Science & Innovation

AAC life cycle

Service life duration of AAC buildings

Loading...

Paweł Walczak: from 2009 – 2015 H+H Polska Sp. z o.o.; Since 2016 Research Center Director at SOLBET SP. Z O.O. In 2010 graduation of AGH – University of Science and Technology in Cracow – M.S.E. title and in 2014 AGH – University of Science and Technology – PhD title – Doktor in Enginering in the field of Chemical Technology. Paweł Walczak holds several fellowships in associations and committees and was/is member of the Scientific Committee of International Conferences (6.ICAAC and 7.ICAAC)

Autoclaved aerated concrete is one of the most popular materials for masonry walls. It is a constantly developing material, as well as a versatile one, which may be produced using various raw materials while delivering comparable products. The origins of AAC in Poland date back to 1951. Over time, a number of technologies have been developed for the production of AAC based on sand or fly ash from coal combustion [1]. In recent years, a number of studies have been conducted to modify the composition of AAC with various additives, ranging from zeolites [2-4], limestone meal [5], glass cullet [6], or fly ash from lignite combustion in fluidized bed boilers [7-9]. The construction site practice has demonstrated that AAC is durable, trustworthy and weather-resistant. When developing an EPD environmental declaration for the entire life cycle of a product, it is necessary to specify the life span of the product. At present, both the AAC road map developed by the European Autoclaved Aerated Concrete Association and the British Precast Concrete Federation’s environmental declaration clearly indicate that the AAC life cycle should be 150 years [10-11]. The conditions affecting exposed AAC masonry walls primarily include contact with carbon dioxide CO2 contained in the air. Carbonation of materials made on the basis of cement and/or lime is a natural phenomenon. The main product of hydration in the process of autoclaving the aerated concrete is tobermorite C5S6H5. In order for carbonation to take place, the carbon dioxide present in the air must overcome a barrier in the form of plaster and often the walls’ thermal insulation to reach the inside of the material. The carbon dioxide must then dissolve in the pore water to form carbonic acid, which can react with calcium oxide derived from hydrated C-S-H calcium silicates, including tobermorite. The reaction can be represented as follows [12-18]:

Carbonation will be accompanied by an increase in volume and weight of the dough, which in the case of AAC is not a negative phenomenon due to its porous structure. Some studies show that aerated concrete undergoes nearly complete carbonation after 60 years and the useful life span should be assumed at 95% of that time, further shortening its useful life [19]. Sixty years’ old buildings must have been built no later than in 1963. In January 1966, there were 11 AAC plants in Poland, which produced 1.8 million m3 of masonry units per annum. In 1962, the production capacity of Polish plants was 1.2 million m3 p.a. This was the second-best result in Europe, just behind Sweden, which at that time manufactured approx. 2 million m3 per year. In the same year, Germany’s annual production was only 460,000 m3. In those years, there were already several AAC plants in Poland in which the manufacturing process relied on technologies shown in Table 1 [1].

Table 1: AAC manufacturing technologies available in Poland in January 1966.

Technology | binder | aggregate | |

UNIPOL | Sand version | Cement + lime + gypsum + some part of aggregate | Sand (wet mill) |

Fly ash version | Siliceous fly ash | ||

Mix version | Mix of sand and siliceous fly ash (wet mill) | ||

SW | Cement + lime | Sand (wet mill) | |

PGS | Lime + gypsum + some parts of fly ash | Siliceous fly ash | |

BLB | Belite cement | Sand (wet mill) | |

As can be seen, in the 1960s the Polish AAC industry developed very rapidly, using many manufacturing variants delivering comparable products. Given the 60 years of the assumed useful life span of AAC masonry units and the production capacity of Polish plants at 1.2 million m3 p.a. in 1962 to 1.8 million m3 p.a. in 1966, Poland should experience a considerable number of construction disasters resulting from to the lapse of the AAC life span. Assuming approx. 50 m3 of aerated concrete per house, about 24,000 houses were built in 1962 and 36,000 houses in 1965. Looking at the fact that the production of AAC in Poland dates back to 1951, hundreds of thousands of autoclaved aerated concrete houses were built in Poland by 1965. Therefore, it seems highly likely that the ‘60 years’ assumption is wrong, as there are no signs that houses from the 1950s and 1960s need to be demolished due to problems with walls made of aerated concrete. Therefore, the research aims to show reliable studies that will determine how the process of re-carbonation takes place in autoclaved aerated concrete, and which scenario about the product’s life span - 60 or 150 years - is realistic.

