Science & Innovation

Structural applications of AAC

Performance of shear keys in AAC slabs subjected to cyclic load

Loading...

Luthfi Muhammad Mauludin is a Lecturer at Civil Engineering Department, Politeknik Negeri Bandung, Indonesia. He received his Doctoral Degree (Dr.-Ing) at the Institute of Structural Mechanics, Bauhaus Universität Weimar, Germany and his M.Sc in Structural Analysis is from Technical University of Catalonia (UPC), Spain and Università Degli Studi di Padova, Italy. luthfi-mm@polban.ac.id

The development of science and technology in the field of construction continues to increase, which is indicated by the presence of various kinds of construction materials. As a consequence, more possibilities for the choice of materials for the construction of a building are available. One of the innovations is Autoclaved Aerated Concrete (AAC), which is concrete made of cement, silica sand, burnt lime, water, and aluminium paste as a chemical agent for the generation of air voids. The AAC material is of light weight, so that the structure receives a smaller load, which automatically allows reducing the dimensions of other elements and which results in a decrease in the total cost of the structure.

AAC slabs are more widely used for residential buildings, shopping centers, factories, hotels, and other buildings [1]. The installation of AAC slabs in buildings can be faster and more practical than conventional construction systems, does not require scaffolding or formwork, and eliminates the need to wait for the concrete curing process. Currently, conventional concrete/steel slabs are used for pedestrian bridge construction. The application of AAC slabs for constructing pedestrian bridges is relatively new and very challenging, since in its application joints always exist between slabs, which requires careful consideration.

The analysis of shear key performance has been carried out for Hollow Core Slab (HCS) precast concrete floors [2]. In [2], the effect of different types of shear keys on longitudinal joints is discussed, which relates to the function as a rigid diaphragm. The objective of this study is to investigate the performance of shear keys in AAC slab systems used as a structural diaphragm that meets the special requirements for earthquake loading according to SNI 2847-2013 [3]. The results of this study are expected to be used as a reference for product manufacturers and to promote the application and development of AAC slab systems.

Methodology

The steps taken in this research can be summarized as follows:

· The research started with studying previous studies on AAC.

· Testing the physical and mechanical properties of AAC materials experimentally to obtain data in terms of compressive strength, modulus of elasticity, specific gravity, moisture content and tensile strength of the steel reinforcement to be used.

· The compressive strength test refers to ASTM C-1693 article 6 [9], which specifies that the number of compressive strength specimens should not be less than 3. The compressive strength test on AAC materials was carried out by taking a sample of the test object using a cube-shaped mould with dimensions of 100 x 100 mm, with the condition that the cube sample had a moisture content of 5-15%.

· The modulus of elasticity test for the AAC material was carried out simultaneously with the compressive strength based on ASTM C-39 [11], where the shortening of concrete at a certain load was measured using a dial gauge. The modulus of elasticity was calculated using data on the shortening of the concrete and the strain that occurs at a certain stress where the value of the modulus of elasticity in each specimen refers to ASTM C-1693 article 9 [9].

· Specific gravity and water content testing refer to ASTM C-1693 article 7 [9].

· Three samples of reinforcement were taken with a length of 500 mm. The samples taken were intact reinforcement that had not been given an anti-corrosion coating. Tensile strength testing of the reinforcement was carried out in the laboratory to obtain yield stress and ultimate stress.

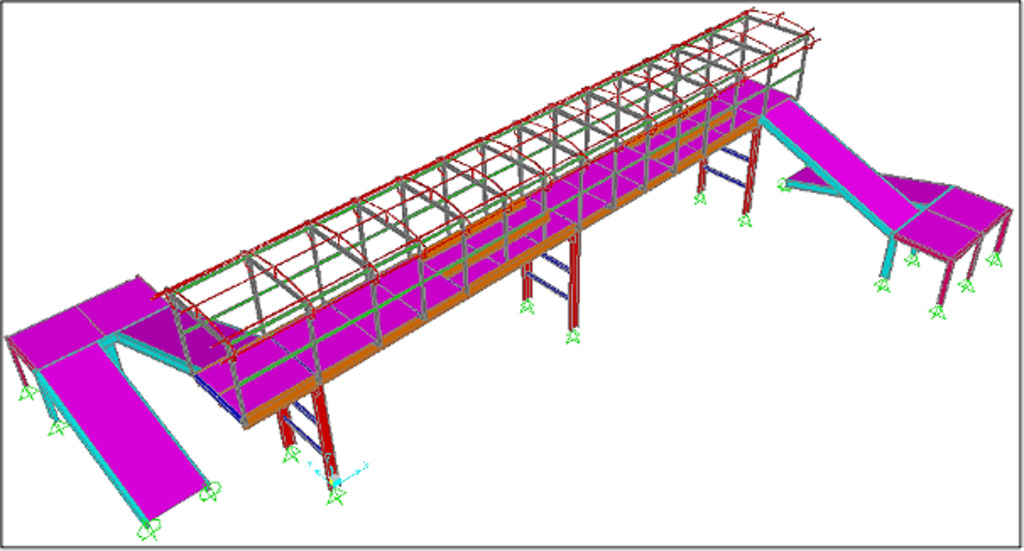

· Numerical modelling of AAC slabs was used to obtain the shear key performance parameters for AAC slabs subjected to cyclic loading. The AAC slabs were modelled for application on a pedestrian bridge using finite element software. The physical and mechanical properties of the AAC materials were used as parameters in this modelling to investigate the behaviour of the bridge using AAC slabs. The numerical simulations of AAC slabs are difficult to find in the literature compared to concrete materials in general [12-14], so this part of the research was very interesting and challenging.

