Science & Innovation

Hefei Sunrise Aluminium Pigments Co., Ltd., Hefei, Anhui, China

The influence of surface treatment processes on the gas generation effect of aluminum powder

Loading...The production process of aluminum powder includes grinding, grading and kneading, and the surface coating of aluminum powder is carried out during the grinding and kneading processes. Grinding usually uses two production processes, dry ball milling and wet ball milling. The dry ball milling process poses certain safety hazards, and the quality of the product is difficult to control. Therefore, wet ball milling is used for the secondary processing of spherical aluminum powder. The wet ball milling process involves adding aluminum powder, grinding aids, grinding media, and solvents to the ball mill. Under the rotation of the ball mill, the spherical aluminum powder is compressed into a flake structure by the grinding media. Due to the cleaning, lubrication, and coating effects of solvents and grinding aids, the produced flake aluminum powder has a uniform particle size and high surface smoothness, thus exhibiting excellent gas generation effect. During the secondary kneading process, a certain proportion of dispersant additives is added. The function of dispersant additives is to coat the surface of aluminum powder twice, making it soluble in water and producing good dispersibility in water.

Grinding stage - stearic acid coating treatment method

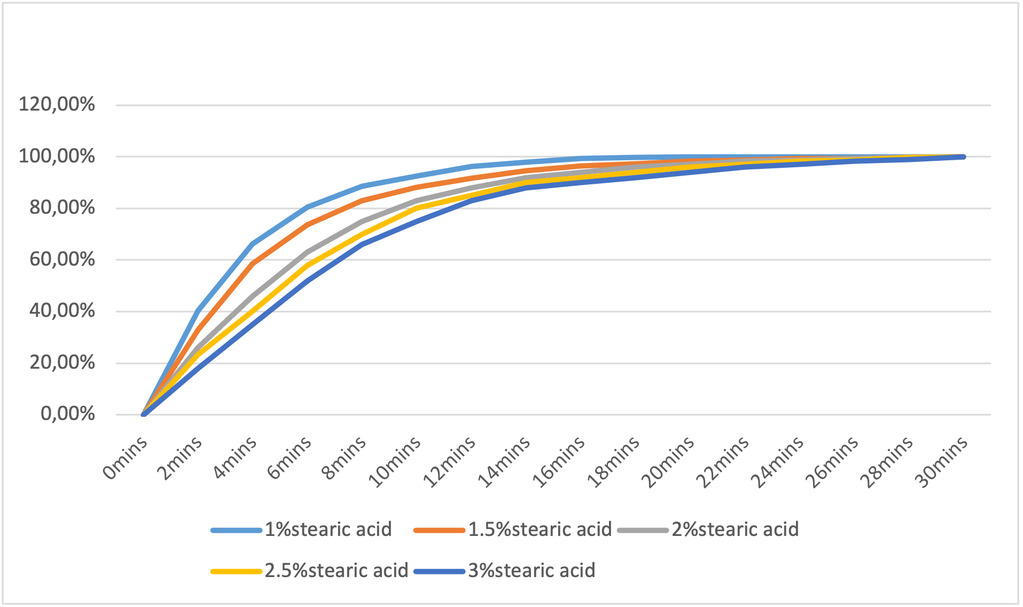

In the process of grinding aluminum powder, stearic acid is added. The addition ratio of different stearic acids has different coating effects on the surface of aluminum flakes, ultimately resulting in different gas generation effects (Fig. 1). It can be seen that as the amount of stearic acid added increases, the gas evolution rate of aluminum powder gradually decreases. The reason for this is that the increase in the amount of stearic acid added during the grinding process results in a thicker and denser stearic acid coating layer on the surface of the aluminum flakes, leading to a decrease in the chemical reaction rate of the aluminum flakes in the same alkaline environment, i.e. a decrease in gas evolution rate.

