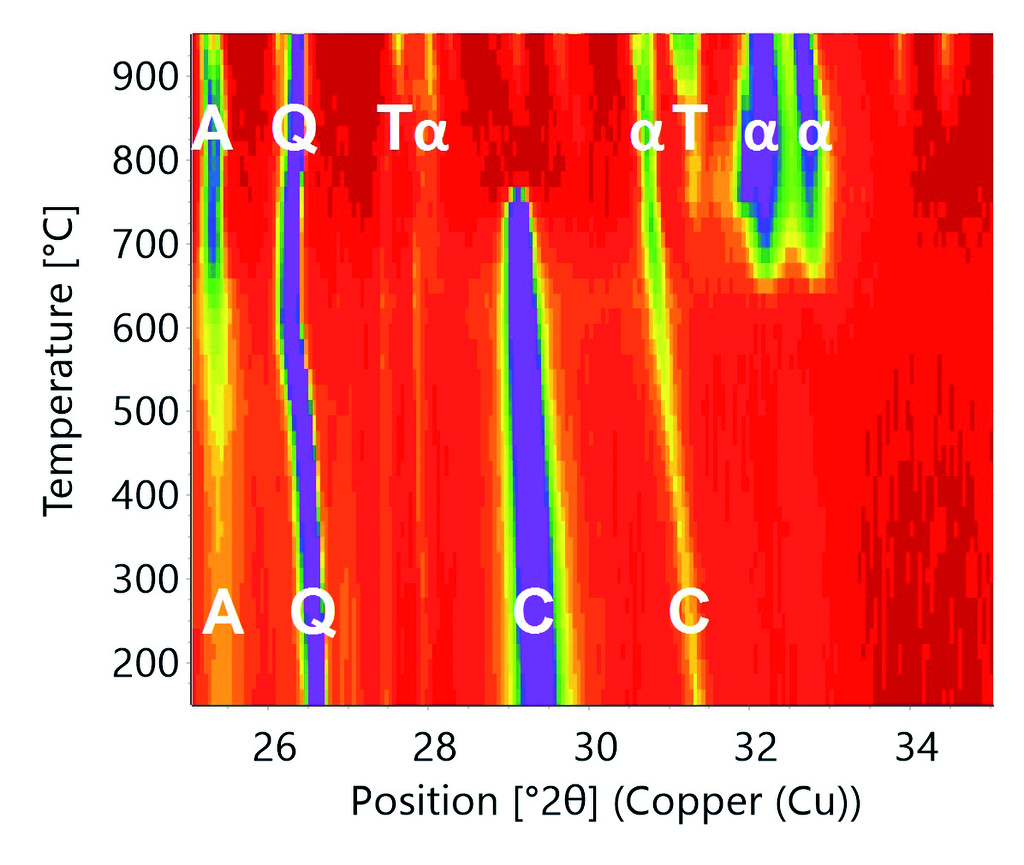

The starting material enters a rotary kiln and undergoes a drying and preheating phase, during which material gradually heats up, and chemically bound water is expelled from mineral phases. The kiln operates in a slightly oxidizing CO2 atmosphere. At about 600°C, calcium silicates from dehydrated pd-AAC and limestone begin to form and release CO2. At a temperature of around 800°C, α'H-C2S is formed. Due to the sulphate contained in pd-AAC, ternesite (Ca5(SiO4)2(SO4)) is also formed - another clinker mineral typical of calcium sulphate-belite cement types [13]. Clinkering is finished at about 1000°C. On cooling to 500°C, α'H-C2S changes to the β-C2S modification, which remains as a metastable phase at room temperature. The cooled clinker is ground in a ball mill to achieve a typical cement fineness [14][15].

Throughout the process, continuous analyses and adjustments are made to ensure the desired composition and properties of the final product (LT-BCC). The addition of corrective limestone and mineralizers, as well as the monitoring of CaO to SiO2 ratio, contributes to the control and optimization of the process.

The process was first optimized for the starting material, pd-AAC, in batches and then for the operation of a continuously operating laboratory rotary kiln. A balance and detailed description of the element-specific material flows in the clinker process could be derived from the laboratory tests [16].