Testing the physical and mechanical properties of AAC material

The investigation included experimental testing of physical and mechanical properties of AAC, which was later used for developing parameters in numerical modelling and application to bridges structures.

Testing the physical and mechanical properties of AAC material experimentally included obtaining data in terms of compressive strength, modulus of elasticity, specific gravity, moisture content and tensile strength of steel reinforcement to be used.

Compressive strength

Compressive testing was carried out in the laboratory and the results are shown in Table 1.

Table 1: Cube compressive strength (fc).

No. test object | fc, 1-day | fc, 28-days |

N/mm2 | N/mm2 | |

#1 | 3.0 | 3.8 |

#2 | 2.4 | 4.7 |

#3 | 3.1 | 4.6 |

Specific gravity and moisture content

The specific gravity test aims at finding out how many units of weight per m3 are in the AAC material mixture. The results of the dry specific gravity test of the cube test object are shown in Table 2. Moisture content testing is carried out to find out how much water absorption is received by AAC concrete. The results of testing the moisture content of the cube test object are shown in Table 3.

Table 2: Cube specific gravity test.

No. Test Object | Specific Gravity | |

gr/mm3 | kg/m3 | |

#1 | 0.000813 | 813 |

#2 | 0.000836 | 836 |

#3 | 0.000851 | 851 |

Table 3: Cube moisture content test.

No. Test Object | Gross Weight | Dry Weight | Moisture Content |

gr | gr | % | |

#1 | 650 | 493 | 31.9 |

#2 | 805 | 634 | 27.0 |

#3 | 818 | 634 | 29.0 |

Modulus of elasticity

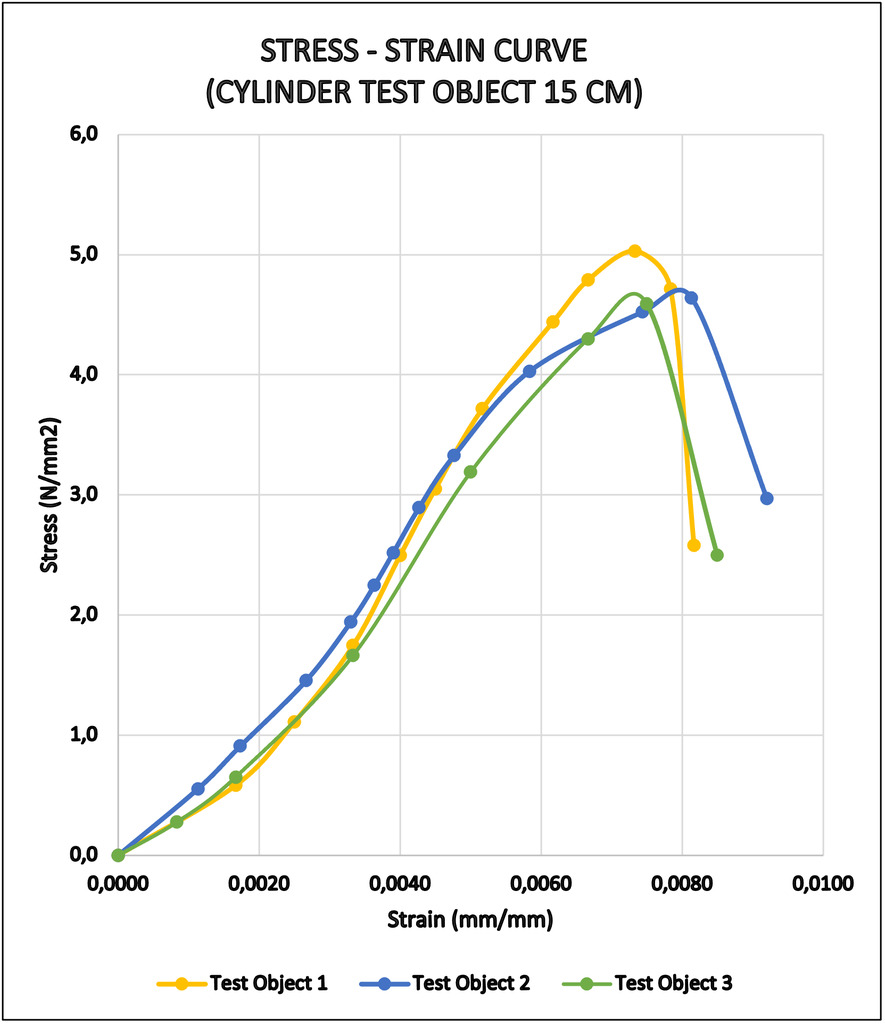

The modulus of elasticity is the ratio of the normal tensile or compressive stress to strain. From the 15/30 cylinder compression test, the AAC modulus elasticity is calculated according to ASTM C-1693 [9]. The results of the modulus of elasticity test are shown in Figure 1 and Table 4.

Table 4: Cylinder Modulus of Elasticity Test.