Kneading stage - secondary coating treatment method for dispersant additives

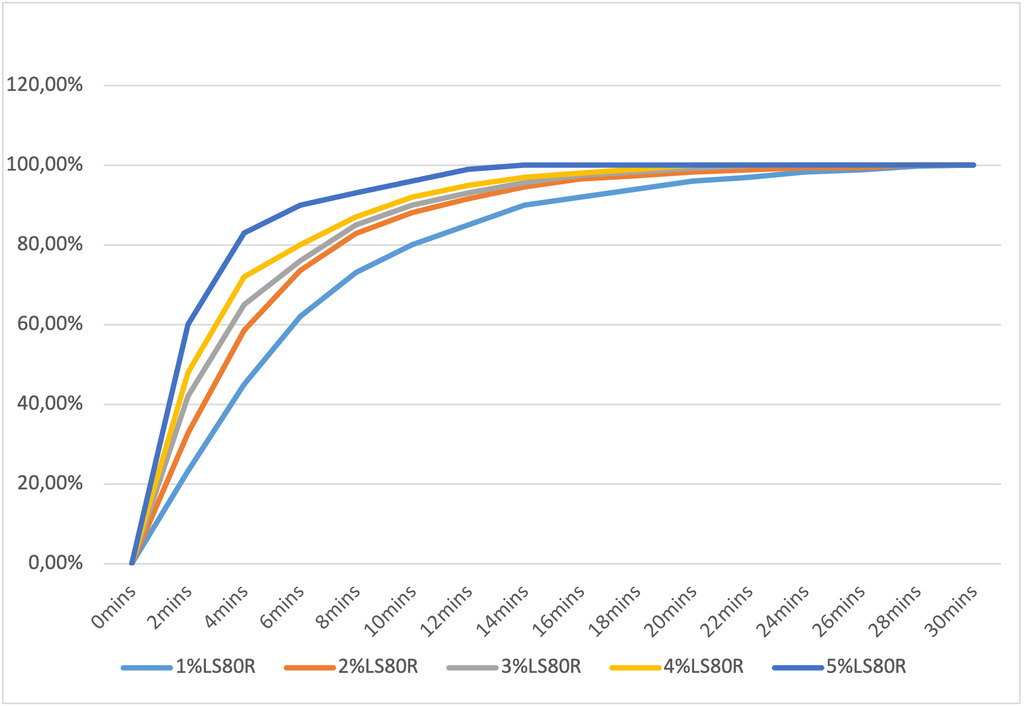

Spherical aluminum powder is coated with a dense coating layer on the surface of the ground flake aluminum powder, making it difficult for the aluminum powder to dissolve in water. At this point, the surface of the aluminum flakes needs to be re-treated. Usually, dispersant additives are added to provide a secondary coat on the surface of aluminum powder, making it soluble in water and giving it good dispersibility. In actual production, a quantitative amount of LS80R (dispersant additive) is added to solve the dispersion problem during the stirring and kneading process of aluminum powder. The effect of different LS80R adding ratios on product gassing rate is shown in Figure 2. It can be seen that as the amount of LS80R added increases, the gas evolution rate of aluminum powder gradually accelerates. The reason for this is that the increase in the amount of LS80R added can improve the secondary coating effect, dispersion, and water solubility of the aluminum flake surface, resulting in an accelerated chemical reaction rate of the aluminum flake in an alkaline environment, i.e. an accelerated gas evolution rate.

In summary, in the production process of aluminum powder, the surface coating process is particularly important. The coating effect of different process treatments can produce different properties, which in turn affects gas generation. In actual production, the production process is often adjusted based on the gas generation rate required by customers - not only the adjustment of particle size, but also the adjustment of the surface coating effect of aluminum powder. The gas evolution rate curves of aluminum powder with different particle sizes and surface coating treatments on aluminum flakes are different, which has a significant impact on the pore structure. The finer the particle size of aluminum powder, the denser the pores of AAC blocks and panels, the smaller the pore size, the more uniform the arrangement and distribution, and the less prone to perforation. The excellent performance of this pore structure has significantly improved the strength of AAC products. Different degrees of coating treatment on the surface of aluminum flakes can control the initial gas release rate of aluminum powder, which can advance or delay the initial gas release.

In the production of AAC blocks or panels, the main raw materials that affect product quality are lime and aluminum powder (aluminum paste). The quality of lime and aluminum powder determines whether the AAC production process is stable. If the process is unstable, the output cannot increase, and the quality is poor. It can be said that the top priority in the production of AAC is to control the quality of lime and aluminum powder. However, the selection of raw materials by most AAC producers is influenced by regional limitations, especially lime. The performance indicators of different limes vary greatly, affecting the thickening speed of the embryo and the gas generation time of aluminum powder in AAC production. Therefore, the compatibility between lime and aluminum powder is crucial in actual production, and different lime characteristics need to be matched with different gas generation aluminum powder.

Hefei Sunrise Aluminium Pigment Co., Ltd is committed to the field of autoclaved aerated concrete and has developed various products with different particle sizes and aluminum flake surface coating treatments to meet different customer needs. It provides special customized services and can match aluminum powder required for different raw materials and production processes in the production of autoclaved aerated concrete. The products are widely used in various countries around the world and have received unanimous praise from customers, overturning the traditional production and processing technology of aerated aluminum powder in China.