Research program

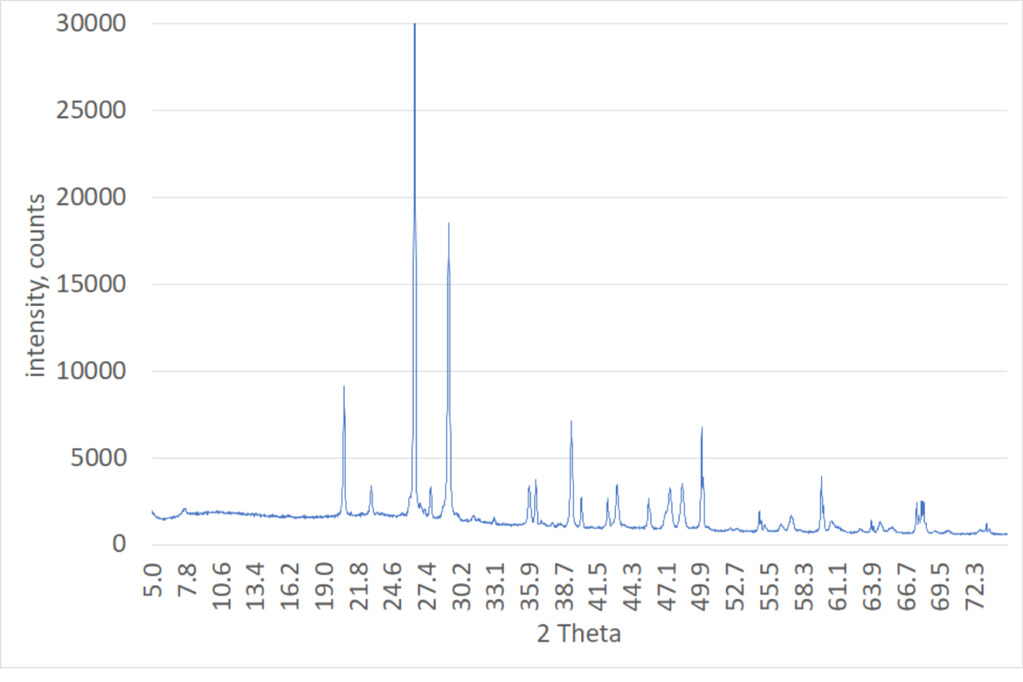

The research program aims to determine changes in the amount of tobermorite in AAC samples over time. The research consists of two interconnected stages. The first stage consists in observing AAC masonry units exposed to natural weather conditions (excluding precipitation), and analysing the composition of aerated concrete from the demolition of existing buildings approx. 60 years old. An XRD phase composition analysis and scanning microscope observations were carried out for all samples. It should be noted that the masonry units studied came from demolished buildings, and the reason for the demolition was the re-development of a post-industrial neighbourhood.

The studies from the first stage cover density classes of 600 in order to include for comparison purposes material with densities as close as possible to those used in the 1950s and 1960s, with a maximum seasoning period of 5 years. The second stage studies include masonry units of density class 700, which was the most popular density class in those years in Poland. At this stage of the study, the analysis was conducted for samples aged for 25, 50 and 60 years.