No. Test Object | Stress Max | Strain Max | Modulus of Elasticity |

N/mm2 | mm/mm | N/mm2 | |

#1 | 5.0306 | 0.0073 | 586.980 |

#2 | 4.5228 | 0.0074 | 560.431 |

#3 | 4.5922 | 0.0075 | 526.850 |

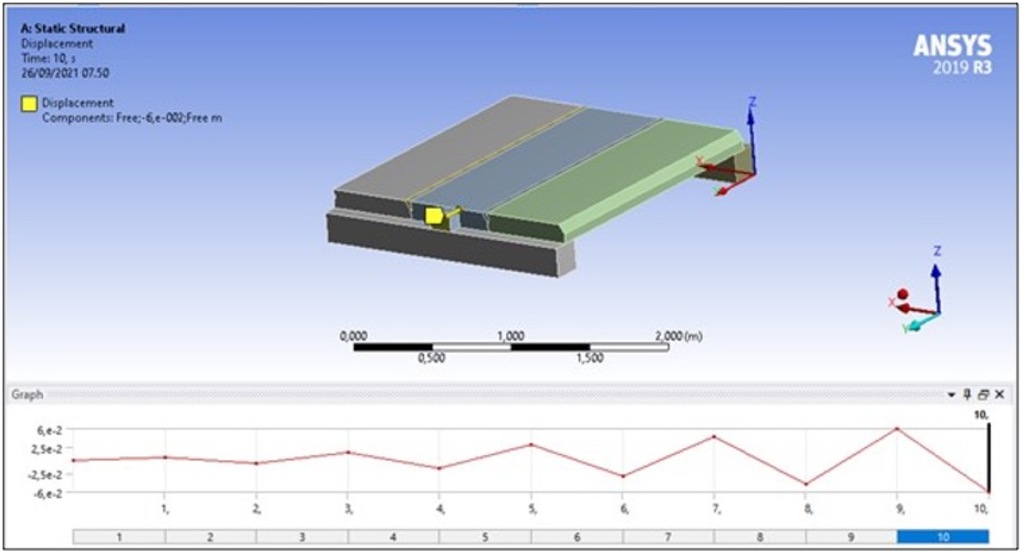

Finite element modelling

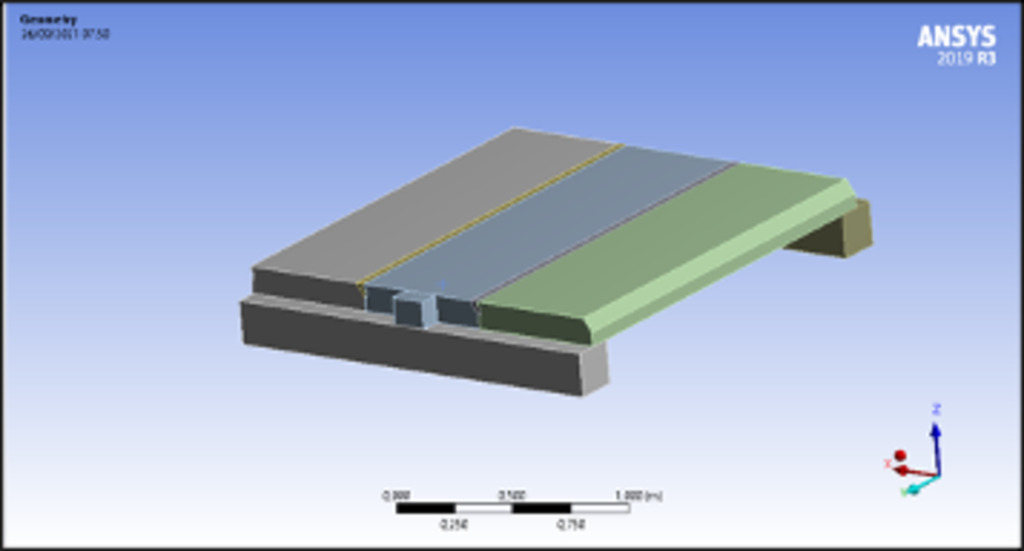

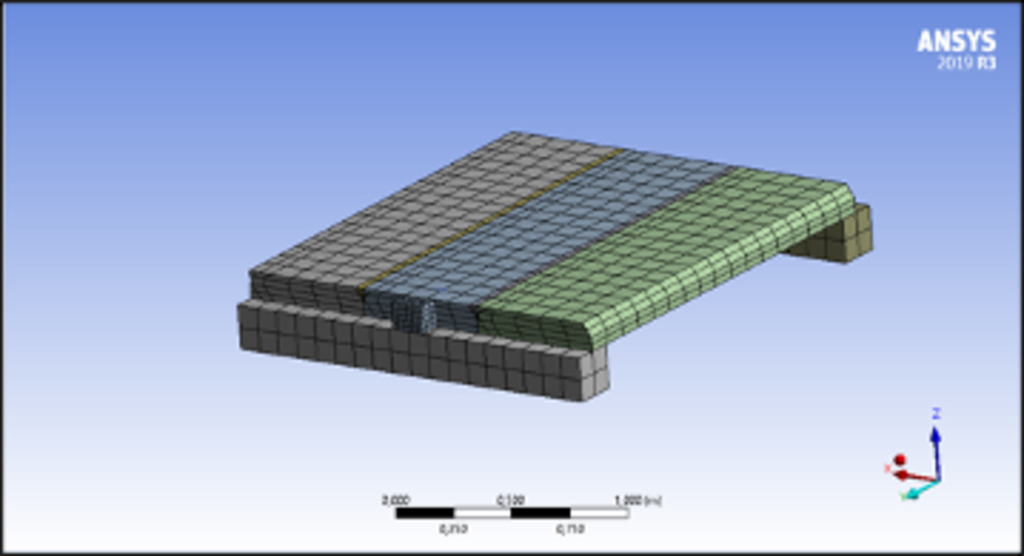

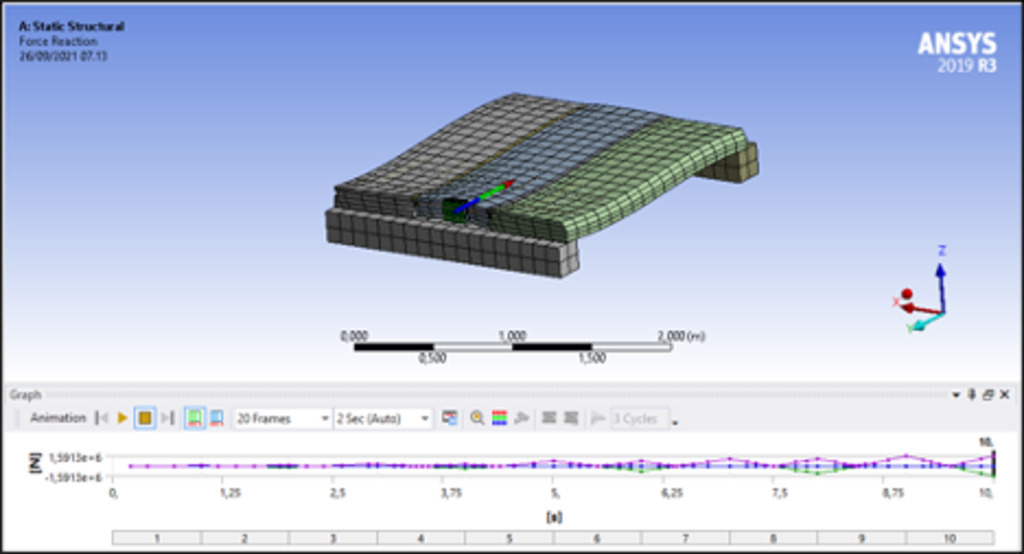

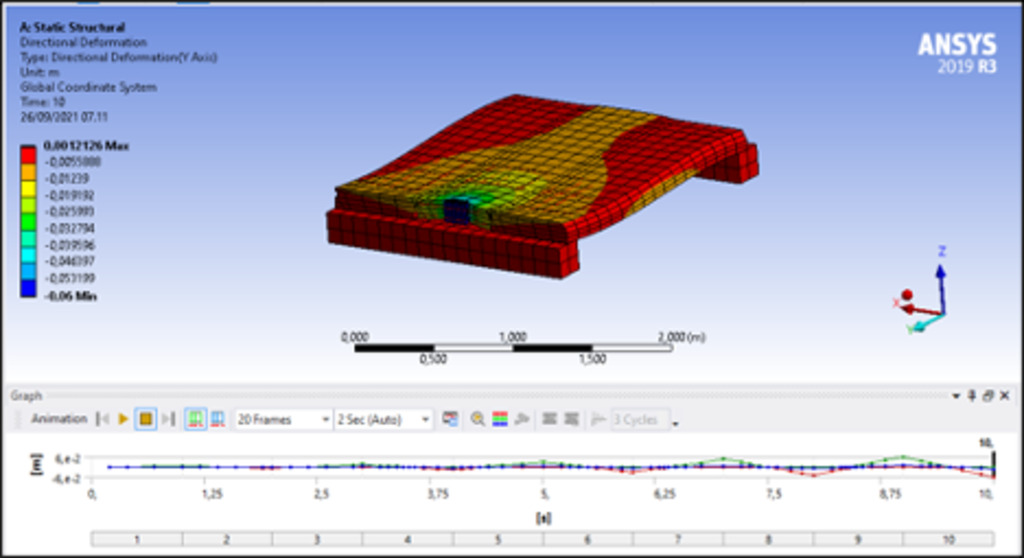

The method used in this research is a numerical simulation using the ANSYS 2019 R3 program. The numerical simulation uses the AAC slab specimen model with dimensions of 1470 x 600 x 125 mm (Fig. 2), with concrete quality and average density from laboratory test results, namely 4,4 MPa and 833 kg/m3. For reinforcement yield stress and tensile strengths, laboratory test results were taken as fy = 335 MPA and fu = 484 MPa.