Life cycle assessment of recycling of pd-AAC to LT-BCC

The LCA of LT-BCC production from pd-AAC was done with the LCA software openLCA [17] and the database ecoinvent 3.8 [18]. The “system expansion” by using the “avoided burden” and “zero-burden” approaches revealed that this closed-loop pd-AAC recycling via the belite route aiming at Portland cement clinker substitution shows significant potential savings in environmental impacts. Savings could reach 0.77 kg CO2-Eq/kg pd-AAC compared to the status quo (landfilling) by using renewable electricity, and 0.34 kg CO2-Eq/kg pd-AAC by using natural gas [14].

Use of LT-BCC in AAC production

After optimizing the process parameters and formulations, a total of 100 kg LT-BCC was synthesized at the Karlsruhe Institute of Technology, Institute for Technical Chemistry (KIT-ITC). The starting materials were pd-AAC in various grades of purity and freshly produced (primary) AAC. The suitability of LT-BCC as a substitute for OPC was investigated on small-scale-level using generic formulations for quality classes PP2-0,35 and PP4-0,50 and 0,55 respectively. Up to 50 wt.-% OPC otherwise used in AAC manufacture could be replaced by LT-BCC – regardless of the base material or mineralizer. Normative and Xella's internal quality requirements were easily achieved. The mineral phase composition corresponded to the reference values of AAC produced with OPC. Figure 4 shows material from a semi-industrial test. Here, 25 wt.-% OPC were substituted by LT-BCC.

Conclusion

Life cycle analyses using a zero-burden and avoided burden methodology were conducted to evaluate the environmental effects of pd-AAC recycling compared to landfilling. The production of AAC through closed-loop recycling of pd-AAC has the potential to significantly mitigate environmental effects, such as greenhouse gas emissions.

When using pd-AAC as secondary raw material in the production of new AAC, CO2e emissions can be reduced by 0.49 kg CO2e/kg pd-AAC (in comparison to landfilling).

Pd-AAC was successfully converted to low temperature belite cement clinker (LT-BCC). The required process temperature of 1000 °C can be achieved by electrical heating, preferably using renewable energies. As in normal cement production, CO2 is released in the process. However, in the present process, the CO2 atmosphere is favorable for the reaction process, as CO2 is chemically bound to pd-AAC in terms of carbonation through mineralization.

Technical trials have shown that low-temperature belite cement clinker (LT-BCC) is a suitable partial cement substitute in the production of AAC. On a laboratory scale, the process of processing LT-BCC from pd-AAC was established by utilizing samples of actual collected waste with varying levels of contamination. Its composition conforms to DIN EN 197-1, the European standard for cement [12]. Clinkering can occur at a significantly lower temperature than OPC (LT-BCC 1000°C vs. OPC 1450°C) due to unique kiln conditions. Significant potential savings of 0.77 kg CO2-Eq/kg pd-AAC compared to the status quo (landfilling) are shown by closed-loop pd-AAC recycling via the belite route by using renewable electricity. Savings with natural gas firing are up to 0.35 kg CO2-Eq/kg pd-AAC.

To improve decision-making, future research should evaluate a pilot plant rather than relying solely on laboratory data. Furthermore, under current or future conditions, such as the spatial and temporal availability of rising pd-AAC, quality aspects, and current regulation, an analysis of the system and network design for a full AAC circularity could aid in determining the best recycling routes, plant capacities, and placements.

Acknowledgements

We gratefully thank the Karlsruher Institut für Technologie, both Institute for Technical Chemistry (Dr. Peter Stemmermann) and Institute for Industrial Production (Dr. Rebekka Volk) and also Otto Dörner Entsorgung GmbH (Enno Simonis, Beate Weiß) for cooperation, constructive support and providing valuable data.

Funding information

This work was supported by the Federal Ministry of Education and Research (BMBF) Germany within the research project REPOST [grant number: 033R249 A-D]. The responsibility for the content of this publication lies with the authors.