Results

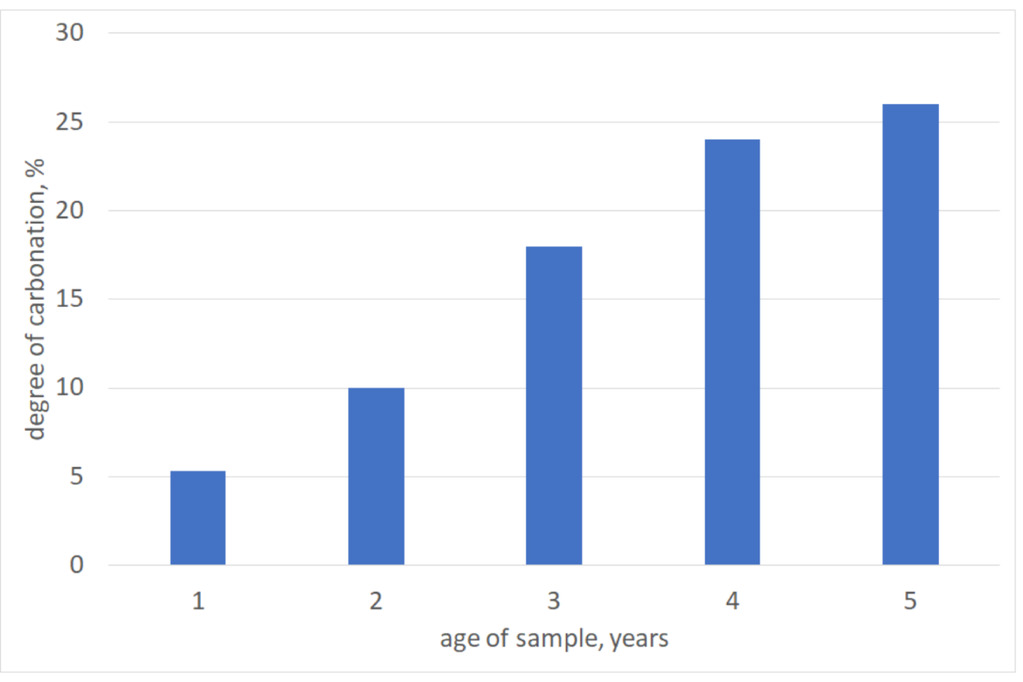

Prior to seasoning, the composition of the AAC was examined straight from the autoclave, where calcium carbonates were found to be present at 1-2%, depending on the density class produced. The AAC masonry units were then exposed to the weather. The samples were only protected from rain by placing a canopy above them. The phase composition was analysed at various time intervals using XRD analysis and scanning microscope observations. The results of the tests carried out over 5 years are shown in Fig. 1 as the degree of carbonation.

The chemical composition of the samples was determined based on chemical tests of the raw materials used for the production of AAC and the analysis of production formulas. Additionally, the chemical composition was confirmed by XRD analysis and XRF to double check the results obtained.