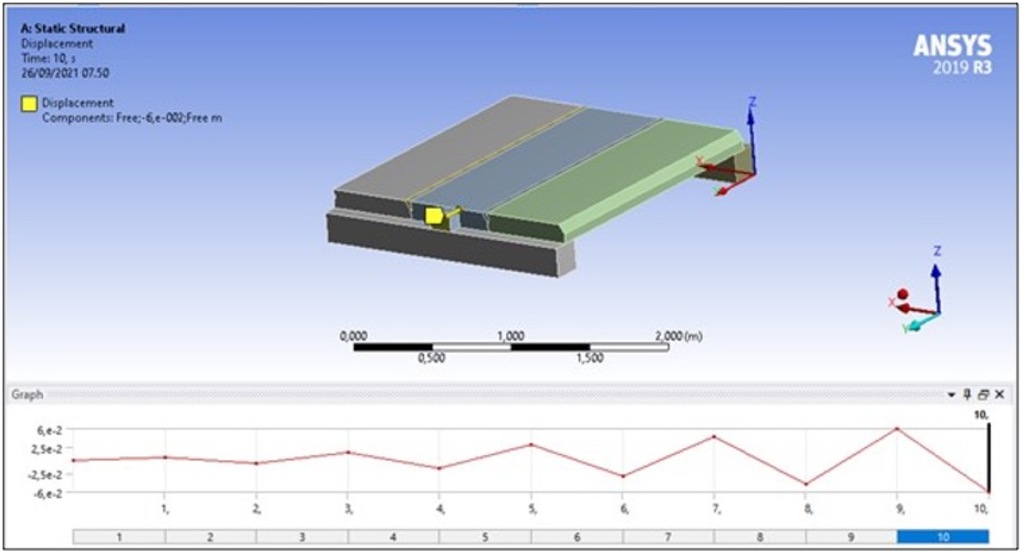

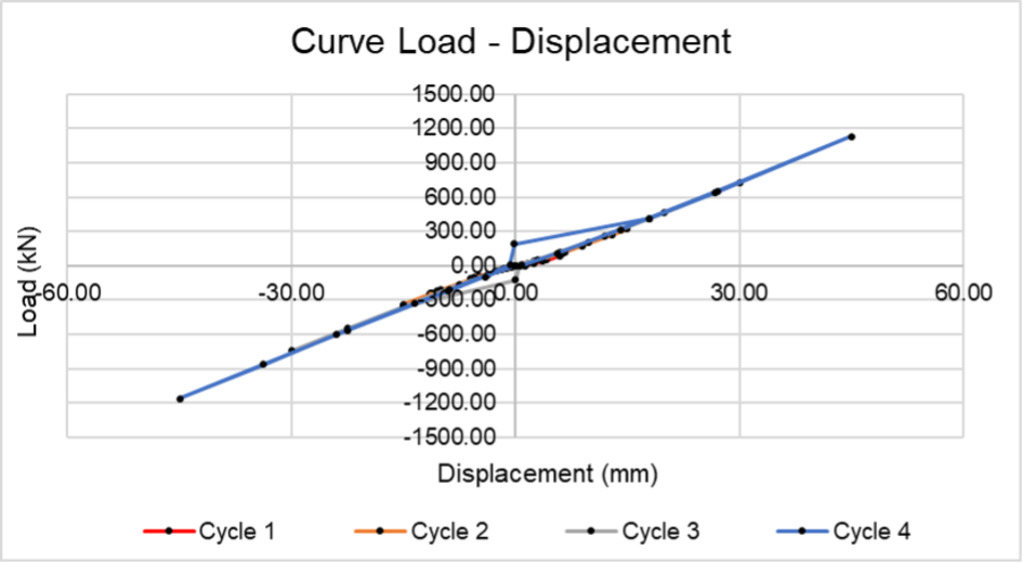

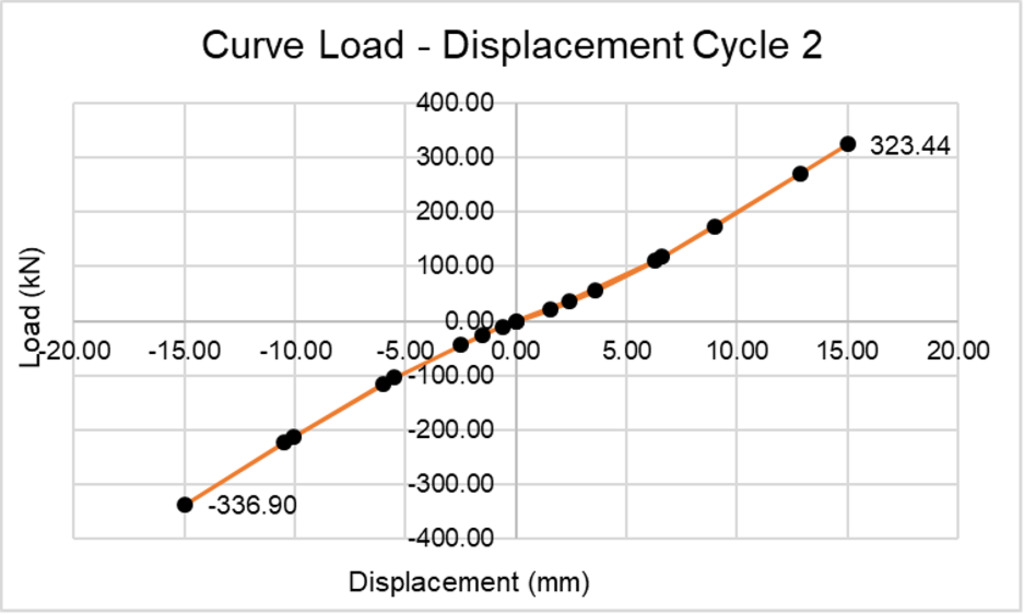

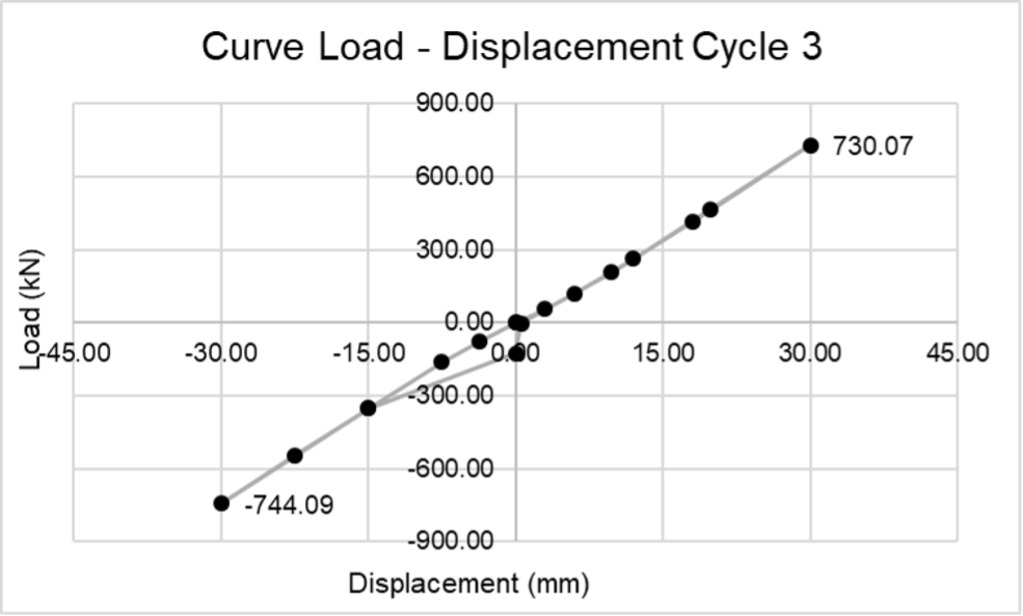

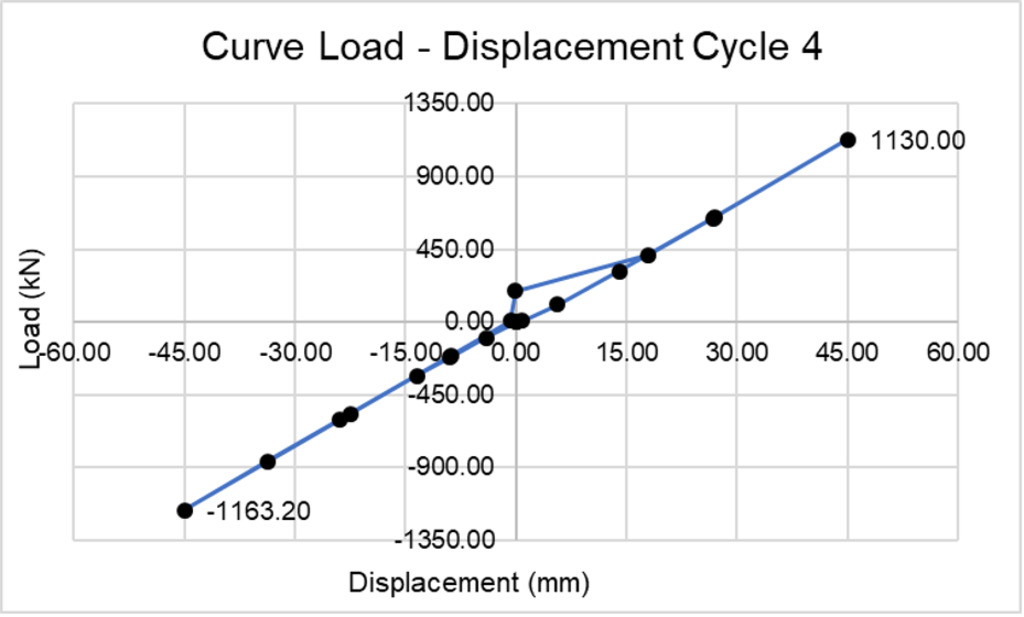

Numerical modelling of AAC slabs using software was used to obtain shear key performance parameters on AAC slabs under cyclic loading. To accurately represent the boundary conditions of the subdiaphragmatic region used in this study, displacement control was carried out.

Table 5: Cyclic test protocol: target shear distortions and displacements.