References

[1] REPOST - Recycling-Cluster Porenbeton: Erarbeitung neuer Optionen für die Kreislaufführung von Porenbeton; Laufzeit: 01.06.2019 31.12.2022; Förderkennzeichen: 033R249 A D; https://innovative-produktkreislaeufe.de/Projekte/REPOST.html

[2] Bundesverband Baustoffe – Steine und Erden e.V. (German Building Materials Association e.V.), 2023, Kreislaufwirtschaft Bau – Mineralische Bauabfälle Monitoring 2020, https://kreislaufwirtschaft-bau.de/Download/Bericht-13.pdf (retrieved: March 12, 2024)

[3] Mitteilung 20 der Länderarbeitsgemeinschaft Abfall (German Federal/State Working Group on Waste). Anforderungen an die stoffliche Verwertung von mineralischen Abfällen, Teil II: Technische Regeln für die Verwertung (Bodenmaterial und sonstige mineralische Bau- und Abbruchabfälle), Version from 05.November 2004.

[4] Deutsches Institut für Normung e.V. (German Institute for Standardization e. V.), DIN EN 771-4:2011+A1:2015, Festlegungen für Mauersteine – Teil 4: Porenbetonsteine, Beuth Verlag GmbH, Berlin

[5] Deutsches Institut für Normung e.V., DIN 20000-404:2015-12, Application of building products in structures – Part 404: Rules for the application of autoclaved aerated concrete masonry units according to DIN EN 771-4:2011-07, Beuth Verlag GmbH, Berlin

[6] Deutsches Institut für Normung e.V., DIN EN 679:2005-09, Bestimmung der Druckfestigkeit von dampfgehärtetem Porenbeton, Beuth Verlag GmbH, Berlin

[7] Deutsches Institut für Normung e.V., DIN EN ISO 12571:2022-04, Wärme- und feuchtetechnisches Verhalten von Baustoffen und Bauprodukten – Bestimmung der hygroskopischen Sorptionseigenschaften, Beuth Verlag GmbH, Berlin

[8] Deutsches Institut für Normung e.V., DIN EN 680:2006-03, Bestimmung des Schwindens von dampfgehärtetem Porenbeton, Beuth Verlag GmbH, Berlin

[9] German Institute for Standardization (Deutsches Institut für Normung e.V.), DIN EN ISO 14040:2021-02, Environmental management – Life cycle assessment – Principles and framework, Berlin, Beuth-Verlag GmbH

[10] Nakatani, J. (2014), Life Cycle Inventory Analysis of Recycling: Mathematical and Graphical Frameworks, Sustainability 6, No. 9, 6158–6169

[11] Volk, R., Steins, J. J., Kreft, O., Schultmann, F (2023), Life cycle assessment of post-demolition autoclaved aerated concrete (AAC) recycling options, Resources, Conservation & recycling 188, 106716

[12] Deutsches Institut für Normung e.V., DIN EN 197-1:2011-11, Zement – Teil 1: Zusammensetzung, Anforderungen und Konformitätskriterien von Normalzement, Beuth Verlag GmbH, Berlin

[13] Dienemann, W., Schmitt, D., Bullerjahn, F., Haha, M. B. (2013) Belite-Calciumsulfoaluminate-Ternesite (BCT) – a new low-carbon clinker technology, Cement International 11, 4, 100‑109

[14] Stemmermann, P., Volk, R., Stein, J. J., Beuchle, G. (2024), Recycling belite cement clinker from post-demolition autoclaved aerated concrete – assessing a new process, Resources, Conservation & recycling 203, 107404

[15] Stemmermann, P., Ullrich, Al, Beuchle, G., Garbev, K., Schweike, U. (2022), Belite cement clinker from autoclaved aerated concrete waste – A contribution towards CO2 -reduced circular building materials. In: CE/Papers 2022 – Xella International Colloquium, 5, 17–26, https://doi.org/ 10.1002/cepa.1879 (retrieved: March 12, 2024)

[16] Ullrich, A., Garbev, K., Bergfeldt, B. (2021), In Situ X-ray Diffraction at High Temperatures: Formation of Ca2SiO4 and Ternesite in Recycled Autoclaved Aerated Concrete, Minerals 11 (8), 789–810

[17] GreenDelta, 2019. openLCA. Version 1.10.1. https://www.openlca.org/. retrieved: 03 May 2023

[18] Ecoinvent, 2021. Ecoinvent v3.8. https://ecoinvent.org/the-ecoinvent-database/data-releases/ecoinvent-3-8/. (retrieved: May 03, 2023).