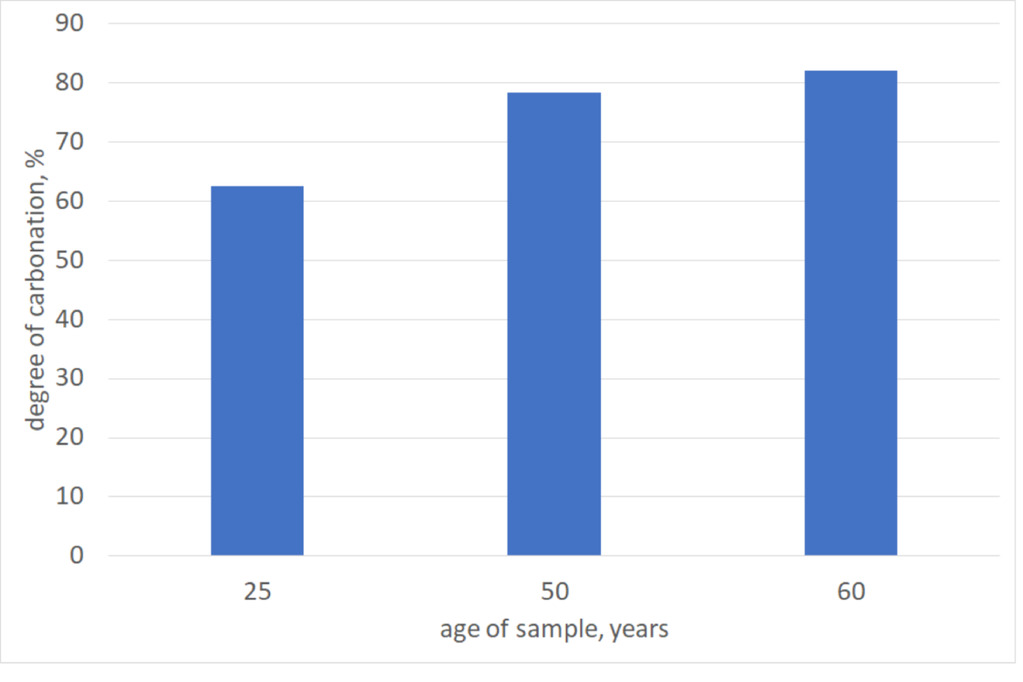

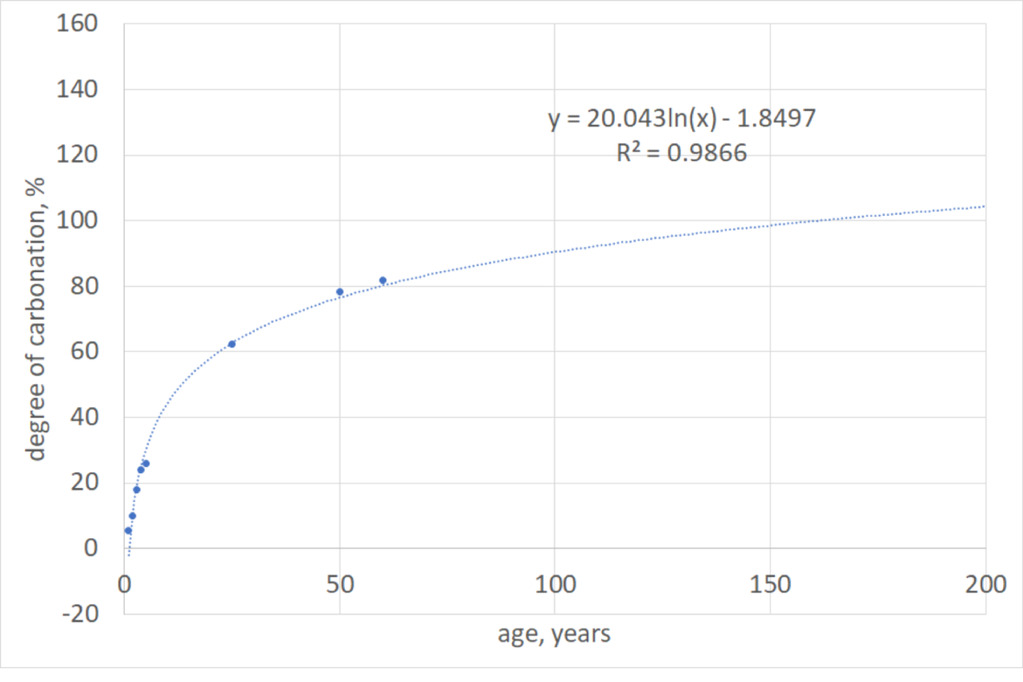

The results of the degree of carbonation for samples from the existing buildings and from buildings to be demolished are shown in Fig. 2. The degree of carbonation was calculated based on the obtained chemical composition of the tested samples. On the basis of XRD and XRF analyses, the initial content of calcium oxides, CaO, and silicon dioxide, SiO2, was calculated, after which the degree of carbonation of the tested samples was determined.

The samples with an age of approx. 60 years came from two different buildings. In both cases, the XRD analysis showed tobermorite in the phase composition of the samples.