Shear distortion (%) | Target displacement (mm) |

0.010 | 6 |

0.025 | 15 |

0.050 | 30 |

0.075 | 45 |

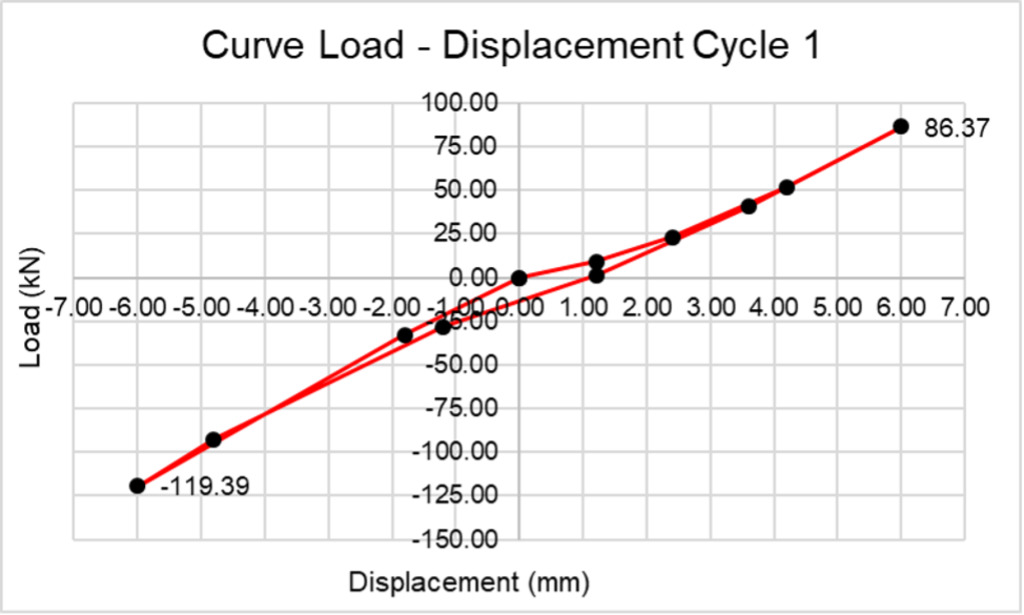

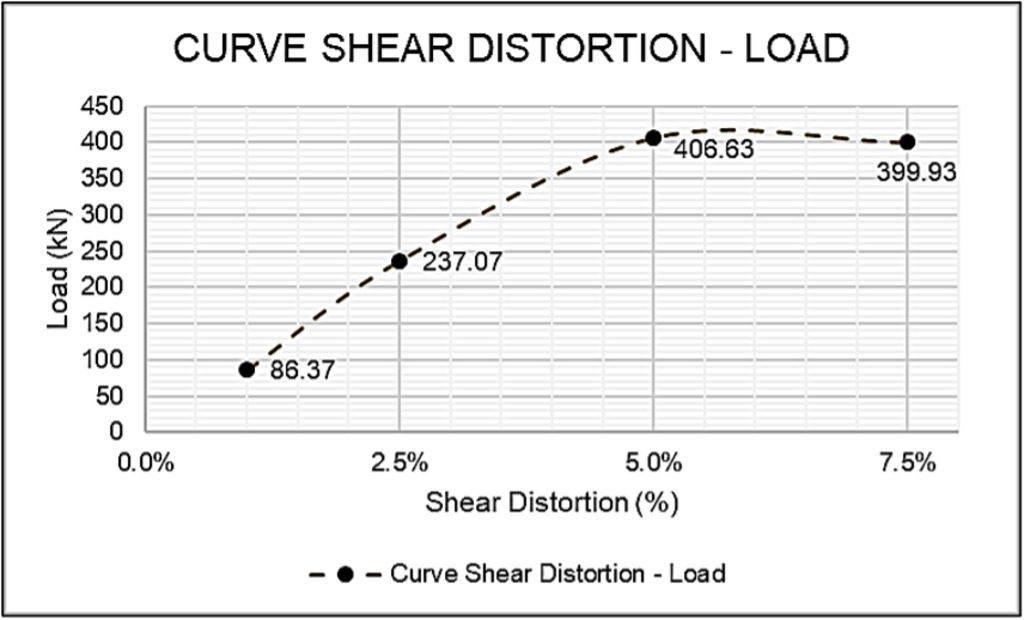

Table 6: Load difference accepted connection between AAC slabs.

Shear Distortion (%) | Load (kN) | The Difference in Charges Received (kN) |

1.0% | 86.4 | 86.4 |

2.5% | 323.4 | 237.1 |

5.0% | 730.1 | 406.6 |

7.5% | 1130.0 | 400.0 |

Applications of AAC slabs for the pedestrian bridge

The structural analysis of the pedestrian bridge modelling aims at comparing the bridge using conventional concrete slabs with bridges using Autoclaved Aerated Concrete (AAC) slabs.

Mode shape structure

The mode shape of the bridge structure for the use of AAC slab and conventional slab can be seen in Table 7.

Table 7: Modal periods and frequencies: pedestrian bridge of slab conventional.

Step type | Step no. | Period | Frequency |

Text | Unitless | Sec | Cyc/sec |

Mode | 1 | 0.401 | 2.495 |

Mode | 2 | 0.239 | 4.180 |

Mode | 3 | 0.206 | 4.852 |

Mode | 4 | 0.200 | 4.999 |

Table 8: Modal periods and frequencies: pedestrian bridge of slab AAC.

Step type | Step no. | Period | Frequency |

Text | Unitless | Sec | Cyc/sec |

Mode | 1 | 0.375 | 2.667 |

Mode | 2 | 0.269 | 3.722 |

Mode | 3 | 0.252 | 3.971 |

Mode | 4 | 0.204 | 4.897 |

Self weight structure

The self-weight of the bridge structure for the use of AAC slab and conventional slab can be seen in Table 9.

Table 9: Self-weight of structure.

Group name | Self-weight | Application |

Text | Tonf | Text |

All | 35.2 | AAC slab |

All | 52.4 | Conventional slab |

Displacement structure

The displacement of the bridge structure for the use of AAC slab and conventional slab can be seen in Tables 10 and 11.

Table 10: Joint displacements: pedestrian bridge of slab conventional.

Joint | OutputCase | CaseType | U3 |

Text | Text | Text | mm |

99 | Envelope | Combination | -13.0 |

Table 11: Joint displacements: pedestrian bridge of slab AAC.

Joint | OutputCase | CaseType | U3 |

Text | Text | Text | mm |

99 | Envelope | Combination | -15.5 |

Conclusions

The results of this study can be concluded as follows:

1. The result of the cube compressive strength test experienced a significant increase from the age of 1 day to 28 days by 53%, with an average modulus of elasticity of 558 N/mm2, an average specific gravity of 833 kg/m3 and an average moisture content of 29.3%.

2. The results of the numerical analysis using the ANSYS 2019 R3 software obtained the connection strength between AAC slabs for a 1% shear target of 86 kN, a 2.5% shear target of 237 kN, a 5% shear target of 407 kN, and a 7.5% shear target of 400 kN, where the strength of the connection between the AAC slab has decreased at a shear distortion target of 7,5% or a displacement control of 45 mm.

3. The results of modelling using the SAP2000 v14 software using the AAC slab on the pedestrian bridge structure can reduce the weight of the structure by 49% compared to the use of a conventional slab. In addition, the use of AAC slabs is not significant in increasing the bridge structure, where the frequency results of an AAC slab are not much different from a conventional slab. The deformation of the bridge structure with the use of an AAC slab is greater than that of a conventional slab, which is influenced by the very low modulus of elasticity of the AAC slab.

Acknowledgments

This work was funded by Politeknik Negeri Bandung (POLBAN) through Post Graduate Research Grant Program (PPS) in 2021 and supported by PT. Beton Elemenindo Perkasa and PT. Beton Elemen Persada (Leicht Beton Element).

References

[1] | PT Beton Elemen Persada, Catalogue Leibel (Leicht Beton Element), Bandung, 2016. |

[2] | G. Soeprapto, M. Sunarso, S. F. Murdono, W. Agustin dan R. Siahaan, “Effect of longitudinal joint on the shear-key of hollow core slab which function as an rigid diaphragm,” MATEC Web of Conferences 101, pp. 1-7, 2017. |

[3] | Badan Standardisasi Nasional, “SNI 2847-2013 About Structural Concrete Requirements for Buildings”, Jakarta,2013 |

[4] | G. Zapotoczna, “Autoclaved Aerated Concrete Properties on the basis current research result conducted by ICiMB - Research and Development Center for Cellular Concrete Industry CEBET and Building Research Institute,” Handbook for AAC producers and users. Magazine of Concrete Producers Association. 5 International Conference of Autoclaved Aerated Concrete, 2011. |

[5] | P. Walczak, “Compressive Strength of Autoclaved Aerated Concrete : Test Methods Comparison,” Brzesc Kujawski : Ernst & Sohn Verlag fur Architektur und Technische Wissenschaften GmbH & Co. KG, Berlin. |

[6] | J. Vengala, S. Mangloor dan T. Krishna, “Performance of Autoclaved Aerated Concrete Blocks Under Varying Temperatures,” International Journal of Recent Technology and Engineering (IJRTE), pp. 615-619, 2019. |

[7] | F. Ma'arif dan S. Widodo, “Experimental Study of Mortar Joint Bond Strength of Autoclaved Aerated Concrete Masonry Prism,” Proceeding of Annual South East Asian International Seminar (ASAIS), pp. 61-66, 2013. |

[8] | J. Tanner, J. Varela, M. Brightman, U. Cancino, J. Argudo dan R. Klingner, “Seismic Performace and Design Of Autoclaved Aerated Concrete (AAC) Structural Systems,” dalam 13th World Conference on Earhquake Engineering, Vancouver, B.C., Canada, 2004 |

[9] | ASTM International, ASTM C1693-09 Standard Specification for Autoclaved Aerated Concrete (AAC), United States, December 2009. |

[10] | T. Zhang, J. Dai dan S. Qin, “Experimental Study on Shear Behavior of Reinforced Autoclaved Aerated Concrete Slab,” International Conference on Electrical Automation and Mechanical Engineering, 2020. |

[11] | ASTM International, ASTM C39/C39M-14 Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens, United States, March 2014. |

[12] | Mauludin, Luthfi M., Xiaoying Zhuang, and Timon Rabczuk. "Computational modeling of fracture in encapsulation-based self-healing concrete using cohesive elements." Composite Structures 196, pp. 63-75, 2018. |

[13] | Mauludin, Luthfi Muhammad, Chahmi Oucif, and Timon Rabczuk. "The effects of mismatch fracture properties in encapsulation-based self-healing concrete using cohesive-zone model." Frontiers of Structural and Civil Engineering 14 (3), pp. 792-801, 2020. |

[14] | Mauludin, Luthfi Muhammad, et al. "Numerical modeling of microcrack behavior in encapsulation-based self-healing concrete under uniaxial tension." Journal of Mechanical Science & Technology 34 (5), 2020. |