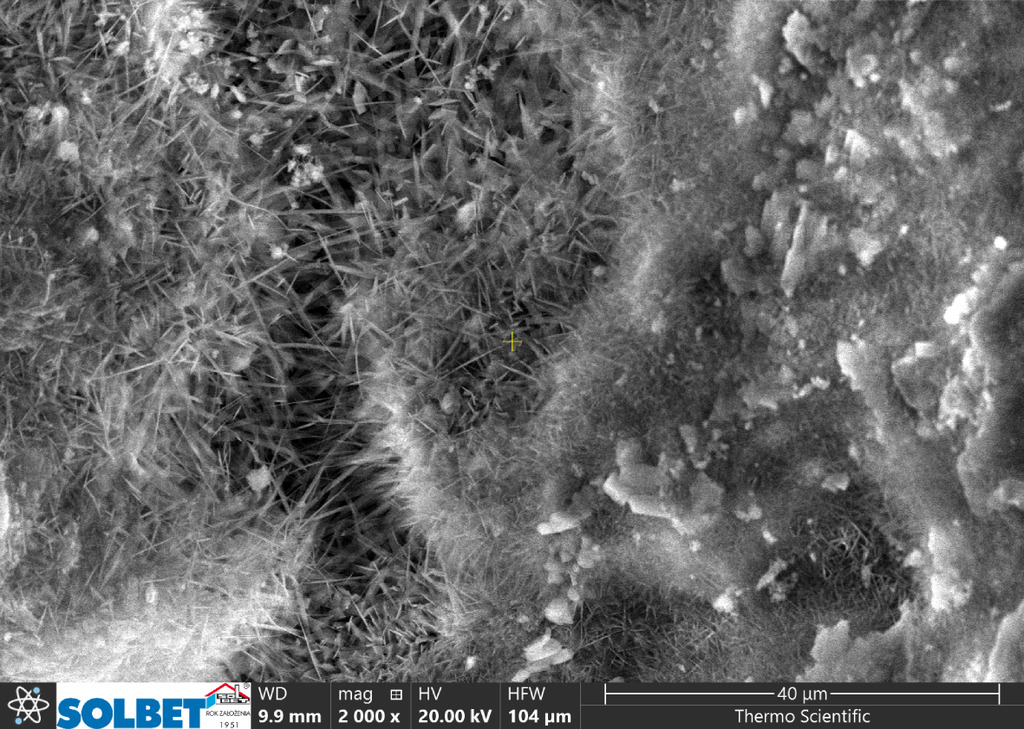

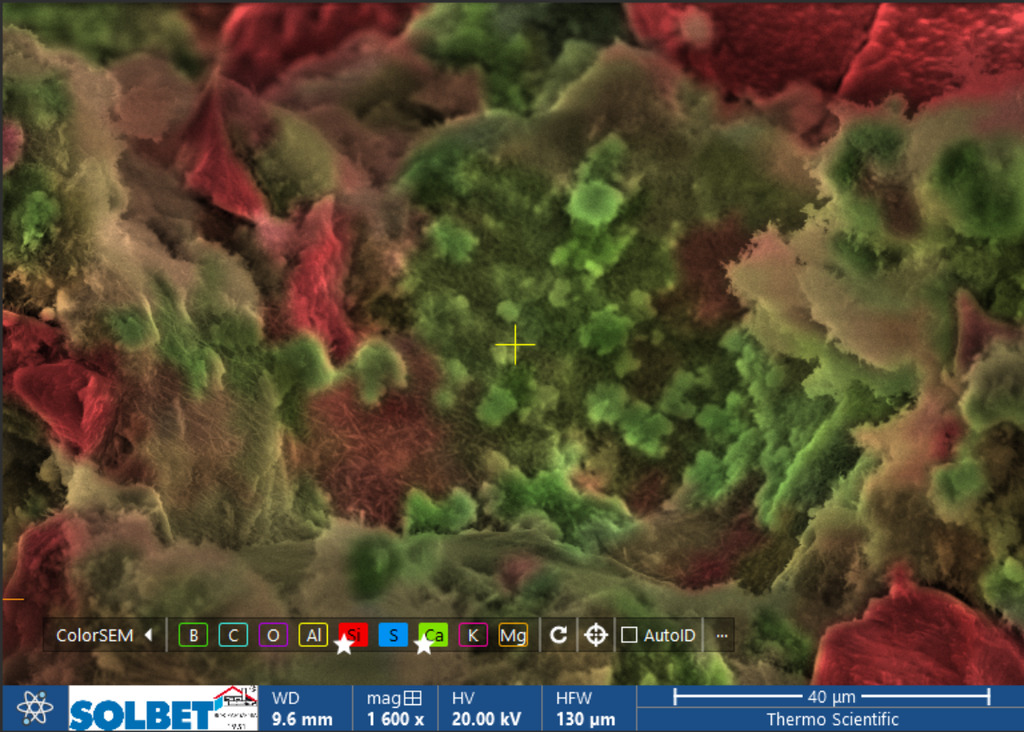

The presence of tobermorite was also confirmed by scanning microscope observations, where tobermorite crystals were still present, as shown in Figure 4, and an analysis using colorSEM technique, as shown in Figure 5.

Discussion of research results

The conducted studies considered carbonation of AAC in two separate stages and may give the impression that carbonation is almost a linear process, based on which it may indeed turn out that aerated concrete will complete its life cycle much sooner than it appears from construction practice. Therefore, the research was aimed at an in-depth analysis of the “big picture”, including the period immediately following the production process. Combining the two stages into one produces a different image of the development of carbonation, as shown in Figure 6.

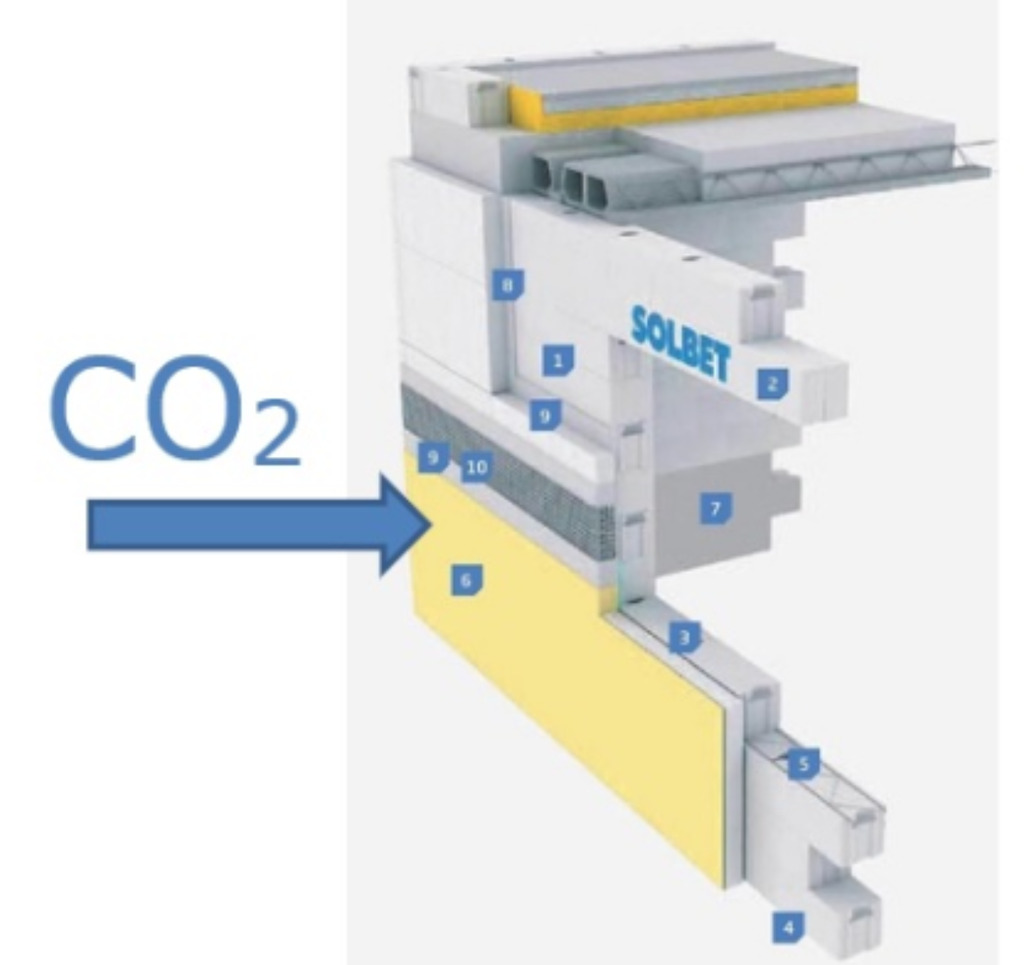

As can be seen, the carbonation process starts off quite rapidly, but after some time it slows down considerably. Please note that the initial carbonation degree (results from step 1) may be higher than the actual one, since the blocks did not have a layer of plaster or thermal insulation on them to impede the penetration of CO2 into the material. In most situations, AAC is a material covered with some kind of insulation, making it difficult for CO2 to penetrate, as shown in Figure 7.

An additional factor mentioned is the moisture content of AAC, which decreases over the years and remains at a very low level. Low moisture content of the masonry wall means less pore water content and thus a decrease in the rate of the carbonation reaction. An additional factor slowing the reaction down over time is the densification of the AAC structure by the resulting calcium carbonate and silica gel, which makes it increasingly difficult for CO2 to penetrate the material.

Conclusions

The research and analysis carried out clearly demonstrate that the assumption of complete carbonation of AAC after 60 years is incorrect. The construction experience, as well as the analysis of the existing buildings and those intended for demolition clearly show that after 60 years tobermorite is still present in the inner structure of AAC. Another point clearly demonstrated by the analysis of the carbonation process is that the assumption laid down in the road map developed by the European Autoclaved Aerated Concrete Association and the British Precast Concrete Federation, i.e. the setting of the life span of AAC masonry units to 150 years, is realistic. Caution is required when analysing the life cycle of AAC and one must account for the “big picture”, as partial test results may wrongly suggest that carbonation is almost a linear process. The most important things is that the end of carbonation is not the end of life for masonry construction made from AAC blocks. Despite of carbonation degree, the properties of AAC are on the stable level.

This article appeared in its original form in the proceedings of ICAAC 2023 (7th International Conference on Autoclaved Aerated Concrete): Walczak P. AAC life cycle: How long can autoclaved aerated concrete buildings be used. Ce papers. 2023;6:41-45.